You can fix a chain hoist by following strict safety procedures and performing regular maintenance. Powerful Machinery stands out for its commitment to safety and innovation in manual and electric chain hoists. You must focus on safety at every step, because most failures—about 70%—come from poor maintenance.

Always use proper safety gear, follow manufacturer guidelines, and rely on expert support for Chain Hoist Maintenance and Troubleshooting to reduce risks.

Key Takeaways

Prioritize safety by using proper gear and following manufacturer guidelines. This reduces risks and ensures safe operation.

Regular maintenance is key. Clean and lubricate your chain hoist monthly to prevent issues like chain jamming and brake failure.

Inspect your hoist before each use. Look for wear, damage, and ensure all components function properly to avoid accidents.

Know when to seek professional help. For complex repairs or unusual noises, contact a certified technician to ensure safety and compliance.

Choose the right hoist for your needs. Understand the differences between manual and electric chain hoists to optimize efficiency and safety.

Chain Hoist Types and Applications

Manual Chain Hoist Overview

You often rely on manual chain hoists for lifting tasks in environments without a power supply. The SK Series from Powerful Machinery gives you a portable and efficient solution. You can use these hoists in factories, warehouses, construction sites, and outdoor settings.

The manual chain hoist operates with a hand chain, allowing you to lift loads smoothly and safely. You benefit from its compact design and low maintenance requirements. You find manual chain hoists ideal for lighter loads and situations where you need flexibility and mobility.

Tip: Manual chain hoists require you to apply physical effort, making them suitable for tasks that do not demand high lifting speeds.

Electric Chain Hoist Features

You choose an electric chain hoist when you need to lift heavier loads quickly and efficiently. The HHSY electric chain hoist from Powerful Machinery offers you a compact design for tight spaces. You use electric chain hoists in warehouses, manufacturing plants, and construction sites where speed and precision matter.

The electric chain hoist operates with minimal physical effort, giving you enhanced control and accurate positioning. You experience faster lifting and lowering speeds, which increases your productivity.

Electric chain hoists lift heavy loads faster than manual hoists, enhancing operational efficiency.

Manual hoists are reliable for lighter tasks but are less efficient for high-capacity applications.

Feature | Electric Chain Hoists | Manual Chain Hoists |

|---|---|---|

Lifting Capacity | Capable of handling heavier loads | Limited to lighter loads |

Operational Efficiency | Faster lifting and lowering speeds | Slower, labor-intensive process |

Physical Effort Required | Minimal physical effort needed | Requires significant physical effort |

Control and Precision | Enhanced control for accurate positioning | Less precise, more manual control |

Powerful Machinery Product Range

You find that Powerful Machinery offers a comprehensive range of chain hoists for various industrial needs. The SK Series manual chain hoist provides you with reliable lifting for lighter loads and flexible applications.

The HHSY electric chain hoist delivers efficient performance in confined spaces and demanding environments. You can select from models with different lifting capacities to match your requirements.

Hoist Model | Lifting Capacity | Applications |

|---|---|---|

SK Series | Up to 20,000 kg | Construction sites, warehouses, and outdoor lifting |

HHSY | Up to 5,000 kg | Warehouses, manufacturing, tight spaces |

Chain Hoist | Up to several tons | Industrial, logistics, cargo handling |

You gain the advantage of certified products that meet international safety standards. You can trust Powerful Machinery to deliver chain hoists that combine durability, safety, and operational efficiency. You improve your workflow by choosing the right manual or electric chain hoist for your specific application.

Safety Precautions for Chain Hoist Maintenance and Troubleshooting

Before you begin any chain hoist maintenance or troubleshooting, you must follow strict safety steps. These steps protect you from injury and prevent damage to your equipment.

Preparing for Inspection and Repair

You should always start with a clear plan. Review the manufacturer’s manual and safety guidelines. Make sure you understand the hoist’s rated capacity and the weight of the load. Conduct a thorough inspection of chains and hooks for damage. Confirm that your setup uses a secure anchor point.

