Web slings and webbing slings play a vital role in lifting and rigging operations. You need to understand their types to ensure safety and prevent costly mistakes. Over 30% of rigging-related accidents happen because of incorrect sling usage, including improper web sling selection.

Industry data shows that using certified webbing slings greatly reduces equipment failures and keeps lifting operations safe. Powerful Machinery stands out as a trusted provider of certified solutions, helping you avoid risks and choose the right tools for every job.

Key Takeaways

Understanding web sling types is crucial for safe lifting operations. Choose the right sling based on load type and environment.

Regular inspections of web slings prevent accidents. Check for wear and damage before each use to ensure safety.

Select slings with appropriate rated capacities. Always match the sling to the load and lifting conditions for optimal performance.

Proper storage extends sling life. Keep slings away from chemicals, UV light, and extreme temperatures to maintain their integrity.

Consult experts for custom solutions. Reach out to professionals for tailored sling options that meet your specific lifting needs.

Web Slings and Webbing Slings Overview

What Are Webbing Slings?

You rely on web slings and webbing slings for safe and efficient lifting in many industries. These slings use strong synthetic materials like nylon or polyester to handle heavy loads. You will find them lightweight, flexible, and easy to position around delicate or irregular objects.

Their design helps distribute pressure evenly, which protects both the load and your equipment.

Here’s a quick comparison to help you understand their features:

Feature | Web Slings | Webbing Slings |

|---|---|---|

Material | Typically nylon or polyester | Typically nylon or polyester |

Stretch | Nylon has more stretch; polyester has minimal | Nylon has more stretch; polyester has minimal |

Load Distribution | Distributes pressure over a wide surface | Distributes pressure over a wide surface |

Applications | Suitable for delicate loads, manufacturing, etc. | Suitable for delicate loads, manufacturing, etc. |

Weight | Lightweight and easy to handle | Lightweight and easy to handle |

Strength | High Working Load Limits | High Working Load Limits |

Connection Type | Various configurations (endless loop, eyes) | Various configurations (endless loop, eyes) |

You will notice that webbing slings stand out for their high strength-to-weight ratio and flexibility. These qualities make them a preferred choice for lifting tasks where you need to protect sensitive materials.

Why Sling Selection Matters?

Choosing the right webbing sling is critical for your safety and the efficiency of your lifting operations. You must consider the type of load, the environment, and the specific strengths and limitations of each sling material. Proper selection helps you avoid accidents, equipment damage, and costly downtime.

You should always match the sling to the load and lifting conditions.

Compliance with OSHA and ASME standards ensures your operation meets safety regulations.

You reduce the risk of load shifting or dropping by using the correct web sling for each task.

Powerful Machinery leads the industry by providing certified lifting solutions that meet international standards. You can trust their web slings and webbing slings for reliable performance in construction, marine, transportation, and cargo handling. Their commitment to quality and safety gives you peace of mind on every lift.

Types of Webbing Slings

You encounter many types of webbing slings in lifting operations. Each web sling type offers unique features, strengths, and recommended applications. Understanding these differences helps you select the safest and most efficient sling for your job.

Nylon Webbing Sling

Nylon webbing slings remain popular in manufacturing and construction. You benefit from their flexibility and high strength. Nylon webbing sling construction uses synthetic yarns that provide excellent load protection and convenience.

You should note that nylon webbing slings absorb moisture and stretch under heavy loads, which helps cushion delicate items. However, you must avoid using nylon webbing slings in environments above 194°F or below -40°F. Long-term UV exposure can weaken the sling.

Always pad nylon webbing slings against sharp edges and avoid dragging them on abrasive surfaces.

Tip: Always inspect nylon webbing slings for signs of wear before each lift.

Characteristics | Details |

|---|---|

Common Materials | Nylon and polyester-type yarns |

Strength | High strength, flexibility, and load protection |

Rated Loads | Depends on material, design, hitch type, angle, and curvature |

Environmental Effects | Avoid extreme temperatures and prolonged UV exposure |

Safe Practices | Pad against sharp edges, avoid dragging, and do not pinch by loads |

Polyester Webbing Sling

Polyester webbing slings serve you well in environments where acid is present. You choose polyester webbing slings when you need minimal stretch and resistance to common acids and bleaching agents. Polyester webbing slings maintain their shape and strength even in harsh conditions.

