You might wonder how long an anchor chain on a modern warship actually is. Most battleships use anchor chains that typically measure between 900 and 1,200 feet, with some larger vessels using chains that can exceed 1,500 feet.

These chains help keep your vessel stable in harsh marine conditions.

Anchor chains for warships must meet strict standards for both length and strength.

When you need to determine ship anchor chain diameter or select the right chain, you must rely on quality and expertise. Powerful Machinery stands out as a trusted supplier, providing certified solutions for the demanding needs of the marine industry.

Key Takeaways

Most battleships use anchor chains that range from 900 to 1,500 feet, ensuring stability in harsh marine conditions.

Select anchor chains based on vessel size, anchoring ground type, and required strength to enhance safety and performance.

Regularly inspect and maintain anchor chains to prevent wear and ensure reliability during operations.

Use a color-coded system during deployment to track chain length and avoid anchor loss.

Choose certified anchor chains to guarantee compliance with international safety standards and enhance vessel safety.

Ship Anchor Chain Length and Structure

Standard Measurements for Warships

When you look at a modern battleship, you will notice that it usually carries two main anchors, each with its own anchor chain. The length of each anchor chain can range from 86 meters to 770 meters, depending on the size and class of the vessel.

You measure these chains in units called “shackles.” One shackle equals 15 fathoms, or 90 feet. Most large ships use 12 shots (shackles) per anchor chain, which gives you a total length of about 1,080 feet for each chain.

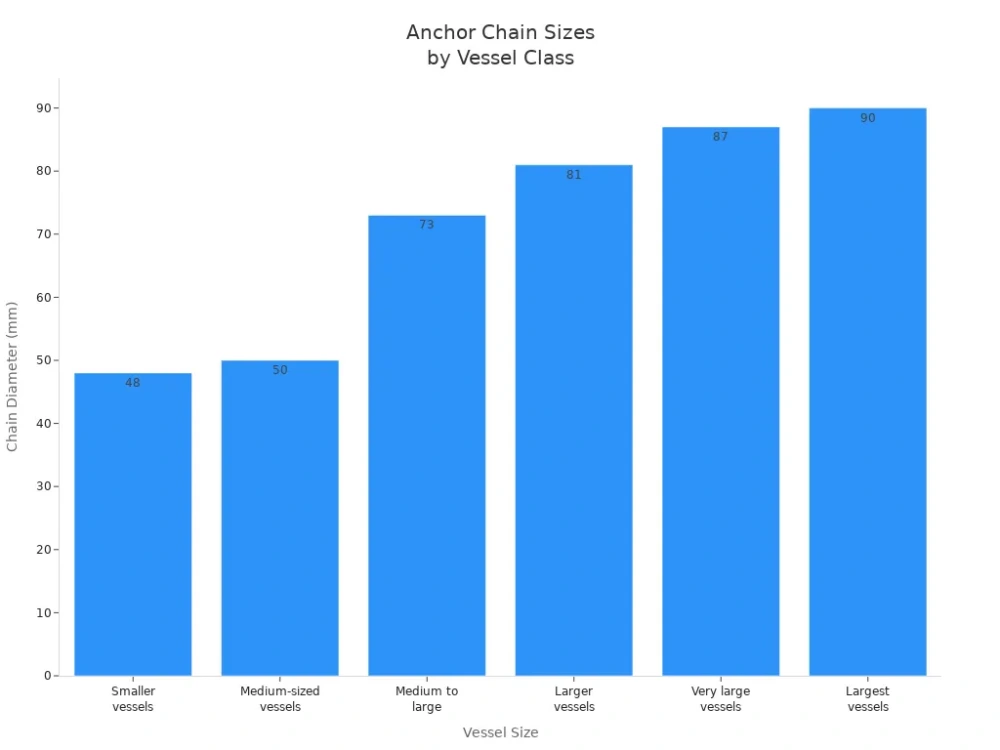

To help you compare anchor chain diameters across different vessel sizes, see the table below:

Vessel Size | Anchor Chain Diameter |

|---|---|

Smaller vessels | 48mm |

Medium-sized vessels | 50mm |

Medium to large | 73mm |

Larger vessels | 81mm |

Very large vessels | 87mm |

Largest vessels | 90mm |

You can also visualize these differences in the following chart:

Powerful Machinery supplies ship anchor chain solutions that meet these demanding specifications. Their products ensure your vessel remains secure, no matter the conditions.