Train yourself and your team on safe lifting and rigging techniques. Regular inspections, proper lubrication, and scheduled electrical checks help you avoid common failures like overheating and motor or brake overheating.

Note: Overloading the hoist, poor rigging, and lack of training are the top causes of accidents. You can prevent these by following best practices and keeping rigging handbooks nearby.

Disconnecting Power and Load

You must disconnect the hoist from all power sources before starting any work. Remove the load completely. This step prevents accidental movement and reduces the risk of overheating or motor or brake overheating during inspection.

For electric chain hoists, check that the main switch is off and locked out. For manual hoists, ensure the hand chain is free, and the load is secure on the ground.

Personal Protective Equipment

You need to wear the right personal protective equipment (PPE) every time. This includes safety gloves, hard hats, and eye protection. PPE shields you from injuries caused by falling objects, pinched fingers, or unexpected overheating. Always check your PPE for damage before use.

When to Seek Professional Help?

You should contact a certified technician for complex repairs or electrical issues. If you notice signs of motor or brake overheating, unusual noises, or persistent overheating, stop work immediately.

Professional help ensures compliance with safety standards like ASME B30, which covers hoists, hooks, and slings. This table summarizes key safety standards:

Aspect | Description |

|---|---|

Standard Name | ASME B30 |

Focus | Safety for hoists, hooks, jacks, and slings |

Purpose | Public safety, best practices, and regulations |

Review Frequency | Every few years, updated for technology and industry needs |

Compliance | Ensures operational safety and regulatory compliance |

You protect yourself and your team by knowing when to call for expert support. This approach keeps your chain hoist running safely and reduces the risk of overheating.

Common Chain Hoist Problems

You encounter a range of common issues when working with chain hoists, whether you use manual or electric models. Powerful Machinery designs its products to minimize these problems, but regular maintenance and periodic inspections remain essential for safe and efficient operation.

Understanding these common problems helps you prevent downtime and maintain productivity.

Chain Jamming and Twisting

Chain jamming is one of the most frequent problems you face during hoist operation. You notice the chain getting stuck or twisted, which can halt lifting or lowering tasks. This issue often results from improper alignment, lack of lubrication, or debris in the chain path.

You must inspect the chain for kinks, twists, or foreign objects. If you ignore chain jamming, you risk damaging the chain or the hoist mechanism.

Tip: Always keep the chain clean and lubricated. You reduce the risk of chain jamming and ensure smooth movement.

You also see chain jamming when the hoist can lift but cannot lower, or when the hoist can lower but cannot lift. These symptoms indicate possible obstructions or misalignment in the chain path. You should check for bent links and ensure the chain is properly seated in the sprocket.

Brake Issues and Slipping

Brake issues and slipping pose serious safety risks. You may find the hoist unable to lift the rated load or notice the load slipping unexpectedly. Powerful Machinery uses high-quality friction plates and brake systems, but wear and tear can still occur.

You must watch for signs like hoist operation unresponsive or periodic control failure.

Cause of Brake Issues and Slipping | Solution |

|---|---|

Worn or Damaged Load Brake | Perform routine maintenance and replace worn brake pads. Avoid abrupt stops to minimize wear. |

Loose Pawl Spring | Replace the spring to restore proper braking. |

Worn Friction Plate | Inspect frequently and replace if oil is present. |

Poor Quality Friction Plate | Use certified chain hoists for better durability. |

You also encounter slippage if the friction plate has excessive oil or if the pawl spring is loose. You should regularly clean the friction plate and replace any faulty components. If you notice the hoist can lift but cannot lower, or the hoist can lower but cannot lift, check the brake system for these issues.

Power and Electrical Failures

Common electric chain hoist repair problems often stem from power supply issues or electrical faults. You may experience a hoist operation unresponsive or periodic control failure.

About 30% of chain hoist failures relate to electrical problems. You should check the power supply connection, inspect the start button, and verify that limit switches are set correctly.

