You want the best when it comes to wire rope clamp manufacturers. Here are the top six you should know:

PowerFul Machinery

Crosby Group

Gunnebo Industries

Van Beest

William Hackett

YOKE Industrial Corp.

Choosing the right manufacturer matters for your safety and performance. Reliable clamps help secure loads, prevent accidents, and keep your projects running smoothly.

For safe lifting, remember:

Set up clamps properly every time.

Position clamps for stability and safety.

Apply loads slowly to avoid shock loading.

Use clamps for vertical pulls only.

Inspect clamps often and follow weight limits.

Key Takeaways

Choose reliable wire rope clamp manufacturers to ensure safety and performance in your projects.

Inspect and maintain clamps regularly to prevent accidents and ensure secure load handling.

Consider manufacturers with strong certifications, as they indicate adherence to safety and quality standards.

Evaluate customer support and logistics capabilities to ensure timely assistance and delivery for your projects.

Use the comparison table to match your project needs with the right manufacturer for better safety and value.

1. PowerFul Machinery

Overview

You want a manufacturer with experience and a strong team. Powerful Machinery started in April 2005 and now has more than 300 staff. The company focuses on high-performance lifting and mooring solutions for construction, marine, transportation, and cargo handling.

You get products that meet strict safety standards and work well in tough environments.

Founding Year | Company Size |

|---|---|

April 2005 | More than 300 staff |

Main Products

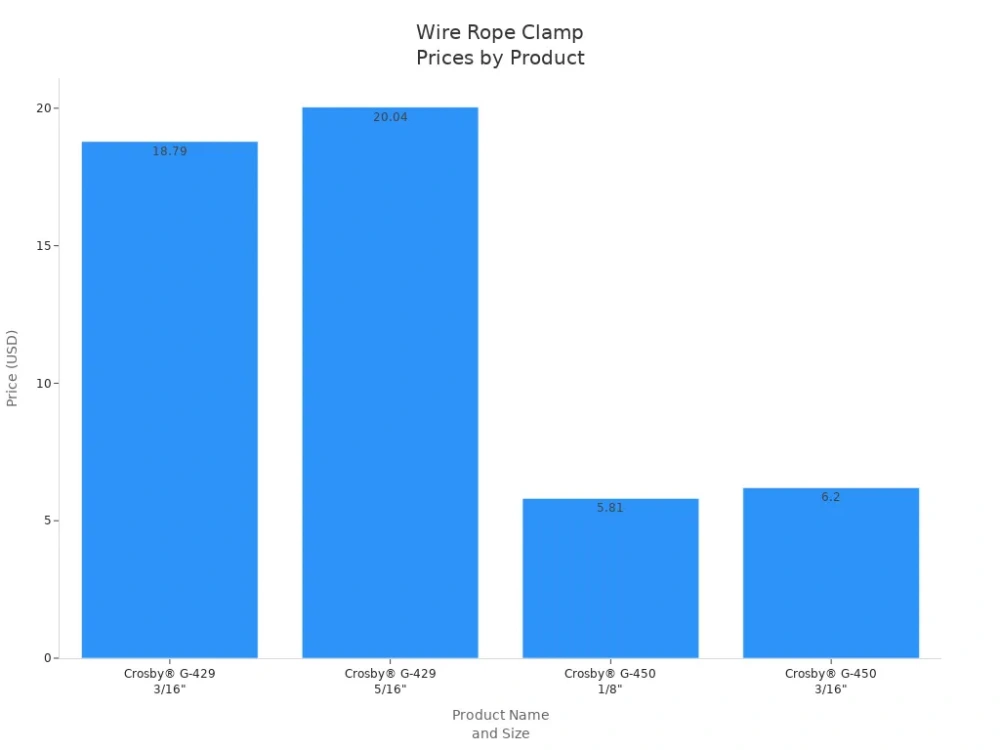

PowerFul Machinery offers a wide range of wire rope clamps and rigging hardware. You can choose from popular products like the Crosby® G-429 Galvanized Fist Grip Wire Rope Clip and the Crosby® G-450 Red-U-Bolt Drop Forged Wire Rope Clip.

These clamps come in different sizes and provide corrosion resistance and high strength.

