Choosing between soft shackles and steel shackles can shape your lifting and recovery outcomes. You need to weigh safety, strength, and maintenance before making a decision. Powerful Machinery stands as a leader in certified lifting and rigging solutions, trusted by professionals worldwide.

Safety is paramount in recovery situations, and soft shackles have a clear advantage here. Unlike steel shackles, if a soft shackle fails under extreme load, it does not become a projectile, which significantly reduces the risk of injury or vehicle damage.

The lack of metal components also means there’s no risk of sparking, a crucial consideration in dry or flammable conditions.

Consider your application—vehicle recovery, lifting, or marine work—to choose the right shackle for your needs.

Key Takeaways

Soft shackles are lightweight and flexible, making them ideal for off-road recovery and marine applications where safety is crucial.

Steel shackles provide unmatched strength and durability, making them suitable for heavy lifting and industrial tasks.

Always match the shackle type to your specific application to ensure safety and performance; soft shackles excel in dynamic environments, while steel shackles are best for static loads.

Regularly inspect both soft and steel shackles for signs of wear or damage to maintain safety during lifting operations.

Consider the total cost of ownership, including maintenance and replacement, when choosing between soft and steel shackles.

Soft Shackles vs Steel Shackles Overview

What Are Soft Shackles?

You may encounter soft shackles in many modern lifting and recovery setups. These innovative connectors use advanced synthetic fibers instead of metal. Most soft shackles feature materials like UHMWPE (Ultra-High-Molecular-Weight Polyethylene) or Spectra® Fiber.

These fibers deliver impressive strength while keeping weight to a minimum. You can easily handle and store a soft shackle, even in tight spaces or challenging environments.

Soft shackles excel in situations where you need flexibility, safety, and quick deployment. Off-road enthusiasts, marine professionals, and rescue teams often choose soft shackles for their lightweight design and resistance to water and corrosion.

Here’s a quick look at the typical materials and their mechanical properties:

Material | Mechanical Properties |

|---|---|

UHMWPE | Strong, lightweight, water-resistant |

Spectra® Fiber | 26% stretch, ideal for kinetic energy transfer |

You can use a soft shackle for connecting recovery straps, winch lines, or even as a temporary link in lifting applications. The absence of metal parts means you reduce the risk of damaging painted surfaces or sensitive equipment.

When comparing soft shackles vs steel shackles, you will notice that a soft shackle offers unmatched versatility and safety in dynamic environments.

What Are Steel Shackles?

Steel shackles, sometimes called hard shackles, have served as the backbone of lifting and rigging for decades. You will find these robust connectors in construction sites, shipyards, and industrial plants.

Steel shackles come in several shapes, such as D shackles, bow shackles, twist shackles, and wide body shackles. Each type uses high-strength metals to ensure reliable performance under heavy loads.

The most common materials for steel shackles include steel alloys, stainless steel, titanium, and galvanized steel. These materials provide exceptional durability and resistance to wear, making steel shackles ideal for demanding tasks.

Shackle Type | Material Used |

|---|---|

D Shackles | Steel alloys |

Bow Shackles | Stainless steel, Titanium |

Twist Shackles | Stainless steel |

Wide Body Shackles | Galvanized steel |

When you need to secure a load, connect lifting slings, or anchor heavy machinery, steel shackles deliver the strength and reliability you require. Powerful Machinery’s certified steel shackles meet strict international standards, ensuring you get consistent quality and safety.

You can trust these hard shackles for critical lifting, marine, and cargo handling operations.

Tip: For static loads, harsh environments, or permanent installations, steel shackles often provide the best solution.

In the debate of soft shackles vs steel shackles, you should consider your application, environment, and safety requirements. Soft shackles shine in flexible, lightweight, and safety-focused scenarios.

Steel shackles dominate in heavy-duty, high-load, and industrial settings. By understanding the strengths of each, you can select the right shackle for your specific needs.

Soft Shackles vs Steel: Strength and Durability

Material Performance

When you compare soft shackles and steel shackles, you see two very different approaches to material performance. Soft shackles use high-modulus polyethylene fibers, such as UHMWPE or Spectra. These advanced fibers give you impressive strength while keeping the weight low.

You can handle a soft shackle with ease, even in wet or muddy conditions. The flexibility of the fibers allows the shackle to conform to various shapes and attachment points. This reduces the risk of damaging painted surfaces or sensitive equipment.

