The global industrial lifting equipment market stands at US$85.5 billion in 2025, with projected growth to US$120.3 billion by 2032. Automation, safety, and industrialization drive this market.

The Asia-Pacific region leads expansion, fueled by infrastructure projects and manufacturing in countries like China and India. Forklifts dominate, while robotic arms show the fastest rise. Powerful Machinery, a trusted provider, delivers certified lifting solutions that support industries worldwide.

Key Takeaways

The global industrial lifting equipment market is projected to grow from $85.5 billion in 2025 to $120.3 billion by 2032, driven by automation and safety.

Forklifts dominate the market, with increasing demand for smart and automated solutions that enhance efficiency and reduce workplace accidents.

Asia-Pacific leads market growth due to rapid industrialization and infrastructure projects, particularly in China and India.

Investing in sustainable and innovative lifting solutions positions companies for long-term success in a competitive market.

Understanding market segmentation helps businesses target specific customer needs and develop tailored lifting equipment solutions.

Market Overview

Market Definition

The industrial lifting equipment market includes devices that help move heavy loads in many industries. These machines reduce manual labor and lower the risk of human error during transportation. Companies use lifting equipment to improve efficiency and safety in their operations.

The market covers a wide range of products, such as hoists, cranes, winches, lifts, and forklifts. These tools play a key role in construction, manufacturing, oil and gas, mining, and logistics. Automation and smart technology continue to shape the market, making lifting tasks safer and more precise.

Industrial Lifting Equipment Market Size

The industrial lifting equipment market size has shown steady growth in recent years. The global industrial lifting equipment market reached a value of $85.5 billion in 2025. Experts expect the market to grow to $120.3 billion by 2032. This growth comes from rising demand for automation, safety, and efficient material handling.

The forklift market, in particular, has seen rapid expansion as industries seek better ways to move goods. The following table shows the market size and projected growth rate:

Year | Market Size (USD Billion) | Projected Growth Rate (CAGR) |

|---|---|---|

2024 | 85.21 | 4.80% |

2025 | 85.5 | 5.0% |

2032 | 120.3 | – |

The forklift market remains a major segment, with forklifts used in warehouses, factories, and construction sites. Forklifts help companies handle materials quickly and safely. Automation in forklift design has improved productivity and reduced workplace accidents.

The market size reflects the growing need for reliable lifting solutions in both developed and emerging economies.

Powerful Machinery stands out as a leading brand in the industrial lifting equipment market. The company offers certified lifting chains, wire ropes, and rigging hardware.

Powerful Machinery supports industries worldwide by providing high-performance products that meet strict safety standards. Their commitment to quality and innovation helps drive the growth of the global industrial lifting equipment market.

Market Segmentation

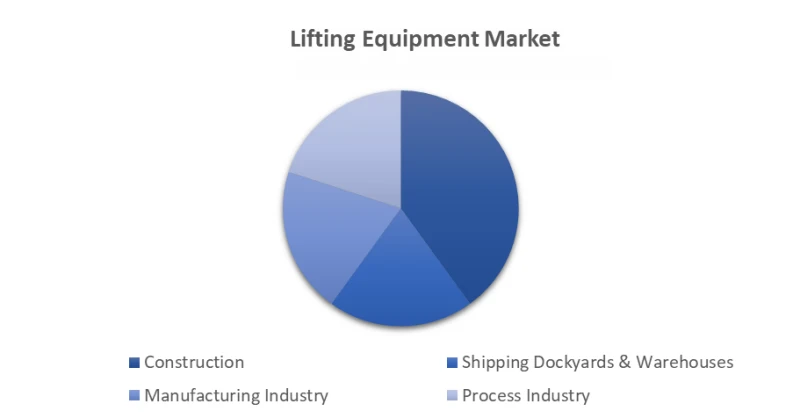

Market segmentation helps companies understand the different needs within the industrial lifting equipment market. The market is divided by product type, application, power source, end-user industry, and region. This approach allows businesses to target specific customer groups and develop products that fit unique requirements.

Category | Details |

|---|---|

Product Type | Hoists, Cranes, Winches, Lifts, Forklifts, Others |

Application | Construction, Manufacturing, Oil & Gas, Mining, Logistics, Others |

Power Source | Electric, Hydraulic, Pneumatic |

End-User Industry | Construction, Automotive, Aerospace, Marine, Others |

Regional Outlook | Asia Pacific leads due to industrialization and infrastructure growth. |

The forklift market dominates the product type segment, with forklifts used in logistics, manufacturing, and construction. Forklifts offer flexibility and speed, making them essential for moving goods. Hoists and cranes also play a vital role in heavy lifting tasks.

