When you select equipment for rigging and lifting safety, it is essential to understand the difference between tensile strength and working load limit.

Tensile strength measures how much force a material can resist before it breaks or deforms, while the working load limit indicates the maximum weight you can safely handle with a piece of equipment during operation. Knowing these limits is crucial for preventing accidents and maintaining safety with every lift.

By respecting these strength ratings in every application, you protect your team and ensure reliable performance.

Key Takeaways

Understand tensile strength as the maximum force a material can withstand before breaking. Choose equipment that meets your lifting needs.

Know the working load limit (WLL) as the safe weight for lifting. Always respect this limit to prevent accidents and equipment failure.

Use safety factors to create a buffer between breaking strength and working load limit. This practice helps account for unexpected loads and wear.

Inspect all rigging equipment before use. Regular checks ensure safety and reliability during lifting operations.

Plan each lift carefully. Know your load weight, choose the right equipment, and communicate clearly with your team for safe rigging.

Tensile Strength and Working Load Limit Basics

What Is Tensile Strength?

You need to understand tensile strength before you select any rigging and lifting equipment. Tensile strength describes the maximum force a material can withstand when you pull it apart.

Manufacturers test materials like steel, wire, and synthetic webbing to determine how much force they can handle before breaking. This property helps you choose the right equipment for your lifting needs.

Here is a table showing common materials used in rigging and lifting, and their typical tensile strength characteristics:

Material Type | Description | Typical Tensile Strength Characteristics |

|---|---|---|

Wire & Chain | Rigid materials provide high tensile strength for heavy loads. | Higher tensile strength compared to synthetic options. |

Webbing | Synthetic materials like nylon and polyester offer flexibility but lower strength. | Lower tensile strength than wire and chain. |

Hooks and Shackles | Made from high tensile strength materials like alloy steel for safety. | Must withstand significant forces during lifting. |

Turnbuckles | Used to tension support lines, made from metal with varying tensile strengths. | Higher tensile strengths are required for functionality. |

Tensile strength is a critical factor in rigging and lifting safety. You must select equipment with enough strength to handle the expected loads. Powerful Machinery uses high-tensile materials and advanced engineering to ensure every product meets strict safety standards.

What Is Working Load Limit?

Working load limit refers to the maximum weight you can safely lift with a piece of equipment during normal working load conditions. Manufacturers set this value after testing and applying a safety factor to the breaking strength. You must always respect the working load limit to prevent accidents and equipment failure.

The working load limit is determined by several factors:

Material strength, including tensile strength and fatigue limits.

Design factors, such as shape, size, and intended use.

Testing, which involves static and dynamic load tests.

Safety factors, which reduce the risk of failure. For example, if a chain has a breaking strength of 10,000 lbs and a safety factor of 5, the working load limit becomes 2,000 lbs.

You can see how the working load limit is calculated:

WLL = Breaking Strength / Safety Factor

Safety factors vary depending on the application:

4:1 for general-purpose lifting slings

5:1 or 6:1 for heavy-duty industrial use

10:1 for personnel lifting

Powerful Machinery ensures every product is rated with a clear working load limit. The company follows international standards like OSHA, ASME, ISO, and EN to guarantee safety and reliability.

Breaking Strength vs Working Load Limit

Breaking strength is the absolute maximum force a piece of equipment can handle before it fails. Working load limit is the safe limit for daily use. You must never use equipment near its breaking strength during normal working load operations.

Here is a table comparing the working load limit and breaking strength:

Aspect | Working Load Limit (WLL) | Breaking Strength |

|---|---|---|

Purpose | Safety limit for regular use | Absolute maximum force capacity |

Set by | Manufacturer | Material properties/testing |

Reflects | Safety, usability, and life of equipment | Material capabilities |

Used for | Daily operations | Testing and certification |

Value | Less than Breaking Strength | Greater than WLL |

Tip: Always use equipment within its working load limit. Exceeding this limit can cause dropped loads, property damage, and serious injuries. Industrial rigging and lifting companies must prioritize safety by understanding and following these limits.