Product Name | Size | Description | Price |

|---|---|---|---|

Crosby® G-429 Galvanized Fist Grip Wire Rope Clip | 3/16″ | Corrosion-resistant, superior strength | $18.79 |

Crosby® G-429 Galvanized Fist Grip Wire Rope Clip | 5/16″ | Corrosion-resistant, superior strength | $20.04 |

Crosby® G-450 Red-U-Bolt Drop Forged Wire Rope Clip | 1/8″ | 80% efficiency, excellent corrosion resistance | $5.81 |

Crosby® G-450 Red-U-Bolt Drop Forged Wire Rope Clip | 3/16″ | 80% efficiency, excellent corrosion resistance | $6.20 |

Strengths

You benefit from custom-engineered solutions. Powerful Machinery uses advanced manufacturing equipment, such as automated welding systems and precision forging presses. You get consistent quality and strong products. The company’s engineers work with you to design clamps that fit your project needs.

Tip: Custom solutions help you solve unique lifting challenges and improve safety.

Certifications

You receive products that meet international standards. Powerful Machinery tests every item to ensure safety and reliability. The company holds certifications for quality and safety, so you can trust their clamps in critical applications.

Global Presence

You get fast delivery and support worldwide. Powerful Machinery has an efficient logistics network. You can order products from anywhere and expect reliable shipping. The company serves clients in many countries, making it a trusted choice among wire rope clamp manufacturers.

2. Crosby Group

Overview

You find Crosby Group at the top of the list when you look for trusted wire rope clamp manufacturers. The company has a long history in the rigging industry and stands out for its strong brand reputation.

Crosby Group reports an annual revenue of $217 million and employs over 500 people. You see their products used in many critical projects because they focus on safety and reliability.

Annual revenue: $217 million (2024)

Employees: 500

Revenue per employee: $434,000

Main Products

You can choose from a range of wire rope clamps, but Crosby Group’s flagship products are the G-460 and G-461 bundle clips. These clamps are designed for tubular handling in the oil and gas sector.

You get forged materials for extra durability, and you can reuse these clips, unlike many single-use options. The G-460 features a unique ‘finger’ on the saddle to keep the sling in place. This design works well for both ‘Shore to Ship’ and ‘Ship to Shore’ applications.

The ergonomic shape also helps you attach thimble eye terminations securely.

Strengths

You benefit from Crosby Group’s focus on safety and innovation. The company invests in research and development to improve its products. You can trust their clamps in demanding environments because they go through rigorous testing. Here’s how Crosby Group compares to other wire rope clamp manufacturers:

Attribute | Crosby Group | Competitors |

|---|---|---|

Brand Reputation | Strong and trusted | Varies by manufacturer |

Commitment to Safety | High priority with rigorous testing | May vary |

Expertise in the Rigging Industry | Long history and proven expertise | Less established |

Innovation | Continuous investment in R&D | Limited focus on innovation |

Reliability in Demanding Applications | Preferred choice for critical projects | Not always guaranteed |

Tip: Choose Crosby Group if you need reliable clamps for high-risk or critical lifting jobs.

Certifications

You get peace of mind with Crosby Group’s certifications. The company meets international standards for quality and safety. Here are some of the certifications you can expect:

Certification Type | Description |

|---|---|

ISO9001 | International standard for quality management systems |

DNV-GL Type Approval | Certification for maritime industry products |

ATEX | Certification for equipment in explosive atmospheres |

IECEx | Certification for equipment in explosive environments |

Global Presence

You can access Crosby Group products almost anywhere in the world. The company has a large distribution network and a strong global presence.

Metric | Value |

|---|---|

Authorized local distributors | 3,500+ |

Factories, offices, & distribution sites | 50+ |

Employees worldwide | 4,000+ |

You get support and fast delivery, no matter where your project is located.

3. Gunnebo Industries

Overview

You find Gunnebo Industries at the top of the list when you look for companies with a long and respected history. The company began as a hammer mill in 1764. Over the years, Gunnebo grew into a global leader in security products.

Major milestones, like the acquisition of Chubb Safes Plc in 2000, helped Gunnebo become a top name in physical security. By 2001, Gunnebo reached sales of SEK 6.8 billion and built a strong market share across Europe and worldwide.

Gunnebo stands out as one of the world’s leading security companies.

The company specializes in fire- and burglar-resistant safes, cash handling security, alarm systems, and access control.

Gunnebo continues to grow through innovation and acquisitions.

Main Products

You can choose from a wide range of lifting and rigging products. Gunnebo Industries offers wire rope clamps, chain slings, lifting hooks, and the innovative GrabiQ system.