Check if the motor receives power and reconnect if needed.

Inspect the start button for poor contact and repair or replace it.

Ensure limiters are reset, and wiring is intact.

Verify the power control switch is closed and look for disconnections in the main control circuit.

Assess for overload conditions, low voltage, or motor overheating if you hear abnormal sounds.

You must address motor overheating quickly. If you ignore it, you risk damaging the hoist and creating unsafe working conditions.

Overloading and Environmental Factors

Overloading remains one of the most common problems. You might try to lift loads beyond the rated capacity, leading to material fatigue and hidden damage. Exceeding the working load limit causes internal stretching and microscopic cracks. These weaknesses may fail even under normal loads later.

Overloading can create hidden damage and metal fatigue.

You should remove any hoist that has been overloaded from service and inspect it thoroughly.

Environmental factors like moisture, dust, and temperature extremes also affect chain hoist performance.

You must perform periodic inspections to detect early signs of wear or corrosion.

If you notice the hoist is unable to lift the rated load, inspect for signs of overloading or environmental damage. You protect your equipment and team by following manufacturer guidelines and never exceeding the working load limit.

Faulty Hooks and Load Blocks

Faulty hooks and load blocks compromise safety and efficiency. You should look for cracks, corrosion, and deformation in these components. Improper safety latch function also signals a problem. You must examine the lifting chain, hand chain, and block body for wear, corrosion, or cracks.

Inspect for bent or cracked parts, especially at attachment points.

Check all bolts, pins, and fasteners for tightness and integrity.

Ensure attachments are free from defects and securely fastened.

Note: Regular inspection of hooks and load blocks prevents accidents and extends the life of your chain hoist.

You reduce the risk of hoist operation unresponsive and periodic control failure by maintaining these critical components. Powerful Machinery recommends thorough inspections to ensure your chain hoist remains safe and reliable.

Common Problems in Chain Hoist Selection and Use

You sometimes face common issues before you even start using your chain hoist. Selecting the wrong voltage, buying the wrong lift height, or choosing a trolley that does not fit the beam size can lead to operational challenges. Failing to set limit switches or leaving a load suspended for long periods also creates risks.

Purchasing the wrong voltage hoist.

Buying the wrong lift height or reach.

Choosing a trolley that does not fit the beam size.

Selecting the wrong speed control.

Failing to set limit switches.

Lifting over people or attempting to lift people.

Leaving a load suspended for extended periods.

You avoid these common problems by reviewing product specifications and consulting Powerful Machinery’s technical support. You ensure safe and efficient hoist operation by making informed choices.

Troubleshooting & Repair Steps

When you encounter issues with your chain hoist, you need a systematic approach to ensure safe and effective repairs. Powerful Machinery recommends following a troubleshooting guide that covers disassembly, inspection, cleaning, and part replacement.

This section provides a comprehensive chain hoist care guide and a step-by-step maintenance guide to help you restore your equipment to optimal condition.

Disassembly and Cleaning

You start the repair process by disconnecting the hoist from any load and power source. Place the hoist on a flat, clean surface to prevent losing small parts. Carefully disassemble the hoist, keeping track of screws, washers, and other components.

Taking photos during each step helps you reassemble the hoist correctly.

Follow these steps for disassembly and cleaning:

Disconnect the hoist from all loads and power sources.

Place the hoist on a stable, clean workbench.

Remove external covers and components, organizing parts in the order you remove them.

Take photos at each stage for reference during reassembly.

Arrange all parts neatly to avoid confusion.

Clean each part with a mild detergent or degreaser.

Use a wire brush to remove rust from metal surfaces.

Inspect every part for wear, focusing on the chain, gears, brake, and hook.

Replace any damaged or worn-out components before reassembly.

Tip: Regular cleaning after each use prevents dust and debris from causing chain jamming or brake issues.

You should use safe cleaning agents, such as mild soap and water, and ensure all parts are completely dry before reassembly. Wipe the hoist with a damp towel after each use, and occasionally wash it to remove stubborn grime.

