You will find several types of lifting chains based on material, grade, and configuration. Alloy steel chains offer high strength, while stainless steel chains resist corrosion. Grades like 80, 100, and 120+ show differences in load capacity and durability.

Welded and non-welded chains serve different lifting needs. Understanding these types helps you choose safe and efficient equipment. Powerful Machinery supplies certified lifting chains trusted in industries worldwide.

Key Takeaways

Lifting chains come in various materials like alloy steel and stainless steel, each suited for different environments and applications.

Understanding chain grades, such as Grade 80 and Grade 100, is crucial for selecting the right chain based on strength and load capacity.

Regular inspection and maintenance of lifting chains ensures safety and compliance with industry standards, preventing accidents.

Choosing the correct lifting chain assembly type, like single or multi-leg, enhances load stability and efficiency during lifting operations.

Utilizing advanced technologies like RFID tracking can improve the management and safety of lifting chains in the workplace.

What Are Lifting Chains?

Definition and Uses

You will find lifting chains in many workplaces that handle heavy materials. These chains help you lift, pull, drag, or secure loads that are too heavy for manual handling. They play a key role in moving items where weight, size, or position create challenges.

Here is a quick overview:

Definition of Lifting Chain | Common Industrial Uses |

|---|---|

Lifting chain assemblies are used in various applications where lifting, pulling, dragging, and winching are required. | Commonly used across many industry sectors to address issues related to the weight, size, position, or location of items. |

You often see lifting chains in factories, construction sites, shipyards, and warehouses. A chain hoist is one example of a mechanical device that uses these chains to move heavy loads. You can use them with cranes, hoists, or winches to make your work safer and more efficient.

Tip: Always check the chain’s load rating before use. This helps you avoid accidents and keeps your lifting equipment in good condition.

Advantages Over Other Lifting Equipment

When you compare lifting chains to other lifting equipment, you will notice several important advantages:

Heat resistance lets you use chain slings in hot environments where other slings might fail.

Chains handle rough or sharp-edged loads without damage, making them ideal for tough jobs.

Many chain slings allow you to adjust their length, so you can lift unbalanced or oddly shaped items with ease.

Chains offer high strength, so you can lift very heavy loads safely.

You can rely on lifting chains for demanding tasks that require durability and flexibility. Their design gives you confidence when you need to move large or awkward items.

Types of Lifting Chains

When you choose lifting chains, you need to understand the main differences in material, construction, application, and link design. Each factor affects how you use the chain and which lifting chain configurations work best for your job.

By Material: Alloy Steel, Stainless Steel

You will find two common materials for lifting chains: alloy steel and stainless steel. Each material offers unique benefits for different environments and lifting chain types. The table below helps you compare their main properties:

Property | Alloy Steel Chains | Stainless Steel Chains |

|---|---|---|

Strength | Improved strength and resistance to wear and fatigue. | High tensile strength and durability. |

Durability | Can be heat-treated for enhanced hardness and toughness. | Requires little maintenance due to rust resistance. |

Corrosion Resistance | Susceptible to corrosion if not treated. | Exceptional corrosion resistance in various environments. |

Alloy steel chains give you high strength and toughness. You can use them for heavy-duty lifting chains in construction or industrial settings. Stainless steel chains resist rust and corrosion, so you can use them in marine, food processing, or chemical environments.

You should select the material based on your working conditions and the required durability.

Tip: If you work in a wet or corrosive area, stainless steel lifting chains will last longer and need less maintenance.

By Construction: Welded, Non-Welded, Calibrated

You will see lifting chains made with different construction methods. Each method changes the strength, weight, and best use of the chain. The table below shows the main characteristics and applications for each type:

Chain Type | Characteristics | Applications |

|---|---|---|

Calibrated Chain | Precision-made to fit load wheel sheaves, strength from 4,500 lbs to 50,400 lbs | Safe lifting of heavy loads |

Welded Chain | Requires welding for connections, typically used for heavy-duty applications | Industrial lifting and rigging |

Non-Welded Chain | Generally lighter, may not require welding, used for lighter loads | General lifting and material handling |

Welded chains give you strong connections and work well for tough jobs. Non-welded chains are lighter and easier to handle, so you can use them for lighter loads or quick setups. Calibrated chains fit perfectly with hoists and lifting equipment, giving you precise movement and reliable lifting chain configurations.

