You want to know what size lifting chain you need for safe lifting. The right answer depends on lifting chain sizes, the weight of your load, the grade of chain, and the type of work you plan to do. Using the wrong lifting chain can put you, your team, and your equipment at risk.

Powerful Machinery gives you certified lifting chains that meet strict safety standards. Trust in quality means you protect your operation and avoid costly mistakes.

Key Takeaways

Choose the right chain diameter for your load. A larger diameter supports more weight, ensuring safety during lifting.

Select the appropriate chain grade based on your lifting needs. Grade 80 is reliable for general tasks, while grade 100 offers higher capacity and efficiency.

Always respect the working load limit of your chain. This limit is crucial for preventing accidents and ensuring safe lifting operations.

Inspect chain slings before each use. Regular checks help identify damage and maintain safety standards.

Consult with experts for custom solutions. Tailored chains can meet specific project requirements and enhance operational efficiency.

Understanding Lifting Chain Sizes

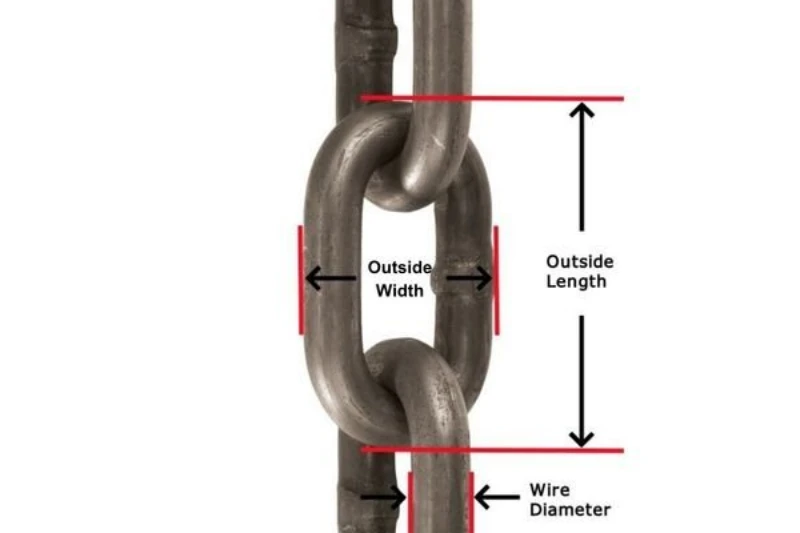

Chain Diameter Basics

You need to understand how chain diameter impacts lifting chain sizes and safety. A larger diameter means the chain can handle more weight. For example, a 16mm diameter grade 100 chain supports much more than a 10mm chain of the same grade. Here are some standard diameters and their load capacities:

Chain Diameter (MM) | Chain Diameter (Inch) | Load Capacity (KG) | Load Capacity (LBS) |

|---|---|---|---|

7.1 | 1/4 | 1430 | 3150 |

8.5 | 5/16 | 2130 | 4700 |

10 | 3/8 | 2990 | 6600 |

12 | 7/16 | 3970 | 8750 |

13.5 | 1/2 | 5130 | 11300 |

16 | 5/8 | 7760 | 17100 |

20.0 | 3/4 | 11200 | 24700 |

Tip: Always check the chain diameter before selecting chain slings for your application.