Chain Composition and Weight

You need to consider both the material and the weight when selecting a ship anchor chain. Most anchor chains for warships use high-strength steel, such as 20Mn (CM490) or 30Mn (CM690). These materials provide the durability and strength needed for heavy-duty marine applications.

Manufacturers often apply surface treatments like hot-dip galvanizing, black paint, or stainless steel finishes to protect the chain from corrosion.

Material Type | Description |

|---|---|

High-Strength Steel | Grades like 20Mn (CM490) or 30Mn (CM690) |

Surface Treatments | Galvanized, stainless steel, black paint, or self-colored finishes for corrosion resistance |

The weight of each anchor chain is significant. For example:

One shot of anchor chain contains 57 links, each weighing about 350 pounds.

Each shot weighs 20,500 pounds.

Twelve shots are needed to hold a single anchor weighing 60,000 pounds.

This heavy construction means your ship anchor chain requires robust support and specialized handling equipment. The chain’s weight also helps create a deep, nearly vertical catenary when you drop the anchor, which improves holding power and stability.

Deployment and Color-Coding

When you deploy an anchor chain, you need to know exactly how much chain you have released. To help with this, most ships use a color-coded system. You will find colored links and detachable links at every 15-fathom interval, marking each shot of chain.

The last shot often uses yellow or red links to warn you that the chain is almost fully deployed.

Tip: Always monitor the color-coded links during deployment. This practice helps you avoid running out of chain and risking anchor loss.

This system ensures you can operate the anchor chain safely and efficiently, even in challenging conditions. Powerful Machinery designs ship anchor chain products with these operational details in mind, providing you with reliable and easy-to-use solutions for your vessel.

Deep-Sea Anchoring Limitations

Why can’t chains reach the Seabed?

You face strict limitations when anchoring a warship in deep water. The length of your anchor chain rarely matches the depth of the open ocean. International maritime standards set clear guidelines for safe anchoring.

For example, the International Association of Classification Societies (IACS) recommends a chain length between six and ten times the water depth. The Admiralty Manual suggests using 1.5 times the square root of the depth in shackles.

The Royal Yachting Association (RYA) advises a minimum of four times the depth. You can see these recommendations in the table below:

Source | Recommendation |

|---|---|

IACS | 6–10 x Depth of Water (in meters) |

Admiralty Manual | 1.5 x √Depth of Water (in shackles) |

RYA | Minimum of 4 x Depth |

Most warships cannot carry enough chain to meet these holding power requirements in deep-sea conditions. Anchoring equipment is designed for temporary mooring in sheltered waters, not for rough weather or extreme depths. You must consider these limits before attempting to anchor in deep water.

Operational and Safety Risks

Anchoring in deep water exposes you to significant risks. Equipment failure becomes more likely when you exceed the recommended chain length. You may experience anchor dragging, grounding, or difficulty recovering the anchor due to water depth.

Human error during anchor handling operations can also lead to accidents. Environmental factors such as wind and current increase the danger.

Equipment failure

Anchor dragging

Grounding

Human error during anchor handling

Difficulty recovering the anchor

Environmental factors (wind, current)

You must ensure your vessel is nearly stopped before anchoring. Even a slow movement can cause equipment to fail. Continuous monitoring of your ship’s position and communication with shore teams helps prevent incidents. Meeting holding power requirements is essential for safety.

Note: VLCCs and large warships require extra caution. Anchoring while moving, even at half a knot, can result in catastrophic equipment failure.

Anchor Abandonment Issues

Anchor abandonment incidents have increased in recent years. You may need to abandon your anchor if you cannot recover it or if environmental conditions change rapidly. Common causes include extreme weather, lack of awareness about equipment limits, and operational practices that ignore environmental loads.

Ships spending more time at anchor, especially in exposed areas, face higher risks.

Extreme weather conditions

Inadequate awareness of anchoring equipment limits

Operational practices not considering environmental loads

Increased time at anchor in exposed areas

Claims data show that vessels with anchor claims dropped their anchors 28% more often and spent 27% longer at anchorage than those without claims. These vessels also spent 18% longer in bad weather.

Environmental risk factors such as weather, currents, water depth, and holding ground contribute to anchor loss. You must always assess these risks before anchoring in deep water.