By Application: Lifting, Lashing, Special Chains

You need to match the chain to your specific task. The types of lifting chains by application include:

Lifting chains help you hoist, pull, and secure loads. You can choose from different grades and materials to match your weight capacity and safety needs.

Lashing chains let you tie down or secure cargo during transport. These chains focus on holding loads in place rather than lifting them.

Special chains, such as fire lifting chains, are designed for unique jobs. You might use these for dangerous goods or in environments with extreme heat.

You should always check the manufacturer’s recommendations for each application. Powerful Machinery offers certified lifting chains for all these uses, so you can find the right solution for your project.

By Link Design: Round, Slot, Special Shapes

You will notice that lifting chains come in several link designs. The shape of the link affects how the chain handles force and fits with other hardware. Common link designs include:

Round links: These links give you even strength and flexibility. You can use them with most lifting chain configurations.

Slot links: These links fit specific hooks or connectors. You might use them when you need a secure fit or special assembly.

Special shapes: Some chains have custom link designs for unique applications. You can find these in industries with strict safety or handling requirements.

You should select the link design based on your lifting chain configurations and the hardware you use. The right design helps you achieve safe and efficient lifting.

Note: Always inspect the link design before use. Damaged or misshaped links can reduce the chain’s strength and safety.

You now have a clear overview of the main types of lifting chains. By understanding material, construction, application, and link design, you can choose the best lifting chain configurations for your needs.

Lifting Chain Grades

You need to know the grade of a lifting chain before you choose it for your job. Each grade shows the chain’s strength, safety, and best use. Let’s look at the main grades you will find in the industry.

Grade 43: Mild Steel

Grade 43 chain is a general-purpose chain made from mild steel. You will see it used in many industries because it is strong and affordable. However, you should not use it for overhead lifting. The table below shows the main features:

Property | Description |

|---|---|

Tensile Strength | 50% higher working load limit than Grade 30 Chain |

Overhead Lifting Approval | Not approved |

Finishes | Self Color, Shot Blasted, Electro-Galvanized, Hot Dipped Galvanized |

Typical Uses | Agriculture, construction, trucking, container securement, logging, farming, towing, and marine applications |

Grade 43 chain gives you better wear resistance than lower grades. You can use it for towing, securing containers, or logging, but never for lifting people or loads overhead.

Grade 80: General Purpose

Grade 80 chain is designed for overhead lifting. You will find it in many industries that need high strength and reliability. This chain has a high working load limit and a strong safety margin. You can use it for lifting slings, hoists, and rigging. Grade 80 chain is a popular choice for most lifting jobs.

Working Load Limit (WLL) shows the maximum safe load.

Minimum Breaking Force is four times the WLL, giving you extra safety.

Grade 100: Heavy Duty

Grade 100 chain is 25% stronger than grade 80 chain. You can use it when you need to lift heavier loads or want a lighter chain for the same job. This chain is common in construction, manufacturing, and heavy transport. Grade 100 chain helps you work safely and efficiently with tough lifting tasks.

Chain Grade | Strength Comparison |

|---|---|

Grade 80 | Baseline |

Grade 100 | 25% stronger than Grade 80 |

Grade 120+: High Performance

Grade 120 and higher chains give you the highest strength in the industry. These chains use high-strength alloy steel and have a bright blue finish for easy identification.

You will see them in construction, heavy industry, and transportation. Grade 120 chains have a working load limit 50% higher than Grade 80 and 20% higher than Grade 100. You should choose these chains for the most demanding lifting jobs.

Feature | Grade 120 Chains |

|---|---|

Material | High-strength alloy steel |

Working Load Limit | 50% higher than Grade 80, 20% higher than Grade 100 |

Identification | Bright blue finish |

Applications | Rigorous and demanding overhead lifting |

Typical Industries | Construction, heavy industry |

Color Coding and Identification

You can use color coding to quickly identify chain grades. For example, Grade 80 chains often have a black finish, while Grade 100 chains may appear in blue or green. Grade 120 chains usually have a bright blue color.

However, you should always check the stamped markings on the chain links and review the test certificates. Paint can wear off, so stamped numbers and documents give you the most reliable information. All lifting chains must meet OSHA and ASME standards for safety and performance.

Tip: Always confirm the chain grade with stamped markings and certificates, not just color.