Breaking strength and working load limit are not interchangeable. Breaking strength tells you the point of failure, while working load limit tells you the safe operating range.

Powerful Machinery rigorously tests every product to ensure the working load limit is accurate and reliable. The company’s certifications, including OSHA, ASME, ISO, and EN, reflect a commitment to safety and quality.

You protect your team and your equipment when you understand the difference between tensile strength, working load limit, and breaking strength. This knowledge helps you make safe choices in every rigging and lifting operation.

Safety Factors in Rigging and Lifting

What Is a Safety Factor?

You must understand the role of a safety factor in rigging and lifting safety. A safety factor acts as a buffer between the actual breaking strength of equipment and the maximum working load you should apply. Manufacturers use safety factors to account for unexpected loads, wear, and environmental conditions.

This practice helps prevent accidents and ensures reliable performance. For example, if a chain has a breaking strength of 10,000 lbs and a safety factor of 5, the working load limit becomes 2,000 lbs. You protect your team by respecting these limits.

Here is a table showing recommended safety factors for different equipment types:

Equipment Type | Recommended Safety Factor |

|---|---|

Rigging Equipment | 4:1 to 7:1 |

Hoisting Devices | 2:1 to 3:1 |

Calculating Working Load Limit with Safety Factor

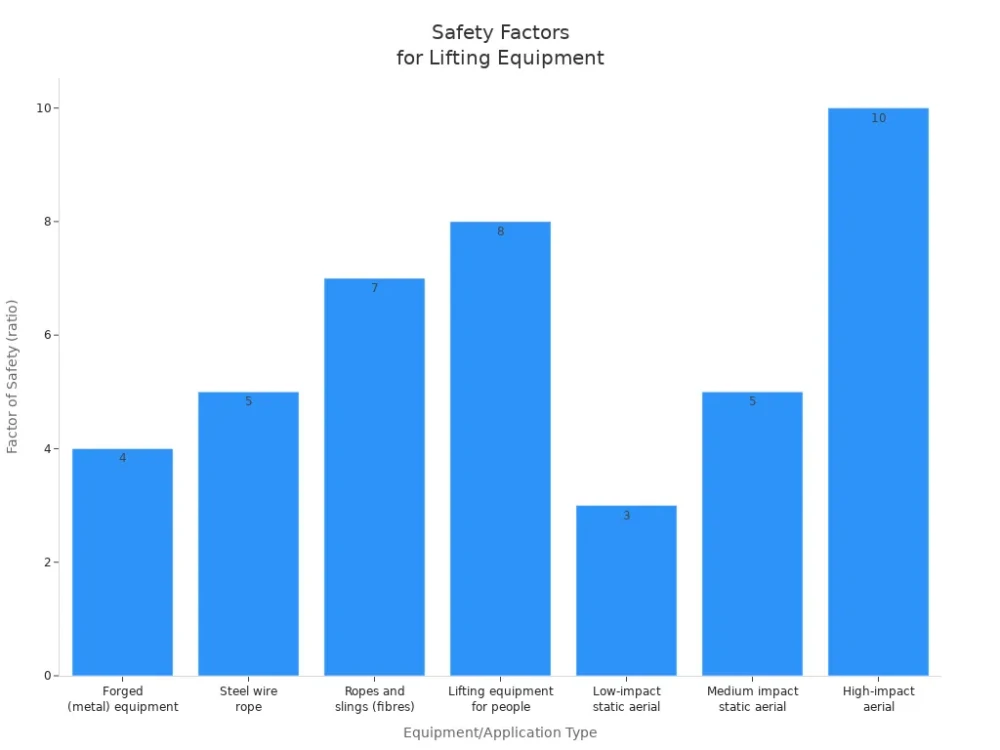

You calculate the working load limit by dividing the minimum breaking strength by the safety factor. This formula ensures that your equipment operates safely under expected loads. Different regions use varying safety factors.

