When you ask what grade 80 chain is, you discover a high-strength alloy steel chain that sets the standard for safe lifting. This chain provides superior lifting capacity and durability for demanding jobs. You rely on certified products to protect workers and equipment. Powerful Machinery delivers grade 80 chain solutions that meet strict safety and quality standards.

Grade 80 chain offers unmatched reliability.

Certification ensures every lift meets industry requirements.

Key Takeaways

Grade 80 chain is made from high-strength alloy steel, ensuring safety and reliability for heavy lifting tasks.

Always check for grade markings and certification stamps on your chain to maintain compliance with safety standards.

Regularly inspect your Grade 80 chain for wear and damage to extend its lifespan and ensure safe operations.

Choose the right chain grade based on your lifting needs; Grade 80 is ideal for overhead lifting, while Grade 70 is better for transport.

Powerful Machinery’s Grade 80 chain meets strict international safety standards, providing peace of mind for every lift.

What is Grade 80 Chain?

When you ask what a g80 chain is, you look at a specialized lifting chain made from high-strength alloy steel. This chain stands out in the world of rigging and material handling. You find it in environments where safety, reliability, and performance matter most.

The g80 chain is engineered for overhead lifting, heavy-duty rigging, and demanding industrial tasks. You rely on it because it meets strict safety standards and delivers consistent results.

Key Features of Grade 80 Chain

You recognize the G80 chain by its unique alloy steel composition. Manufacturers use a precise blend of elements to create a chain that balances strength and ductility. Here is a breakdown of the chemical composition found in alloy chain grade 80:

Element | Composition (%) |

|---|---|

Ni | 0.4 |

Cr | 0.4 |

Mo | 0.15 |

P | 0.030 |

S | 0.030 |

Al | 0.025 |

You benefit from this advanced metallurgy because it gives the g80 chain a minimum tensile strength of 800 MPa. This strength allows you to lift heavy loads with confidence. The chain’s heat treatment process, including quenching and tempering, ensures it can handle shock loads and harsh environments.

You also notice powder-coated finishes and clear grade markings, which help you identify and trace each chain for safety and compliance.

Recent advancements have made the g80 chain even more reliable. Enhanced welding techniques and improved heat treatment methods increase durability and structural integrity. Manufacturers now use eco-friendly materials, supporting sustainable practices in the industry.

Advancement Type | Description |

|---|---|

Enhanced Welding Techniques | Improved welding methods contribute to the overall strength and durability of Grade 80 chains. |

Heat Treatment Methods | Advanced heat treatment ensures structural integrity under high temperatures, crucial for heavy-duty applications. |

Eco-friendly Materials | The use of sustainable materials reflects a trend towards environmentally responsible manufacturing. |

You see these features come together to create a lifting chain that performs in the toughest conditions. The g80 chain is not just strong; it is also lightweight, making it easier for you to handle and install.

Powerful Machinery’s G80 Chain Standards

When you choose Powerful Machinery, you select a partner with over 20 years of expertise in manufacturing g80 chain. You trust their commitment to quality, safety, and innovation. Powerful Machinery uses only premium alloy steel and advanced production techniques.

Every g80 chain undergoes rigorous heat treatment and proof testing before it reaches you.

You can rely on Powerful Machinery’s g80 chain because it meets or exceeds major international safety standards. Here is how the company ensures compliance:

Compliance Standard | Description |

|---|---|

ASME | Specifies the mechanical properties, dimensions, and testing requirements for Grade 80 chains. |

OSHA | Ensures safety and performance in lifting applications, requiring adherence to specific regulations. |

You find that Powerful Machinery’s g80 chain is manufactured from heat-treated alloy steel. The design balances strength and ductility, making it suitable for marine and shock-load environments.

Each chain features powder-coated finishes and clear grade markings for traceability, so you always know you are using certified equipment.

The company’s production process focuses on quality at every stage:

Process Stage | Importance |

|---|---|

Raw Material Selection | Ensures high-quality inputs for manufacturing strong chains. |

Final Testing | Guarantees that the chains meet safety and performance standards before use. |

You benefit from Powerful Machinery’s dedication to safety standards and performance. The company’s g80 chain solutions help you meet the strictest requirements in lifting and rigging.