Lifting Chain Assemblies and Configurations

Common Diameters and Strength

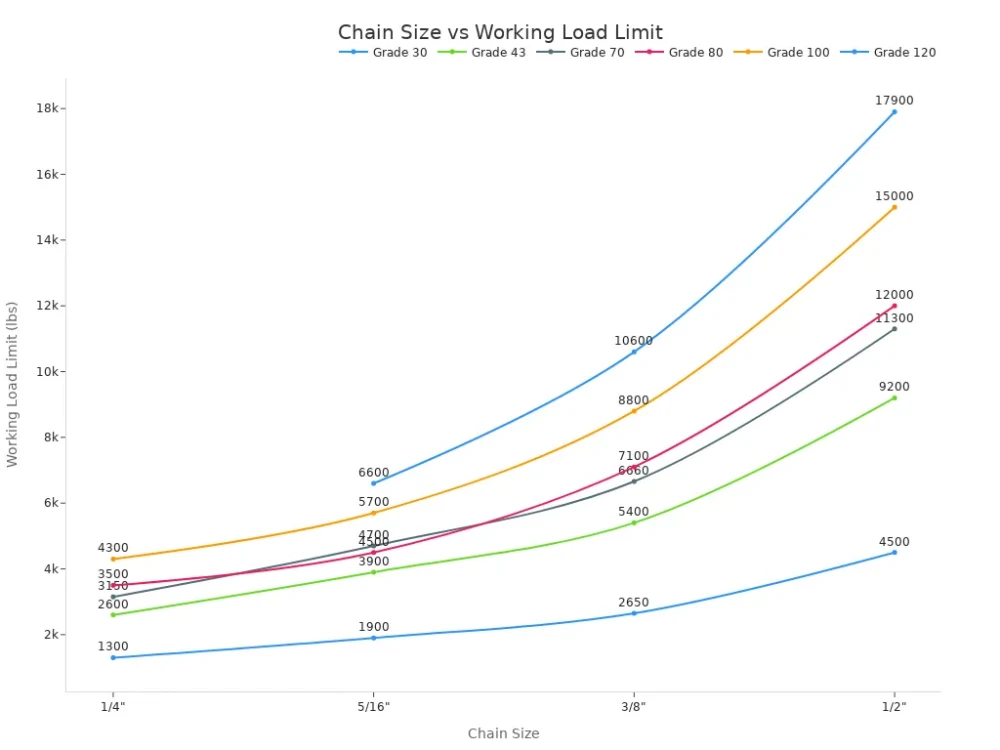

When you select lifting chain assemblies, you need to know the most common chain diameters and how they relate to strength. Chain size directly affects the working load limit. The table below shows how different diameters and grades compare:

Chain Size | Grade 30 | Grade 43 | Grade 70 | Grade 80 | Grade 100 | Grade 120 |

|---|---|---|---|---|---|---|

1/4″ | 1,300 lbs | 2,600 lbs | 3,150 lbs | 3,500 lbs | 4,300 lbs | – |

5/16″ | 1,900 lbs | 3,900 lbs | 4,700 lbs | 4,500 lbs | 5,700 lbs | 6,600 lbs |

3/8″ | 2,650 lbs | 5,400 lbs | 6,660 lbs | 7,100 lbs | 8,800 lbs | 10,600 lbs |

1/2″ | 4,500 lbs | 9,200 lbs | 11,300 lbs | 12,000 lbs | 15,000 lbs | 17,900 lbs |

You can see that larger diameters and higher grades give you greater strength. Always match the chain size and grade to your lifting chain assembly needs.

Assembly Types: Single, Double, Multi-Leg, Endless

You will find several types of lifting chain assemblies. Each type offers different load distribution and stability. The table below helps you compare their features and uses:

Type of Sling | Load Distribution Characteristics | Common Applications |

|---|---|---|

Connects directly to the lifting device, best for lighter loads | Simple tasks, limited stability for unbalanced loads | |

Two branches improve stability and load distribution | Heavier loads, two anchor points, require adjustment | |

Adds a third leg for extra support | Unevenly shaped loads, better balance | |

Four branches for maximum stability | Extremely heavy or large loads, precise setup needed | |

Endless Chain Sling | Versatile, adapts to many lifting tasks | Construction, manufacturing, warehousing, shipbuilding, mining, oil and gas |

You should choose the assembly type based on your load shape and weight. Multi-leg lifting chain assemblies give you better stability for large or uneven loads.

Tip: Always check the sling configuration before lifting. Proper setup prevents accidents and improves safety.

