You play a vital role in ensuring every safe and efficient lift at your workplace. Lifting means moving loads, while rigging involves preparing and securing those loads before any movement begins.

Clear separation between lifting and rigging tasks helps you select the right tools for each job and improves both safety and productivity. The synergy between these two activities keeps operations smooth and reduces risks. Consider the latest workplace statistics:

Statistic Description | Value |

|---|---|

Average annual crane-related deaths | 42 to 44 |

Total workplace fatalities in 2023 | 5,283 |

Fatal injury rate per 100,000 workers | 3.5 |

OSHA violations from crane incidents | 838 |

Injuries from crane incidents | 133 |

Fatalities from crane incidents | 133 |

Crane accidents caused by human error | ~90% |

Increase in OSHA Form 300A submissions (2023) | 11% increase |

Understanding Lifting and Rigging Safety gives you the knowledge to prevent accidents and protect your team.

Key Takeaways

Understand the difference between lifting and rigging. Lifting moves loads, while rigging prepares and secures them.

Always inspect your lifting and rigging equipment before use. Regular checks prevent accidents and ensure safety.

Communicate clearly with your team during lifting operations. Use standard signals to avoid confusion and enhance safety.

Invest in ongoing training for lifting and rigging. Continuous education helps you stay updated on safety practices and equipment use.

Select the right equipment for each task. Using appropriate tools reduces risks and improves efficiency in lifting operations.

Understanding Lifting and Rigging

What Is Lifting?

You perform lifting when you move a load from one place to another using mechanical force. Lifting operations involve cranes, hoists, or other machines that raise, lower, or shift heavy objects. You must always consider the weight, size, and shape of the load before starting any lifting task.

Industry safety organizations like OSHA, ASME, and ANSI set strict standards for lifting operations to protect you and your team. These standards help you choose the right equipment and follow safe procedures every time.

Organization | Definition |

|---|---|

OSHA | Occupational Safety and Health Administration, which publishes federal standards and general safety requirements for various industries. |

ASME | American Society of Mechanical Engineers, known for publishing detailed and current standards often referenced by OSHA. |

ANSI | American National Standards Institute, a private organization that provides a framework for standards development across industries. |

Powerful Machinery specializes in high-performance lifting solutions. You can trust their certified lifting chains, wire ropes, and hardware to meet or exceed these industry standards.

What Is Rigging?

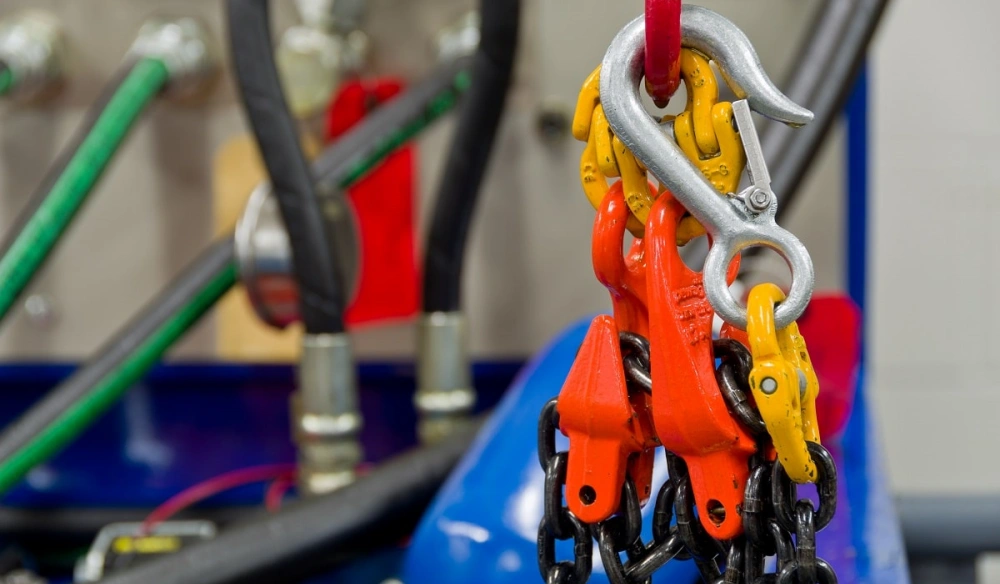

Rigging is the process you use to prepare and secure a load before any lifting begins. You select the right slings, hooks, shackles, and other hardware to attach the load safely to the lifting device. Rigging requires careful planning and attention to detail.

You must inspect all rigging gear and ensure every connection is strong and secure. Proper rigging prevents accidents and keeps lifting operations running smoothly. Powerful Machinery offers a full range of rigging hardware, including master links, wire rope fittings, and custom-engineered accessories for complex jobs.

How They Work Together?