Automation and smart features in these machines improve safety and efficiency.

In terms of application, construction and manufacturing lead the demand for lifting equipment. The oil and gas sector also relies on robust lifting solutions for safe operations. The logistics industry uses forklifts and hoists to streamline warehouse management.

Asia Pacific holds the largest share of the industrial lifting equipment market. Rapid industrialization and infrastructure projects in China and India drive this growth. The forklift market in this region continues to expand as companies invest in modern equipment.

Powerful Machinery addresses the needs of each segment by offering a wide range of lifting products. Their solutions support construction, marine, transportation, and logistics industries. The company’s focus on safety, automation, and certified quality sets them apart in the industrial lifting equipment market.

Note: Market segmentation helps companies identify trends and growth opportunities in the industrial lifting equipment market. Businesses can use this information to develop targeted strategies and stay ahead of competitors.

Market Dynamics

Key Drivers

The industrial lifting equipment market continues to expand due to several important drivers. Automation plays a major role in transforming warehouses and factories. Automated systems, such as robotic arms and smart monitoring devices, help companies optimize storage and retrieval processes.

Safety remains a top priority for industries. Many businesses upgrade their lifting equipment to comply with strict safety regulations and improve worker safety. Industrialization and the rise of e-commerce also drive growth.

The expansion of logistics and supply chain networks increases the need for efficient forklift and crane solutions. Companies seek advanced safety features and digital control systems to boost productivity and reduce accidents.

Driver | Description |

|---|---|

Automation | Automated warehouses increasingly rely on lifting systems to optimize storage and retrieval processes. |

Safety | Compliance with stringent safety regulations encourages industries to upgrade their lifting systems. |

Industrialization | Growth in e-commerce and supply chain networks demands faster and safer material movement. |

The forklift market shows rapid growth as businesses invest in smart lifting solutions. Technological advancements, such as IoT-enabled monitoring and industrial automation, improve safety and efficiency.

The global industrial lifting equipment market benefits from these trends, with market size projected to reach new heights.

Challenges

The industrial lifting equipment market faces several challenges. High initial costs make it difficult for small and medium-sized businesses to invest in advanced forklift and crane systems. Skilled labor shortages present another obstacle. As equipment becomes more complex, companies struggle to find qualified operators.

Regulatory compliance adds to market challenges. Businesses must meet safety regulations and environmental standards, which often require ongoing investments in equipment upgrades and personnel training. These factors can slow market growth and limit access to the latest lifting technologies.

High initial costs for advanced lifting equipment

Skilled labor shortages, especially in developing regions

Regulatory compliance with safety and environmental standards

Opportunities

Opportunities in the industrial lifting equipment market arise from sustainability and innovation. Industries now focus on eco-friendly and energy-efficient lifting solutions. Companies adopt digital technologies to reduce waste and improve operational practices.

Powerful Machinery leads the way by offering certified lifting products that meet international safety standards. Their commitment to innovation and sustainability helps clients achieve safer and more efficient lifting operations.

As businesses prioritize worker safety and advanced safety features, demand for smart lifting equipment continues to grow. The forklift market and crane segment will benefit from these trends, driving further market expansion.

Note: Companies that invest in sustainable and innovative lifting solutions position themselves for long-term success in the global industrial lifting equipment market.

Market Size and Trends Analysis

Historical Growth

The industrial lifting equipment market has experienced steady growth over the past decade. Companies in construction, manufacturing, and logistics have increased their investments in lifting solutions. Forklift market expansion has played a major role in this growth.

The demand for forklifts, hoists, and cranes has risen as industries seek safer and more efficient ways to move heavy loads.

The following table shows the historical market size and growth rates:

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2024 | 84.52 | N/A |

2025 | 88.33 | 4.5 |

2029 | 107.94 | 5.1 |

Forklift market growth has remained strong, with forklifts becoming essential tools in warehouses and factories. The U.S. market reached $22.6 billion in 2024, while China’s market is projected to hit $25 billion by 2030. Forklifts and lifts have shown consistent growth, driven by automation and safety improvements.