Steel shackles, often called hard shackles, rely on forged steel alloys or stainless steel. These metals provide unmatched durability and resistance to abrasion. You can trust a hard shackle to perform in harsh environments, including construction sites, marine settings, and industrial plants.

The rigid structure of steel ensures that the shackle maintains its shape under heavy loads. This gives you confidence in critical lifting and rigging operations.

Note: Soft shackles can match or even surpass the tensile strength of steel shackles under standardized testing conditions. You get significant load-handling capability without the added weight of metal.

The durability of each type depends on the application. Steel shackles resist wear and tear from repeated use and exposure to the elements. Soft shackles, on the other hand, show excellent performance in environments where corrosion or electrical conductivity pose risks.

You can use a soft shackle in marine or rescue operations without worrying about rust or sparks.

Load Capacity and Reliability

You need to consider both load capacity and reliability when choosing between soft shackles and hard shackles. Typical soft shackles are rated for a maximum load capacity of 3 to 5 tonnes. This makes them suitable for off-road recovery, marine towing, and many industrial tasks.

Powerful Machinery’s steel bow shackles, such as the 3/4″ anchor bow shackle, offer a vertical working load limit of 9,500 lb (4.75 tons). This means that, in many cases, a soft shackle can match or even exceed the load limits of some steel shackles. However, the specific ratings depend on the type and manufacturer.

Durability testing shows that soft shackles can withstand repeated load cycles. For example:

The soft shackle was cycled 200 times at loads between 14,000 lbs and 20,000 lbs without any damage.

When the load increased to between 20,000 lbs and 25,000 lbs, the shackle broke after 73 cycles at a maximum load of 25,182 lbs.

These tests simulated real-world conditions by not allowing the shackle to cool down between cycles.

Hard shackles, especially those from Powerful Machinery, are engineered for reliability in the toughest environments. You benefit from products that meet or exceed international standards, such as AS2741, ISO9001, and TUV Rheinland.

These certifications guarantee that each steel shackle delivers consistent performance and safety. You can rely on a hard shackle for heavy lifting, static loads, and permanent installations.

Soft shackles offer lightweight flexibility and reduce the risk of damaging loads or attachment points. They have become popular in marine, off-road, industrial, and rescue operations. Hard shackles provide a secure connection and, in some cases, integrate load monitoring mechanisms.

This feature allows you to measure weight directly, improving safety during critical lifting tasks.

Shackle Type | Typical Load Capacity | Durability Features | Best Use Cases |

|---|---|---|---|

Soft Shackle | 3–5 tonnes | Flexible, corrosion-resistant, lightweight | Off-road, marine, rescue |

Steel Shackle | Up to 9,500 lb (4.75 tons) | Rigid, abrasion-resistant, certified | Construction, lifting, cargo |

You should always match the shackle type to your application. Soft shackles excel in dynamic, safety-focused environments. Steel shackles dominate in heavy-duty, high-load, and industrial settings. Powerful Machinery’s certified products ensure you get the highest level of strength and durability for every job.

Pros and Cons of Soft Shackles

Advantages of Soft Shackles

You gain several advantages when you choose soft shackles for your rigging and lifting needs. The most noticeable benefit is their lightweight and flexible design. You can carry multiple shackles without adding bulk to your gear.

This makes them ideal for applications where a lighter weight is desired, such as vehicle recovery or marine operations.

Soft shackles offer unmatched ease of use. You can attach and remove them quickly, even with gloves or in wet conditions. Their flexible construction allows you to connect to a variety of anchor points, which is essential in applications where flexibility is important.

You also reduce the risk of damaging painted surfaces or sensitive equipment because soft shackles do not have hard edges.

The safety advantages stand out, especially in off-road recovery and marine environments. You avoid the risk of injury from flying metal if a soft shackle fails. The material does not store kinetic energy, so you stay safer during demanding tasks.

Soft shackles are rust-proof and gentle on equipment, which means you do not compromise safety or performance.

Here’s a quick table summarizing the main safety advantages:

Safety Advantage | Description |

|---|---|

Lightweight Nature | Soft shackles are significantly lighter than metal shackles, reducing the overall weight during recovery operations. |

Reduced Risk of Injury | Unlike metal shackles, soft shackles do not store kinetic energy, minimizing the risk of injury if they fail. |

Easy Attachment and Removal | Their design allows for quick and hassle-free attachment and detachment, enhancing operational safety. |

Rust-Proof and Gentle on Equipment | Soft shackles are rust-proof and do not damage anchor points, ensuring a secure connection without compromising safety. |

Environmentally Friendly | When used with tree savers, they provide a safe method for securing vehicles without harming the environment. |

You will find soft shackles excel in off-road recovery, marine towing, and rescue operations. Their lightweight and flexible nature makes them the preferred choice for professionals who value ease of use and safety.