Lifting and rigging always go hand in hand. You start by planning the rigging setup, making sure the load is balanced, and all gear is rated for the task. You then move to the lifting stage, where you operate the machinery to raise or shift the load. The process usually follows these steps:

Determine the weight of the load.

Find the center of gravity.

Measure the load’s dimensions.

Locate approved lifting points.

Select the right rigging gear.

Check for height restrictions.

Complete a risk assessment.

Prepare a method statement.

Modern technology, such as wireless lift controls and computer-guided rigging equipment, helps you monitor every step in real time. This technology improves safety and efficiency during lifting operations.

Powerful Machinery leads the industry by providing advanced solutions that support both lifting and rigging, ensuring you get reliable performance on every project.

Rigging and Lifting Safety Protocols

Common Hazards

You face many risks during material handling, especially when you perform lifting and rigging tasks. Overexertion and improper lifting techniques often cause injuries. Moving machine parts can trap hands or feet. Sharp edges and rough surfaces can lead to cuts or friction injuries.

Equipment failure or a dropped load may occur if you do not maintain your gear. Environmental factors like poor visibility or high winds increase risk. You must also watch for swinging loads, pinch points, and slippery surfaces. In crane operations, human error accounts for over 90% of rigging safety incidents.

Exceeding load capacities and contact with power lines are major contributors. Lack of safety training and poor communication often lead to accidents.

Cause of Accident | Percentage |

|---|---|

Human error | >90% |

Exceeding load capacities | 80% |

Contact with power lines | 45% |

Lack of proper training and communication | Major factor |

Safety Practices

You can reduce risk by following safe work practices and proper rigging techniques. Always inspect slings, hooks, and other material handling equipment before use. Remove worn or damaged gear from service. Secure loads correctly to prevent shifting or slippage.

Only authorized personnel should operate lifting equipment. Use a written lift plan for every high-hazard task. Conduct pre-work risk assessments and control measures to identify hazards. Maintain clear communication during all rigging safety operations.

Document inspections, weather conditions, and crane setup to meet insurance and regulatory requirements. Powerful Machinery supports your efforts by providing certified, high-quality material handling products that meet international standards.

Training and Planning

You need a strong training program to build safety awareness and reduce risk. Certified safety training gives you the skills to handle lifting and rigging equipment safely. You learn about roles, responsibilities, and the characteristics of different loads. Ongoing safety training helps you understand hazards and best practices.

Pre-lift planning, including site hazard assessments and detailed lift plans, is essential for risk management. Powerful Machinery’s commitment to rigging safety includes supporting your training needs and providing resources for continuous improvement in material handling.

Equipment and Industry Applications

Lifting Equipment

You rely on a wide range of lifting equipment to move heavy loads safely and efficiently. In industrial settings, you often use overhead cranes, gantry cranes, hoists, and jib cranes. These machines handle large materials in factories, warehouses, and construction sites.

You also use lever hoists, beam trolleys, support structures, moving skates, hand trucks, pallet jacks, and forklifts for different lifting tasks. Overhead cranes help you manage materials in manufacturing, while gantry cranes adapt to both indoor and outdoor projects.

Hoists allow you to lift heavy items, and jib cranes simplify repetitive lifting on production lines.

Powerful Machinery provides certified lifting equipment, including high-tensile chains and wire ropes. You benefit from their products meeting international standards such as ISO, LOLER, and LEEA. Regular inspections and load testing ensure your lifting equipment remains safe and reliable.

Inspection Type | Frequency |

|---|---|

Periodic Inspection | At least once a year |

Load Testing | As required |

Detailed Inspection | As per standards |

Rigging Hardware

You need dependable rigging hardware to secure loads before lifting. Powerful Machinery offers a full range of rigging products, including blocks, pulleys, eye bolts, rigging hooks, wire ropes, and stainless steel nuts. Each category serves a specific purpose.

Blocks and pulleys reduce the force needed for hoisting. Eye bolts act as anchor points. Rigging hooks allow quick attachment. Wire ropes and accessories provide secure connections. Stainless steel nuts connect and secure hardware, giving you flexibility for different applications.

Category | Description |

|---|---|

Blocks & Pulleys | Lift heavy loads with less effort |

Eye Bolts | Anchor points for rigging |

Rigging Hooks | Quick attachment for diverse lifting needs |

Wire Ropes & Accessories | Essential for lifting and rigging, secure connections |

Stainless Steel Nuts | Connect and secure hardware, flexible for various uses |

Industry Use Cases

You see lifting and rigging equipment in action across many industries. In construction, you use cranes and rigging hardware to erect buildings and bridges, ensuring safety and precision. The marine industry depends on lifting equipment for transporting materials on offshore platforms, often under harsh conditions.

In transportation, you move heavy machinery and components, using cranes and rigging to position items accurately during assembly.