When you need to answer what a grade 80 chain is, you can point to Powerful Machinery’s certified products as the industry benchmark.

Tip: Always check for grade markings and certification stamps on your g80 chain before use. This simple step helps you maintain compliance with safety standards and ensures every lift is secure.

You now understand what a grade 80 chain is and why it is trusted in critical lifting applications. Powerful Machinery’s expertise and commitment to quality give you the confidence to tackle any heavy-duty job.

G80 Chain Specifications and Ratings

Grade 80 Chain Working Load Limit and Strength

You need to understand the working load limit when you select a g80 chain for lifting operations. This value tells you the maximum weight the chain can safely handle during rigging operations.

Powerful Machinery’s g80 chain offers high strength and durability for overhead lifting. The chain uses premium alloy steel and advanced heat treatment to achieve impressive performance.

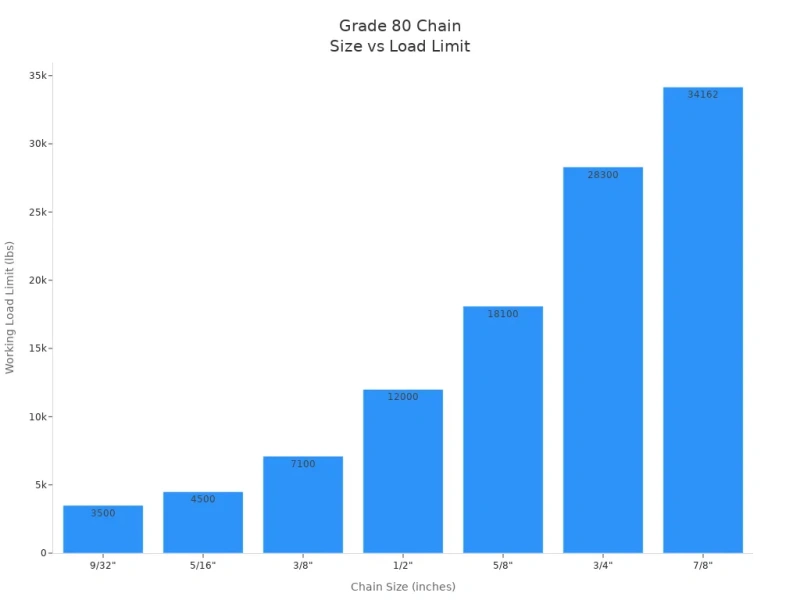

Here is a quick reference for common g80 chain sizes and their working load limits:

CHAIN SIZE INCH | WORKING LOAD LIMIT (LBS) |

|---|---|

9/32″ | 3,500 |

5/16″ | 4,500 |

3/8″ | 7,100 |

1/2″ | 12,000 |

5/8″ | 18,100 |

3/4″ | 28,300 |

7/8″ | 34,162 |

You see that the g80 chain meets tough load requirements for heavy-duty lifting operations. The chain’s high tensile strength and proof testing ensure safety in every lift.

Markings and Identification

You must check the markings on your G80 chain before every use. Each chain from Powerful Machinery features clear grade markings, manufacturer identification, and traceability codes. These markings help you confirm the chain’s grade and origin during rigging operations.

You can quickly verify that your equipment matches the required specifications for lifting operations. Proper identification also supports compliance with safety standards and helps you avoid costly mistakes.

Compliance with International Standards

You want confidence that your G80 chain meets global safety requirements. Powerful Machinery’s g80 chain complies with major standards, including NACM, ASTM, ISO, and OSHA. These standards set strict rules for material quality, proof loading, and identification.

Standard | Key Requirements |

|---|---|

ASME B30.20 | Identification and markings requirements for below-the-hook lifting devices. |

OSHA | Regulations require that all overhead lifting slings must comply with. |

ASME B30.9 | Requires proofloading of alloy lifting chain assemblies before initial use. |

NACM | Specifies chain specifications and requirements for safe use. |

ASTM | Sets standards for materials and performance of chains used in lifting. |

Most G80 chain products, including those from Powerful Machinery, meet ASTM and NACM requirements. You can trust that your chain will perform reliably in lifting and rigging operations worldwide.