The GrabiQ combines several functions in one component, making your lifting tasks easier and safer. The FlexiLeg system lets you add or remove slings as needed, giving you more flexibility on the job.

Strengths

You benefit from Gunnebo’s focus on quality and innovation. Every link in their chains is calibrated and pull tested to 62% of the minimum breaking force. The company’s products stand out for their:

Strengths | Description |

|---|---|

Innovative Product Designs | The GrabiQ system combines multiple functions for better usability. |

High-Quality Manufacturing | Each link is calibrated and tested for strength and safety. |

Flexible Product Usage | The FlexiLeg concept allows easy adjustment for different lifting needs. |

Tip: Choose Gunnebo for advanced features and reliable performance in demanding environments.

Certifications

You get peace of mind knowing Gunnebo Industries follows strict industry standards. All products are marked for full traceability back to the raw material source. Each lifting component is tested to at least twice the working load limit and visually inspected by experts.

Certification Focus | Details |

|---|---|

Compliance with Industry Standards | Manufactured to meet top industry requirements. |

Traceability | Full traceability of raw materials for every product. |

Rigorous Testing | Each component is tested twice the working load limit. |

Visual Inspection | Expert personnel inspect every item for quality. |

Global Presence

You can rely on Gunnebo Industries wherever your project takes you. The company operates in 25 countries and has manufacturing sites in the USA, Europe, and China. Offices in every region help you solve local challenges quickly. Gunnebo employs about 3,400 people and reported global revenue of MEUR 418 in 2021.

Manufacturing in the USA, Europe, and China

Offices in every region for local support

3,400 employees worldwide

If you want a trusted name among wire rope clamp manufacturers, Gunnebo Industries delivers quality, innovation, and global reach.

4. Van Beest

Overview

You discover Van Beest as a company with a rich history that began in 1922. Dirk van Beest, a blacksmith in Sliedrecht, Netherlands, started the business by making components for the dredging and shipbuilding industries.

Over time, Van Beest became known for its Green Pin® shackles, which set a high standard for safety and reliability. Today, you see Van Beest as a leader in lifting and lashing equipment, always focused on creating failsafe products and delivering excellent service.

Main Products

You can choose from a wide range of products under several trusted brands:

Green Pin®: Premium lifting and lashing equipment, including shackles and hooks.

Irizar Forge: Standardized and custom crane components.

Heuer Hebetechnik: Lifting technology for many applications.

Sling Supply International: Customized lifting and lashing solutions.

Enduro Softslings: Innovative soft slings with strong customer support.

When you need wire rope clamps, Van Beest offers drop forged clips designed for secure wire rope connections. Here’s a quick look at their wire rope clamp options:

Product Name | Price Range | Applications | Standards | Finish Options |

|---|---|---|---|---|

Van Beest Wire Rope Drop Forged Clip | $4.50 – $24.25 | Eye-loop connections, complete loops, where splicing is not feasible | EN13411-5, US Federal, DIN | Electro-galvanized, hot-dipped |

Strengths

You benefit from Van Beest’s focus on innovation and quality. The company serves industries like construction, marine, and oil & gas. You get fast and reliable delivery worldwide, dedicated customer support, and products tested to meet international safety standards.

Van Beest offers a wide selection, so you can find the right solution for your project.

Tip: Van Beest’s continuous product improvement helps you stay ahead in safety and efficiency.

Certifications

You can request a works certificate for your wire rope clamps. Van Beest tests all products to meet strict international safety standards. This gives you confidence in every lift.

Global Presence

You access Van Beest products through a strong global network. The main distribution center in Sliedrecht, Netherlands, covers 6,000 m² and sits near Rotterdam, a major European seaport.

In the United States, you find large stock locations in Houston, Texas, and Chicago, Illinois. Van Beest supports over 900 distributors in 90 countries, so you always have local access to Green Pin® products.

If you want a trusted name among wire rope clamp manufacturers, Van Beest delivers quality, reach, and reliability.

5. William Hackett

Overview

You find William Hackett as a respected name in lifting and rigging hardware. The company started in the United Kingdom and has built a reputation for quality and safety. William Hackett focuses on engineering excellence and innovation. You see their products used in construction, mining, marine, and industrial projects.

The company invests in research to improve product performance and reliability.

Main Products

You can choose from a wide range of wire rope clamps and rigging accessories. William Hackett offers drop forged wire rope clips, U-bolt clamps, and thimbles. These products help you secure wire ropes in lifting and lashing applications.