Technical Challenges of Anchor Chains

Handling Heavy Equipment

You face major engineering challenges when you deploy and retrieve heavy anchor chains on a battleship. Each chain can weigh many tons, so you need specialized equipment and careful planning. Engineers use two main inspection methods to keep anchor chains in top condition:

Inspection Method | Description |

|---|---|

Dock Inspection | Lay the chain out on a dry surface for cleaning and inspection during repairs. |

Offshore Inspection | Pay out the chain fully and inspect it as you bring it back into the locker. |

These inspections help you spot wear, corrosion, or damage before it becomes a problem. Powerful Machinery designs anchor chains to handle these tough conditions, using high-strength steel and advanced coatings for maximum durability.

Crew Safety and Machinery

You must protect your crew during anchor chain operations. Heavy machinery and moving chains create risks, so strict safety protocols are essential. The table below shows some of the most important safety measures:

Safety Protocols | Description |

|---|---|

Design Standards | Winches have adjustable speed, tension control, overload alarms, and emergency release systems. |

Operational Requirements | Only trained crew operate winches, with all actions planned and supervised. |

Maintenance | Follow strict guidelines; remove unsafe winches from service until repaired. |

Testing | New systems require commissioning trials and regular retesting every five years. |

You reduce accidents by following these protocols. Powerful Machinery’s anchor chains and hardware meet international safety standards, giving you peace of mind during every operation.

Power System Considerations

You rely on powerful windlasses to handle anchor chains. Most modern warships use electric windlasses with 3-phase AC motors for efficiency. Hydraulic drives work best for high-torque needs and connect to the ship’s central hydraulic system. Automation and remote controls make operations safer and more efficient.

If your ship loses power during anchoring, you risk drifting in the wind and waves. Large warships, such as aircraft carriers, can take over ten hours to restore power. This makes it unsafe to anchor in deep water if you cannot guarantee a steady power supply.

Key factors in determining ship anchor chain diameter include vessel size, anchor weight, and expected environmental loads. Powerful Machinery offers solutions that match these requirements, ensuring your anchor chain system works reliably in all conditions.

Choosing Anchor Chains for Warships

Key Selection Factors

When you select anchor chains for warships, you must consider several important factors. These choices impact the safety and performance of your vessel.

Vessel size and weight: Larger ships need stronger chains.

Type of anchoring ground: Mud, sand, or rock seabeds require different chain types for secure holding.

Chain material: High-strength steel or stainless steel improves durability.

Chain coating: Galvanized or painted coatings protect against corrosion.

Chain length: Sufficient length ensures effective anchoring in various conditions.

You should also think about how often your vessel anchors and the environments you operate in. These details help you choose the right anchor chains for warships.