Segment | Market Value (2030) | CAGR (%) |

|---|---|---|

Forklifts | $25.5 Billion | 5.1 |

Lifts | N/A | 4.2 |

U.S. Market | $22.6 Billion (2024) | N/A |

China Market | $25 Billion (2030) | 7.2 |

Industrial lifting equipment market growth has been shaped by several milestones. Companies have adopted smart technologies, such as IoT-enabled monitoring and automated control systems. These advancements have improved safety compliance and reduced operational interruptions.

The integration of smart features has made lifting equipment more reliable and user-friendly.

Forecast and Projections

Experts predict continued growth in the global industrial lifting equipment market. The market size is expected to reach $110.86 billion by 2030, with a compound annual growth rate (CAGR) of 5.10%. Forklift market expansion will remain a key driver, as industries focus on automation and safety.

Segment | Market Value (2030) | CAGR (%) |

|---|---|---|

Forklifts | $25.5 Billion | 5.1 |

Lifts | N/A | 4.2 |

Global Industrial Market | $110.86 Billion | 5.10 |

Major trends will shape the future of the industrial lifting equipment market. Companies are shifting toward intelligent, data-driven lifting solutions. Predictive maintenance capabilities are becoming more common, helping businesses avoid downtime and improve safety compliance.

Digitalization is transforming industrial operations, with smart technologies like IoT and AI enabling real-time monitoring and automated control.

Note: The ongoing shift toward sustainable practices is likely to boost demand for eco-friendly and electric-powered lifting solutions.

Key trends in the industrial lifting equipment market include:

Integration of smart technologies, such as IoT and AI, for real-time monitoring and predictive maintenance.

Adoption of automated lifting solutions, including robotic cranes and automated guided vehicles (AGVs), in smart factories.

Focus on safety compliance and operational efficiency through digitalization.

Growing demand for sustainable and electric-powered lifting equipment.

Forklift market growth will continue as companies invest in advanced lifting solutions for logistics and material handling. The crane segment will also benefit from technological advancements and increased safety standards.

The market size and trends analysis show that innovation and automation will drive future growth in the industrial lifting equipment market.

Market Segmentation

By Equipment Type

Industrial lifting equipment market analysis begins with a breakdown by equipment type. The market includes a wide range of machines designed for moving heavy loads. Forklift market growth remains strong, with forklifts used in warehouses, factories, and construction sites.

Lifts, pallet trucks, hoists, stackers, and robotic arms also play important roles. Powerful Machinery offers certified lifting equipment such as wire rope pulling hoists, chain pulley blocks, and I Beam Hoist Clamps. These products support worker safety and meet strict safety regulations.

The following table shows common equipment types and examples:

Equipment Type | Examples |

|---|---|

Lifts | Various types of lifts |

Pallet Trucks | Manual and electric pallet trucks |

Forklifts | Counterbalance and reach forklifts |

Hoists | Chain and wire rope hoists |

Stackers | Manual and electric stackers |

Robotic Arms | Industrial robotic arms |

Forklift market trends show increasing demand for smart and automated solutions. Technological advancements in industrial automation drive the adoption of robotic arms and automated guided vehicles.

By Application

Industrial lifting equipment market segmentation by application reveals several key areas. Construction leads the market, driven by infrastructure growth and urbanization. Manufacturing relies on forklifts and hoists for efficient production.

Logistics and warehousing use advanced lifting systems to manage inventory and support e-commerce. Retail, food and beverage, and healthcare require specialized equipment for safety and compliance.

Powerful Machinery’s lifting solutions serve these diverse applications, helping companies meet market size targets and improve worker safety. The table below highlights major application areas and their contributions:

Application Area | Contribution to Market Demand |

|---|---|

Construction | Infrastructure development and urbanization drive demand for cranes and hoists. |

Manufacturing | Efficient production and automation boost forklift use. |

Logistics and Warehousing | E-commerce and inventory management propel AGVs and robotic systems. |

Retail and E-commerce | Online shopping growth requires advanced material handling solutions. |

Food and Beverage | Safety standards and logistics increase specialized equipment demand. |

Pharmaceuticals and Healthcare | Regulatory requirements and precise handling drive specialized equipment demand. |

Forklift market expansion in logistics and manufacturing supports the global industrial lifting equipment market. Automation and safety remain top priorities in every application.