You also find chain slings, shackles, and lifting points in their catalog. Each product meets strict safety standards and comes in various sizes to fit your needs.

Tip: Use William Hackett’s wire rope clamps for both temporary and permanent connections. Their clamps provide a strong grip and long-lasting durability.

Strengths

You benefit from William Hackett’s commitment to safety and compliance. The company tests every product to meet or exceed international standards. You get reliable performance in harsh environments. William Hackett also offers design and assembly services.

You can request custom solutions for unique lifting challenges. The company’s technical team supports you from selection to installation.

You receive expert advice for choosing the right clamp.

You get access to certified products for critical applications.

You can rely on fast response and technical support.

Certifications

You gain confidence knowing William Hackett holds certifications for quality and safety. The company follows ISO 9001 standards for manufacturing. You also find compliance with EN and BS standards for lifting equipment. Each product comes with traceability and test certificates.

This ensures you meet project requirements and industry regulations.

Global Presence

You can access William Hackett products in markets across Europe, Asia, Africa, and the Americas. The company uses direct sales, distributors, and e-commerce platforms to reach you wherever you work.

William Hackett serves industrial clients, construction firms, and automotive manufacturers. The company continues to expand in emerging markets and offers a diverse product portfolio.

Aspect | Details |

|---|---|

Global Markets | North America, Europe, Asia, Africa, and the Americas |

Distribution Channels | Direct sales, distributors, e-commerce platforms |

Clientele | Industrial clients, construction firms, automotive manufacturers |

Strategic Focus | Expanding into emerging markets, diversifying product portfolio |

Service Capabilities | Design, assembly, certification, compliance, and distribution services |

You benefit from a global network that ensures support and delivery for projects worldwide.

6. YOKE Industrial Corp.

Overview

You find YOKE Industrial Corp. in Taiwan. This company stands out as a leader in manufacturing lifting accessories. YOKE focuses on safety and innovation. You see their products used in construction, offshore, and heavy industry projects. The company invests in technology to improve product tracking and sustainability.

Aspect | Details |

|---|---|

Company Name | YOKE Industrial Corp. |

Location | Taiwan |

Industry | Manufacturing of lifting accessories |

Manufacturing Standards | EN 1677 standards |

Main Products

You can choose from a wide range of lifting components. YOKE offers Grade 80 and Grade 100 lifting parts. Their catalog includes:

Wire rope terminations

ROV hooks

Lifting points

Contact swivels

Hoist hooks

Snatch blocks

These products help you handle loads safely and efficiently. YOKE designs each item to meet strict industry standards.

Strengths

You benefit from YOKE’s focus on digital innovation. The company equips products with Digital Product Passports (DPP). You can track each item using RFID chips. This technology records important data, such as material composition, energy performance, maintenance guidelines, and recycling methods.

YOKE also supports the EU’s Ecodesign for Sustainable Products Regulation (ESPR). This commitment helps you meet modern sustainability goals.

Tip: Use YOKE’s RFID-enabled products to simplify inspections and improve asset management.

Certifications

You gain confidence with YOKE’s strong certification portfolio. The company holds H91 certification and ISO 9001. You also see type approvals from API, SABS, ABS, BG Prufzert, and DNV. These certifications show YOKE’s commitment to quality and safety.

Global Presence

You can access YOKE products worldwide. The company exports to many countries and supports clients in diverse industries. YOKE’s global network ensures you receive reliable service and fast delivery wherever your project takes you.

Wire Rope Clamp Manufacturers Comparison

Feature Table

You want to compare wire rope clamp manufacturers before making a decision. The table below helps you see the most important factors side by side. You can check product quality, innovation, pricing, support, global reach, certifications, reputation, and customization.

