Ready to learn how to loosen a ratchet chain binder without stress? You just need the right tools and a little know-how. Safety comes first, so grab certified products from Powerful Machinery for peace of mind. Whether you’re new or you’ve handled cargo for years, this process stays simple.

Follow the steps, use a quality chain binder, and avoid the common mistakes that can lead to trouble.

Key Takeaways

Always prepare before loosening a ratchet chain binder. Gather certified tools like a ratchet binder, a matching chain, gloves, and safety glasses.

Inspect your equipment and work area for damage. Look for cracks, rust, or bent parts to ensure safe operation.

Release tension by turning the ratchet handle counterclockwise. Use lubricant if the handle feels stuck, and maintain a safe body position.

Detach hooks carefully after releasing tension. Ensure all load binders are loose before moving chains to prevent accidents.

Store your load binder properly in a dry place. Good storage prevents rust and extends the life of your equipment.

How to Loosen a Ratchet Chain Binder: Preparation

Before you start learning how to loosen a ratchet chain binder, you need to get ready. Good preparation keeps you safe and makes the job easier. Let’s break down what you need to do before you even touch the ratchet binder.

Gather Tools for Load Binder

First, grab all the tools you’ll need. You want to use a certified chain binder and load binder from Powerful Machinery. These products meet or exceed major international safety standards, so you know you’re working with reliable gear. Here’s a quick checklist:

Ratchet binder or load binder

Matching chain (check the size and grade)

Work gloves for hand protection

Safety glasses

Lubricant (for stuck or rusty parts)

A sturdy pipe for extra leverage if needed

Tip: Always use certified load binders and chains. Powerful Machinery’s products are tested for tough jobs and demanding environments.

Inspect Chain Binder and Area

Next, take a close look at your equipment and the area around you. You want to spot any problems before they cause trouble. Here’s a table to help you know what to look for:

Damage Type | Description | Required Action |

|---|---|---|

Stretched or Bent Links | Links that have been elongated or bent due to excessive load | Replace the chain immediately |

Cracks and Gouges | Cracks or gouges in the chain material, especially at stress points | Replace the chain immediately |

Hook and Connector Damage | Deformation, throat opening expansion, or latch malfunction | Replace the damaged hook or connector |

If you see rust, dirt, or stuck parts, spray a little lubricant to keep things moving smoothly.

Safety Checks Before Operating

Now, run through a few safety checks before you start loosening anything. Make sure your securing devices are tight, but not overtightened. Always use a ratchet-style load binder for the best control. Here’s a quick list to follow:

Check that all chains and hooks are secure.

Confirm that the ratchet binder handle moves freely.

Wear your gloves and safety glasses.

Clear the area of bystanders or obstacles.

Getting ready the right way makes learning how to loosen a ratchet chain binder much safer and faster. Take a few minutes to prepare, and you’ll avoid most common problems with load binders.

Release Tension on Chain Binder

Loosening a ratchet chain binder doesn’t have to be complicated. You just need to follow a clear process and keep safety in mind. Let’s walk through how to loosen a ratchet chain binder step by step, using Powerful Machinery ratchet load binders for reliable results.

Position for Safe Operation

Before you touch the ratchet binder, make sure you’re standing in a safe spot. Your body position matters a lot. You want to avoid injury if something slips or the handle moves unexpectedly. Here’s what you should do:

Stand with a solid footing or kneel beside the load.

Keep your face and body out of the handle’s path.

Set up clear “danger zones” around the area where you’ll be working.

Make sure no one else is close to the tension hook or chain binder.

Tip: Always check your surroundings before you start. A safe position helps you react quickly if the load shifts.

Twist the Ratchet Handle to Release

Now you’re ready to release the tension. Grab the ratchet binder handle and start turning it counterclockwise. This action will slowly loosen the chain and reduce the pressure on the load binder. Here’s a step-by-step guide:

Hold the handle firmly and pump it back and forth. You’ll feel the tension start to ease.

Take your time. Don’t rush the process. Check the chain and binder after each adjustment.

If the ratchet load binders feel stuck, spray a little lubricant. Zep45, white lithium grease, or fluid film works well. These keep the mechanism moving smoothly, even in tough conditions.

For extra leverage, slide a sturdy pipe over the handle. This gives you more control and makes it easier to loosen a tight load binder.

Watch the tension hook as you work. Make sure it doesn’t snap or slip off the chain.

