When you need a reliable alloy steel chain manufacturer, Powerful Machinery stands out worldwide. You benefit from a company that uses high-grade alloy steel and meets strict certifications like ISO9001 and ASTM. Industry leaders trust Powerful Machinery for quality, safety, and innovation in lifting solutions.

The G80 Alloy Chain and diverse Chains range meet international standards, ensuring you get dependable performance. Advancements in technology and a focus on durability help Powerful Machinery earn global recognition in the construction, marine, and transportation sectors.

Key Takeaways

Choose a manufacturer with strong certifications like ISO9001 and ASTM. This ensures quality and safety in your alloy steel chains.

Powerful Machinery serves various industries, including construction and marine. Their chains are trusted for durability and performance.

The G80 Alloy Chain offers high strength and safety, making it ideal for lifting and hoisting tasks in demanding environments.

Look for responsive customer support and clear warranty terms. This helps you resolve issues quickly and protects your investment.

Always check for product traceability and quality testing. This guarantees you receive reliable chains that meet industry standards.

Why Choose Powerful Machinery as Your Alloy Steel Chain Manufacturer?

Global Certifications and Industry Standards

When you select an alloy steel chain manufacturer, you want proof of quality and safety. Powerful Machinery gives you that confidence. The company holds certifications like ISO9001, ISO14001, TUV Rheinland, and ASTM. These certifications show that every product meets strict international standards.

You can trust that each chain passes rigorous tests for strength and durability.

Powerful Machinery also follows NACM, OSHA, and EURO CERT guidelines. This means you receive chains that work safely in demanding environments. The company uses advanced technology and skilled workers to produce chains that meet or exceed industry requirements.

You get peace of mind knowing your equipment is reliable and compliant.

Tip: Always check for certifications when choosing an alloy steel chain manufacturer. Certified products help you avoid safety risks and costly downtime.

Trusted by Leading Industries

You need a partner who understands your industry. Powerful Machinery serves construction, marine, transportation, and cargo handling companies around the world. These industries rely on strong, dependable chains for daily operations.

When you choose Powerful Machinery, you join a group of professionals who value safety and performance.

Customers like Ben Carter from Canada and David Müller from Germany have shared positive feedback. Ben praised the chains for their durability in harsh weather.

David highlighted the reliability during heavy lifting projects. Liam O’Connell from Australia trusts Powerful Machinery for consistent quality and full certifications.

Industries Served:

Construction

Marine and Offshore

Transportation and Logistics

Cargo Handling

You can see why so many professionals choose Powerful Machinery as their alloy steel chain manufacturer. The company’s reputation for quality and service makes it a top choice worldwide.

Product Range: G80 Alloy Chain and More

G80 Alloy Chain Features and Benefits

When you look for a chain that handles tough jobs, the G80 Alloy Chain stands out. Powerful Machinery designs this chain with high-quality alloy steel. It goes through special heat treatment to boost strength and durability. You can use it for lifting, hoisting, and rigging in many industries.

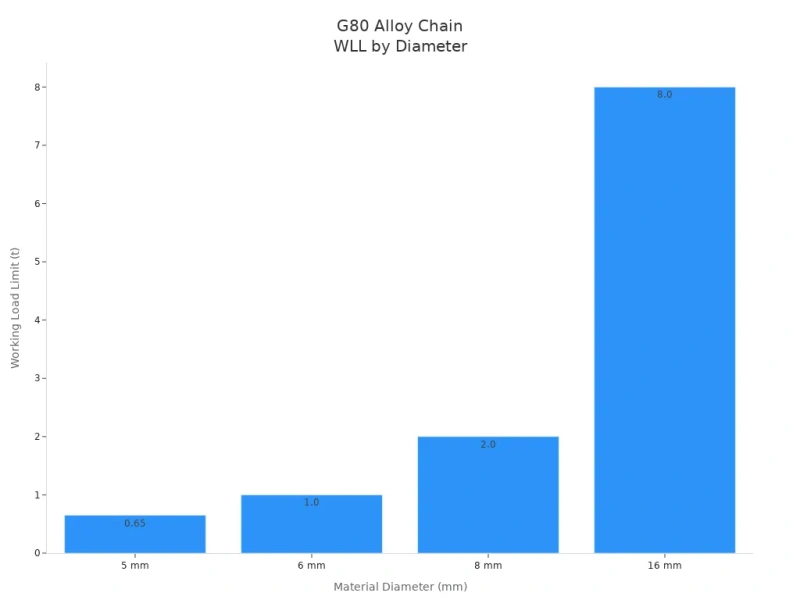

The G80 Alloy Chain meets strict NACM and ASTM standards. Each chain is stamped for easy identification and traceability. The working load limit is high, and the breaking load is four times the rated working load. This means you get extra safety during every lift.