Inspecting and Replacing Parts

During chain hoist maintenance and troubleshooting, you must inspect all critical components for signs of damage. Pay close attention to the lifting chain, wire rope, and tensioning chains on lever hoists. Look for inner link wear, gouges, nicks, and twists.

Bent or broken links can compromise safety and require immediate replacement.

Common signs of wear include:

Nicks, gouges, and deformation on load chains.

Distortion, kinking, or broken strands in wire ropes.

Chemical damage or corrosion on metal surfaces.

Visible stretch or deformation compared to manufacturer specifications.

Improper reeving or misalignment of chains and ropes.

Component | Signs of Wear | Action Required |

|---|---|---|

Load Chain | Nicks, gouges, twists | Replace immediately |

Wire Rope | Broken strands, kinks | Replace immediately |

Hooks | Cracks, corrosion, and bending | Replace immediately |

Gears & Sprockets | Excessive wear, rust | Clean and lubricate |

You should replace any part that shows significant wear or damage. Proper lubrication ensures smooth articulation and extends the lifespan of your chain hoist.

Chain Hoist Care Guide

You maintain your chain hoist by following a regular cleaning and lubrication schedule. Apply fresh lubricant to the chain monthly, making sure it penetrates between every link. Wipe off excess oil to prevent dust accumulation. Lubricate the gears and sprockets using the manufacturer’s recommended products.

Key care tips:

Clean the chain surface to remove rust and dust.

Lubricate the chain evenly to reduce friction and wear.

Check chain tension periodically and adjust as needed.

Inspect for chain wear and replace if necessary.

Clean and lubricate sprockets and gears to ensure smooth operation.

Note: Conduct pre-use checks for visible wear or damage before every operation. Schedule comprehensive inspections by qualified technicians to ensure compliance with manufacturer specifications.

You should maintain a regular maintenance schedule, performing cleaning and lubrication at least once or twice a year. This chain hoist care guide helps you prevent common problems and extend the life of your equipment.

Step-by-Step Maintenance Guide

You follow a step-by-step maintenance guide to keep your chain hoist in top condition. Begin by cleaning the chain surface to remove rust and dust. Lubricate the chain to decrease friction and avoid wear.

Periodically check chain tension and adjust as needed. Inspect for chain wear and replace damaged links. Clean and lubricate sprockets and gears to remove contaminants.

Routine maintenance steps:

Clean the chain surface after each use.

Apply lubricant monthly, ensuring even coverage.

Check and adjust chain tension regularly.

Inspect for wear, nicks, or deformation.

Replace worn or damaged parts promptly.

Clean and lubricate gears and sprockets.

Schedule annual inspections by a qualified technician.

⚙️ Pro Tip: Always use the lubricant recommended by Powerful Machinery for best results.

You ensure safe operation and reduce downtime by following these chain hoist maintenance and troubleshooting procedures. This repair process keeps your equipment reliable and compliant with safety standards.

Table: Chain Hoist Maintenance and Troubleshooting Checklist

Task | Frequency | Responsible Person |

|---|---|---|

Clean chain and hoist | After each use | Operator |

Lubricate chain | Monthly | Operator |

Inspect for wear/damage | Before each use | Operator |

Adjust chain tension | Quarterly | Technician |

Replace worn parts | As needed | Technician |

Clean/lubricate gears | Monthly | Operator/Technician |

Annual inspection | Yearly | Certified Technician |

You follow this checklist to ensure your chain hoist remains safe, efficient, and ready for use. Powerful Machinery provides product support and official guidelines to help you with every step of the repair process.

Troubleshooting Guide Summary

You address chain hoist maintenance and troubleshooting by following a systematic approach. Disassemble and clean your hoist, inspect and replace worn parts, and maintain a regular care schedule.

Use this chain hoist care guide and step-by-step maintenance guide to keep your equipment in optimal condition. Rely on Powerful Machinery’s product support for expert advice and certified replacement parts.