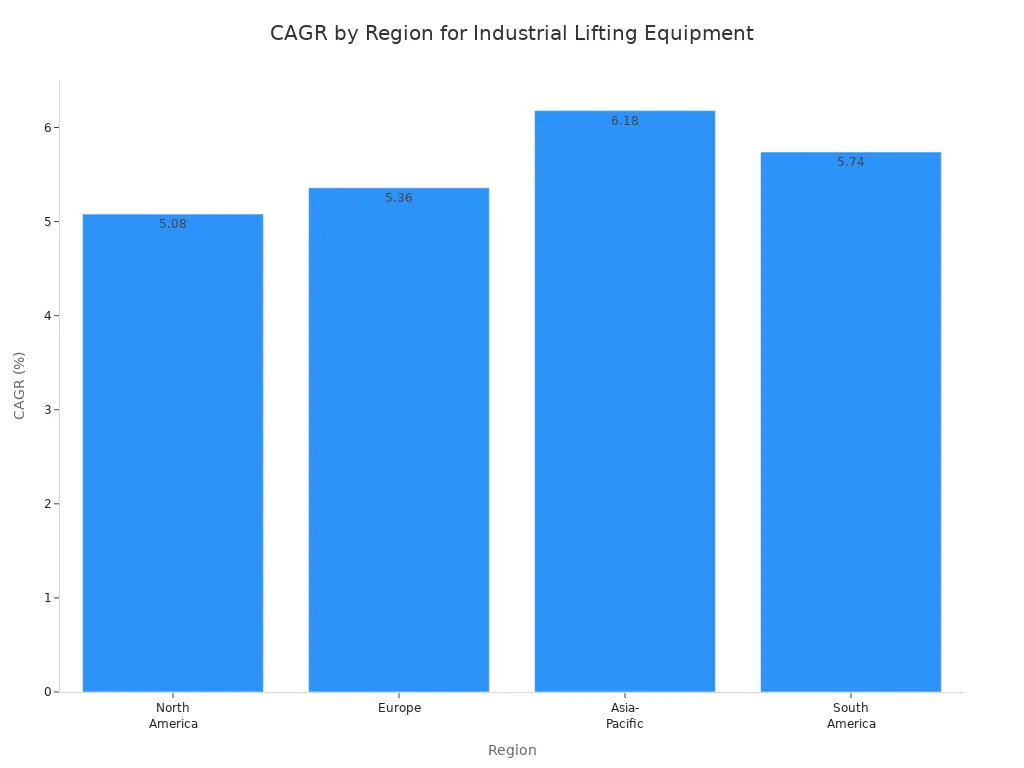

By Region

Market segmentation by region shows where growth is strongest. Asia-Pacific leads the market, driven by rapid industrialization and a growing consumer base. North America and Europe follow, supported by technological infrastructure and sustainability initiatives.

South America and the Middle East offer emerging opportunities. Powerful Machinery, based in China, influences the Asia-Pacific market with certified lifting products. The table below presents regional market growth rates:

Region | CAGR (%) |

|---|---|

North America | 5.08 |

Europe | 5.36 |

Asia-Pacific | 6.18 |

South America | 5.74 |

North America benefits from strong technology and high adoption rates.

Europe focuses on sustainability and innovation.

Asia-Pacific shows the fastest growth due to industrialization.

Latin America and the Middle East present new investment opportunities.

Industrial lifting equipment market analysis shows that regional trends, equipment type, and application all shape market size and future growth. Companies like Powerful Machinery help drive the global industrial lifting equipment market with advanced lifting solutions.

Technological Trends

Automation and Robotics

The industrial lifting equipment market has seen rapid growth in automation. Companies now use advanced robots to improve forklift and crane operations. Collaborative robots, or cobots, work with employees to boost safety and productivity.

Autonomous mobile robots move materials in warehouses and factories without human help. Artificial intelligence lets these robots analyze data and adjust tasks in real time. Digital twin technology creates virtual copies of equipment, helping engineers test and improve designs before building them.

End-to-end automation makes manufacturing more efficient and competitive. The forklift market benefits from these advancements, as smart robots handle heavy loads and reduce workplace risks.

Advancement | Description |

|---|---|

Collaborative Robots (Cobots) | Work with humans, using sensors and AI for safety and productivity. |

Autonomous Mobile Robots (AMRs) | Move materials independently, optimizing logistics and warehouse tasks. |

AI Integration | Analyze data in real time, adapting to changes and improving efficiency. |

Digital Twin Technology | Simulate and optimize equipment and processes virtually. |

End-to-End Automation | Streamline manufacturing, making the market more competitive. |

Powerful Machinery leads the market by adopting these technological trends in its lifting solutions.