Limitations of Soft Shackles

You should also consider the disadvantages when evaluating the pros and cons of soft shackles. While soft shackles are lightweight and flexible, they have some limitations compared to a hard shackle. Abrasion resistance is lower, so you need to use protective sleeves or guards when working around rough surfaces.

The minimum breaking strength can decrease when the shackle gets wet, which may affect performance in certain environments.

The low melting point of the material means you should avoid using soft shackles in high-temperature settings. You must also pay attention to the bend radius. Using small hardware can reduce the strength of the shackle.

For best results, you should rethink your rigging setup around square edges or use smooth intermediaries to prevent damage.

Here’s a table outlining the main disadvantages:

Limitation Type | Description |

|---|---|

Bend Radius | A generous bend radius preserves strength; smaller hardware reduces strength. |

Protective Measures | Protective sleeves and abrasion guards are necessary for contact with rough surfaces. |

Rigging Considerations | Rethink setups around square edges or use smooth intermediaries to avoid damage. |

The minimum breaking strength decreases when wet.

The low melting point poses risks in high-temperature environments.

You should always match the shackle type to your application. For ease of use, lightweight and flexible performance, and safety, soft shackles are an excellent choice. For heavy-duty lifting or static loads, a hard shackle may be more suitable.

Steel Shackles: Features and Benefits

Powerful Machinery Product Highlights

When you choose steel shackles from Powerful Machinery, you invest in advanced engineering and proven safety. These metal shackles use high-quality steel to deliver unmatched strength and reliability.

You will notice several design features that set these shackles apart from a typical hard shackle or soft shackle. The table below highlights the key elements that enhance both safety and usability:

Design Feature | Description |

|---|---|

Load Distribution | Ensures even force application during lifting, preventing excessive pressure on any single point. |

Pin Retention | Keeps the pin securely in place, preventing unintentional sliding or rotation during use. |

Alignment | Maintains proper alignment between the pin and shackle body, reducing wear and enhancing reliability. |

Safety Enhancement | Acts as a stop for the pin, minimizing the risk of accidental disengagement and enhancing safety. |

You can trust these steel shackles because Powerful Machinery tests every product to meet or exceed ASME and OSHA standards. Each shackle includes proper markings for traceability and clearly defined working load limits.

The company selects materials based on environmental conditions, ensuring that every steel shackle performs in the toughest settings. Powerful Machinery holds certifications from major classification societies and complies with international bodies, including ISO and CE.

Adherence to ASME B30.26 guidelines ensures safety in design, manufacturing, and inspection.

Application Scenarios

You will find steel shackles essential in industries where strength and durability matter most. These metal shackles excel in heavy lifting, static loads, and harsh environments. You can use them in manufacturing to lift and secure heavy machinery or materials.

In construction, steel shackles secure equipment and materials during complex projects. Shipping operations rely on these metal shackles for lifting and securing cargo on vessels. The oil and gas sector uses steel shackles for handling offshore containers and rigging tasks.

Heavy engineering projects depend on these shackles for complex lifting and securing loads.

Different types of metal shackles serve specific roles. Bow shackles connect multiple slings, while dee shackles handle straight lifting. Screw pin shackles work well for temporary setups, and bolt-type shackles are ideal for heavy-duty jobs. Chain shackles tackle the toughest tasks.

Each type ensures safety and efficiency in lifting operations. You should always match the shackle type to your application, whether you need a hard shackle for static loads or a soft shackle for flexibility. Steel shackles from Powerful Machinery give you the strength and reliability you need for every challenge.

Safety Considerations

Failure Risks and Injury Prevention

You need to prioritize safety every time you use shackles in lifting or recovery operations. Both soft shackle and hard shackle options come with unique risks, but you can minimize these by following best practices. Soft shackle designs offer a safety advantage because they store less kinetic energy.

If a soft shackle fails, it does not become a dangerous projectile. This enhanced safety feature makes them popular for off-road recovery and dynamic pulls.

To prevent injuries, you should:

Remove soft shackles from recovery points when traveling over rough terrain. This prevents abrasion from sharp rocks, which can weaken the fibers.

Always secure steel shackles properly. An unsecured hard shackle can come undone and cause accidents.

