You use a chain hoist to lift heavy loads with less effort. The gear and chain mechanism inside multiplies your input force, allowing you to move objects that would otherwise be impossible to lift by hand.

Many industries rely on this tool, including automotive, mining, metal production, and general manufacturing. Powerful Machinery stands out as a trusted provider of high-performance lifting solutions for demanding environments worldwide.

Key Takeaways

A chain hoist allows you to lift heavy loads with less effort by using a gear and chain mechanism that multiplies your input force.

Understanding the main components of a chain hoist, such as the drive device and load hook, is essential for safe and efficient operation.

Choose the right type of chain hoist based on your needs: manual for simple tasks, electric for heavy-duty jobs, and pneumatic for environments with electrical risks.

Always prioritize safety by inspecting your hoist before use, ensuring proper load alignment, and following best practices for operation.

Select a chain hoist that meets your weight capacity needs and environmental conditions, ensuring it complies with safety certifications for reliable performance.

What Is a Chain Hoist?

Definition and Main Uses

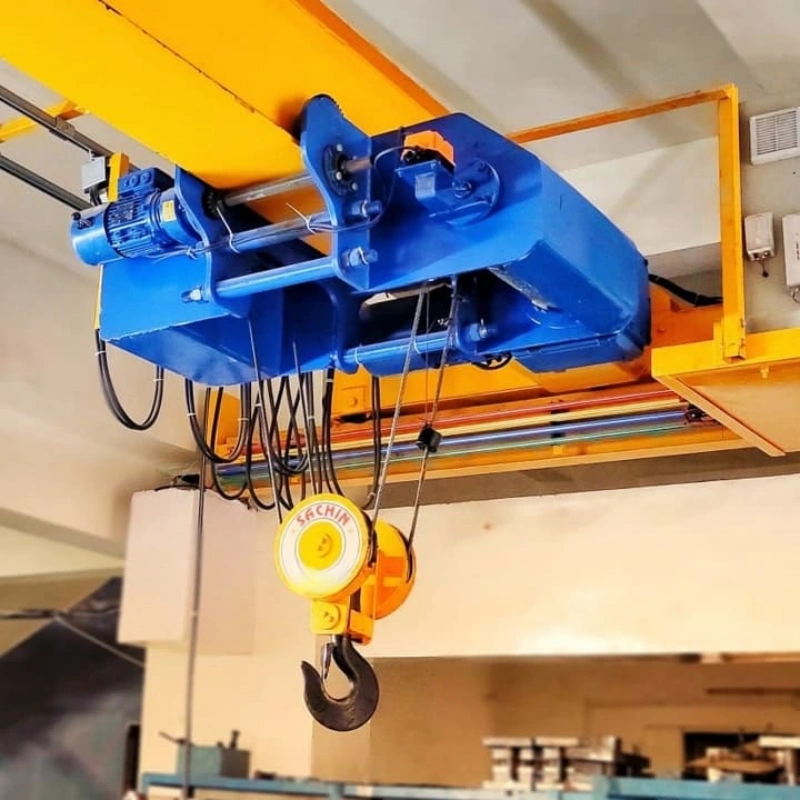

You use a chain hoist to lift and move heavy objects with ease. This lifting device converts manual or powered input into vertical movement, making it possible to raise loads that would be difficult to handle by hand. A chain hoist consists of a chain, pulleys, and a load hook.

These parts work together to create a mechanical advantage, so you need less force to lift more weight. You find chain hoists in manufacturing, construction, automotive, warehousing, and marine sectors.

Each industry relies on chain hoists for tasks like transferring raw materials, setting steel beams, lifting engines, and handling equipment in harsh environments.

Chain hoists offer durability and reliability, making them essential tools for professionals who need safe and efficient lifting solutions.

