You often see grab hooks in places where workers need to secure heavy loads. When you ask what a grab hook is, you learn it is a strong metal hook that grabs and holds chain links tightly.

Grab hooks help you control chains during lifting and rigging tasks. Industries like steel production, construction, automotive, oil extraction, and mining rely on grab hooks for safe load handling.

Industry | Use of Grab Hooks |

|---|---|

Steel Production | Lifting heavy slabs and coils |

Construction | Moving structural materials |

Automotive | Handling specialty parts |

Oil Extraction | Lifting equipment and pipes |

Mining | Handling machinery and equipment |

Key Takeaways

Grab hooks securely hold chain links, making them essential for safe lifting and rigging tasks.

Always check the working load limit (WLL) before using a grab hook to ensure safety during operations.

Choose the right type of grab hook, like clevis or eye hooks, based on your specific lifting needs.

Inspect your grab hook and chain for wear or damage before each use to maintain safety.

Use certified grab hooks from trusted providers to ensure durability and reliability in demanding environments.

What is a Grab Hook?

When you ask what a grab hook is, you discover it is a specialized tool used in lifting and rigging. In industrial rigging terminology, what is a grab hook? It is a type of lifting hardware designed to securely hold and lift loads. The unique shape of a grab hook allows you to attach it to a chain or cable and keep it in place.

You often see this tool in construction, transportation, and material handling because it gives you control over heavy objects.

Powerful Machinery stands out as a trusted provider of grab hooks and rigging hardware. The company offers Grade 100 hooks and fittings made from high-quality alloy steel. You can rely on their products for safety, versatility, and consistent performance in demanding environments.

Design and Features

You may wonder what makes a grab hook different from other hooks. The answer lies in its design. A grab hook features a closed or semi-closed shape that enhances load retention. The eye of the grab hook lets you attach chains or cables, while the clevis attachment provides a secure connection to other rigging components.

Tip: Always check the working load limit (WLL) before using a grab hook. Manufacturers often recommend reducing the WLL by 20% for safe operation.

The main features of a grab hook include:

A shallow throat opening that prevents chains from slipping off.

Sharp, curved edges that resemble claws allow the hook to grip irregular or uneven objects.

Easy and secure engagement with chains for quick setup and adjustment.

You will find grab hooks made from strong materials. The most common are heat-treated forged steel and high-strength alloy steel. These materials give the hook excellent load-bearing capabilities and resistance to wear.

Material Type | Description |

|---|---|

High-strength alloy steel | Provides excellent load-bearing capabilities and resistance to wear and tear. |

Heat-treated forged steel | Ensures incredible mechanical performance, making it ideal for heavy-duty applications. |

Grab hooks are especially useful in industries like forestry, logging, and salvage operations. Their sharp, curved edges help you grasp objects with irregular shapes or uneven surfaces. This gripping ability makes them essential for handling logs, machinery, and other heavy materials.

Differences from Other Hooks

You might ask what a grab hook is compared to other hooks. The main difference is in the throat design and how the hook holds the chain. A grab hook has a narrow throat that grips a chain link securely without the need for a latch.

This design keeps the chain from sliding through the hook, which is important for load control and chain shortening.

Other hooks, such as slip hooks, have a wide throat and require a latch to prevent the load from sliding off. Slip hooks are better for applications where you need the chain to move freely. In contrast, a grab hook gives you firm control and prevents unwanted movement.

Grab Hooks: Narrow throat, no latch needed, grips chain links securely.

Slip Hooks: Wide throat, latch required, allows chain movement.

When you choose a grab hook from Powerful Machinery, you get a product that meets high industry standards. The company invests in security, availability, and processing integrity. You can use their hooks for chain-to-chain connections, vehicle stabilization, and many other tasks.

If you want to know what a grab hook is and why it matters, remember that this tool gives you safety, control, and reliability in lifting and rigging operations.