You find polyester sling options ideal for outdoor use because they resist UV rays and moisture. You rely on polyester webbing slings for lifting sensitive loads in chemical plants, warehouses, and outdoor construction sites.

Polyester webbing slings resist acids and bleaching agents.

You experience minimal stretch, which improves load control.

Polyester sling options work best for outdoor and chemical environments.

Polypropylene Webbing Sling

You select polypropylene webbing sling types for excellent chemical resistance. Polypropylene webbing slings do not absorb moisture, making them suitable for wet environments.

You should avoid using polypropylene webbing slings outdoors for extended periods because UV exposure degrades the material. Polypropylene webbing slings offer moderate durability compared to nylon and polyester webbing slings.

Material | Chemical Resistance | UV Resistance | Moisture Absorption | Durability |

|---|---|---|---|---|

Polypropylene | Excellent | Poor | Virtually none | Moderate |

Nylon | Moderate | Moderate | 4-10% | High |

Polyester | Good | Excellent | Less than 1% | Very High |

Polypropylene webbing slings excel in chemical environments.

You should use polyester webbing slings for outdoor tasks.

Nylon webbing slings work well for general lifting, but absorb moisture.

Round Webbing Sling

You gain superior performance with Powerful Machinery’s round slings. These round slings use 100% polyester yarn and feature a non-load-bearing tubular sleeve for extra wear resistance. You benefit from color-coded identification, which helps you select the right round sling for each load.

Powerful Machinery’s round slings meet EN 1492-1 and EN 1492-2 standards and come with CE certification. You can customize round slings for length and branding, making them versatile for many industries.

Feature | Description |

|---|---|

Advanced Manufacturing Techniques | Fully automatic sewing machines for precision |

Comprehensive Product Range | Variety of slings for diverse needs |

High-Precision Equipment | Shuttle looms ensure consistent quality |

Enhanced Productivity | Large rotary hooks and bobbin capacity reduce downtime |

Note: Powerful Machinery’s round slings offer high strength, low elongation, and superior durability for sensitive and heavy loads.

You also find Powerful Machinery’s flat web slings and slings & tie downs valuable for heavy-duty lifting. Flat web slings distribute weight evenly and resist wear, while slings & tie downs provide secure solutions for transportation and cargo handling.

Specialty Webbing Sling

You encounter specialty webbing slings in unique industrial scenarios. These types of webbing slings include slings designed for lifting construction materials, machinery, cargo, and marine equipment.

Specialty webbing slings protect sensitive surfaces and provide control in tight spaces. You use corrosion-resistant webbing slings for offshore and marine lifting. Specialty webbing slings support precision lifting and industrial maintenance.

Lifting and positioning construction materials

Machinery and industrial equipment handling

Loading and unloading cargo

Offshore and marine lifting applications

Industrial maintenance and precision lifting

You select specialty webbing slings for tasks that require adaptability, protection, and specialized performance.

Summary Table: Types of Webbing Slings and Their Key Features

Sling Type | Material | Strength | Best Use Case | Limitations |

|---|---|---|---|---|

Nylon Webbing Sling | Nylon | High | Delicate loads, general lifting | Sensitive to moisture/UV |

Polyester Webbing Sling | Polyester | Very High | Acidic, outdoor environments | Limited stretch |

Polypropylene Webbing Sling | Polypropylene | Moderate | Chemical, wet environments | Poor UV resistance |

Round Sling | Polyester | Extreme | Sensitive, heavy, irregular loads | Must avoid sharp edges |

Specialty Webbing Sling | Varies | Varies | Unique, precision, marine tasks | Task-specific |

You improve lifting safety and efficiency by matching the right web sling type to your application. Powerful Machinery’s web slings and webbing slings deliver certified performance for every lifting scenario.

Standard Webbing Sling Constructions

Understanding webbing sling constructions helps you select the right tool for every lifting scenario. Each construction type offers unique advantages for specific tasks. You can find these options in Powerful Machinery’s certified product range, ensuring safety and reliability.

Flat Eye

Flat eye slings feature flat, reinforced loops at each end. You use flat eye slings for vertical, choker, or basket hitches. The flat design allows easy attachment to hooks or lifting points.

You benefit from even load distribution, which protects both the sling and the load. Powerful Machinery’s Flat Web Slings include flat eye models, making them ideal for warehousing, automotive, and agriculture.