Note: Avoid over-tightening or forcing the handle. Gentle, steady movements protect your equipment and cargo.

Detach Hooks from Chain

Once you’ve released most of the tension, you can remove the hooks from the chain. This step is simple but still requires care:

Unhook the tension hook from the chain.

Lift the chain binder away from the cargo.

Double-check that all load binders are loose before moving the chains.

If you’re working with multiple binders, distribute them evenly across the cargo. This keeps everything balanced and prevents sudden shifts.

Safety Reminder: Always keep your hands clear of pinch points when detaching hooks. Gloves help protect your fingers from sharp edges.

Learning how to loosen a ratchet chain binder gets easier with practice. Powerful Machinery’s load binders and chain binder products are designed for smooth operation, so you can trust them to perform every time.

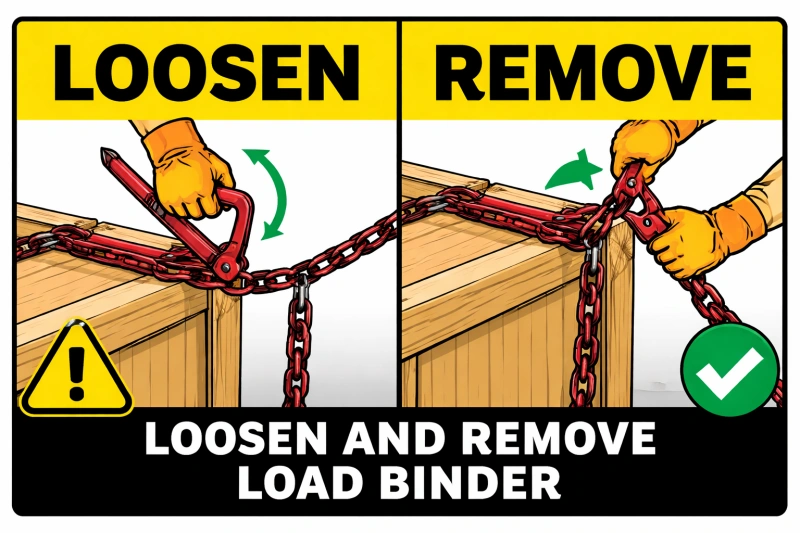

Loosen and Remove Load Binder

Turn the Handle Counterclockwise

You’re almost done. To finish loosening the chain binder, grab the ratchet binder handle and turn it counterclockwise. This step releases any remaining tension. You’ll notice the tension hook moving freely as the pressure drops. If you feel resistance, check for rust or dirt.

A quick spray of lubricant can help. Powerful Machinery ratchet load binders make this step smooth, so you don’t have to struggle. Always keep your hands clear of pinch points and move slowly to avoid sudden releases.

Remove Binder from Chain

Once the tension is gone, you can remove the load binder from the chain. Lift the binder off carefully. Make sure the chain isn’t tangled or caught on anything. If you’re working with multiple load binders, take them off one at a time. This keeps your cargo balanced and prevents shifting. Watch out for these common mistakes:

Applying too much or too little tension before removal

Skipping inspections for cracks or deformation

Using incompatible rigging equipment

Failing to secure the handle, which can cause a sudden release

Reusing damaged load binders

Using the wrong type of chain for your binder

You can avoid these problems by checking your gear before each use and sticking with certified products.

Store Load Binder Safely

Proper storage keeps your load binders working like new. After you remove the binder, store it in a dry, cool place. Moisture causes rust and weakens metal. Use racks or hangers to keep everything organized and easy to grab. Dedicated storage solutions, like hooks or trays, prevent tangling and damage.

Organize your binder chains between uses to reduce wear and tear. Regular maintenance and inspections help you catch issues early and extend the life of your equipment.

Tip: A little care goes a long way. Powerful Machinery load binders are built for durability, but good storage and maintenance make them last even longer.

Operating a Ratchet Load Binder: Safety Tips

When you’re operating a ratchet load binder, safety should always come first. Powerful Machinery puts safety at the heart of every product, so you can trust your equipment on the job. Here’s how you can protect yourself and keep your gear in top shape.