How Grab Hooks Work?

Attaching to Chains

You attach a grab hook to a chain by slipping the chain link into the hook’s throat. The U-shaped clevis design makes this process simple and secure. You do not need extra tools or complicated steps. The clevis pin passes through the chain link and the hook, locking them together.

This connection gives you stability, especially during overhead lifting or when you need to shorten a chain.

The Clevis Grab Hook from Powerful Machinery uses a bolt and cotter pin system. This design prevents accidental detachment and keeps your load secure. You can trust this hook for heavy-duty tasks in construction, marine, and mining environments.

Tip: Always match the grab hook to the correct chain size for safety and performance.

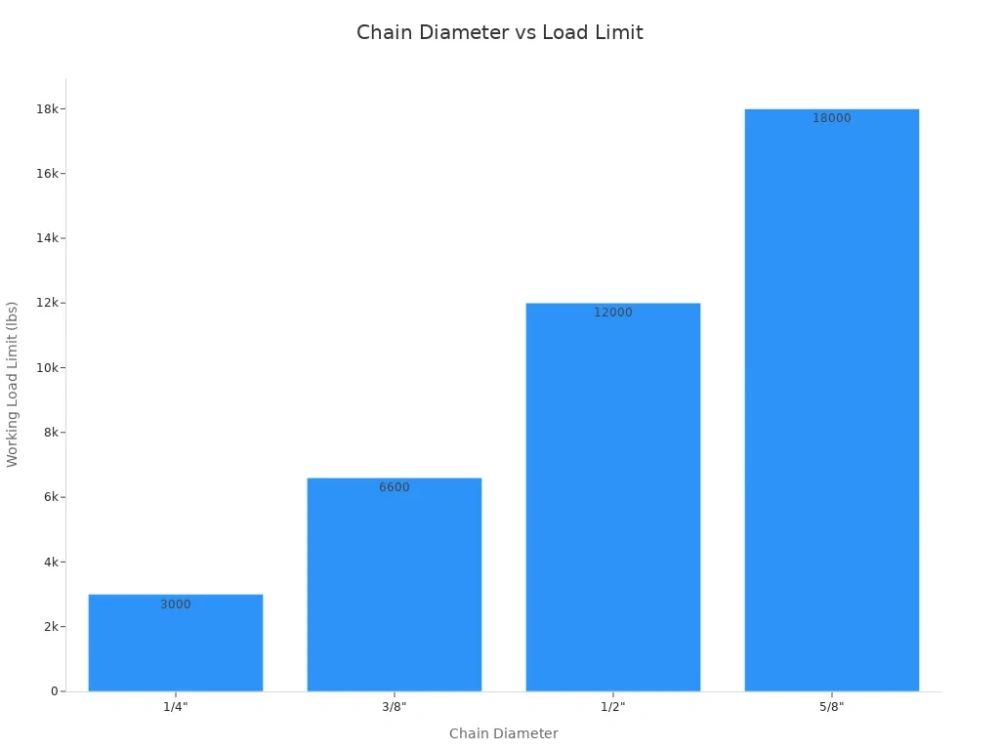

Here is a table showing common chain diameters and their working load limits:

Chain Diameter | Working Load Limit | Typical Application |

|---|---|---|

1/4″ | 3,000 lbs | Light heavy-duty loads |

3/8″ | 6,600 lbs | Standard heavy-duty loads |

1/2″ | 12,000 lbs | Heavy-duty loads requiring high securement |

5/8″ | 18,000 lbs | Very heavy-duty loads or extreme conditions |

You can also visualize the working load limits for different chain sizes:

Grabbing Mechanism

The grabbing mechanism sets this hook apart from others. When you insert a chain link into the narrow throat, the hook grips the link tightly. The shape prevents the chain from sliding or shifting. You get precise control over the chain’s length and tension. This feature is important for load binding and securing cargo.