North America often uses 5:1, while Europe may require 10:1 or higher. Asia sometimes applies lower safety factors for simple pulling or lashing. The type of equipment and application also affects the safety factor.

Forged metal equipment, like shackles and chains use a 4:1 safety factor, steel wire rope uses 5:1, and artificial fiber slings require 7:1. Lifting people demands even higher safety measures.

Type of Equipment | Factor of Safety |

|---|---|

Forged (metal) equipment (shackles, chains) | 4:1 |

Steel wire rope | 5:1 |

Ropes and slings (artificial fibres) | 7:1 |

Lifting equipment not designed for people (when used for lifting people) | 8:1 (doubled) |

Low-impact static aerial exercises | 3:1 |

Medium impact static aerial techniques | 5:1 (dynamic) |

High-impact aerial applications | 10:1 (dynamic) |

Note: Dynamic loads, such as moving performers or shifting cargo, require higher safety factors than static loads.

Industry Standards and Powerful Machinery

You rely on international safety standards to guide your rigging and lifting operations. Standards like ISO12100, IEC60204-1, ISO13849-1, ISO14119, and ISO13850 set requirements for risk assessment, electrical safety, control systems, and emergency stops.

Powerful Machinery meets or exceeds these safety standards. The company complies with OSHA, ASME, and ISO regulations, ensuring every product delivers reliable tensile strength and working load performance.

Powerful Machinery conducts thorough risk assessments, uses machine guards, and implements emergency stop features. You benefit from equipment that passes rigorous inspections and meets global safety benchmarks.

By choosing Powerful Machinery, you ensure your rigging and lifting safety measures align with the highest industry standards.

Real-World Safety Applications

Equipment Selection and Overload Prevention

You must select the right rigging equipment to ensure safety in every material handling operation. Start by identifying the weight of your load and matching it to the working load limit of your gear.

Always check the equipment’s tensile strength and breaking strength to confirm it meets your needs. Follow these best practices to prevent overload:

Determine the exact weight of your load and compare it to the working load limit.

Choose the correct hitch type for secure lifting.

Maintain proper sling angles to avoid extra tension and reduce working load.

Inspect all rigging hardware for wear or damage before use.

Use sling protection to prevent breaking from sharp edges.

Balance the load around its center of gravity.

Perform a test lift to verify the setup.

Use tag lines to control load movement.

Clear the area of hazards before lifting.

Common causes of overload incidents include exceeding the working load limit, improper securing, and unbalanced loads. You can prevent these issues by following the table below:

Cause of Overload Incidents | Prevention Methods |

|---|---|

Exceeding the crane’s load capacity | Stay within the working load limit |

Improper securing of loads | Properly secure the load |

Unbalanced loads during lifting | Balance the load |

Managing Shock Loads

Shock loads can quickly exceed the working load limit and compromise safety. You must understand that sudden movements or impacts can cause breaking, even if the equipment’s tensile strength is high. To manage shock loads, use proper rigging techniques and stabilize the load.

Always keep the center of gravity below the hook and use hardware like shackles and below-the-hook devices for better control. Environmental factors, such as wind, can also affect load stability. Use tag lines and lifting hooks with latches to prevent breaking during unexpected shifts.

Powerful Machinery designs equipment with high tensile and breaking strength to withstand demanding material handling scenarios.

Manufacturer’s Rated Capacity and Powerful Machinery

Manufacturers determine rated capacity, also called working load limit, through engineering calculations and destructive testing. They consider tensile strength, breaking strength, and intended use.

Standards like ASME B30.9 and CSA G4 require proof testing and third-party certification. Powerful Machinery follows these strict guidelines. The company provides documentation for every product, showing compliance with international safety standards.

You benefit from custom-engineered solutions that maximize load-bearing capacity and ensure reliable performance in material handling. Powerful Machinery’s certified products give you confidence that your equipment will meet or exceed the required working load for every lift.

Proof Testing and Quality Control

What Is Proof Test Load?

