You must always prioritize safety when you plan to shorten a lifting sling. Rely on approved techniques and the manufacturer’s guidelines to protect both your team and your equipment. Regular inspection and sling protection play a critical role in lifting sling safety.

Common causes of sling failure include visible wear, edge damage, and choosing the wrong sling for the load. Powerful Machinery’s certified products help you avoid these risks, ensuring every lift meets the highest standards.

Key Takeaways

Always inspect lifting slings before use. Look for damage, wear, and ensure labels are legible to maintain safety.

Use only manufacturer-approved methods to shorten slings. Avoid knots, bolts, or makeshift devices to prevent sling failure.

Store slings in a cool, dry place away from chemicals and sunlight. Proper storage extends sling lifespan and ensures safety.

Regularly maintain slings with inspections and cleaning. This practice helps prevent accidents and prolongs the life of your equipment.

Follow industry safety standards and guidelines. Compliance reduces legal risks and enhances confidence in lifting operations.

Lifting Sling Safety And Prohibited Methods

General Safety Practices

You must follow strict lifting sling safety protocols every time you handle or adjust a sling. Industry standards, such as OSHA regulations, require you to inspect rigging before each shift and remove any damaged slings immediately. Always use gear with clear, legible tags and never exceed the rated load.

Qualified personnel should operate cranes and rigging equipment. You should proof-test any special or custom lifting accessories before use. These practices help you maintain lifting sling safety and prevent accidents.

Tip: Store slings in a cool, dry place away from chemicals to extend their lifespan and maintain lifting sling safety.

What Not To Do When You Shorten A Sling?

You must avoid unsafe methods when shortening a sling. The following table highlights prohibited techniques and explains why they compromise lifting sling safety:

Prohibited Method | Description |

|---|---|

Shortening with knots or bolts | Weakens the sling and can cause sudden failure |

Use of makeshift devices | Devices may fail under load, leading to serious accidents |

Never knot, twist, or use unauthorized hardware to adjust sling length. These actions can damage the sling’s structure and put your team at risk. Always rely on manufacturer-approved methods and certified products from Powerful Machinery to ensure lifting sling safety.

Inspection Before Use

You must inspect every sling before use to guarantee lifting sling safety. Look for visible damage, illegible labels, or signs of wear. The table below outlines inspection types and their recommended frequency:

Inspection Type | Frequency/Details |

|---|---|

Daily Inspection | Check for damage or defects before each use |

Additional Inspections | Inspect during use if service conditions change |

Periodic Inspection | Conduct thorough checks every 6 to 12 months based on usage |

Record Keeping | Maintain records of the most recent inspection for each sling |

Remove slings from service if you find broken wires, deformed links, excessive corrosion, cut fibers, or any abnormal wear. These steps are essential for lifting sling safety and help you avoid costly accidents.

Approved Ways To Shorten A Sling

When you need to shorten a sling, you must use only methods approved by the manufacturer or a qualified person. Powerful Machinery’s certified lifting solutions, including Round Webbing Slings, Chain Slings, and Flat Web Slings, provide you with safe and reliable options for every lifting scenario.

Wire Rope Slings: Safe Adjustment

You should never knot, tie, or twist wire rope slings to adjust their length. These actions weaken the sling and create a serious safety hazard. Instead, follow these approved practices:

Use only hardware or adjustment devices specified by the sling manufacturer.

Consult a qualified person before making any modifications.

Remove the sling from service if you find any damage during inspection.

By following these steps, you maintain the integrity of your wire rope sling and protect your team.

Synthetic Web Slings: Manufacturer-Approved Methods

Synthetic web slings, such as Powerful Machinery’s Flat Web Slings and Round Webbing Slings, require special care when you shorten a sling. Always use hardware like adjustable hooks or shortening links that meet the sling’s rated capacity.

Never use knots or makeshift devices. You can also select slings with built-in adjustment features for added safety.