The Clevis Grab Hook from Powerful Machinery stands out for its robust construction. It uses heat-treated alloy steel, which gives you high strength and durability. You can compare its performance to industry standards:

Feature | Grade 80 | Grade 100 | Grade 120 |

|---|---|---|---|

Relative Strength | Baseline | ~25% stronger than G80 | ~50% stronger than G80 |

Material | Heat-Treated Alloy Steel | Higher-Spec Alloy Steel | Premium Alloy Steel |

Primary Benefit | Cost-effective industry standard | Higher strength-to-weight ratio | Maximum strength-to-weight ratio |

Typical Use Case | General construction, manufacturing | Demanding environments, mobile cranes | Specialized, high-capacity lifts |

You can rely on the Clevis Grab Hook for both general and demanding applications. Its secure attachment and strong grip help you avoid accidents and ensure safe lifting.

Typical Applications

You will find grab hooks in many industries because they offer reliable performance and easy operation. Here are some common uses:

Chain sling assemblies for lifting and rigging

Towing and recovery operations

Material handling in construction and industrial settings

Rigging for hoisting and positioning heavy loads

Load securing during transportation

You also see these hooks on construction equipment like excavators and cranes. In transportation, they secure cargo on trucks and trailers. Farmers use them on agricultural machinery, and manufacturers rely on them for moving products on assembly lines.

Note: Always inspect your grab hook and chain before each use. Look for signs of wear or damage to maintain safety.

A grab hook gives you a simple but powerful way to control heavy loads. When you choose a certified product from Powerful Machinery, you get the strength, reliability, and safety you need for your toughest jobs.

Types of Grab Hooks and Sling Hooks

When you work with lifting and rigging, you need to know the differences between grab hooks and sling hook types. Each type serves a unique purpose and offers specific advantages for your job.

Type of Grab Hook | Description | Working Load Limit (WLL) Consideration |

|---|---|---|

Standard Grab Hook | Designed for tie-down applications, less common, requires a 20% reduction in WLL when used. | Reduction of 20% in WLL based on usage configuration. |

Cradle Grab Hook | Replaces standard grab hooks, provides better support for engaged chain links, no reduction in WLL when used as designed. | No reduction in WLL when used correctly. |

You also find several sling hook types in the market:

Eye hooks

Swivel hooks

Grab hooks

Shur-loc hooks

Snap hooks

Clevis Grab Hook

You often choose a clevis grab hook for heavy-duty lifting and towing. This hook uses a clevis pin to attach directly to a chain, giving you a secure and stable connection. Powerful Machinery’s clevis grab hook stands out because it is made from Grade 100 alloy steel, which increases strength and durability.

The engineered clevis head reduces mismatches with chains. The saddle supports the chain without reducing the working load limit. You get a tough powder coat finish for extra durability. Every clevis grab hook is proof tested and certified, so you can trust its performance in demanding environments.

Eye Grab Hook

An eye grab hook features a solid loop, or “eye,” at the top. You use this hook when you want to connect it to a sling or another rigging component. The eye design gives you flexibility and helps prevent twisting during lifts.

Eye grab hooks work well with chain slings and are compatible with many rigging systems. You often see them in construction, agriculture, and industrial settings. When you need a reliable connection point, the eye grab hook is a smart choice.

Choosing the Right Hook

Selecting the right grab hook or sling hook depends on your specific lifting needs. Follow these steps to make the best choice:

Evaluate the load. Check the weight, size, and shape to ensure the hook can handle it.

Understand the application. Identify the lifting operation and choose the right hook type.

Evaluate environmental conditions. Think about temperature, corrosion, and chemicals.

Adhere to safety standards. Make sure your hook meets industry regulations.

Consult with experts. Ask rigging professionals or manufacturers for advice.

Powerful Machinery offers a wide range of grab hooks and sling hooks in sizes and load ratings. For example, you can select a 3/8-inch grab hook with a working load limit of 7,100 lbs. All hooks are proof tested and certified, so you can work with confidence.