Tip: Use flat eye slings when you need a secure grip and minimal twisting during lifts.

Twisted Eye

Twisted eye slings have one or both eyes twisted at a 90-degree angle. This design lets you attach the sling to hardware from different directions. You gain flexibility when lifting loads with limited space or unusual angles.

Twisted eye slings work well in manufacturing and machinery handling. Powerful Machinery offers twisted eye options in its flat web sling series.

Endless

Endless slings form a continuous loop with no end fittings. You can rotate the sling to distribute wear evenly, extending its service life. Endless slings adapt to various hitch types, including vertical, choker, and basket.

You find endless slings in Powerful Machinery’s Slings & Tie Downs collection. These slings suit material handling, rigging, and entertainment industries.

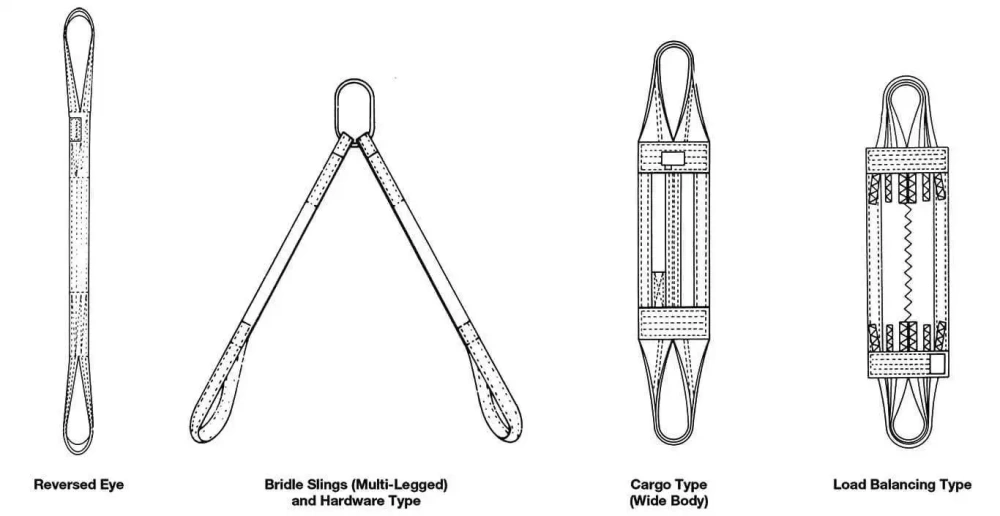

Reverse Eye

Reverse eye slings feature eyes formed by folding back the sling body and sewing it to itself. This construction increases strength at the connection points. You use reverse eye slings for heavy-duty lifting in construction and transportation. They handle steel beams, concrete panels, and large machinery with ease.

Web-Trap and Unilink Types

Web-Trap and Unilink slings offer specialized connections for unique lifting challenges. You use these types for quick attachment and release, especially in logistics and cargo handling. They provide secure connections without traditional hooks or shackles.

Powerful Machinery can customize these solutions for your project needs.

Type of Sling | Description | Typical Applications |

|---|---|---|

Flat Eye | Flat, reinforced loops at each end | Warehousing, automotive, agriculture |

Twisted Eye | Eyes twisted 90°, flexible attachment | Manufacturing, machinery handling |

Endless | Continuous loop, even wear distribution | Material handling, rigging, and entertainment |

Reverse Eye | Eyes formed by folding and sewing the sling body | Construction, transportation |

Web-Trap/Unilink | Specialized connections for quick attachment | Logistics, cargo handling |

You improve lifting safety and efficiency by matching the sling construction to your application. Powerful Machinery’s certified slings cover all these construction types, supporting your operations across construction, logistics, manufacturing, and more.

Key Features and Advantages of Webbing Slings

Material Properties

You gain many advantages when you choose webbing slings for your lifting operations. These slings use high-strength synthetic fibers like polyester, which deliver excellent resistance to chemicals, UV rays, and moisture.

You benefit from a high strength-to-weight ratio, making each web sling lighter and easier to handle than steel alternatives. The soft and flexible web material protects delicate surfaces and adapts to irregular shapes. You can select from multiple configurations, widths, and end fittings to match your lifting needs.