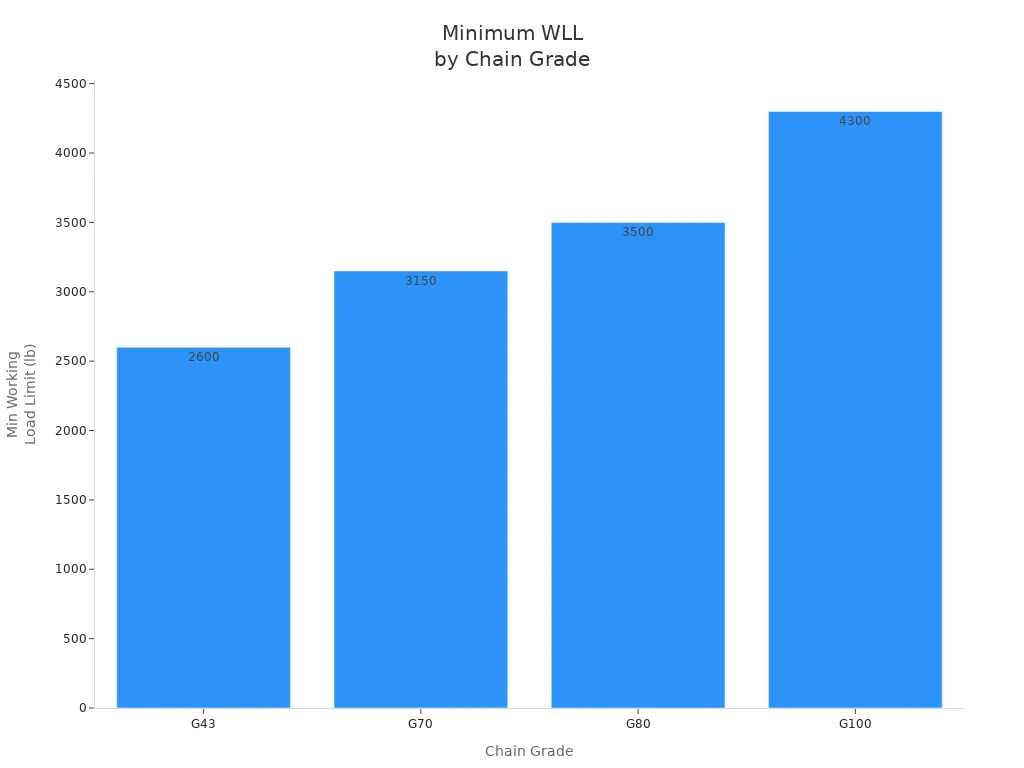

Chain Grades Overview

Chain grade tells you the strength and best use for each chain. You will find four main grades: G43, G70, G80, and G100. Each grade has different properties and uses:

Chain Grade | Design Factor | Working Load Limit (WLL) | Material Composition | Overhead Lifting Rating |

|---|---|---|---|---|

G43 | 3:1 | 2,600lb – 13,000lb | Carbon Steel | No |

G70 | 4:1 | 3,150lb – 15,800lb | High Strength Carbon Steel | No |

grade 80 | 4:1 | 3,500lb – 18,100lb | High-Tensile Alloy Steel | Yes |

grade 100 | 4:1 | 4,300lb – 22,600lb | High-Grade Alloy Steel | Yes |

Grade 80 and Grade 100 chain slings are the top choices for overhead lifting. Grade 100 offers higher tensile strength, so you can lift heavier loads with the same size chain or use a smaller chain for the same working load limit. This makes grade 100 chain slings more efficient and easier to handle.

Working Load Limits

You must always respect the working load limit for any lifting chain. The working load limit is about one-third of the chain’s break strength. Both diameter and grade affect this limit. Chains are marked with their grade and size, so you can quickly check if a chain sling meets your needs.

Grade 80 and grade 100 chain slings are rated for overhead lifting, while G70 is mainly for securing loads in transport.

Powerful Machinery Chain Standards

Powerful Machinery manufactures lifting chains that meet strict international standards. You get products that comply with ISO 16872:2008, ISO 16877:2008, ISO 3056:1986, and ISO 3075:1980. These standards cover tolerances, strength, inspection, and safe handling.

Powerful Machinery holds certifications such as LEEA, ISO 9001:2015, COR®, and DNV. You can trust that every grade 80 and grade 100 chain sling from Powerful Machinery is tested for safety and reliability in demanding environments.

Choosing the Right Lifting Chain Size

Assessing Load Requirements

You must start by understanding your load before selecting any lifting chain sizes. Consider these key factors:

Identify the maximum weight of your load and its dimensions.

Determine the type of load—rigid, flexible, or unevenly shaped.

Check the number and position of lifting points.

Evaluate the angle at which you will lift, as sling angles affect the force on each leg.

Review the environment, including temperature extremes, moisture, and chemical exposure.

Inspect the frequency of lifts and the need for regular maintenance.

Note: Always assess the center of gravity and ensure the load is balanced. Uneven distribution can overload one or more chain slings, increasing the risk of failure.

You should also consider how the load will move during lifting. For example, a load with a high center of gravity may shift, requiring extra care in sling selection and rigging.

Selecting Chain Grade

Choosing the right chain grade is essential for both safety and efficiency. Grade 80 and grade 100 are the most common choices for overhead lifting. Grade 80 offers reliable strength for general lifting tasks and is cost-effective.

Grade 100 provides higher capacity and lighter weight, making it ideal for demanding applications where you need to maximize lifting performance.

Environmental conditions also play a role. Grade 100 chain slings perform well in cold environments due to their fine-grain structure, which improves impact resistance.