Sector | Application Description |

|---|---|

Manufacturing | Transfer raw materials, flip weldments, load/unload fixtures, often used beneath cranes. |

Construction | Hoist rebar, set stair flights, and assist with steel beam placement at job sites. |

Automotive | Lift engines and components for service, using portable hoists for fine control. |

Warehousing | Electric chain hoists transfer heavy items in hard-to-reach areas. |

Marine | Handle heavy equipment on ships and offshore platforms in harsh environments. |

Key Components

You need to understand the main parts of a chain hoist to operate it safely and efficiently. Each component serves a specific function:

Component | Function |

|---|---|

Drive device | Converts electrical energy into mechanical energy, powering the hoist. |

Chain | Transmits power, enabling the load to move up or down. |

Upper and lower hoppers | Load and transport materials during lifting. |

Guiding device | Ensures correct movement of the chain, improving accuracy and stability. |

Anti-collision mechanism | Prevents collisions, protecting equipment and materials. |

Frame | Supports and fixes all other components, withstanding operational forces. |

Feeding/discharging ports | Allow entry and exit of materials during transportation. |

You also find hooks, gears, and brake systems in most chain hoists. These features help you secure loads and control lifting speed.

Types of Chain Hoists

You can choose from several types of chain hoists, each designed for specific tasks and environments. Manual chain hoists require human effort and suit simple lifting jobs. Electric chain hoists use motors for faster, more efficient lifting.

Pneumatic hoists operate with compressed air, making them ideal for continuous use in demanding settings. You also find gear hoists, rotary vane hoists, and piston hoists, each offering unique benefits.

Manual chain hoists: Hand-operated, portable, best for basic lifting.

Electric chain hoists: Motor-powered, efficient for frequent or heavy-duty jobs.

Pneumatic hoists: Use compressed air, suitable for environments where electrical equipment may pose risks.

Gear hoists: Rely on gears for mechanical advantage, handle heavy loads.

Rotary vane hoists: Use a rotor to create a vacuum for controlled lifting.

Piston hoists: Operate with fluid pressure for specialized tasks.

Powerful Machinery offers a complete range of chain hoists, including manual, electric, and pneumatic hoists. You can select the right model for your application, whether you need a compact solution for tight spaces or a heavy-duty hoist for industrial lifting.

How Does a Chain Hoist Work?

Gear System and Mechanical Advantage

When you operate a chain hoist, you rely on its internal gear system to multiply your input force. The gear train inside the hoist is essential for force multiplication. You pull the hand chain, and the gears transfer your effort to the load chain, making it possible to lift weights much heavier than you could manage alone.

This mechanical advantage is what sets chain hoists apart from simple pulleys.

The gear system in a chain hoist enables you to lift heavy objects by multiplying the force you apply. This mechanism works in both manual and electric models, so you can handle substantial loads with minimal effort.

Consider the following table to understand how the gear stages multiply force:

Stage | Force Multiplication |

|---|---|

1 | 4 |

2 | 5 |

Total | 20 |

You benefit from a gear ratio that can reach 50:1 or even 100:1 in some models. For example:

Gear Ratio | Description |

|---|---|

50:1 | For every 50 units of distance you pull, the load is lifted by 1 unit, multiplying your force by about 50 times. |

100:1 | Pulling 100 feet of hand chain lifts the load by only 1 foot, with 100 times the force applied. |

Without this gear system, you would need to exert force equal to the load’s weight. The mechanical advantage provided by the gear train is the reason you can use a chain hoist for lifting engines, steel beams, and other heavy equipment with ease.

Chain Path and Lifting Action

The chain path inside a chain hoist plays a crucial role in lifting and lowering loads. You find that the chain wraps around a sprocket, which is central to the lifting process. When you operate the lever handle or activate the motor, the sprocket turns and pulls the chain, raising or lowering the attached load.

The chain wraps around a sprocket, enabling smooth lifting and lowering.

Operating the lever handle or motor turns the sprocket, moving the chain and the load.

The chain’s design supports substantial weights, ensuring safe and controlled movement.