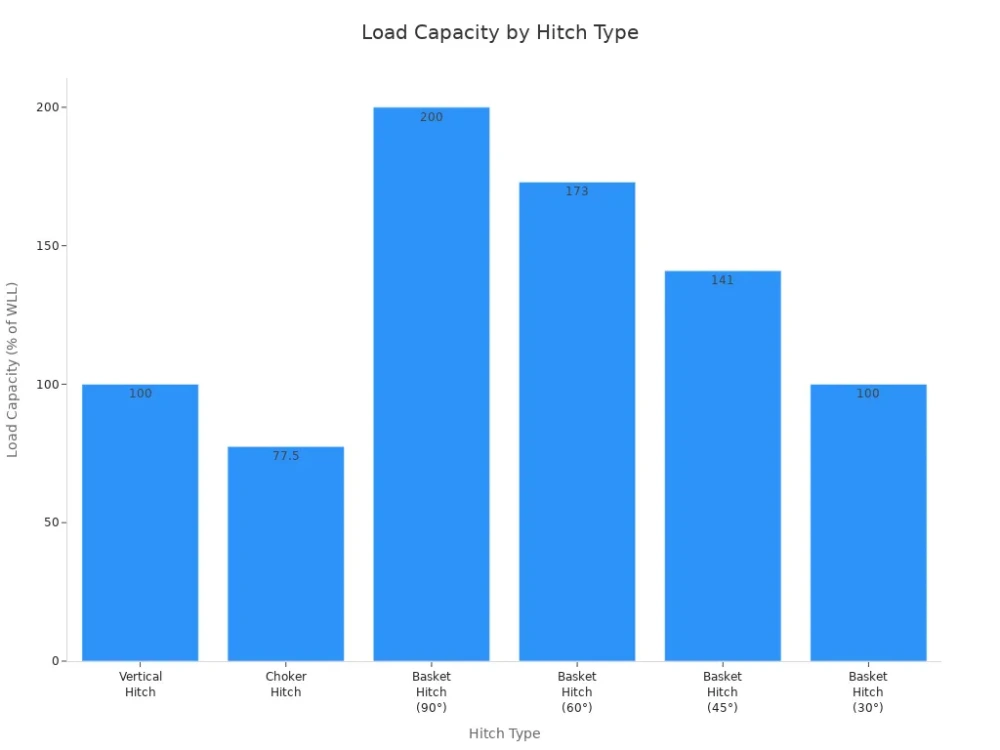

Note: Always check the Working Load Limit (WLL) after adjustment. The hitch type affects the load capacity, as shown below:

Hitch Type | Load Capacity |

|---|---|

Vertical Hitch | 100% WLL |

Choker Hitch | ~75-80% WLL |

Basket Hitch (90°) | 200% WLL |

Basket Hitch (60°) | 173% WLL |

Basket Hitch (45°) | 141% WLL |

Basket Hitch (30°) | 100% WLL |

Chain Slings: Using Turnbuckles And Hoists

Chain slings from Powerful Machinery offer you flexibility and strength. You can safely shorten a sling by using chain shorteners, grab hooks, or devices like the Crosby Eliminator. These components allow you to adjust the length without compromising the sling’s rated capacity.

Always ensure the hardware matches the chain’s grade and configuration. For heavy-duty applications, turnbuckles and hoists provide precise adjustment and secure load control.

By using only approved hardware and following manufacturer guidelines, you keep your lifting operations safe and efficient.

Step-by-Step Guide For Lifting Slings

Pre-Adjustment Inspection

You must inspect lifting slings before making any adjustments. This process helps you prevent an accident and ensures the sling remains safe for use. Follow these steps:

Conduct a visual inspection. Look for tears, cuts, frayed edges, and chemical damage.

Verify the label and identification. Make sure the sling’s tag is legible and accurate.

Check all hardware and attachments. Inspect hooks, latches, and anchor points for bending, cracking, or malfunction.

Confirm there are no knots or twists in the sling.

Examine for UV damage, discoloration, mold, or mildew.

Maintain records of your inspection and note any actions taken.

Common defects you may find include loose or broken stitching, faded webbing color, and malfunctioning latches. If you discover any of these issues, remove the sling from service immediately.

Tip: Always inspect the anchor area for signs of wear or damage. A compromised anchor can lead to sling failure.

How To Shorten Wire Rope Slings?

You must use approved tools and methods when you shorten wire rope lifting slings. Unsafe practices can weaken the sling and increase the risk of an accident. Here is a safe procedure:

Measure the required length twice and mark the cut location with a permanent marker.

Wrap both sides of the mark with electrical or vinyl tape. This step prevents the rope from fraying.

Use dedicated wire rope cutters or an angle grinder with a thin metal cut-off wheel to make a clean cut.

Remove the tape and smooth the cut end to eliminate sharp edges.

You should always inspect the anchor and attachment points after shortening. Never attempt to shorten a sling with carabiner wraps or makeshift devices. Only use manufacturer-approved hardware for wire rope slings.

How To Shorten Synthetic And Flat Web Slings?

Synthetic and flat web lifting slings require special care during adjustment. You must avoid knots, bolts, or unauthorized hardware. Instead, follow these steps:

Select adjustable hooks or shortening links rated for the sling’s capacity.

Attach the hardware securely to the anchor and load points.

Adjust the sling to the desired length, ensuring the webbing remains flat and untwisted.

Confirm the working load limit after adjustment. The hitch type affects the load capacity, so always check the rating.

If you need to shorten one sling for a specific lift, choose the right type of lifting sling for the job. Powerful Machinery’s Flat Web Slings and Round Webbing Slings offer color-coded identification and reinforced eyes for added safety. Inspect the anchor area and hardware before and after adjustment.

Note: Never attempt to shorten a sling with knots or carabiner wraps. These methods compromise sling integrity and can cause an accident.

How To Shorten Chain Slings?

Chain lifting slings provide flexibility and strength for heavy-duty applications. You must use only approved hardware when you shorten chain slings. Follow this procedure:

Use grab hooks or shortening clutches designed for chain slings.

Attach the hardware to the anchor and load points, ensuring a secure fit.