Here is a quick look at some key specifications:

Item No. | Material Dia (mm) | Inside Length (mm) | Outside Width (mm) | WLL (t) | Min Breaking Load (t) | Weight (kg/m) |

|---|---|---|---|---|---|---|

AW-80-05 | 5 | 15.00 | 16.25 | 0.65 | 2.60 | 0.50 |

AW-80-06 | 6 | 18.00 | 19.50 | 1.00 | 4.00 | 0.80 |

AW-80-08 | 8 | 24.00 | 26.00 | 2.00 | 8.00 | 1.40 |

AW-80-16 | 16 | 48.00 | 52.00 | 8.00 | 32.00 | 5.60 |

You can see how the working load limit increases with the diameter. The chart below shows this relationship:

Note: The G80 Alloy Chain is approved for overhead lifting and performs well in extreme temperatures. Its surface treatments help resist corrosion and wear.

Versatile Chains for Diverse Applications

Powerful Machinery offers more than just the G80 Alloy Chain. The Chains product category includes many types and grades, such as G43, G70, G80, and G100. You can choose from different materials like alloy steel and stainless steel. Each chain meets international standards, including NACM2010, DIN, and Australian standards.

You can use these chains in many industries:

Industrial lifting and hoisting: Cranes, hoists, and slings

Transportation and logistics: Securing cargo for safe transport

Agriculture and forestry: Pulling trees and connecting machinery

Security and protection: Creating barriers and locks

If you need a custom solution, Powerful Machinery can help. You can select the size, grade, and finish that fit your project. This flexibility makes Powerful Machinery a top alloy steel chain manufacturer for many professionals.

Manufacturing Excellence and Safety Commitment

Advanced Production Processes

You want your alloy steel chains to perform at the highest level. Powerful Machinery uses advanced manufacturing technology to make sure every chain meets strict standards. The production process starts with heat treatment, where steel is heated to temperatures between 1,200°C and 1,300°C.

This step makes the steel malleable and ready for shaping. Induction hardening and tempering follow, which boost the chain’s hardness, strength, and toughness.

The company shapes steel bars into links using hot rolling or forging. Workers then use precise cutting, machining, punching, and bending to form each link. At every stage, quality inspections take place. These include both mechanical and non-destructive tests to catch any flaws early.

Heat treatment at high temperatures for malleability

Induction hardening and tempering for strength

Hot rolling or forging to create chain links

Precise cutting, machining, and bending

Rigorous quality inspections with mechanical and non-destructive tests

A skilled workforce plays a key role in this process. Well-trained workers know how to spot and fix problems quickly. Their knowledge of quality control systems helps reduce defects and warranty claims. Stable staffing means you get consistent quality with every order.

Quality becomes everyone’s responsibility, which builds trust with you as a customer.

Rigorous Safety and Compliance Testing

You need chains that meet the highest safety standards. Powerful Machinery follows strict regulations and testing procedures to keep you safe. The company complies with rules from organizations like OSHA and ASME. The table below shows some of the main standards:

Regulation | Description |

|---|---|

OSHA 1910.5 (c) (1) | Specific standards take precedence over general standards. |

ASME B30.9-1.10.1 (c) | Never exceed the rated load of the sling. |

OSHA 1910.184 (e) (1) | Identification tags are required for all alloy steel chain slings. |

OSHA 1910.184 (e) (2) (i) | Attachments must match the chain’s rated capacity. |

OSHA 1910.184 (e) (2) (ii) | Makeshift links or fasteners are not allowed. |

You can expect every chain to go through careful inspections before use. Workers inspect chain slings before each use and document annual checks by a qualified person. Written records of all inspections and repairs are kept. Proof testing certificates stay on file for each sling.

Identification tags remain attached and easy to read at all times.

Note: These steps ensure you receive alloy steel chains that are safe, reliable, and ready for demanding jobs.

Customer Support and After-Sales Service

Responsive Support Systems

You deserve support that responds quickly and solves problems efficiently. Powerful Machinery gives you access to multiple customer support channels. You can reach out for help whenever you need it. The company works with Elite Sales to provide expert assistance for industrial chain inquiries.