Components: Master Links, Hooks, Connectors

You need to understand the main lifting chain components in every lifting chain assembly. Each part plays a key role in safe lifting:

Master links collect multiple sling legs into one connection point. You use oblong master links at the top of multi-leg lifting chain assemblies. Pear-shaped master links work well for smaller assemblies.

Hooks connect the chain sling to the load. They ensure secure handling and easy attachment.

Connectors let you adjust your rigging setup. You can change the configuration for different lifting tasks.

Links and rings also help you create strong connection points in your rigging. You should inspect all lifting chain components before each use. Reliable parts keep your lifting chain assemblies safe and effective.

Certification of Lifting Chains

Key Standards and Regulations

You must follow strict standards when you use certified lifting chains. These standards protect you and your team from accidents and ensure every chain meets safety requirements. Three main organizations set the rules for lifting chain certification:

Organization | Role | Key Functions |

|---|---|---|

OSHA | Enforcer | Inspects workplaces, issues citations, and can shut down operations for violations. |

ASME | Developer | Creates standards for equipment design, inspection, and training. |

ANSI | Facilitator | Accredits organizations and approves standards to promote safety. |

You need to inspect your lifting chains before each use. You should also perform a thorough visual examination every six months or every year. Proof load tests are required every two or four years. These steps help you maintain safe lifting practices and comply with regulations.

Tip: Regular inspections and tests keep your lifting chains reliable and safe for every job.

Identity Tags and Documentation

Every certified lifting chain must have clear identity tags and documentation. These tags help you trace the chain’s history and confirm its specifications. You will find important information on each tag:

Specification | Requirement |

|---|---|

Tagging Requirements | Manufacturer’s name, sling diameter, rated load, and hitch type. |

Unique Identification | A unique serial number for traceability. |

Additional Information | Optional details like hitch configuration and date of manufacture. |

You should check for these details:

Manufacturer of the sling assembly or the most recent entity to repair the sling

The material the sling is manufactured from

Rated load for at least one hitch type

Individual sling identification (e.g., serial number)

Manufacturer code or stock number

Number of legs (for bridle assemblies)

Proper documentation gives you confidence in the chain’s quality and safety. Always keep records for each lifting chain in your inventory.

Powerful Machinery’s Certified Products

You can trust Powerful Machinery for certified lifting chains that meet or exceed international standards. The company tests every product to guarantee safety, reliability, and performance in tough environments.

Powerful Machinery’s products are fully certified and undergo chemical analysis, dimensional verification, and proof-load testing. These steps ensure every batch meets strict global standards. You receive peace of mind knowing your lifting chains are ready for demanding jobs.

Note: Powerful Machinery’s commitment to certification of lifting chains helps you meet legal requirements and maintain a safe workplace.

Selection Criteria for Lifting Chains

Load Capacity and WLL

You must always check the load capacity and working load limit (WLL) before choosing a lifting chain. These values tell you how much weight the chain can safely handle. Several factors influence load capacity:

Material strength, including tensile and yield strength, sets the base for how much weight a chain can support.

Design factors, such as the shape and size of the links, affect the chain’s ability to carry loads.

Safety factors are built in to account for dynamic forces and unexpected stress.

Testing ensures each chain meets strict standards for both static and dynamic loads.

The type of load—whether static, dynamic, or shock—can change the effective weight capacity.

Environmental conditions, like extreme temperatures or corrosion, may reduce the chain’s strength.

Regular inspections help you spot wear and tear that can lower the chain’s weight capacity over time.

Always select a chain with a WLL higher than your maximum expected load. This keeps your lifting operation safe.

Environmental Factors

You need to consider the environment where you will use the chain. Moisture, temperature extremes, and chemical exposure can all affect performance and lifespan. Here are some important factors:

Moisture, such as rain or saltwater, can cause corrosion and weaken steel chains.

High temperatures may evaporate lubricants and reduce material strength.

Low temperatures can make steel brittle and less flexible.

Chemicals like acids or solvents can damage chains, even with brief contact.

UV radiation from sunlight can degrade synthetic materials.

Abrasive surfaces or sharp edges may cause extra wear.

Choosing the right chain for your environment helps you maintain weight capacity and safety.

Application Recommendations

You should match the lifting chain to your specific application. Start by selecting a trusted brand and the correct style for your job. Next, pick the right chain diameter, since larger diameters offer higher load capacity and weight capacity. Common diameters include 1/4”, 5/16”, 3/8”, and 1/2”.