Testing and Verification

After you complete repairs or maintenance on your Powerful Machinery chain hoist, you must verify that every function works safely and reliably. Testing ensures that your equipment meets industry standards and protects you and your team from unexpected failures.

Brake and Load Tests

You begin by checking the brake system. Lift a load just off the ground and release the lever. The load should remain suspended without slipping. This confirms that the brake holds securely. You then perform a controlled load test. Use a test weight equal to 125% of the hoist’s rated capacity.

Observe the hoist as it lifts and lowers the load. The movement should be smooth, and the brake must engage instantly when you stop. Record the results in a written report for future reference.

Tip: Always have a qualified professional supervise load tests for maximum safety.

Test Step | Purpose | Expected Result |

|---|---|---|

Brake Function Check | Verify load holding | Load remains in place |

Confirm capacity and control | Smooth, safe operation |

Chain Movement and Noise Checks

You operate the hoist without a load to check the chain movement. The chain should move smoothly through the mechanism. Listen for abnormal sounds such as grinding, squealing, or clicking. These noises often signal lubrication problems or worn internal parts.

If you notice erratic movement or unusual sounds, stop and inspect the chain and gears. Address these issues before returning the hoist to service.

Quiet operation means the hoist is in good condition.

Grinding or squealing suggests lubrication issues.

Clicking or rattling may indicate loose or misaligned parts.

Recognizing abnormal chain movement or noise early helps you prevent mechanical failures.

Safety Feature Verification

You must verify all safety features before using the hoist. Start with a visual inspection. Check for visible damage, twisted chains, and proper hook safety latch function.

Test the emergency stop button and operate the hoist through its full range of motion without a load. Measure the load chain for stretching and inspect hooks for cracks or deformation. Schedule frequent and periodic inspections, including internal checks of gears and the braking system.

Daily inspections catch obvious issues before operation.

Frequent inspections document wear and measure chain stretching.

Annual inspections by a qualified technician ensure long-term reliability.

Thorough testing and verification keep your Powerful Machinery chain hoist safe, reliable, and ready for demanding tasks.

Chain Hoist Maintenance and Troubleshooting Tips

Cleaning and Lubrication Schedules

You keep your Powerful Machinery chain hoist in top condition by following a regular cleaning and lubrication schedule. Cleaning the chain surface removes rust and dust, preventing stiffness and wear. You should disassemble the hoist for thorough cleaning at least once or twice a year.

Lubricate the chain evenly with the correct lubricant to reduce friction and wear. Always consider your operating environment when choosing lubricants.

Best practices for cleaning and lubricating chain hoists:

Clean the chain surface after each use to remove dust and debris.

Disassemble the hoist for deep cleaning once or twice a year.

Apply lubricant evenly to the chain, focusing on every link.

Wipe off excess oil to prevent dust buildup.

Use manufacturer-recommended lubricants for optimal performance.

Regular cleaning and lubrication extend the lifespan of your chain hoist and support routine maintenance.

Inspection Checklist

You follow a maintenance checklist to ensure your chain hoist operates safely. Daily visual inspections help you catch abnormalities early. You check hoist nameplates, safety labels, and run test lifts to confirm proper function.

Inspect hooks for cracks or deformation, and verify that latches work. Examine the load chain for nicks and proper lubrication. For electric models, check limit switches and listen for unusual sounds.

Inspection Item | Description |

|---|---|

Visual Inspection | Check for abnormalities during daily operation |

Hoist Nameplates | Verify presence and completeness |

Safety Labels | Ensure warning labels are legible |

Test Run | Confirm all motions match control device markings |

Load Drift | Check that the hoist holds the load without drifting |

Hook Damage | Inspect for cracks, nicks, and deformation |

Hook Latch | Ensure latch is present and operational |

Load Chain | Look for nicks, deformation, and proper lubrication |

Cable Hoist Wire Rope | Check for broken wires and deformation |

Limit Switches | Confirm that the upper limit device stops the lifting motion correctly |

Body Frame | Inspect for deformation and corrosion |

Oil Leakage | Check for signs of oil leakage |

Unusual Sounds | Listen for abnormal noises during operation |

You also check for missing bolts, inspect the push-button switch, and confirm the power source connection.