Both grade 80 and grade 100 maintain their working load limit up to 400°F, but you should always consult manufacturer guidelines for use in higher temperatures. If your operation involves exposure to moisture, salt water, or chemicals, consider chains with enhanced corrosion resistance.

Stainless steel options from Powerful Machinery can meet these needs.

Tip: Never use grade 80 or grade 100 chain slings around acids or caustic chemicals unless the manufacturer approves them. Chemical exposure can cause hidden damage.

Matching Chain Size to Application

Selecting the correct chain size involves more than just matching weight. You must look at the entire lifting scenario:

Assess the weight, size, and shape of your load.

Choose the appropriate chain grade based on the required capacity.

Decide on the sling configuration—single-leg, double-leg, or multi-leg—based on load stability.

Consider environmental factors such as temperature and corrosion.

Ensure the chain size and grade exceed the working load limit for a safety margin.

Application Aspect | What to Consider |

|---|---|

Load Characteristics | Weight, dimensions, shape, and center of gravity |

Chain Grade | Grade 80 for general lifting, grade 100 for higher capacity and efficiency |

Sling Configuration | Single-leg for simple lifts, multi-leg for stability and balanced load support |

Environmental Factors | Temperature, moisture, and chemical exposure |

Safety tips for chain slings: Always select a chain with a higher capacity than your calculated load. This extra margin accounts for dynamic forces, sling angles, and unexpected shifts.

Powerful Machinery Chains for Every Need

Powerful Machinery offers a complete range of lifting chains and chain slings to fit every application. You can choose from grade 80 and grade 100 options, available in various diameters and link configurations.

If your project requires a unique solution, Powerful Machinery provides custom-engineered chains tailored to your specifications. Options include different materials like alloy steel and stainless steel, as well as custom surface treatments for enhanced durability.

Feature | Description |

|---|---|

Customization Options | Chains tailored for specific industrial needs |

Chain Size | Multiple sizes to match unique lifting requirements |

Material | Alloy steel, stainless steel, and more for different environments |

Surface Treatment | Custom finishes to boost durability and performance |

You can rely on Powerful Machinery’s certified lifting chains to meet or exceed international standards. Every chain undergoes rigorous testing to ensure safety and reliability, even in the most demanding environments.

Whether you need standard lifting chain sizes or a custom solution, Powerful Machinery delivers the right product for your lifting chains and chain slings.

Safety with Lifting Chains

Inspection and Maintenance

You must inspect chain slings before each use to ensure safety and reliability. Clean the sling to reveal hidden damage. Check the identification tag for legibility. Level the chain and untwist any sections to spot distortions. Measure the sling length and remove it if stretched.

Schedule thorough inspections at least once a year, and increase frequency for harsh environments or heavy-duty tasks. Use the following table to guide your inspection process:

Inspection Step | Details |

|---|---|

Slings | Check for cuts, tears, burns, broken wires, stretched or damaged links. Ensure capacity tags are present and readable. |

Shackles | Look for bent bodies, pin damage, and mismatched parts. Ensure proper fit and engagement of pins. |

Hooks | Inspect for deformation, cracks, and missing latches. Check for signs of shock loading. |

Tip: Initial inspections should occur before first use. Perform frequent checks daily or before each shift. Conduct special inspections after incidents or repairs.

Avoiding Damaged Chains

Remove chain slings from service if you notice any of the following signs:

Deformed or cracked coupling links, master links, or other components

Cracks in hooks or hook throat openings are more than 15% larger than normal

Twisted hooks beyond 10 degrees from the plane

Bent links, nicks, gouges, or cuts in the chain

Visible stretching or bending of links

Knots in any part of the sling

Heat or chemical damage, such as melting or discoloration

Chain links worn past the manufacturer’s limits

Cracks, nicks, gouges, or corrosion on metal fittings or chain

Attachments that do not hinge freely with adjacent links

Improper installations, overload, damaged synthetic slings, and stretched or bent links often cause damage in industrial environments.

Proper Use and Handling

Follow safety tips for chain slings to maximize safety and equipment lifespan. Clean slings before inspection. Inspect chain links for bending, cracking, elongation, or twisting. Check for surface wear, corrosion, and pitting. Ensure attachments like hooks and rings are in good condition.

Use stable lifting points and maintain load balance during lifts. Select appropriate hitch types based on load capacity. Utilize tag lines for load control. Ensure hooks have latches to prevent disengagement. Use shackles with proper load limits and secure them properly.