Watch for sharp edges when using a soft shackle. Sharp surfaces can cut or damage the fibers, reducing strength.

Use protective padding, such as tubular webbing, to cover sharp edges and preserve the integrity of your soft shackle.

By following these steps, you add important safety features to your rigging setup and reduce the risk of injury.

Impact on Vehicles and Equipment

The type of shackles you choose affects both your equipment and your vehicle’s recovery points. Soft shackle and hard shackle designs each have different impacts on longevity and safety. The table below compares key features:

Feature | Soft Shackles | Steel Shackles |

|---|---|---|

Weight | Lighter and easier to handle | Heavier and bulkier |

Safety on Failure | Safer due to less kinetic energy | Risk of injury from kinetic energy |

Durability | Prone to abrasion damage | Durable and reliable under heavy loads |

Replacement Frequency | May need to be replaced more often | Generally longer-lasting |

Energy Storage | Stores less energy | Stores more energy, can rebound on failure |

You will find that soft shackle options protect painted surfaces and delicate equipment. They do not scratch or dent recovery points. Hard shackle models, while more durable, can cause wear or damage if not used carefully.

Always inspect your shackles for signs of wear and replace them as needed to maintain safety.

Versatility and Use Cases

Multi-Industry Applications

You will find shackles in almost every major industry that requires secure lifting, towing, or rigging. Soft shackle and hard shackle options each bring unique advantages to different sectors. In construction, you need safer and more efficient alternatives to traditional rigging hardware.

Mining operations benefit from reduced equipment weight and improved worker safety. Logistics companies use shackles to boost productivity and handle a wide range of tasks. Marine professionals rely on these connectors for safe handling of heavy loads on ships and docks.

Automotive specialists integrate soft shackle and hard shackle designs into towing and recovery systems, especially for off-road use. Industrial settings favor these products for their versatility and safety in lifting operations.

Here is a quick overview of how different industries use shackles and what they require:

Industry | Unique Requirements |

|---|---|

Construction | Safer and more efficient alternatives to traditional rigging hardware. |

Mining | Reduces equipment weight and enhances worker safety. |

Logistics | Improves overall productivity and is suitable for a wide range of tasks. |

Marine | Crucial for safe handling of heavy loads in maritime operations. |

Automotive | Integrated into towing and recovery systems for off-road use. |

Industrial | Favored for versatility and safety in lifting operations. |

You can see that soft shackle and hard shackle solutions both play important roles, but the best choice depends on your specific applications.

Choosing the Right Shackle for Your Needs

You should always match your shackle choice to the demands of your task. Soft shackle products work best when you need lightweight, flexible, and easy-to-handle connectors. You can stow them easily and use them for occasional or low-abrasion applications.

Hard shackle options, such as steel shackles from Powerful Machinery, excel in high-abrasion environments and heavy-duty utility work. You will appreciate their higher breaking strength and durability when handling static loads or permanent installations.

Consider the following criteria when selecting between soft shackle and hard shackle options:

Criteria | Soft Shackles | Steel Shackles |

|---|---|---|

Weight | Much lighter than metal shackles | Heavier than a soft shackle |

Breaking Strength | 29,700 lbs. and 36,000 lbs. | Generally higher than a soft shackle |

Ease of Handling | Easy to handle and use | Can be cumbersome due to weight |

Potential for Abrasion Damage | More prone to damage by abrasion | Less prone to abrasion damage |

Storage | Compact, can be stowed easily | Takes up more space |

Energy Storage | Stores less potential energy | Stores more potential energy |

Application Suitability | Best for occasional use and low-abrasion tasks | Better for high-abrasion utility work |

Tip: For marine, construction, and automotive applications, review your environment and load requirements before making a decision. You will achieve the best results by choosing the shackle that matches your safety and performance needs.

You can trust Powerful Machinery to provide certified shackles for every industry and application.

Environmental Impact and Maintenance

Corrosion and Chemical Resistance

You need to consider how shackles perform in harsh environments. When you use a soft shackle, you benefit from materials that resist rust and corrosion. This makes a soft shackle a strong choice for marine work or wet conditions. You can use a soft shackle in saltwater without worrying about rapid deterioration.

In contrast, a hard shackle made from stainless steel offers superior corrosion resistance. You will find these shackles designed for heavy-duty lifting in marine environments. They also work well in chemical plants and refineries where harsh chemicals are present.

Stainless steel hard shackle options resist corrosion in saltwater and chemical exposure.

You can rely on these shackles for long-term use in demanding settings.

