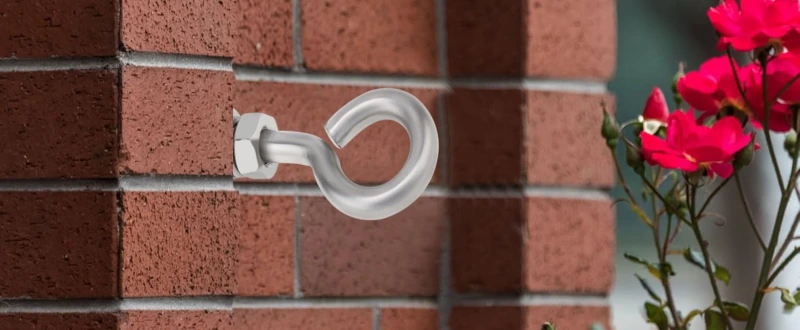

You want a secure and lasting result when you tackle eye bolt installation in brick wall projects. Many homeowners and professionals use eye bolts in brick for sandbags, hammocks, swing sets, fences, anti-theft doors and windows, canopies, air conditioning fixing, home decoration, and engineering.

To achieve reliable performance, you must follow critical safety warnings and prioritize safety measures during installation. Always start by wearing appropriate safety gear to protect yourself. This guide ensures you get professional outcomes by using certified products that meet the highest standards.

Key Takeaways

Always wear safety gear, including goggles and gloves, to protect yourself during installation.

Select high-quality eye bolts that meet safety standards for durability and reliability.

Drill clean holes in solid brick, avoiding mortar joints, to ensure strong anchor support.

Perform load tests after installation to verify the strength and safety of your eye bolt setup.

Regularly inspect and maintain eye bolts to prevent wear and ensure long-term performance.

Eye Bolt Installation in Brick Wall: Tools and Materials

Essential Tools and Safety Gear

Before you begin, you need to gather the right tools and materials for a safe and effective installation. This guide recommends using certified equipment and following industry standards to protect yourself and ensure a secure result.

The following table lists the most commonly recommended safety gear and tools for installing eye bolts in brick walls:

Safety Gear | Tools and Hardware |

|---|---|

Eye protection | Hammer drill |

Ear protection | Adjustable wrench or torque wrench |

Dust mask | Tape measure and marker |

Gloves | Wire brush and compressed air source |

Hard hat | Correct eye bolt anchor, nuts, and washers |

You should always wear eye protection and gloves when working with masonry. A dust mask helps prevent inhalation of brick particles. Use a hard hat if you work in areas with overhead hazards.

Select tools that match the job requirements. A hammer drill creates clean holes in brick, while a torque wrench ensures proper tightening.

Choosing Powerful Machinery Eye Bolts

Selecting high-quality materials is critical for safety and durability. Powerful Machinery offers stainless steel eye bolts designed for demanding applications. These products feature corrosion resistance and robust construction, making them suitable for both indoor and outdoor use.

You can choose from several grades, including AISI 304, AISI 316, and Duplex 2205. Each grade meets international standards such as ASTM, DIN, and ISO, ensuring reliable performance.

Grade | Description | International Standards |

|---|---|---|

AISI 304 | Corrosion-resistant | ASTM A193, EN 10088, JIS G4303 |

AISI 316 | Marine-grade, Mo-alloyed SS | ASTM A276, BS 970, DIN 17440 |

Duplex 2205 | High strength, chloride resistance | ASTM A479, EN 1.4462 |

Powerful Machinery eye bolts comply with safety standards like ASME B30.26 and OSHA 1910.184. You benefit from products that undergo rigorous testing and certification. Always check for manufacturer identification, working load limit, and material grade before installation.

Using certified materials reduces risk and increases the longevity of your installation.

Tip: Inspect all tools and materials before starting your project. Confirm that each eye bolt matches the load requirements and installation standards.

Installing Eye Bolts in Brick: Step-by-Step Guide

Planning and Marking the Wall

Start your eye bolt installation in brick wall projects by planning the exact location for each anchor point. Assess the weight and type of load you want to support. Use a tape measure to determine spacing and alignment. Mark each spot with a visible marker.

Always avoid mortar joints, as these areas do not provide the same strength as solid brick. Careful planning ensures your installation will remain secure and durable.

Tip: Double-check your measurements before you drill. Proper spacing and alignment help distribute weight evenly and prevent unnecessary stress on the masonry.