IoT and Predictive Maintenance

IoT technology has transformed the industrial lifting equipment market. Sensors collect data from forklifts and hoists, turning them into smart devices. Real-time monitoring tracks performance and environmental conditions. Predictive maintenance uses this data to spot problems before they cause breakdowns.

Automated scheduling ensures repairs happen at the right time, reducing downtime. Managers use data-driven decisions to improve operations. Remote management lets teams check equipment status from anywhere, which is important for companies with many sites.

Over time, IoT data helps businesses find patterns and make long-term improvements. The forklift market uses these tools to keep lifting equipment safe and reliable.

Electric and Hybrid Equipment

Electric and hybrid lifting equipment is gaining popularity in the market. North America and Europe lead this shift, driven by sustainability goals and new regulations. The electrical segment is expected to grow faster than traditional models from 2025 to 2032.

Companies choose electric forklifts for lower emissions and quieter operation. This trend supports the overall growth of the forklift market and helps businesses meet environmental standards. Powerful Machinery offers electric-powered lifting solutions that support these market changes.

Safety Innovations

Safety remains a top priority in the industrial lifting equipment market. New operator safety features include active anchoring systems and secondary guarding that stop machines in dangerous situations. Sensors monitor critical thresholds and alert workers to risks.

Worksite safety tools, such as obstacle and pedestrian detection, prevent accidents. Transport safety improvements, like high-visibility baskets and advanced lighting, make loading and unloading safer. These innovations protect workers and equipment.

Powerful Machinery designs lifting products with advanced safety features, helping clients meet strict safety standards and maintain trust in the market.

Note: Companies that invest in smart, automated, and safe lifting equipment will lead the market as technological trends continue to shape the future.

Regional Insights

Asia-Pacific

Asia-Pacific leads the global industrial lifting equipment market with rapid growth. The region shows the fastest expansion, driven by industrialization and infrastructure projects. China, India, and Southeast Asia invest heavily in highways, railways, and airports.

Urbanization and a construction boom increase demand for advanced lifting equipment. Companies in this region focus on renewable energy projects, which require specialized crane solutions. Advancements in crane technologies, such as IoT and automation, improve operational efficiency and safety.

Sustainable construction practices also influence market demand. Port expansion and increased trade activities boost the need for heavy-duty lifting equipment in logistics.

Growth Factor | Description |

|---|---|

Infrastructure Development | Investments in highways, railways, and airports drive demand for advanced lifting equipment. |

Renewable Energy Projects | Wind and solar farms require specialized cranes for heavy lifting. |

Advancements in Crane Technologies | IoT and automation enhance efficiency and safety. |

Urbanization and Construction Boom | Large-scale projects increase demand for cranes in confined spaces. |

Sustainable Construction Practices | Eco-friendly cranes with lower emissions are in demand. |

Increased Trade and Port Expansion | Port growth drives demand for cargo handling equipment. |

Powerful Machinery, based in China, plays a key role in this region. The company supplies certified lifting solutions that support construction, logistics, and renewable energy projects.

North America

North America holds a significant share of the industrial lifting equipment market. The market value is projected to reach $22.6 billion in 2024. The forklift market in this region is expected to grow to $25.5 billion by 2030, with a CAGR of 5.1%. North America accounts for 36.14% of the market revenue.

Growth comes from infrastructure spending, industrial expansion, and the rise of e-commerce. Companies invest in advanced forklift and lifting solutions to improve safety and efficiency in logistics and manufacturing.

Market value: $22.6 billion (2024)

Forklift market: $25.5 billion (2030), 5.1% CAGR

Market share: 36.14%

Key drivers: Infrastructure, industrial growth, e-commerce

Europe

Europe’s industrial lifting equipment market evolves with technology and regulation. Companies adopt AI, IoT, and automation to enhance efficiency and performance. The region sees rising demand for sustainability and eco-friendly lifting solutions. Regulatory pressures and consumer preferences drive this trend.

The market shifts toward cloud-based and subscription models, offering flexibility and cost-effectiveness. Forklift market growth in Europe reflects the focus on innovation and safety.