Soft shackle materials do not rust, but you should still inspect them for wear after chemical exposure.

Choosing the right type of shackles helps you reduce environmental impact and extend service life.

Care and Inspection Tips

Proper maintenance keeps your shackles safe and reliable. You should inspect a hard shackle regularly for rust and corrosion. Apply lubrication to the pin and threads to prevent seizing.

For a soft shackle, check for signs of wear or fraying. Replace a soft shackle if you see damage. You should perform monthly inspections, focusing on attachment points and visible damage.

Rinse a soft shackle with fresh water after each use to remove salt and debris.

Allow a soft shackle to air dry completely before storage to prevent mold or mildew.

Store a soft shackle in a cool, dry place away from direct sunlight.

Rinse all shackles with fresh water after use in marine or chemical environments.

Store shackles properly to maximize their lifespan.

Tip: Consistent care and inspection routines help you avoid unexpected failures and keep your lifting operations safe.

You can trust that regular maintenance will keep both soft shackle and hard shackle options performing at their best.

Cost and Value

Price Comparison

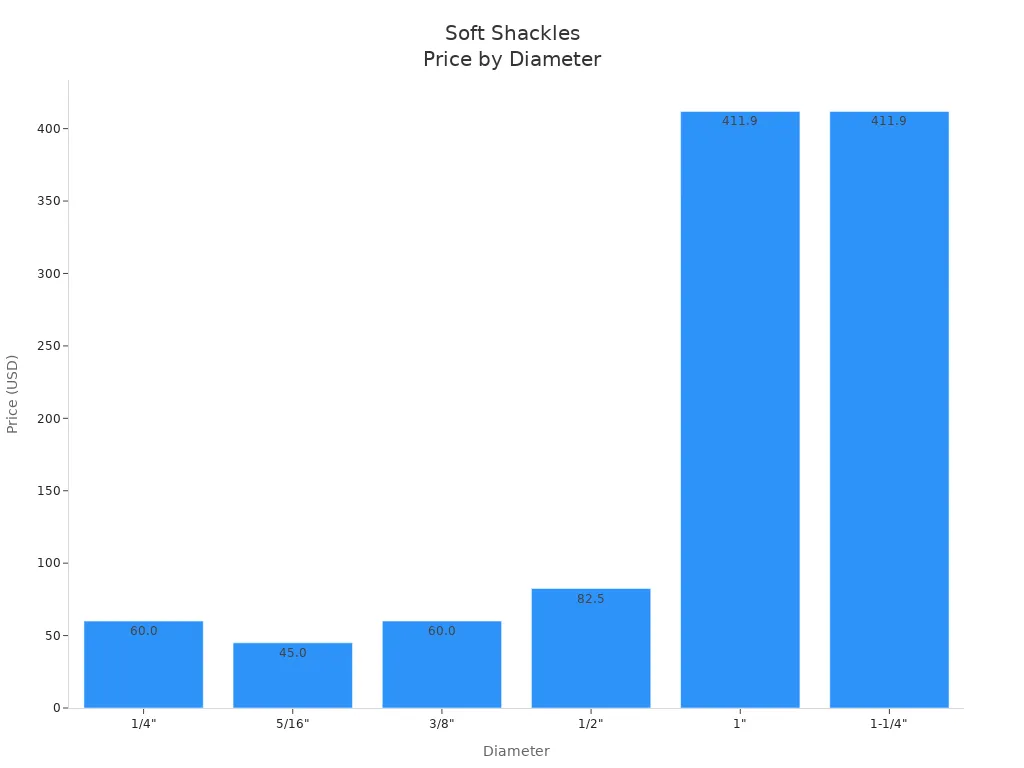

You want to make the best investment when choosing between shackles. Price plays a big role in your decision. When you compare a soft shackle to a hard shackle, you see differences in cost based on size and strength.

For example, a soft shackle with a 1/4″ diameter and a minimum breaking strength of 20,000 lb costs about $60.00. If you need more strength, a 1/2″ soft shackle with a 62,500 lb rating costs around $82.50. The price increases with the diameter and load rating.

Here is a table that shows typical prices for soft shackle options:

Diameter | Min Breaking Strength | Price |

|---|---|---|

1/4″ | 20,000 lb | $60.00 |

5/16″ | 29,000 lb | $45.00 |

3/8″ | 43,500 lb | $60.00 |

1/2″ | 62,500 lb | $82.50 |

1″ | 220,000 lb | $411.90 |

1-1/4″ | 330,000 lb | $411.90 |

You will notice that a hard shackle with similar load ratings often costs less than a soft shackle. The price difference comes from the advanced materials and manufacturing process used for soft shackle products. You should always compare the specifications and certifications before making a purchase.