Drilling and Preparing Holes

Select a masonry drill bit that matches the diameter of your anchor. Attach the bit to a hammer drill for best results. Drill straight into the marked spots on the brick, not the mortar. Maintain a steady hand and keep the drill perpendicular to the wall. Drill to the recommended depth for your eye bolt.

After drilling, use a wire brush and compressed air to remove all dust and debris from the hole. Clean holes allow anchors to grip the masonry securely.

Material | Recommended Drill Bit | Anchor Type | Installation Best Practices |

|---|---|---|---|

Brick | Masonry | Heavy-duty | Avoid mortar joints, clean the hole |

Note: Drilling pilot holes helps prevent cracking and ensures a snug fit for the anchor. Clean holes are essential for a strong connection.

Securing the Eye Bolt

Insert the heavy-duty anchor into the cleaned hole. Apply thread sealant if needed for extra security. Take your Powerful Machinery stainless steel eye bolt and screw it into the anchor by hand. Use an adjustable wrench or torque wrench to tighten the eye bolt until it feels secure.

Do not overtighten, as this can damage the masonry or the anchor. The robust construction and corrosion resistance of Powerful Machinery eye bolts make them ideal for both indoor and outdoor installations.

Use only certified eye bolts that display the working load limit and material grade.

Confirm that the eye bolt sits flush against the brick surface.

Tighten gradually to avoid stressing the masonry.

Leveling and Testing

Place a level against the installed eye bolt to check for straightness. Adjust as needed before fully tightening. Once you finish installing eye bolts, perform a load test. Hang a test object that matches the intended weight. Observe the anchor and the brick for any movement or signs of stress.

Load pull testing verifies the strength and durability of your installation. Regular inspections and periodic load tests help maintain safety, especially in critical applications.

Safety Alert: Never skip the testing phase. Proper testing ensures your eye bolt installation in a brick wall meets safety standards and can handle the required load.

By following this guide, you ensure that each step of installing eye bolts in brick is completed with precision and care. Powerful Machinery products provide the reliability and certification you need for peace of mind in every masonry project.

Installation Tips and Troubleshooting

Expert Tips for Strong Installation

You can achieve a secure and durable result by following proven installation tips. Always inspect eye bolts for any damage before starting your project. Confirm that the working load limit matches the expected load to maintain a proper safety factor. Avoid making modifications to the eye bolt, as changes can reduce its strength.

Ensure the thread diameter and pitch are compatible with the receiving hole or nut. Keep threads clean and free of debris to prevent installation issues. Align the load with the plane of the eye, and use washers if needed for better load distribution.

These tips help you follow installation best practices and improve the safety factor for every project.

Inspect eye bolts for damage and suitability.

Confirm the working load limit for the expected load.

Avoid modifications to maintain strength.

Ensure thread compatibility.

Keep threads clean.

Align the load with the eye’s plane, using washers if necessary.

Tip: Always use certified wall anchors from Powerful Machinery to maximize safety and reliability.

Common Issues and Solutions

You may encounter several challenges during installation. The following table provides a quick guide to common problems and recommended solutions. Use these installation tips to troubleshoot and maintain a high safety factor.

Issue | Solution |

|---|---|

Anchor not expanding properly | Ensure the hole is clean and free of dust. Use a wire brush and compressed air to clean it. |

Anchor pulling out | Use a stronger anchor or multiple anchors to distribute the load. |

Anchor spinning in a hole | Use a larger anchor or fill the hole with epoxy before reinserting the anchor. |

Concrete cracking | Follow recommended edge distance guidelines for your anchor type. |

Difficulty drilling | Move the hole location slightly or use a rebar-cutting drill bit if necessary. |

Note: Regular inspection and maintenance of wall anchors help prevent failures and improve the safety factor.

Installing Eye Bolts in Concrete Walls

If you need to install eye bolts in concrete, you should follow a similar guide to that for brick. Select high-quality wall anchors designed for concrete applications. Use a hammer drill with a masonry bit to create a clean hole. Clean the hole thoroughly before inserting the anchor.

Powerful Machinery offers certified products that simplify installing eye bolts in concrete. Always check the working load limit and safety factor for each anchor. Secure the eye bolt using a torque wrench, and test the installation with a load that matches your requirements.

These installation best practices ensure reliable performance and long-term safety.

Tip: For heavy-duty applications, use multiple wall anchors to distribute the load and increase the safety factor.

Product Guide and Supplier Recommendations

Selecting the Right Eye Bolt

You need a clear guide when choosing the best eye bolt for your brick wall project. Start by defining the load, including total weight and any dynamic factors. Assess the substrate to confirm it is solid brick and measure the available depth for proper anchor selection.