Adjust the chain to the required length. Confirm that the hardware matches the chain’s grade and configuration.

Never use knots, bolts, or makeshift devices to shorten chain slings.

Inspect the anchor area and all connections after adjustment. Powerful Machinery’s chain slings come in multiple configurations and grades, allowing you to tailor the sling to your lifting needs.

Safety Alert: Always double-check the anchor and hardware before lifting. Improper adjustment can lead to sling failure and an accident.

Post-Adjustment Inspection

After you adjust lifting slings, you must re-inspect them to confirm safety and integrity. Look for the following types of damage:

Cuts, holes, tears, or snags

Tensile damage, such as stiffened or fuzzy web yarn

Faded webbing color or visible reduction in elasticity

Heat or UV damage

Worn or broken stitching, especially in load-bearing splices

Acid or caustic burns

Check the anchor points and hardware for signs of wear or malfunction. If you find any damage, remove the sling from service immediately.

Service Condition | Inspection Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified person |

Maintain a record of all inspections and adjustments. Regular inspection and documentation help you prevent accidents and extend the life of your lifting slings.

Tip: Store lifting slings in a clean, dry area away from direct sunlight and chemicals. Proper storage protects the anchor and sling material, ensuring long-term safety.

Sling Protection And Maintenance Tips

Common Mistakes To Avoid

You must recognize common mistakes to ensure effective sling protection. Many users damage slings by using them on sharp edges or in corrosive environments. Others fail to match the sling material to the load, which can result in sudden failure.

Improper hitching creates unsafe lifting conditions. You should also avoid these frequent errors:

Skipping regular inspections, which allows hidden damage to go unnoticed.

Using the wrong sling size can destabilize the load.

Neglecting sling protection, which accelerates wear and reduces lifespan.

Storing slings in areas exposed to UV rays or chemicals can lead to material degradation.

Slings may look intact, but can have internal wear. Overloading weakens fibers and increases the risk of failure. Improper rigging causes uneven load distribution and potential accidents.

Maintaining Sling Integrity

You can extend the life of your lifting slings by following best practices for sling protection. Start with regular inspections. Check for visible signs of wear before each use.

Clean slings after every job to remove contaminants. Rotate usage so one sling does not bear all heavy loads. Handle slings carefully to avoid unnecessary strain.

Use edge protection products such as corner pads, wear pads, or reinforced eyes. These tools create a barrier between the sling and sharp surfaces. Covers and sleeves work well for synthetic slings.

Powerful Machinery’s slings feature reinforced eyes and durable construction, meeting certifications like ISO 9001, TUV Rheinland, and OSHA. These certifications guarantee you receive reliable sling protection for every lift.

Certification Name |

|---|

ISO 9001 |

ISO 14001 |

TUV Rheinland |

EURO CERT |

EAC |

Tested Safety |

OSHA |

ASTM |

China Classification Society |

Korean Register |

Storage Recommendations

You must store lifting slings properly to maintain their integrity. Hang slings on racks, hooks, or shelves to prevent tangling or crushing. Choose a clean, dry, and temperature-controlled area. Avoid direct sunlight and keep slings away from chemicals.

Label storage areas by sling type, capacity, or size for easy identification. Maintain an average temperature between -40 and +100 degrees Fahrenheit.

Improper storage exposes slings to moisture, UV rays, and chemicals, which can lead to corrosion, mold, and reduced strength. Good storage practices support long-term sling protection and help you avoid unnecessary replacements.

Tip: Consistent sling protection and maintenance can increase sling lifespan by up to 35% and reduce safety incidents to zero.

Conclusion

You protect your team and equipment when you follow approved lifting sling procedures and perform regular inspections. Certified slings from Powerful Machinery deliver safety, reliability, and compliance. The table below highlights key benefits:

Benefit | Description |

|---|---|

Safety Compliance | Meets industry safety standards |

Legal Risk Reduction | Lowers legal and insurance risks |

Increased Confidence | Supports high-load applications |

Routine Inspection | Enables traceability and ongoing safety |

You reduce accidents and equipment failure by prioritizing sling protection and maintenance. Consistent care ensures every lift meets the highest standards.

FAQ

How often should you inspect a lifting sling?

You should inspect lifting slings before each use and perform a thorough inspection at least once a year. Increase inspection frequency if you use slings in harsh environments or for heavy-duty applications.

Can you repair a damaged lifting sling?

You should never repair a damaged lifting sling. Remove it from service immediately. Only use certified, undamaged slings from trusted suppliers like Powerful Machinery to ensure safety and compliance.

What is the safest way to shorten a chain sling?

You should use manufacturer-approved hardware, such as grab hooks or shortening clutches. Never use knots, bolts, or makeshift devices. Always verify the hardware matches the chain’s grade and configuration.

Why is sling protection important during lifting?

Sling protection prevents cuts, abrasions, and premature wear. You should use edge protectors, sleeves, or reinforced eyes. This practice extends sling’s life and reduces the risk of accidents.

Tip: Always follow the manufacturer’s guidelines for sling protection and maintenance.