Long-Term Investment

You need to think beyond the initial price when you buy shackles. A soft shackle gives you lightweight handling and safety benefits, but it may require more frequent replacement if used in abrasive environments.

A hard shackle, especially one from a trusted brand, offers durability and long service life. You can use a hard shackle for years with proper maintenance.

When you invest in high-quality shackles, you reduce downtime and improve safety. You also lower the risk of equipment failure. Over time, a hard shackle can provide better value for heavy-duty or permanent applications.

A soft shackle works best for flexible, temporary, or safety-focused tasks. You should match your investment to your needs and the demands of your work environment.

Tip: Always consider the total cost of ownership, including maintenance and replacement, when choosing between a soft shackle and a hard shackle.

Building a Complete Recovery Kit

Combining Soft and Steel Shackles

You need a complete recovery kit to handle any challenge in the field. You should include both soft shackle and hard shackle options in your setup. Each type brings unique strengths to your recovery operations. A soft shackle gives you flexibility and safety for quick connections.

You can use a soft shackle when you need to protect painted surfaces or delicate equipment. A hard shackle provides unmatched durability and strength for static loads. You will rely on a hard shackle for heavy lifting or when you need a secure anchor point.

You should pack at least two soft shackle units and two hard shackle units in your kit. This approach prepares you for different scenarios during recovery operations. You can use a soft shackle for connecting recovery straps or winch lines.

You can use a hard shackle for attaching to fixed recovery points or handling high-abrasion tasks. You will find that combining both types of shackles increases your safety and efficiency during vehicle recovery.

Tip: Always inspect each soft shackle and hard shackle before and after every use. Replace any shackle that shows signs of wear or damage.

Powerful Machinery Solutions

You can trust Powerful Machinery to supply all the shackles you need for your recovery operations. The company offers a wide range of hard shackle options, including European and U.S. types. You will find Dee and Bow shapes, as well as screw pin and bolt-type closures.

Each hard shackle meets strict international standards for safety and performance. You can select the right hard shackle for construction, marine, or industrial recovery operations.

If you need a custom solution, Powerful Machinery can help. The company works with you to design shackles that fit your unique requirements. You can count on certified products that deliver reliability in the toughest environments.

Visit Powerful Machinery’s shackles page to explore the full range and build a recovery kit that covers every scenario.

Shackle Type | Best Use Case | Key Benefit |

|---|---|---|

Soft shackle | Quick, flexible connections | Lightweight, safe |

Hard shackle | Heavy-duty, static loads | Durable, high-strength |

You will achieve the best results in recovery operations when you combine both soft shackle and hard shackle options in your kit.

Conclusion

You gain robust performance from soft shackle options, which excel in vehicle recovery, high-angle rescues, and wet conditions. Hard shackle products from Powerful Machinery deliver durability and reliability for heavy loads and static lifting. Consider these factors when choosing shackles:

Soft shackle offers lightweight handling and safety.

Hard shackle resists abrasion and supports demanding tasks.

Match shackles to your working load limit and environment.

Always inspect and maintain shackles for safe operation.

Certification | Description |

|---|---|

ISO 9001 | Quality management for shackles |

ISO 45001 | Occupational health and safety for hard shackles |

Select Powerful Machinery shackles for certified, high-performance lifting and recovery.

FAQ

What is the main difference between a soft shackle and a steel shackle?

You will notice that a soft shackle uses synthetic fibers for flexibility and light weight. A steel shackle uses metal for maximum strength and durability. Your choice depends on your application and safety needs.

How do I know when to replace my shackle?

You should inspect your shackle before each use. Replace it if you see fraying, rust, deformation, or any sign of damage. Regular checks help you maintain safety and performance.

Can I use a soft shackle in marine environments?

You can use a soft shackle in marine environments. It resists corrosion and does not rust. Always rinse it with fresh water after saltwater exposure and let it dry before storage.

Are steel shackles suitable for heavy lifting?

You should choose steel shackles for heavy lifting tasks. They provide high load capacity and meet strict safety standards. You can rely on them for construction, cargo handling, and industrial lifting.

What certifications should I look for in shackles?

You should look for certifications like ISO9001, AS2741, and TUV Rheinland. These standards ensure your shackles meet international safety and quality requirements.