Property | Description |

|---|---|

Safe Working Load (SWL) | The maximum weight the sling can safely lift |

Length and Width | Suitability for various lifting applications |

Colour Coding | Prevents errors by identifying the correct sling for the task |

Reinforced Loops | Extra strength and durability, minimizing fraying or tearing |

Material | Polyester for high strength and resistance to chemicals/UV |

Durability | Abrasion resistance and long service life |

Regular Inspection | Ensures safe operation and prolongs sling life |

Load Capacity and Safety Factor

You must always consider the load-lifting capacity and safety factor when selecting a webbing sling. The working load limit (WLL) is calculated by dividing the minimum breaking strength by the safety factor.

Most webbing slings from Powerful Machinery feature safety factors of 5:1, 6:1, or 8:1, which means you get extra strength for dynamic forces. Each web sling comes with a tag that shows the WLL for vertical, choker, and basket hitches.

Hitch Type | Capacity Adjustment Factor | Notes |

|---|---|---|

Vertical Hitch | 1.0 | Full rated capacity |

Choker Hitch | 0.8 (or 80%) | Reduces capacity by 20% |

Basket Hitch | 2.0 (if vertical) | Doubles capacity, angle-dependent |

You should always check the tag before every lift to confirm the correct load-bearing capability.

Durability and Wear Resistance

Webbing slings offer moderate durability and wear resistance for repeated use. The polyester web material resists abrasion, chemicals, and UV exposure, making these slings suitable for both indoor and outdoor environments. Reinforced loops and PU-impregnated sleeves on Powerful Machinery’s slings add extra protection.

You extend the lifespan of your slings by rotating them and performing regular inspections. While wire rope and chain slings provide higher durability in extreme conditions, webbing slings excel in applications where surface protection and flexibility matter most.

Ergonomics and Ease of Use

You experience less physical strain when you handle webbing slings. Their lightweight design and flexible web construction make lifting, positioning, and storing much easier than with wire rope or chain slings. The soft textile web reduces the risk of hand injuries and adapts to different load shapes.

You can transport and deploy these slings quickly, improving efficiency and safety on the job.

Tip: Always store your slings in a dry, clean area to maintain their lifting capabilities.

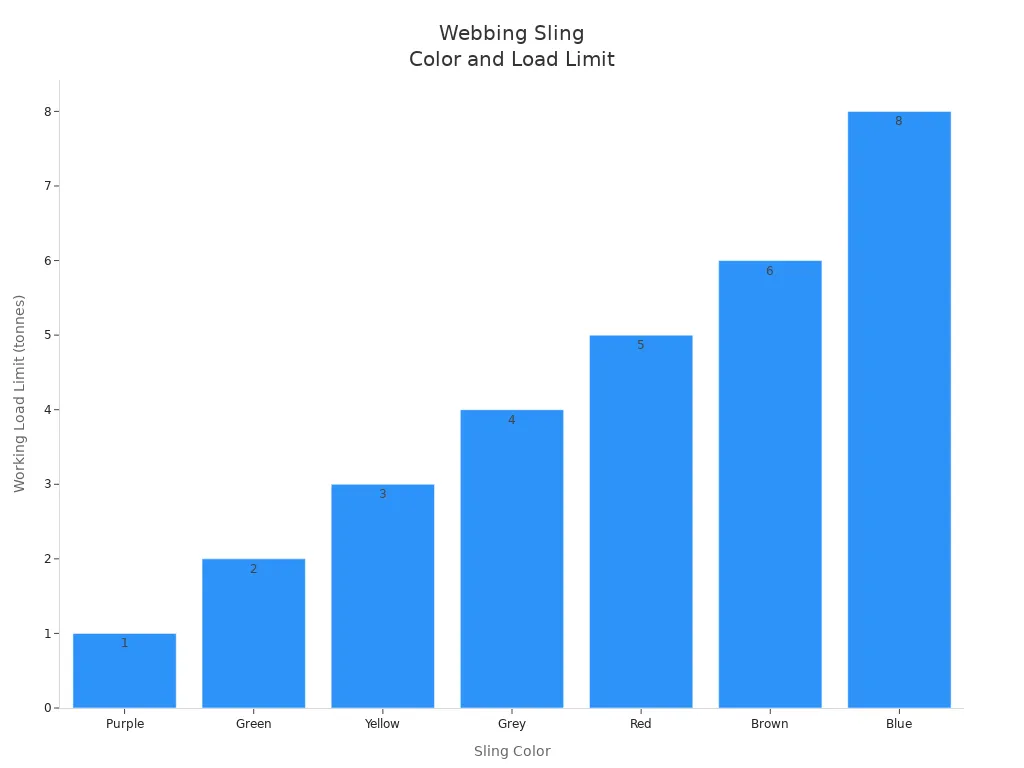

Certifications, Color-Coding, and Compliance

You ensure safety and compliance by choosing webbing slings with proper certifications and color-coding. Powerful Machinery’s slings meet international standards such as EN 1492-1, EN 1492-2, and ASME B30.9.