Industry | Application |

|---|---|

Construction | Erecting buildings and bridges, requiring skilled rigging and lifting for heavy materials |

Marine | Offshore platforms, transporting materials and equipment under challenging conditions |

Transportation | Moving heavy machinery and components, ensuring precise positioning during assembly |

You benefit from Powerful Machinery’s commitment to quality and safety. Their products meet strict certification requirements and support your operations in the construction, marine, and transportation sectors.

Key Differences and Impact

Comparison Summary

You need to understand the differences between lifting and rigging to manage your operations safely and efficiently. The following table gives you a clear, side-by-side comparison:

Aspect | Lifting | Rigging |

|---|---|---|

Main Function | Hoisting or moving loads using machinery | Preparing and securing loads for safe movement |

Equipment Used | Cranes, hoists, lifting machines | Slings, hooks, shackles, wire ropes, rigging gear |

Personnel Role | Operate lifting equipment, monitor conditions | Select, inspect, and attach rigging hardware |

Process Focus | Actual movement of the load | Preparation and attachment of the load |

Safety Standards | Equipment inspection, load monitoring | Gear certification, secure connections |

You use lifting equipment to move heavy objects. You rely on rigging hardware to prepare and secure those objects before any movement begins. Rigging includes selecting the right gear and fastening loads, while lifting involves operating cranes or similar machines. Both roles require specialized skills and close coordination.

Why Differences Matter?

You improve lifting and rigging safety when you clearly define each task. Misunderstanding the differences between lifting and rigging can lead to serious accidents.

You may face dropped loads, collisions, or equipment failures if you skip proper rigging steps or overload your gear. Inadequate communication between teams often confuses and increases risk.

You can prevent these problems by following these best practices:

Use the correct rigging equipment for each load.

Inspect all gear before use and remove damaged items.

Communicate clearly with your team using standard signals or radios.

Assign one person to signal the crane operator and confirm all instructions.

Stop the lift if you have any doubt or notice unsafe conditions.

You also reduce costs and project delays when you identify lifting and rigging tasks correctly. Selecting the right equipment helps you meet deadlines and avoid expensive mistakes. Prioritizing safety in crane rigging improves project outcomes and keeps your team protected.

Tip: Schedule regular training and inspections to maintain high safety standards and keep your lifting and rigging operations running smoothly.

Real-World Scenarios

You see the impact of clear roles and responsibilities in many industries. For example, construction companies that separate lifting and rigging duties report fewer accidents and better project efficiency. They plan safe lifting operations, strengthen operator training, and practice emergency response drills.

These steps help you avoid common mistakes like skipping training, ignoring load limits, or overlooking environmental hazards.

If you do not follow proper procedures, you risk costly incidents. In 2022, companies lost 108 million workdays and faced $167 billion in economic costs due to workplace accidents. The human cost is even greater, affecting workers and their families.

You can improve your safety record by:

Training all operators in industry standards and safety responsibilities.

Keeping detailed records of inspections and certifications.

Using clear communication protocols, such as hand signals and two-way radios.

Stopping operations immediately if you detect confusion or danger.

When you understand the differences between lifting and rigging, you create a safer, more efficient workplace. You protect your team, reduce costs, and deliver successful projects every time.

Conclusion

You improve workplace safety and efficiency when you understand the differences between lifting and rigging. Always focus on these essentials:

Assess load weight and characteristics before every lift.

Select slings and hardware with the right capacity.

Inspect equipment regularly and keep loads balanced.

Communicate clearly with your team and use proper safety gear.

Invest in ongoing rigging and lifting training.

Powerful Machinery supports your operations with certified equipment, training resources, and custom safety programs:

Contribution | Description |

|---|---|

Certified Equipment | Products meet international safety standards. |

Training Resources | Inspection checklists and training materials are available. |

Customized Safety | Tailored safety programs for your unique needs. |

Ongoing Education | Skill development and continuous training are encouraged. |

Quality and Reliability | Products designed for tough environments and rigorous testing. |

Stay committed to training, planning, and awareness to prevent accidents and achieve operational success.

FAQ

What is the main difference between lifting and rigging?

You perform lifting when you move a load using machinery. You handle rigging when you prepare and secure the load before lifting. Each task requires different equipment and skills.

Why do you need certified lifting and rigging equipment?

Certified equipment ensures you meet safety standards. You reduce the risk of accidents and protect your team. Powerful Machinery provides products that pass rigorous international certifications.

How often should you inspect lifting and rigging gear?

You should inspect your equipment before every use. Schedule periodic inspections at least once a year. Document all findings to maintain compliance and safety.

Which industries use lifting and rigging solutions?

You see lifting and rigging in construction, marine, transportation, and cargo handling. Each industry relies on specialized equipment to move heavy materials safely.

What training do you need for safe lifting and rigging?

You need certified safety training. Learn how to select equipment, assess loads, and communicate with your team. Ongoing education helps you prevent accidents and improve efficiency.