Match the material to your environment, considering corrosion risk and aesthetics. Select the shank diameter and length based on the substrate and embedment requirements. Check the eye opening to ensure it fits your thickest rope or hook with extra clearance.

Confirm the safety factor by dividing the manufacturer’s static rating by four for general loads or five for overhead applications. Order extra eye bolts to account for breakage or future adjustments.

Define the load and dynamic factors.

Assess substrate and depth for anchor selection.

Match material to corrosion risk and appearance.

Select shank diameter and length for embedment.

Verify eye opening for rope or hook clearance.

Confirm the safety factor meets your calculated load.

Order extra for adjustments.

You will encounter several types of eye bolts, including shoulder, non-shoulder, and long shank designs. Each type suits different anchor selection needs and load requirements.

Why Choose Powerful Machinery?

Powerful Machinery offers a wide range of types of eye bolts with certified quality and robust construction. You benefit from products that meet international standards such as ISO9001, TUV Rheinland, and ASTM.

The company provides expert advice, technical support, and custom-engineered solutions for unique anchor selection challenges. You receive personal assistance for matching types of eye bolts to your specific project.

Powerful Machinery emphasizes safety and proper installation practices, ensuring you achieve reliable results.

Diameter | Straight Pull (lbs) | 45° Pull (Shoulder Only) (lbs) |

|---|---|---|

1/4″ | 500 | 125 |

5/16″ | 900 | 225 |

3/8″ | 1,300 | 325 |

1/2″ | 2,400 | 600 |

5/8″ | 4,000 | 1,000 |

3/4″ | 5,000 | 1,250 |

1″ | 9,000 | 2,250 |

1-1/4″ | 15,000 | 3,750 |

2″ | 38,000 | 9,500 |

You gain corrosion resistance, durability, and swivel action for safe and efficient anchor selection in brick wall installations.

Feature | Benefit |

|---|---|

Corrosion Resistance | SS316 material resists rust and pitting for long life in harsh environments. |

Durability | Maintains integrity under challenging conditions. |

Swivel and Pivot | Handles full rated load from any direction, improving safety. |

Where to Buy

You can purchase Powerful Machinery types of eye bolts from reputable suppliers. Bay Supply is a trusted online source for anchor selection and lifting hardware. Yojiu offers industrial-grade options for various applications. For direct product recommendations and technical support, visit Powerful Machinery’s official website:

Tip: Always consult with Powerful Machinery’s support team for anchor selection and installation recommendations tailored to your project.

Conclusion

You achieve secure eye bolt installation in brick walls by following each step in this guide and prioritizing safety. Remember these essential measures:

Wear safety goggles, ear protection, and a dust mask.

Clean holes thoroughly with compressed air or a wire brush.

Inspect and maintain eye bolts regularly to prevent wear and corrosion.

Advantage | Description |

|---|---|

Safety | Certified products ensure higher safety standards in lifting operations. |

Reliability | Rigorous testing guarantees dependable performance under load. |

Compliance | International standards confirm quality and safety. |

Long-term Durability | Engineered for harsh environments and lasting performance. |

Schedule inspections based on risk: every 6 months for high-risk, yearly for medium-risk, and every 2 years for low-risk structures. Visit Powerful Machinery’s website for expert support and product details.

FAQ

How do you choose the right anchors for brick walls?

You should select anchors based on the load, brick type, and environment. Stainless steel anchors resist corrosion and provide strength. Always match the anchor size to your eye bolt. This guide helps you pick anchors that meet safety standards and ensure a secure installation.

Can you reuse anchors after removing an eye bolt?

You should avoid reusing anchors. Once you remove anchors from the brick, their holding power decreases. For maximum safety, install new anchors each time you reposition or replace an eye bolt. This practice prevents failures and keeps your installation reliable.

What is the best way to clean holes before inserting anchors?

Use a wire brush and compressed air to remove dust and debris from drilled holes. Clean holes allow anchors to grip the brick securely. You should never skip this step, as it ensures anchors perform at their rated capacity and maintain long-term strength.

How many anchors do you need for heavy loads?

For heavy loads, use multiple anchors to distribute weight evenly. Check the load rating for each anchor and never exceed the manufacturer’s recommendations. This guide suggests using extra anchors for critical applications to increase safety and prevent brick damage.

Do anchors work differently in concrete compared to brick?

Yes, anchors behave differently in concrete and brick. Concrete provides a denser substrate, so anchors may hold more weight. In brick, you must avoid mortar joints and use anchors designed for hollow or solid brick. Always follow the guide for anchor selection in each material.