You need to understand proof test load to ensure rigging and lifting equipment meets strict safety standards. Proof testing involves applying a controlled load to equipment, usually above its working load limit, to verify its strength and integrity.

This process helps confirm that chains, slings, hooks, and other hardware can handle the expected capacity without permanent deformation or failure. Proof testing is not the same as testing for breaking strength.

Instead, it checks that the equipment maintains a safety margin and performs reliably under real-world conditions.

Here is a table showing typical proof testing requirements for different types of lifting equipment:

Equipment Type | Testing Requirement | Standard |

|---|---|---|

Overhead/Gantry Cranes | 1.0 to 1.25 times WLL | 29 CFR 1910.179 |

Hoists | 1.0 to 1.25 times WLL | ASME B30.16 |

Chain/Wire Rope Slings | 2.0 times WLL | ASME B30.9 |

Rigging Hardware | 2.0 times WLL | ASME B30.26 |

Spreader Beams | 1.25 to 2.0 times WLL | ASME BTH-1 |

Below-Hook Devices | 1.0 to 1.25 times WLL | ASME B30.20 |

Tip: Always check that your equipment has passed proof testing before use. This step helps you avoid unexpected failures and supports a strong safety culture.

Ensuring Reliability and Compliance

You rely on proof testing to improve equipment reliability and maintain safety. Proof testing calculates the probability of failure on demand, helping you set proper testing intervals and identify potential weaknesses. This process ensures that the safety functions of your rigging gear remain effective throughout its service life.

You must remember that while proof testing reduces the risk of failure, human error during testing can introduce new risks. Regular inspections and careful documentation help you minimize these risks.

Powerful Machinery follows a rigorous quality control process to guarantee compliance with international standards. You benefit from:

Compliance with ISO 9001 for quality management and ISO 12100 for machine safety.

Adherence to OSHA regulations for workplace safety.

Regular testing and certification of all lifting and rigging products.

You can trust Powerful Machinery to:

Research and apply relevant standards for your industry.

Collaborate with regulatory experts to address compliance early.

Design equipment with built-in safety features.

Conduct ongoing testing and certification to maintain high standards.

You gain confidence knowing that Powerful Machinery’s products meet strict requirements for tensile strength, working load limit, and breaking strength. This commitment to quality ensures every piece of equipment delivers reliable capacity and maintains a robust safety margin.

Conclusion

You improve rigging and lifting safety by understanding the differences between tensile strength, working load limit, and breaking strength. Breaking strength shows the maximum force before failure, while the working load limit ensures safe operation with a safety margin.

Choosing certified equipment from Powerful Machinery reduces risk and streamlines inspections. To maintain safety, always know your load weight, inspect hardware, and plan every lift. Use proper techniques and communicate clearly with your team for reliable rigging and lifting results.

Term | Role in Safety |

|---|---|

Tensile Strength | Maximum force before breaking |

Working Load Limit | Safe load during use |

Breaking Strength | Failure threshold |

Know your load weight

Inspect equipment before use

Plan each lift for safety

FAQ

What is the difference between tensile strength and working load limit?

Tensile strength shows the maximum force a material can handle before breaking. Working load limit tells you the safe weight you can lift during normal use. Always use equipment within its working load limit for safety.

How do manufacturers determine the working load limit?

Manufacturers test equipment to find its breaking strength. They divide this value by a safety factor to set the working load limit. You can trust certified products from Powerful Machinery for accurate ratings.

Why should you never exceed the working load limit?

Exceeding the working load limit increases the risk of equipment failure and accidents. You protect your team and property by staying within safe limits. Always check load ratings before lifting.

What does proof testing mean for lifting equipment?

Proof testing means applying a controlled load above the working load limit to verify strength and reliability. You ensure equipment safety and compliance by choosing products that pass proof testing.

How can you identify certified lifting equipment?

Look for markings, labels, or certificates showing compliance with standards like ISO, OSHA, or ASME. Powerful Machinery provides documentation for every product, so you can confirm safety and reliability.