Then, choose the hook type that fits your lifting needs, such as sling hooks, grab hooks, foundry hooks, or self-locking hooks. Following these steps helps you meet the demands of your application and ensures safe lifting.

Expert Assessment and Custom Solutions

Sometimes, standard chains do not fit your needs. You may face non-standard load shapes, limited clearance, or special stability requirements. In these cases, expert assessment is vital. Custom rigging solutions can improve safety and efficiency.

You can work with professionals to design lifting chains that match your exact application and weight capacity needs. This approach reduces risk and helps you comply with industry standards.

Consult experts when your lifting operation involves unusual loads or challenging environments. Custom solutions keep your workplace safe and productive.

Inspection, Maintenance, and Safety

Lifting Chain Inspection Procedures

You need to follow proper inspection steps to keep lifting chains safe and reliable. Start by cleaning the chain to remove dirt and grease. This makes it easier to spot problems.

Look closely for damage such as bent, cracked, or broken links. Check for inner link wear and signs of chemical damage. Make sure the chain is well lubricated to extend its life.

You should inspect chains when you receive them, then perform daily visual checks before each use. Schedule a documented inspection at least once every 12 months, or more often if chains see heavy use. Only qualified personnel should carry out these inspections.

Always follow OSHA and ASME safety regulations for inspection frequency and removal criteria.

Tip: Regular inspection helps you catch problems early and prevents accidents.

Maintenance and Storage

Proper maintenance and storage help you maximize the service life of your lifting chains. Avoid exposing chains to extreme temperatures, which can weaken the metal. Keep chains away from chemicals that may change their physical properties.

Store chains out of direct sunlight to prevent UV damage, especially for synthetic materials. Use edge protection when lifting sharp-edged loads to prevent cutting and abrasion.

You should always store chains in a dry, clean area. Hang them on racks or hooks to prevent tangling and damage.

Avoid moisture and corrosive environments.

Use protective covers when storing chains for long periods.

Inspect chains for wear and lubrication before storage.

Safe Use Guidelines

You must follow safety procedures every time you use lifting chains. Check chain links for bending, cracking, elongation, or twisting. Remove any damaged links right away. Inspect for surface wear, corrosion, and pitting.

Make sure hooks, rings, and fittings are secure and in good condition. Verify that markings for working load limit and manufacturer details are clear.

Choose stable lifting points and use padding to protect chains from sharp edges. Understand hitch types and their load capacities. Use tag lines to control loads and avoid sudden movements. Select hooks with latches and rated shackles.

Train all personnel on ASME B30.10 safety regulations for chain sling use.

Safety Guideline | Description |

|---|---|

Chain Links Inspection | Remove damaged links immediately. |

Surface Wear Check | Look for corrosion and pitting. |

Attachments Inspection | Ensure hooks and fittings are secure. |

Markings Verification | Confirm clear WLL and manufacturer details. |

Rigging Best Practices | Use padding and stable lifting points. |

Hitch Selection | Know hitch types and capacities. |

Load Control | Use tag lines for steady movement. |

Tool Selection | Use proper hooks and shackles. |

Compliance | Train personnel on safety regulations. |

Remember: Following safety procedures protects you, your team, and your equipment.

Technological Advancements

RFID and QR Tracking

You can now track lifting chains with advanced technology. RFID tags and QR codes help you manage your equipment more easily. When you scan a chain’s tag, you see its inspection history, load tests, and compliance with standards. This makes it simple to check if a chain meets safety standards before use.

You can also update records quickly, which helps you follow industry standards for documentation. Many companies use these tools to improve traceability and meet strict standards in their operations.

Tip: Use RFID and QR tracking to keep your lifting chains organized and always in line with safety standards.

Advanced Materials and Coatings

You will notice big changes in the materials and coatings used for lifting chains. Manufacturers now use high-performance fibers like HMPE and aramid in chain jackets. These fibers increase abrasion resistance and help chains last longer.

New coating technologies also protect chains from harsh environments and help you meet standards for durability.

Here are some of the latest coating options and their effects:

Coating Type | Advantages | Challenges |

|---|---|---|

Zinc Coatings | Cost-effective, fights corrosion | Wears off, limited wear protection |

Polymer Coatings | Better wear resistance, chemical protection | May add weight, can degrade under UV light |

Ceramic/Nanotech Coatings | Excellent abrasion and corrosion resistance | Higher cost, complex to apply |

Self-Healing Coatings | Repairs damage, boosts durability | Not widely available, expensive |

You can choose coatings that help your chains meet industry standards for performance. Many companies also focus on reducing creep and extending chain life to comply with safety standards. These advancements make it easier for you to follow maintenance standards and keep your equipment in top shape.