Avoid applying pressure on the point of the hook. Never jerk the load or drag loads with chain slings. Discard damaged or worn slings immediately.

Proper handling of lifting chains enhances safety, increases equipment lifespan, and improves operational efficiency.

International Safety Standards

You must follow international safety standards for chain slings used in overhead lifting. Powerful Machinery demonstrates compliance with regulations such as OSHA 1910.5 (c) (1), ASME B30.9-1.10.1 (c), and OSHA 1910.184 (e). These standards require identification tags, matching attachments, and prohibit makeshift links.

The table below highlights key standards:

Standard | Description |

|---|---|

ASME B30.16 | Covers construction, installation, operation, inspection, testing, and maintenance of hoists, including chain hoists. |

ASME B30.9 | Addresses fabrication, use, inspection, and maintenance of slings, including those made from alloy steel chain. |

Powerful Machinery’s certified lifting chains meet or exceed these requirements, ensuring your operation remains safe and compliant.

Quick Guide to Lifting Chain Selection

Checklist for Safe Selection

You need a clear process to select safe lifting chains for your operation. Follow these steps to ensure every lift meets industry standards and protects your team:

Verify that the lifting chain carries third-party certifications based on international standards such as ASME or CE marking.

Inspect the chain and hooks before each shift. Look for visible damage, wear, or deformation.

Test the hoist’s functions without a load. Confirm smooth operation and proper engagement of all components.

Schedule periodic inspections by a competent person. Check for wear, corrosion, and document all findings.

Match the chain slings to your load requirements. Consider weight, shape, and lifting angles.

Select the correct chain grade and diameter for your application.

Ensure the working load limit exceeds your calculated load for a safety margin.

Review environmental factors such as temperature, moisture, and chemical exposure.

Use only chain slings that meet Powerful Machinery’s certified standards for reliability and safety.

Consult product support if you have unique requirements or need custom-engineered solutions.

Tip: Regular inspections and certification checks help you avoid unexpected failures and maintain compliance.

Flowchart for Choosing Chain Size

You can simplify your selection process by following this flowchart:

Step | Decision Point | Action |

|---|---|---|

1 | What is the maximum load weight? | Identify the total weight to lift. |

2 | What is the load shape and lifting angle? | Assess stability and sling configuration. |

3 | Which chain grade suits your application? | Choose grade 80 or grade 100 for overhead lifting. |

4 | What diameter matches your load and grade? | Refer to load charts for safe selection. |

5 | Are environmental factors present? | Select stainless steel or treated chains if needed. |

6 | Does the chain meet Powerful Machinery’s standards? | Confirm certifications and product support. |

You can always reach out to Powerful Machinery for expert advice and custom solutions. Their team helps you select the right chain slings for every lifting scenario.

Conclusion

Choosing the right lifting chain size keeps your operation safe and efficient. Powerful Machinery’s certified chains deliver reliability and meet global standards. You gain peace of mind, support your safety goals, and pass inspections with ease. Review the table below to see the main benefits:

Benefit | Description |

|---|---|

Compliance with Standards | Chains meet or exceed global safety standards. |

Custom Engineering | Solutions tailored for demanding projects. |

Positive Customer Feedback | Clients praise durability and reliability. |

Follow the steps in this guide and consult lifting chain experts for your specific needs. Visit Powerful Machinery to explore certified lifting solutions.

FAQ

What is the difference between chain grade 80 and grade 100?

Grade 100 chains have higher tensile strength than grade 80. You can lift heavier loads with the same diameter. Grade 100 also offers better efficiency and lighter weight for demanding lifting tasks.

How do you identify the correct lifting chain size?

You should check the chain’s diameter and grade stamped on the links. Refer to the manufacturer’s load chart to match your load weight. Always select a chain with a working load limit above your maximum load.

Can you use Powerful Machinery chains outdoors?

Yes. Powerful Machinery chains use high-quality alloy steel or stainless steel. These materials resist corrosion and wear. You can use them in outdoor and marine environments with confidence.

How often should you inspect lifting chains?

Tip: Inspect lifting chains before every use. Schedule a thorough inspection at least once a year. Increase inspection frequency for harsh environments or heavy-duty operations.

Which industries use Powerful Machinery lifting chains?

Industry | Application |

|---|---|

Construction | Lifting and rigging |

Marine | Mooring and cargo handling |

Transportation | Securing heavy loads |

Logistics | Material handling |

You can find Powerful Machinery chains in many critical sectors.