Note: Always match your g80 chain to the load requirements and check for proper certification before starting any lifting operations.

Common Uses of G80 Chain

Overhead Lifting and Rigging

You often use the g80 chain in overhead lifting and rigging. This chain supports heavy-duty lifting in environments where safety matters most. You see it in crane operations, hoisting, and winching. The g80 chain handles large weights and resists shock loads. You rely on it for the securement of suspended loads.

Proper use of the g80 chain ensures that you meet strict safety standards during every lift. You can trust this chain for load securement in construction, shipyards, and manufacturing plants.

Material Handling and Transport

You use the g80 chain for material handling and transport tasks. It excels in load-bearing applications where you need to move or secure heavy items. You find it on flatbed trucks, in warehouses, and at shipping docks. The chain’s strength makes it ideal for securing loads during transit.

You can use it for load securement of machinery, steel coils, and building materials. G80 chain also supports load securement in rail and marine transport, giving you confidence that your cargo stays in place.

Industries Served by Powerful Machinery

You see g80 chain in many industrial applications. Powerful Machinery supplies this chain to industries that demand reliability and safety. The company’s customer base includes leaders in construction, marine, and mining.

You can review the table below to see how different industries use the g80 chain for securement and load securement:

Industry | Application Description |

|---|---|

Construction | Used for crane lifting and load securing, ensuring safety and reliability on sites. |

Marine & Offshore | Withstands saltwater exposure, securing heavy loads in shipping and offshore operations. |

Mining | Handles extreme weight and harsh environments for the safe transport of materials. |

You benefit from the versatility of the g80 chain. It adapts to a wide range of industrial applications, from securing loads on construction sites to supporting offshore operations. You can count on Powerful Machinery for certified chains that deliver consistent performance in every load securement scenario.

Tip: Always inspect your g80 chain before each use. Regular checks help you maintain safety and extend the life of your equipment.

Advantages and Safety of Grade 80 Chain

Benefits Over Other Chain Grades

You gain several advantages when you choose Grade 80 chain for lifting and rigging. This chain uses heat-treated alloy steel, which gives it a high strength-to-weight ratio. You can lift heavy loads safely without adding unnecessary weight to your equipment.

Grade 80 chain stands out for overhead lifting, recovery, and towing. You see its strength and durability in industries like flatbed trucking, where securement of heavy-duty loads is critical.

Grade 80 chain offers more safety and reliability than Grade 70 chain, and it remains easier to handle than Grade 100 chain in many applications.

Inspection and Maintenance Tips

You protect your investment and ensure safety by following proper inspection and maintenance routines. Start with a visual check before each use. Look for stretched links, cracks, missing tags, or signs of heat damage. Schedule periodic inspections by a qualified person, especially if you use the chain in harsh environments.

Remove the chain from service if you find excessive wear, corrosion, or weld defects. Common causes of chain failure include high cyclic loading, improper heat treatment, and insufficient alloying elements.

You extend the lifespan of your Grade 80 chain by keeping it clean, lubricated, and stored in a dry place. Regular maintenance helps you avoid unexpected failures and keeps your lifting operations safe.

Tip: Never exceed the working load limit of your chain. Overloading can lead to premature failure and safety risks.

Safety and Certification by Powerful Machinery

You trust Powerful Machinery because every Grade 80 chain meets strict safety standards. The company follows OSHA 1910.184 and ASME B30.9 guidelines for fabrication, marking, and testing. These standards ensure your chain is safe for lifting and easy to identify. You benefit from a certification process that includes:

Standard | Description |

|---|---|

OSHA 1910.184 | Governs use, inspection, and removal criteria for lifting slings. |

ASME B30.9 | Guides the fabrication, marking, and testing of lifting chains. |

You can rely on Powerful Machinery’s certified chains for consistent performance and peace of mind in every lift.