Integration of advanced technologies

Demand for sustainable, eco-friendly lifting equipment

Shift to cloud-based and subscription models

Emerging Markets

Emerging markets, especially in the Asia-Pacific region, show the fastest growth in industrial lifting equipment demand. China, India, and Southeast Asia lead this trend. Rapid industrialization, infrastructure expansion, and logistics modernization drive market growth.

The forklift market in these regions expands as companies seek reliable lifting solutions for new projects.

Note: Regional trends shape the future of the global industrial lifting equipment market. Companies like Powerful Machinery influence growth with advanced lifting products and a strong focus on safety.

Competitive Landscape

Major Players

The industrial lifting equipment market features several leading companies that shape the competitive landscape. These major players drive innovation and set industry standards. Some of the top names include:

Anhui Heli Co., Ltd.

HAULOTTE GROUP

Ingersoll-Rand

SSAB

Zoomlion Heavy Industry Science&Technology Co., Ltd.

Hyster-Yale Materials Handling, Inc.

PALFINGER AG

Cargotec Corporation

These companies compete in the forklift market by offering advanced lifting solutions for construction, logistics, and manufacturing. Each player invests in research to improve forklift and crane technology, helping the market grow and evolve.

Product Innovation

Product innovation remains a key factor in the forklift market. Manufacturers introduce new lifting equipment to meet changing industry needs. Recent developments focus on safety, efficiency, and operator comfort. The table below highlights some notable innovations:

Product Name | Description | Manufacturer |

|---|---|---|

SPT1009 Mini Crane | 10,000 kg lifting capacity, advanced technology | Uplifter GmbH & Co. KG |

Ergonomic Lifting Aids | Safer, more efficient load handling for production and logistics | Uplifter GmbH & Co. KG |

Companies like PALFINGER and Terex Utilities showcase new forklift market advancements at major industry expos. Many manufacturers now design lifting equipment to reduce operator fatigue and improve ergonomics.

These trends help the market address safety and productivity challenges in logistics and forklift operations.

Strategic Partnerships

Strategic partnerships play a vital role in the forklift market and the broader lifting equipment sector. Companies form alliances to expand their reach and enhance technology. These collaborations support market growth and strengthen competitive positions. Key trends include:

A rise in strategic collaborations and partnerships across the market

Focus on expanding geographical presence and technological capabilities

Efforts to improve product offerings through joint ventures

Powerful Machinery stands out in the competitive landscape. The company holds certifications such as ISO9001, ISO14001, TUV Rheinland, and OSHA. These achievements show a strong commitment to quality and safety.

Powerful Machinery has expanded its logistics network and improved delivery times for international clients. The brand has also received awards for design and innovation, earning trust from customers in the forklift market and beyond.

Note: The competitive landscape in the industrial lifting equipment market continues to evolve as companies invest in new forklift and lifting technologies, form partnerships, and pursue global growth.

Conclusion

The industrial lifting equipment market shows strong growth as automation, sustainability, and new technology drive demand. Companies use IoT and AI to improve safety and efficiency. Many industries now choose eco-friendly lifting solutions to meet global standards.

Market segmentation and regional trends reveal high growth in China and steady expansion in the U.S. Powerful Machinery stands out by offering certified, innovative products that support these trends.

Segment | Expected Growth (CAGR) | Market Value (2030) |

|---|---|---|

Forklifts | 5.1% | $25.5 Billion |

Lifts | 4.2% | N/A |

U.S. Market | N/A | $22.6 Billion (2024) |

China Market | 7.2% | $25 Billion (2030) |

Industry professionals should focus on automation, invest in sustainable equipment, and track regional opportunities for long-term success.

FAQ

What drives growth in the industrial lifting equipment market?

Automation, safety improvements, and industrialization drive market growth. Companies invest in advanced lifting solutions to increase efficiency and reduce workplace accidents. Asia-Pacific leads expansion due to rapid infrastructure development.

How does technology impact lifting equipment?

Technology brings automation, IoT, and robotics to lifting equipment. These advancements help companies monitor equipment, predict maintenance needs, and improve safety. Smart features make lifting operations faster and more reliable.

Why do industries choose Powerful Machinery?

Industries trust Powerful Machinery for certified, high-performance lifting solutions. The company offers products that meet strict international standards. Clients value the brand’s focus on safety, innovation, and customer support.

What are the main types of industrial lifting equipment?

Forklifts

Hoists

Cranes

Winches

Lifts

Each type serves different industries and applications. Powerful Machinery provides a wide range of these products to meet diverse needs.