Tip: Always match your grab hook or sling hook to the chain and lifting task for maximum safety and efficiency.

How to Use a Grab Hook Safely?

Step-by-Step Guide

You need to know the proper way to use a grab hook to keep your worksite safe. Follow these steps when attaching a grab hook to chains or lifting slings:

Align Hook and Chain Link

Position the grab hook and chain link so the hook’s throat faces the direction of the load. This helps prevent twisting and keeps the connection stable.Insert Pin and Secure

Slide the clevis pin through the grab hook and the chain link. Secure it with a cotter pin or safety latch. This step ensures the hook stays attached during lifting.Final Safety Check

Inspect the setup before you begin lifting. Make sure all parts are secure and functioning. Check the grab hook, chain, and lifting slings for any signs of wear or damage.

🛠️ Tip: Always use certified grab hooks from Powerful Machinery. Their secure attachment points and built-in locking mechanisms help you maintain load stability and prevent accidents.

Safety Tips

You can avoid common mistakes and keep your team safe by following these safety tips:

Never hook the grab hook on the welded side of the chain link.

Always seat the hook fully into the chain link to prevent slippage.

Avoid using a cheater bar to force the hook or chain. This can cause overload and failure.

Watch for changes in load direction. Sudden shifts can overload the hook or chain.

Inspect all equipment before each use. Look for wear, cracks, or improper placement.

Safety Feature | Description |

|---|---|

Built-in locking mechanisms | Prevent accidental disconnection during operation, keeping the load secure. |

Safety straps | Hold the load securely, reducing the risk of slips or falls during lifting operations. |

Ease of use | Simple design lets you connect and disconnect lifting slings without hassle. |

You should always communicate with your team before and during the lift. Make sure everyone understands the plan and signals. Never stand or walk under a suspended load. Use smooth, controlled motions when lifting or lowering to keep the load stable and reduce stress on your lifting slings and grab hooks.

✅ Note: Powerful Machinery’s certified grab hooks and lifting slings promote efficiency and safety. Their straightforward design reduces the risk of accidental disengagement and ensures load stability during hoisting.

Conclusion

You now understand that a grab hook gives you secure control over chains during lifting and rigging. Using the right hook type, such as clevis or eye hooks, helps you match your application. Always check the working load limit and choose certified products for safety.

Powerful Machinery’s hooks offer durability, safety, and efficiency. The table below highlights key benefits:

Benefit | Description |

|---|---|

Safety | Reliable load control protects your team and equipment. |

Durability | Robust design withstands harsh conditions for long-term use. |

Efficiency | Streamlined workflow reduces downtime and boosts productivity. |

Remember to inspect your equipment and follow safety guidelines for every lift.

FAQ

What is the main purpose of a grab hook in rigging?

You use a grab hook to secure chain links during lifting or load control. The hook helps you adjust the length of a sling and keeps the chain from slipping. This tool gives you safe and reliable load management.

Can you use a grab hook with any sling type?

You can use a grab hook with many sling types, including chain sling and wire rope sling. Always check the compatibility between the hook and the sling. Make sure the sling matches the hook’s working load limit for safety.

How do you inspect a grab hook before using it with a sling?

You should look for cracks, wear, or deformation on the grab hook. Check the throat opening and the pin for damage. Inspect the sling for fraying or broken wires. Replace any damaged sling or hook before lifting.

What safety steps should you follow when using a grab hook with a sling?

You need to seat the hook fully into the chain link. Avoid hooking on the welded side of the chain. Inspect the sling and hook before each use. Communicate with your team and never stand under a suspended sling or load.

How do you choose the right grab hook for your sling application?

You should match the grab hook to the sling type and load weight. Check the working load limit and the environment. Consult with experts if you have questions. Powerful Machinery offers certified grab hooks for every sling and lifting need.