Manufacturer | Product Quality & Range | Innovation & Technology | Pricing & Value | Customer Support & Service | Global Presence & Distribution | Compliance & Certifications | Reputation & Track Record | Customization & Flexibility |

|---|---|---|---|---|---|---|---|---|

PowerFul Machinery | High, certified, wide | Advanced manufacturing | Competitive | Dedicated engineering | Worldwide logistics | ISO, international | Strong, trusted | |

Crosby Group | Premium, durable | R&D focused | Value for quality | Technical assistance | Global distribution | ISO, DNV-GL, ATEX, IECEx | Industry leader | Specialized designs |

Gunnebo Industries | Reliable, innovative | GrabiQ system | Competitive | Local offices | 25 countries, global sites | Full traceability | Long history | Flexible systems |

Van Beest | Wide selection | Continuous improvement | Affordable | Fast delivery | 900+ distributors, global | EN13411-5, US, DIN | Well-known | Custom certificates |

William Hackett | Certified, robust | Engineering excellence | Fair pricing | Expert advice | Expanding worldwide | ISO, EN, BS | Respected | Design services |

YOKE Industrial Corp. | Grade 80/100, RFID | Digital passports | Competitive | Global support | Exports worldwide | H91, ISO, API, DNV | Reliable | RFID tracking |

Manufacturer Advantages

You see, each manufacturer offers unique strengths. Here is what sets them apart:

PowerFul Machinery gives you custom-engineered solutions and advanced manufacturing for tough jobs.

Crosby Group stands out with premium quality, strong safety focus, and innovative designs for critical lifts.

Gunnebo Industries provides reliable products and flexible systems, making your lifting tasks easier.

Van Beest delivers a wide selection and fast global delivery, helping you meet project deadlines.

William Hackett supports you with expert advice and certified products for safe lifting.

YOKE Industrial Corp. leads in digital innovation, offering RFID tracking and strong certifications.

Tip: Use this comparison to match your project needs with the right manufacturer. You get better safety, value, and support when you choose wisely.

Choosing Wire Rope Clamp Manufacturers

When you select wire rope clamp manufacturers, you want to make the best choice for your project. Use these tips to guide your decision:

Quality & Standards

Check if the manufacturer uses high-grade materials.

Look for products that pass strict quality tests.

Ask about the manufacturing process. Reliable companies use advanced equipment and skilled workers.

Choose clamps that meet or exceed industry standards. This helps you avoid failures and keeps your team safe.

Tip: Always inspect sample products before placing a large order.

Certifications

Review the certifications each manufacturer holds.

ISO 9001 and other international certificates show a strong focus on quality.

Some projects need special certifications, like DNV or ATEX. Make sure the manufacturer can provide these if needed.

Request documentation for every batch you buy.

Pricing & Value

Compare prices, but do not pick only the cheapest option.

Consider the value you get for your money. High-quality clamps last longer and reduce replacement costs.

Ask about bulk discounts or special offers for large orders.

Factor | What to Check |

|---|---|

Price | Competitive, transparent |

Value | Durability, warranty, support |

Customer Support

Choose a manufacturer with strong customer service.

You want quick answers to your questions and help with technical issues.

Good support includes clear instructions, training, and after-sales service.

Note: Fast and helpful support can save you time and prevent mistakes.

Logistics

Check if the manufacturer can deliver to your location on time.

Ask about shipping options and delivery times.

Reliable logistics help you avoid project delays.

When you match the strengths of wire rope clamp manufacturers to your project needs, you get better results. Focus on quality, certifications, value, support, and logistics to make a smart choice.

Conclusion

You have seen the top 6 wire rope clamp manufacturers and what makes each one stand out:

Powerful Machinery: Custom solutions and advanced manufacturing.

Crosby Group: Premium quality and safety focus.

Gunnebo Industries: Innovative systems and reliable products.

Van Beest: Wide selection and fast delivery.

William Hackett: Certified products and expert support.

YOKE Industrial Corp.: Digital innovation and strong certifications.

Use the comparison table and selection tips to choose the best manufacturer for your project. Focus on quality, certifications, and support to ensure safety and value.

FAQ

What is a wire rope clamp used for?

You use a wire rope clamp to secure the loose end of a wire rope loop back to the main rope. This creates a strong connection for lifting, rigging, or anchoring tasks.

How do you choose the right size wire rope clamp?

You match the clamp size to your wire rope diameter. Always check the manufacturer’s sizing chart. Using the correct size ensures a secure grip and safe operation.

How many wire rope clamps should you use for a connection?

You usually need at least three clamps for a safe connection. The exact number depends on the rope diameter and the manufacturer’s recommendations. More clamps increase safety.

Can you reuse wire rope clamps?

You can reuse some wire rope clamps if they show no signs of wear or damage. Always inspect clamps before reuse. Replace any clamp that looks worn or bent.

What certifications should you look for in wire rope clamps?

You should look for ISO 9001, DNV, or other international certifications. These show the clamps meet strict quality and safety standards. Certified clamps help you avoid accidents.