Each web sling features a color code that matches its working load limit, helping you select the right sling at a glance.

You can trust that every webbing sling from Powerful Machinery is tested and certified for reliable performance in demanding environments.

Applications of Webbing Slings

Industry Use Cases

You see web slings used across many industries because they adapt to different lifting operations. Each sector relies on slings to move, secure, or position heavy loads safely. The table below shows where you might use each sling and the typical scenarios you face:

Industry | Typical Lifting Scenarios |

|---|---|

Construction and Rigging | Lifting irregularly shaped objects requires different angles and adjustments. |

Warehousing and Material Handling | Securing loads of varying shapes and sizes in storage facilities. |

Automotive Industry | Handling car engines or components requiring balanced lifting. |

Manufacturing Facilities | Transferring heavy machinery or parts between areas. |

Shipping and Dockyards | Loading and unloading containers or oversized cargo. |

Mining Industry | Lifting and transporting equipment in rough terrain. |

Chemical Plants | Handling equipment in environments with chemical exposure. |

Aerospace and Aviation | Managing heavy, high-value, or sensitive components. |

Oil and Gas Industry | Handling heavy equipment in harsh conditions like offshore oil rigs. |

Heavy Industrial Lifting | Applications requiring extremely high strength in low-weight slings. |

You depend on web slings for safe and efficient lifting equipment in these demanding environments. Powerful Machinery supports your operations with certified products designed for construction, marine, transportation, and cargo handling.

Matching Sling Type to Application

You must match the right sling to your lifting operations to protect both your load and your team. Start by considering the weight and size of your heavy loads. Always choose a web sling rated above the heaviest item you plan to lift.

For delicate surfaces, select softer slings such as polyester web slings. For rugged or abrasive items, chain or wire rope slings work best.

Environmental conditions play a big role in your decision. Use metal slings in high-temperature or chemically hazardous areas. Synthetic slings may degrade in UV light or oily environments, so you should check the worksite before selecting your lifting equipment. If you lift frequently, chain slings offer the durability you need.

For occasional tasks, synthetic web slings provide flexibility and ease of use.

Tip: The right sling protects your cargo from saltwater erosion, UV damage, and other environmental threats. This choice reduces repair costs and keeps your lifting operations running smoothly.

When you choose Powerful Machinery, you access a full range of slings for every application. Their polyester round webbing slings excel in construction and marine projects. Flat web slings handle transportation and warehousing tasks. Specialty slings support unique lifting operations in aerospace, mining, and chemical plants.

You can trust their certified solutions to keep your team safe and your projects on track.

Webbing Sling Safety and Inspection

Manufacturer Guidelines

You protect your team and equipment by following manufacturer guidelines for webbing sling use. Powerful Machinery recommends that you train all users in safe lifting practices. Always inspect slings before each lift to spot visible damage. Maintain your slings properly to extend their service life.

You should check the manufacturer’s reference and visually inspect slings for wear. Avoid dragging slings across abrasive surfaces or exposing them to extreme temperatures. These steps help you meet occupational health and safety requirements and prevent accidents.

Train all users in safe sling handling.

Maintain slings according to manufacturer instructions.

Check references and perform visual inspections.

Avoid dragging slings or exposing them to heat.

Routine Inspection Steps

You ensure ongoing safety by performing regular inspections. Powerful Machinery recommends three types of inspections:

Inspection Type | Description |

|---|---|

Initial Inspection | Check specifications, load capacity, and damages before first use. |

Frequent Inspection | Visually inspect before each use for damage or defects. |

Periodic Inspection | Have a qualified person inspect annually or as needed based on usage and conditions. |

During inspections, you look for abrasions, acid damage, cuts, and tensile damage. Follow these steps for a thorough check:

Examine stitching for loose threads or broken stitches.

Look for chemical damage or deterioration.

Confirm labels are legible and accurate.