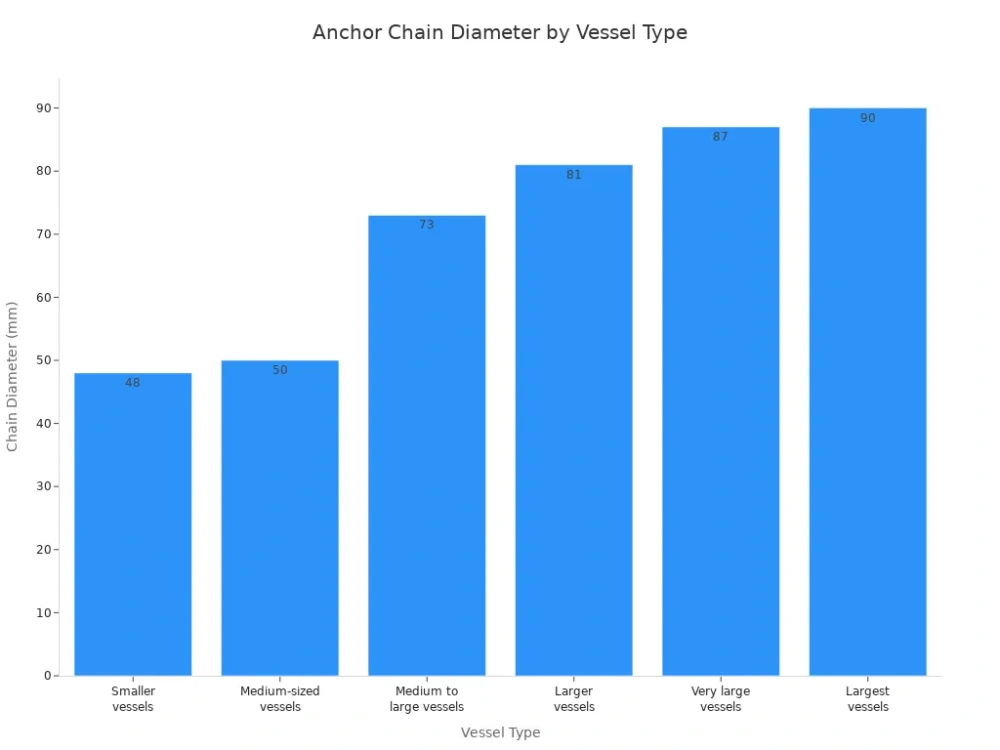

Diameter and Material Standards

Anchor chain diameter plays a critical role in holding power and safety. You must match the anchor chain diameter to your vessel’s size and operational needs. The table below shows typical anchor chain diameter recommendations for different vessel types:

Diameter (mm) | Suitable For |

|---|---|

48 | Smaller vessels or boats with lighter weight |

50 | Medium-sized vessels with moderate anchoring needs |

73 | Medium to large vessels with higher demands |

81 | Larger vessels such as cargo ships and tankers |

87 | Very large vessels like oil tankers and carriers |

90 | Largest vessels in the maritime industry |

You must also select the right material. High-grade steel and corrosion-resistant coatings extend the life of anchor chains for warships.

Product Features from Powerful Machinery

Powerful Machinery provides anchor chains for warships with advanced features. You benefit from a modular design that makes installation easy. The chains save weight and space compared to traditional hydraulic units.

Maintenance requirements stay low, and you can operate the band brake and wildcat independently. The optional capstan head handles heavy loads up to 300,000 lbs. You also get a PLC-driven digital chain counter for precise control.

Feature | Description |

|---|---|

Modular Design | Compact and easy to install |

Weight Savings | Reduces overall vessel weight |

Maintenance | Lower maintenance than hydraulic systems |

Independent Ops | Band brake and wildcat declutched for flexibility |

Capstan Head | Handles up to 300,000 lbs |

Control System | Digital chain counter with control station display |

Custom Solutions and Certifications

You can customize anchor chains for warships to meet your exact needs. Powerful Machinery offers a range of certifications, including BV, RINA, ABS, LR, and DNVGL. Material options include galvanized and stainless steel. All products meet ISO 1704, ISO, and DIN standards.

Custom grades are available for special projects, and every chain is built for reliability in harsh marine environments.

Feature | Details |

|---|---|

Certifications | BV, RINA, ABS, LR, DNVGL |

Material | Galvanized, Stainless Steel |

Standards | ISO 1704, ISO, DIN |

Customization | Custom grades for unique requirements |

Durability | Designed for demanding marine conditions |

Tip: Always verify that your anchor chains for warships carry the proper certifications. Certified chains ensure compliance, safety, and long-term reliability.

Conclusion

You now understand that battleships require anchor chains ranging from 900 to 1,500 feet, with strict technical and operational limits. Selecting certified, high-quality chains protects your vessel and ensures compliance.

Powerful Machinery delivers solutions that meet international standards and provide reliable performance.

Benefit | Description |

|---|---|

Safety Standards | Certification ensures chains meet international safety standards (ISO 1704). |

Tensile Strength | Guarantees tensile strength and fatigue resistance for vessel safety. |

Regulatory Compliance | Non-compliant chains risk vessel safety and regulatory penalties. |

Compliance with IMO and SOLAS standards prevents incidents.

Immediate replacement reduces downtime and maintains readiness.

For expert guidance or custom solutions, visit Powerful Machinery.

FAQ

How do you determine the correct anchor chain length for your warship?

You calculate the required length based on your vessel’s size and typical anchoring depth. Most experts recommend a chain length of six to ten times the water depth for secure holding.

What maintenance does your anchor chain require?

You should inspect your anchor chain regularly for wear, corrosion, and damage. Clean and lubricate the links. Replace any worn or damaged sections immediately to ensure safety.

Can you customize anchor chains for special vessel requirements?

Yes, you can request custom lengths, diameters, and materials. Powerful Machinery offers tailored solutions and certifications to match your vessel’s unique needs.

What certifications should your anchor chain have?

Always look for chains certified to ISO 1704, BV, ABS, LR, or DNVGL standards. Certified chains guarantee compliance, safety, and long-term reliability for your warship.