Sustainability Trends

You will see more companies using eco-friendly materials and energy-saving production methods. Manufacturers design lifting chains with recyclable materials to meet environmental standards.

They also use energy-efficient processes to lower their impact on the planet. Smart technologies help you use chains more efficiently and meet modern standards for sustainability.

Trend | Description |

|---|---|

Eco-friendly materials | Chains made with recyclable materials to meet green standards |

Energy-efficient production | Factories use less energy to follow environmental standards |

Smart technologies | Digital tools improve efficiency and help you meet operational standards |

Many industries now prefer products that meet strict environmental standards. You can expect more lifting chains to follow these trends as standards continue to evolve.

Leading Manufacturers and Powerful Machinery

Overview of Major Brands

You will find several global leaders in the lifting chain industry. Each manufacturer offers unique strengths and product ranges. The table below helps you compare the top brands:

Manufacturer | Product Range | Certifications & Reputation | Key Strengths |

|---|---|---|---|

Fengtong | Wide variety of lifting chains | Strict quality control meets international standards | Customization services, professional after-sales support |

Columbus McKinnon | Comprehensive range of lifting products | Strong brand image, global presence | Innovative technology, sustainability focus |

KITO Corporation | High-quality lifting chains | High safety standards, long-term experience | Anti-corrosion treatment, user-friendly design |

Powerful Machinery | Full spectrum of lifting chains, wire rope, rigging hardware | ISO9001, ISO14001, TUV Rheinland, EURO CERT, EAC, Geprufte Sicherheit, OSHA, ASTM, China Classification Society, Korean Register | Competitive pricing, customization, certified quality, and excellent after-sales support |

You can see that Powerful Machinery stands out with a broad product range and a strong commitment to international certifications. This ensures you receive reliable and safe lifting solutions.

Powerful Machinery’s Achievements

Powerful Machinery has built a reputation for quality and safety over the past 20 years. You benefit from products that meet or exceed major global standards. The company’s achievements include:

Full certification to ISO, TUV Rheinland, EURO CERT, OSHA, ASTM, and more.

Custom-engineered lifting chains and assemblies for demanding projects.

Trusted by clients in construction, marine, transportation, and cargo handling.

Positive feedback from customers like Ben Carter in Canada and David Müller in Germany, who praise the durability and reliability of Powerful Machinery’s products.

Powerful Machinery’s commitment to innovation and customer satisfaction helps you tackle tough lifting challenges with confidence.

Industry Applications

You will find Powerful Machinery’s lifting chains in many industries. Construction sites use them for heavy lifting and secure rigging. Marine operations rely on their corrosion-resistant chains for mooring and cargo handling.

Transportation companies choose Powerful Machinery for safe and efficient load securing. Warehouses and factories use their certified assemblies for daily material handling.

Construction: Heavy-duty lifting and rigging

Marine: Mooring, cargo handling, corrosion resistance

Transportation: Load securing, safety compliance

Warehousing: Material handling, assembly operations

You can trust Powerful Machinery to deliver solutions that fit your specific industry needs. Their products help you maintain safety, efficiency, and compliance in every application.

Conclusion

You now know how to identify, compare, and select the right lifting chains and assemblies for your needs. Always check chain grades, materials, and configurations before use.

Certification and regular inspection keep your workplace safe. For expert advice and certified products, consult Powerful Machinery or another trusted supplier.

Stay informed and follow safety guidelines to protect yourself and your team during every lifting operation.

FAQ

What is the difference between Grade 80 and Grade 100 lifting chains?

Grade 100 chains have 25% higher strength than Grade 80 chains. You can lift heavier loads with Grade 100. Both grades work for overhead lifting, but Grade 100 offers more efficiency.

How often should you inspect lifting chains?

You should inspect lifting chains before each use. Schedule a thorough inspection at least once every 12 months. Heavy use may require more frequent checks.

Can you use lifting chains in wet or corrosive environments?

You can use stainless steel lifting chains in wet or corrosive environments. Alloy steel chains need protective coatings. Always choose the right material for your workplace.

What information must appear on a lifting chain’s identity tag?

You must see the manufacturer’s name, chain diameter, rated load, and serial number on the tag. This helps you verify safety and trace the chain’s history.