Storage and Environmental Protection

You protect your chain hoist by storing it in a climate-controlled area. Humidity causes rapid corrosion of steel components, threatening structural integrity. Extreme temperatures lead to mechanical wear and affect performance.

Corrosive elements damage hoist components, especially the load chain. Anti-corrosion finishes and proper storage help you mitigate these risks.

Environmental Factor | Impact on Chain Hoists |

|---|---|

Humidity | Causes rapid corrosion of steel components |

Temperature Extremes | Leads to mechanical wear and performance issues |

Corrosive Elements | Damages hoist components, especially the load chain |

Protective Measures | Anti-corrosion finishes and climate-controlled storage extend life |

Store your hoist indoors and away from moisture to maximize durability.

Manufacturer Guidelines

You follow manufacturer guidelines to prevent unsafe hoisting practices. Powerful Machinery recommends reviewing the operating manual for your specific model. The guidelines include warnings and best practices based on ASME B30.16 standards.

You avoid unsafe practices that could result in injury or property damage. For electric and air-powered hoists, you pay special attention to electrical safety and proper operation.

Review the manual for recommended practices for hand chain hoists.

Follow warnings and operating practices from ASME B30.16.

Avoid unsafe hoisting practices to protect yourself and your equipment.

For electric hoists, check electrical connections and follow safety protocols.

Adhering to manufacturer guidelines ensures safe operation and supports effective chain hoist maintenance and troubleshooting.

When to Contact Powerful Machinery Support?

You should know when to reach out to Powerful Machinery support for your chain hoist. Some issues go beyond routine maintenance and require expert attention to keep your equipment safe and reliable.

Complex Repairs and Electrical Issues

If you notice any unusual sounds from your hoist—such as grinding, clicking, or squealing—stop using it right away. Unload the hoist if possible and mark it as “Out of Service.” Report the problem to your supervisor or a qualified technician before using the hoist again.

These noises can signal deeper mechanical or electrical problems that need professional inspection.

You should contact Powerful Machinery or a certified professional for the following repairs:

Motor repairs, including overheating or unexpected shutdowns

Transformer repairs, such as reduced power or humming noises

Circuit breaker repairs, especially if tripping occurs often

Wiring and conduit repairs, including exposed wires or frequent trips

Lighting repairs, like non-functional or flickering lights

Control panel and switchgear repairs, such as warning lights or unresponsive switches

Grounding system repairs to prevent electrical shocks

Always prioritize safety. If you are unsure about any repair, seek professional help.