Grade 80 Chain vs Other Grades

Grade 70 vs Grade 80 Chain

You often see Grade 70 and Grade 80 chains used in different environments. Grade 70 chain works well for transport and tie-down tasks. It is not rated for overhead lifting. Grade 80 chain, on the other hand, is designed for lifting and rigging. You can trust it for critical applications where safety is a priority.

Grade 80 chain offers higher strength than Grade 70 chain of the same size. For example, a 3/8″ Grade 70 chain has a working load limit (WLL) of 6,600 lbs, while a 3/8″ Grade 80 chain handles 7,100 lbs. As the chain size increases, the difference in capacity becomes even more significant.

Grade 80 chain can reach up to 47,700 lbs in larger sizes, making it suitable for heavy-duty lifting.

Chain Size (inch) | Grade 70 WLL (lbs) | Grade 80 WLL (lbs) |

|---|---|---|

1/4″ | 3,150 | 3,500 |

5/16″ | 4,700 | 4,500 |

3/8″ | 6,600 | 7,100 |

7/16″ | 8,760 | 10,000 |

1/2″ | 11,300 | 12,000 |

5/8″ | 15,800 | 18,100 |

You also notice a price difference. Grade 70 chain costs less, usually $1.00–$2.50 per foot. Grade 80 chain ranges from $2.00–$4.00 per foot. You pay more for Grade 80 because it meets strict safety standards for lifting applications.

Grade 80 vs Grade 100 Chain

You may consider a Grade 100 chain for the most demanding lifting jobs. Grade 100 chain uses high-performance alloy steel and advanced heat treatment. It provides about 25% higher working load limit than the Grade 80 chain of the same diameter. This means you can use a smaller, lighter chain for the same load.

Grade 100 chain costs more, usually $3.00–$6.00 per foot. You choose Grade 100 when you need maximum strength and efficiency. Grade 80 chain remains a reliable choice for most lifting and rigging applications, balancing strength, safety, and cost.

Choosing the Right Chain for Your Needs

You must select the right chain for your specific applications. Start by understanding the differences in chain grades, including material, heat treatment, and ultimate strength. Always check the working load limit for safe lifting. Consider the nature of your lift and the environment.

For overhead lifting, Grade 80 or Grade 100 chains are essential. For transport or tie-down, Grade 70 may be enough.

You should also choose the correct size and style of chain and hooks. Proper selection is not just a recommendation—it is a safety requirement. Store and inspect your chains regularly to maintain integrity. Using the right chain for the job protects you and your team.

Tip: Never use a chain above its rated working load limit. Always match the chain grade to your lifting or securing needs.

Conclusion

You see why Grade 80 chain stands as the industry standard for lifting and rigging. Certified chains from Powerful Machinery give you high strength, wear resistance, and compliance with ISO and EN safety standards.

Reason for Preference | Description |

|---|---|

OSHA Recommendation | Grade 80 chain is recommended by OSHA for overhead lifting applications. |

Strength Retention | Retains a higher proportion of the working load limit under demanding conditions. |

You benefit from lower cost, wide availability, and forgiving material properties.

Regular inspection and proper selection reduce risks and keep your team safe.

Choose certified Grade 80 chain to ensure reliable performance and workplace safety every time.

FAQ

What makes Grade 80 chain different from regular chains?

Grade 80 chain uses premium alloy steel and advanced heat treatment. You get higher strength, better durability, and certification for overhead lifting. Regular chains often lack these features and cannot handle critical lifting tasks.

Can you use Grade 80 chain for overhead lifting?

Yes, you can. Grade 80 chain is specifically designed and certified for overhead lifting. Always check for proper markings and certifications before use to ensure safety.

How do you identify a Grade 80 chain?

Look for clear grade markings, manufacturer identification, and traceability codes stamped on each link.

Marking Type | Example |

|---|---|

Grade | “G80” |

Manufacturer | “PM” |

How often should you inspect your Grade 80 chain?

You should inspect your chain before each use. Schedule regular, detailed inspections by a qualified person. Remove the chain from service if you find wear, cracks, or deformation.