You see different materials used for load chains, each chosen for specific properties:

Material Type | Key Properties | Common Uses |

|---|---|---|

Carbon Steel Chains | Versatile, not ideal for acidic environments | Heavy cargo tie-downs, container securement |

Alloy Steel Chains | High strength-to-weight ratio, approved for overhead | Sling assemblies, securement, towing tasks |

Stainless Steel Chains | Wear and corrosion resistance, lightweight, strong | Hoisting, material handling, traction |

The lifting mechanism of different types of hoists relies on the strength and durability of these chains. You can trust that the chain hoist will support your load securely, whether you use it in a warehouse, on a construction site, or in marine applications.

Braking and Safety Features

Safety is a top priority when you use a chain hoist. Modern chain hoists feature advanced braking mechanisms to prevent accidental load drops and ensure secure operation. Most hoists include a mechanical load brake within the gearbox, which stops the load if the motor or primary brake fails.

The mechanical load brake sits inside the gearbox and holds the load during failures.

European-style hoists may lack a secondary brake, increasing vulnerability.

Dual brake designs offer significant safety improvements over single brake systems.

Dual redundant holding brakes ensure maximum safety by providing a backup system should the primary brake fail. This feature is crucial for critical lifts and demanding environments.

Some hoists also use overspeed sensors to engage both primary and secondary brakes if the load moves too quickly. These safety features minimize the risk of falling loads, protecting you and your equipment.

You should always look for chain hoists that meet international safety certifications. Powerful Machinery’s products comply with major standards, ensuring you get reliable and certified lifting solutions:

Certification Type | Description |

|---|---|

ANSI/ASME standards | Compliance with American National Standards |

ISO 9001 | Quality management system certification |

TUV-CE certification | European safety certification |

ASME B30.21 | Safety standards for chain hoists |

ASME B30.16 | Safety standards for overhead hoists |

When you ask, “How does a chain hoist work?” you see that the answer lies in the combination of mechanical advantage, robust chain design, and advanced safety features. These elements work together to provide you with a reliable and efficient lifting tool for any demanding application.

How to Use a Chain Hoist?

Manual Chain Hoist Operation

You operate a manual chain hoist by following a clear sequence of steps. Begin by attaching the manual chain hoist to a secure anchor point. Make sure the anchor can support the weight you plan on lifting. Next, connect the load to the hoist using the load hook.

Align the hoist vertically above the load for safe lifting. Test the setup with a small lift to confirm stability. Pull the hand chain in a steady motion to start lifting a load. Always monitor the process and keep your hands clear of moving parts. After use, inspect the manual chain hoist for wear and perform routine maintenance.

Step-by-step guide for manual chain hoists:

Attach the manual chain hoist to an anchor point.

Secure the load to the hoist.

Align the hoist vertically.

Test with a small lift.

Operate the hand chain to lift.

Monitor the process.

Perform maintenance after use.

Electric Chain Hoist Operation

Electric chain hoists offer faster lifting speeds and handle heavier loads with minimal effort. You operate these hoists using a push-button control. Before starting, verify the available power supply matches the hoist’s requirements. For lighter loads, use 120 volts. For heavier lifts, ensure at least 230 volts.

Connect the electric chain hoist to a secure anchor point. Attach the load and confirm alignment. Use the control pendant to lift or lower the load. Electric chain hoists require more frequent maintenance due to their complex components. Always check the motor and electrical connections before operation.

Key points for electric chain hoists:

Use a motor for lifting a load quickly.

Operate with push-button controls.

Verify power supply and voltage.

Attach and align the load.

Inspect motor and connections regularly.

Safety Steps and Best Practices

You must follow best practices for operating a chain hoist to ensure safety. Start with a pre-operation inspection. Check the chain, hooks, and brake system for wear or damage. Confirm the hoist is mounted securely and aligned properly. Balance the load before lifting.

Lift slowly and stay out of the danger zone. Monitor the load at all times. Use hoists rated for your environment, especially in extreme temperatures. Lubricate moving parts and replace damaged components immediately. Schedule regular inspections and follow the manufacturer’s maintenance guidelines.

Train all operators on proper procedures and safety protocols.

Tip: Use a daily checklist and schedule periodic inspections to prevent accidents and maintain reliable performance.