Inspect hooks and latches for damage.

Remove knots and ensure slings lie flat.

Assess for discoloration or brittleness from UV exposure.

If you find any damage, remove the sling from service immediately.

Common Hazards and Prevention

You avoid common hazards by staying alert and following best practices. Inspect slings for cuts, tears, and fraying before each use. Always check the weight capacity to prevent overloading. Select the right sling type for each load. Use edge guards or sleeves to protect slings from sharp edges.

Regularly check hooks and shackles for cracks or wear. Follow proper lifting procedures, including load centering and clear communication.

Powerful Machinery ensures compliance with international safety standards such as IMCA, DNV-GL, API RP 2D, FAA, and NADCAP. You benefit from thorough inspections, proper storage, load testing, and comprehensive training. These measures help you maintain safe lifting operations and protect your team.

Webbing Sling Selection Tips

Assessing Load and Environment

You improve safety and efficiency when you assess the load and environment before choosing a webbing sling. Start by identifying the type of load you plan to lift. Consider the environment, such as temperature extremes or chemical exposure, which can affect sling performance.

Review your operational requirements and select the right hitch configuration. Always maintain sling angles at 60° or greater to avoid dangerous tension.

Factor | Description |

|---|---|

Load Type | Select slings based on the type of load being lifted. |

Environment | Consider environmental factors such as temperature and chemical exposure. |

Operational Requirements | Assess the specific needs of the operation, including handling requirements. |

Sling Angle | Maintain angles at 60° or greater to avoid dangerous tension increases. |

Different hitch methods affect sling capacity and force distribution. |

Tip: Always match the sling to both the load and the working environment for optimal performance.

Understanding Capacity and Certification

You must verify the capacity and certification of every webbing sling before use. Check that each sling is marked with the manufacturer’s name, rated load, and material type.

Inspect slings for damage before every lift. Remove any sling with missing or illegible identification, acid or caustic burns, or visible holes, tears, or cuts. Schedule periodic inspections by a qualified person at least once a year. Store slings properly to prevent unnecessary wear.

Inspect slings for damage regularly, removing any that are damaged.

Ensure slings are marked with the manufacturer’s name, rated load, and type of material.

Conduct frequent inspections before each use, especially in severe service conditions.

Perform periodic inspections at regular intervals, not exceeding one year, by a qualified person.

Note: Proper maintenance and inspection routines help you avoid accidents and extend sling life.

Consulting Experts for Custom Solutions

You may encounter lifting challenges that require more than standard products. When your project demands custom-engineered solutions, consult with experts at Powerful Machinery. Their team can help you select or design slings that fit your unique lifting requirements.

You receive guidance on sling selection, compliance, and safe operation. Powerful Machinery offers tailored solutions to ensure your lifting equipment matches your specific needs.

Reach out to Powerful Machinery for expert advice and custom webbing sling solutions that meet international safety standards.

Conclusion

You improve lifting safety and efficiency when you select the right webbing sling and follow best practices. Routine inspection, proper storage, and ongoing training help you prevent accidents. Review the table below for key takeaways:

Key Aspect | Details |

|---|---|

Rated Capacities | Choose slings with proper design factors for safe lifting. |

Inspection Frequency | Inspect slings visually before each shift, more often in tough service. |

Damage Response | Remove slings from service if you find any damage. |

Storage Conditions | Store slings away from chemicals, UV, and extreme temperatures. |

Knowledge Requirement | Understand sling materials for safe operation. |

Explore Powerful Machinery’s certified lifting solutions and consult their experts for tailored support. Visit Powerful Machinery for more information.

FAQ

What is the difference between a round sling and a flat web sling?

You use a round sling for lifting fragile or irregular loads. It offers flexibility and load protection. You choose a flat web sling for even weight distribution and heavy-duty tasks. Both types meet strict safety standards.

How do you identify the working load limit (WLL) of a webbing sling?

You check the color code and the label attached to the sling. The label shows the WLL for different hitch types. Always verify the information before each lift.

How often should you inspect your webbing slings?

You inspect your slings before every use. Schedule periodic inspections by a qualified person at least once a year. Remove any sling from service if you find damage or illegible labels.

Can you use webbing slings in outdoor environments?

You can use polyester webbing slings outdoors. They resist UV rays and moisture. Store your slings in a dry, clean place when not in use to extend their lifespan.