Wear Protective Gear

You want to protect your hands and eyes every time you use load binders. Gloves help you grip the handle and shield your skin from cuts or scrapes. Safety glasses keep your eyes safe from flying debris or sudden movements. Many hand injuries happen because people skip this step. Here are some common injuries you can avoid:

Sprains and strains from using too much force

Bruising or soreness from slipping handles

Cuts or fractures from sharp edges or snapping chains

Always choose gloves that fit well and don’t slip. Make sure your safety glasses are clean and comfortable.

Keep Hands Clear

Keep your hands and fingers away from pinch points and moving parts. When you release tension, the handle or chain can snap back quickly. This is especially true if you use a cheater bar for extra leverage. Ratchet binders need less force than lever binders, but you still need to stay alert. Here’s what you should do:

Stand to the side of the handle, not in front of it

Hold the handle firmly, but never wrap your fingers around moving parts

Watch for sudden releases or shifting chains

If you stay focused and keep your hands clear, you’ll lower your risk of injury.

Inspect Equipment Regularly

Regular inspections keep your tools safe and reliable. Check your ratchet load binder for cracks, rust, or bent parts before each use. For equipment you use every day, plan a full inspection at least once a year. If you work in tough conditions, check your gear every month or quarter.

For special jobs, ask a qualified person to set a custom inspection schedule. Here’s a quick guide:

Yearly inspection for everyday use

Monthly or quarterly checks for heavy-duty work

Custom schedule for special projects

If you find any damage, replace the part right away. Powerful Machinery’s certified products make it easy to spot problems and keep your equipment in top condition.

Tip: Safe habits and regular checks help you avoid accidents and keep your work running smoothly.

Powerful Machinery Chain Binder Troubleshooting

Even with the best equipment, you might run into a few hiccups. Don’t worry—Powerful Machinery chain binders are built tough, but a little troubleshooting can keep you moving. Let’s look at some common problems and how you can fix them fast.

Binder Stuck or Jammed

You might notice your ratchet chain binder feels stuck or won’t budge. This happens more often if you work in wet or dirty environments. Here’s what usually causes the problem:

Rust or corrosion from moisture

Dirt or debris is blocking the moving parts

Overloading the binder past its rated limit

To get things working again, try these steps:

Spray a lubricant like WD-40 on the moving parts. This helps loosen rust and stuck components.

Use needle-nose pliers to gently move small parts if they’re jammed.

Wipe away dirt and extra lubricant with a dry cloth.

Tip: Regular cleaning and a quick spray of lubricant after each use can prevent most jams.

Handle Won’t Move

Sometimes, the handle just won’t turn. First, check if you’ve released all the tension from the chain. If the handle still feels stuck, look for signs of rust or bent parts. You can apply a little more lubricant and gently tap the handle to free it up. Never force the handle—this can damage your binder.

If you see any cracks or serious wear, swap out the binder for a new one from Powerful Machinery. Safety always comes first.

Chain Tension Issues

If your chain feels too loose or too tight, you need to adjust the binder. Make sure you’re using the right size chain and binder for your load. Double-check the working load limit marked on your equipment. If the chain keeps slipping, inspect the hooks and links for wear.

Replace any damaged parts right away. For extra help, reach out to Powerful Machinery’s support team—they’re ready to guide you through any challenge.

Remember: Quick checks and simple fixes keep your gear reliable and your cargo secure.

Conclusion

You just learned how to loosen a ratchet chain binder in three simple steps. Using certified products like Powerful Machinery’s load binder gives you access to best-practice cargo safety, reliable tension, and legal peace of mind.

Remember to check your gear, secure loads properly, and follow safety tips for smooth operation. For more support, training, and product info, visit Powerful Machinery’s website:

Resource Type | Link |

|---|---|

Product Catalogs | |

Customer Support | Customer Support |

Stay safe and keep your cargo secure every time!

FAQ

How often should you inspect your ratchet chain binder?

You should check your ratchet chain binder before every use. Look for cracks, rust, or bent parts. Regular inspections keep your equipment safe and reliable.

Can you use a ratchet chain binder in wet conditions?

Yes, you can use a ratchet chain binder in wet conditions. Powerful Machinery binders have corrosion-resistant coatings. Dry your binder after use to prevent rust.

What size chain works best with Powerful Machinery load binders?

Choose a chain that matches the binder’s working load limit. Check the product label for compatible chain sizes. Using the right size ensures safe cargo securement.

What should you do if the ratchet handle gets stuck?

Spray lubricant on the moving parts. Gently tap the handle to loosen it. Never force the handle. If it stays stuck, replace the binder for safety.