Safety Checklist Item | Description |

|---|---|

Inspect chains and hooks | Look for wear, corrosion, or deformation |

Test brake system | Ensure no slippage or excessive wear |

Confirm secure mounting | Check the anchor point and alignment |

Lubricate moving parts | Reduce friction and prevent failures |

Train operators | Review safety protocols and operation steps |

You protect yourself and your equipment by following these steps and maintaining your chain hoist regularly. Understanding how to use a chain hoist and applying best practices for operating a chain hoist will help you achieve safe and efficient lifting every time.

Choosing the Right Chain Hoist

Weight Capacity and Application

You need to assess your lifting requirements before selecting a chain hoist. Start by determining the maximum weight you plan to lift. Build in a safety buffer by operating the hoist at 75-80% of its rated capacity to reduce wear and stress.

Establish the lift height for your application and consider the mounting point for the hoist. If you use the hoist frequently, choose an electric model for efficiency. For occasional lifting, a manual hoist is often sufficient. Always match the hoist to your environment, whether you work in a warehouse, construction site, or marine setting.

Tip: For most commercial manual hoists, the maximum weight capacity reaches up to 3,000 lbs (1.5 tons). Always check the specifications for your chosen model.

Selection Criteria

When you select a chain hoist, you must evaluate several key factors. The following table outlines important criteria to guide your decision:

Criteria | Description |

|---|---|

Load Assessment | Understand the weight, shape, and center of gravity of your load. |

Weight Determination | Compare the load’s weight against the hoist’s Working Load Limit (WLL). |

Dynamic Load Consideration | Account for dynamic forces during lifting, not just static weight. |

Environmental Factors | Consider humidity, dust, and chemical exposure in your workspace. |

Maintenance | Follow a proactive maintenance schedule for safe operation. |

Total Cost of Ownership (TCO) | Evaluate purchase price, operating costs, maintenance, and salvage value over the hoist’s lifespan. |

You should also verify certifications such as ISO and CE. Certified hoists undergo rigorous testing and proof load checks, ensuring reliability and compliance with global safety standards.

Why Choose Powerful Machinery?

You benefit from choosing Powerful Machinery for your lifting needs. The company offers a wide range of certified chain hoists, including manual and electric models. Each product meets international standards like ISO and CE, assuring quality and safety.

Customers value the compact size and favorable price point of Powerful Machinery’s hoists. You receive all the features of full-size models in a space-saving design.

Powerful Machinery delivers custom solutions for unique project requirements, ensuring you get the right tool for your application. You gain peace of mind knowing your equipment is tested, certified, and trusted by professionals worldwide.

Note: Powerful Machinery’s commitment to quality, safety, and customer satisfaction makes it a leading choice for reliable lifting solutions.

Conclusion

You gain efficiency and safety when you understand how a chain hoist operates. Always inspect your equipment, know your load weight, and use the hoist above the center of gravity. Modern designs, smart technologies, and ergonomic features reduce failure rates and operator fatigue.

Feature | Impact on Safety and Efficiency |

|---|---|

Smart technologies | Lower equipment failure rates |

Ergonomic designs | Reduce operator fatigue |

Calculate your load, analyze your environment, and select certified equipment. Powerful Machinery offers reliable solutions that meet global standards for every lifting need.

FAQ

How do you maintain a chain hoist?

You inspect the chain and hooks regularly. Lubricate moving parts and check for wear. Replace damaged components immediately. Schedule routine maintenance to ensure safe operation.

What is the difference between manual and electric chain hoists?

Manual chain hoists require you to pull a hand chain. Electric chain hoists use a motor for lifting. Electric models offer faster operation and handle heavier loads with less effort.

Can you use a chain hoist outdoors?

You can use a chain hoist outdoors. Choose a model with corrosion-resistant materials. Always protect the hoist from moisture and debris. Inspect the equipment before each use.

How do you select the right chain hoist capacity?

You determine the weight of your load. Add a safety margin of at least 25%. Select a chain hoist with a rated capacity higher than your calculated requirement.

Tip: Always check the manufacturer’s specifications before lifting.