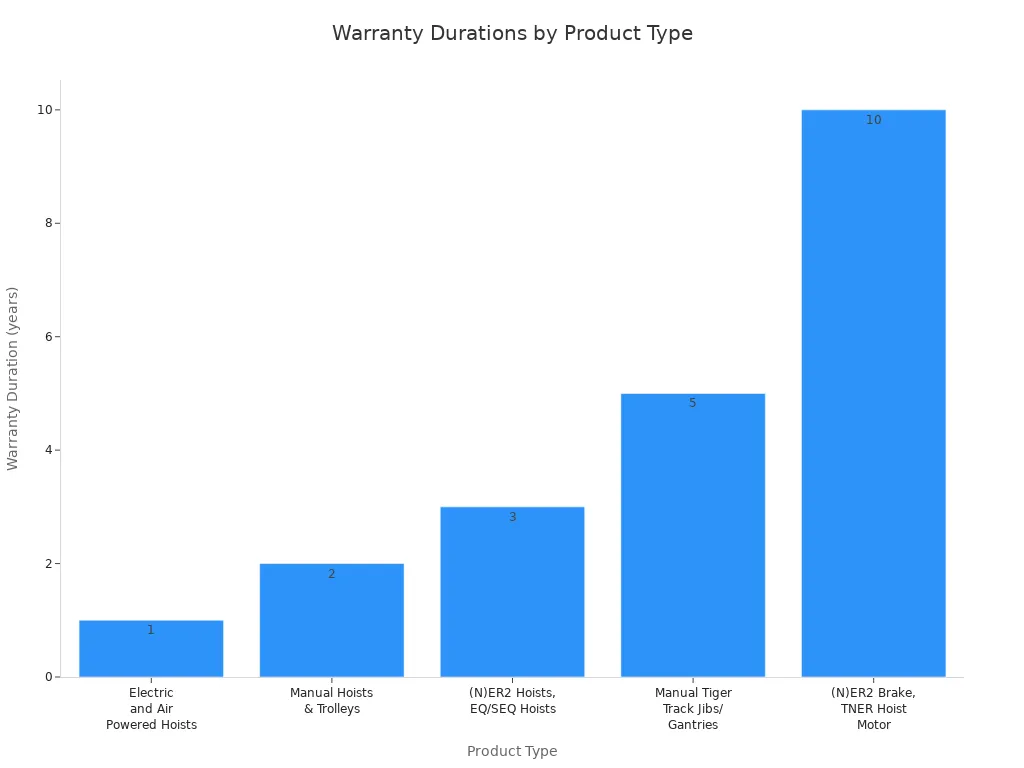

Warranty and Professional Services

Powerful Machinery stands behind its products with strong warranty coverage and professional services. You can rely on these warranties for peace of mind and long-term support.

Product Type | Warranty Duration |

|---|---|

Electric and Air Powered Hoists | 1 year |

Manual Hoists & Trolleys | 2 years |

(N)ER2 Hoists, EQ/SEQ Hoists | 3 years |

Manual Tiger Track Jibs/Gantries | 5 years |

(N)ER2 Brake, TNER Hoist Motor | 10 years |

You benefit from professional services that include certified repairs, technical support, and access to genuine replacement parts. Always check your product’s warranty status before arranging repairs.

Product Resources and Manuals

You can access official product resources and manuals to help with installation, operation, and troubleshooting. These guides provide step-by-step instructions and safety information for your specific hoist model.

Manual Chain Hoists: Tractel

Lodestar NH Entertainment: CMCO

Using the correct manual ensures you follow best practices and keep your chain hoist in top condition.

Conclusion

You protect your team and equipment when you prioritize regular chain hoist maintenance and troubleshooting. Powerful Machinery delivers certified products and expert support to help you achieve safe, reliable lifting operations. You gain long-term benefits by following a structured care plan:

Prevent equipment failure and keep everyone safe.

Reduce unplanned downtime and boost productivity.

Meet safety regulations and avoid legal issues.

You should always use step-by-step guides for maintenance. For complex repairs, consult professionals and never compromise on safety.

FAQ

How often should you inspect your chain hoist?

You should inspect your chain hoist before each use. Schedule a thorough inspection by a qualified technician at least once a year. Regular checks help you catch wear, corrosion, or damage early.

What lubricant works best for chain hoists?

You should use a manufacturer-recommended lubricant. Powerful Machinery suggests a high-quality chain oil that resists rust and reduces friction. Apply lubricant evenly to every link for best performance.

Can you repair a chain hoist yourself?

You can handle basic cleaning and part replacement if you follow the manual. For electrical issues or complex repairs, contact Powerful Machinery support or a certified technician. This ensures safety and compliance.

What should you do if your hoist makes unusual noises?

Stop using the hoist immediately. Unusual noises often signal mechanical or electrical problems. Mark the hoist as “Out of Service” and contact a professional for inspection.

Where can you find official manuals for Powerful Machinery hoists?

You can download official manuals from the Powerful Machinery website. These guides provide step-by-step instructions for installation, operation, and troubleshooting.