You can contact an Elite Sales representative to get answers about products, orders, or technical issues.

You can call the support team for urgent questions.

You can use live chat for instant help.

You can email for detailed requests.

You can connect with virtual assistants for quick solutions.

Powerful Machinery uses several strategies to make sure you get fast and reliable support. The table below shows how the company handles customer inquiries and technical support:

Strategy | Description |

|---|---|

Proactive Maintenance | Predictive analytics monitors machinery health and reduces downtime. |

24/7 Availability | Support is available all day and night through phone, chat, and virtual assistants. |

Operator Training | Training programs teach you basic troubleshooting and maintenance skills. |

Spare Parts and Logistics Support | Efficient inventory and logistics systems provide quick access to spare parts and minimize delays. |

You get peace of mind knowing help is always available. The support team works hard to resolve issues and keep your operations running smoothly.

Warranty and Service Guarantees

You want confidence in your purchase. Powerful Machinery offers strong warranty coverage on alloy steel chains and lifting products. If you face any issues, the company will repair or replace defective items within the warranty period. You receive clear service guarantees that protect your investment.

Fast delivery ensures you get products when you need them. Flexible payment options make ordering easy. The price match guarantee means you always get competitive rates. Powerful Machinery stands behind every product, making sure you feel secure and satisfied with your purchase.

Tip: Always ask about warranty terms and service guarantees before you buy. Reliable support and clear policies help you avoid unexpected costs and delays.

How to Select the Right Alloy Steel Chain Manufacturer?

Buyer’s Checklist

Choosing the right alloy steel chain manufacturer can make a big difference in your project’s success. You want to work with a supplier who meets your needs and delivers quality every time. Use this checklist to guide your decision:

Criteria | Description |

|---|---|

Product Range and Availability | Look for a supplier with a wide selection of alloy steel grades and chain types. |

Quality Standards and Certifications | Make sure the manufacturer holds certifications like ISO 9001 and provides traceability. |

Technical Expertise and Support | Choose a company with knowledgeable staff who can answer your questions and offer guidance. |

Logistics, Lead Times, and Reliability | Check if the supplier can deliver on time and communicate clearly about your order. |

Tip: Always ask for Mill Test Reports (MTRs) and proof of certifications. Powerful Machinery provides these documents, giving you confidence in every purchase.

Evaluating Reliability and Value

You need to know that your alloy steel chain manufacturer stands behind their products. Reliable suppliers follow strict quality systems and test every chain for strength and safety. Use these metrics to compare manufacturers:

Metric/Indicator | Description |

|---|---|

Documented Quality Systems | Shows the company follows set quality protocols. |

Comprehensive Testing Protocols | Confirms chains meet strength requirements. |

Industry Certifications | Proves compliance with global standards. |

Material Grade | Reflects the quality of steel used. |

Manufacturing Quality | Indicates strong production processes. |

Heat Treatment | Ensures chains have the right strength and durability. |

Link Geometry | Checks for proper design and safety. |

Safety Factors | Verifies chains can handle rated loads. |

Inspection Protocols | Details how products are checked before delivery. |

Traceability Documentation | Allows you to track materials and processes. |

Benchmarking helps you compare one alloy steel chain manufacturer to another. You can look at industry standards and see how each company performs. Powerful Machinery stands out by offering certified products, advanced testing, and reliable delivery.

Their focus on quality and customer support means you get long-term value and peace of mind.

When you choose a trusted alloy steel chain manufacturer, you invest in safety, reliability, and lasting performance.

Conclusion

You want a partner who delivers certified quality, reliable products, and expert support. Powerful Machinery stands out as a trusted alloy steel chain manufacturer because you get all three. See how key standards shape their reputation:

Standard | Description | Importance |

|---|---|---|

ISO 2414 | Handles high stress and load-bearing needs | Ensures safety and strength |

DIN 3054 | Guarantees corrosion resistance and durability | Supports long-term use |

You benefit from a full range of hardware, technical guidance, and tailored solutions. Procurement professionals and industry leaders—get a free quote today and experience unmatched value.

FAQ

What certifications do Powerful Machinery chains have?

You receive chains certified to ISO9001, ISO14001, TUV Rheinland, and ASTM standards. These certifications ensure you get products that meet strict international safety and quality requirements.

Tip: Always check for certification marks on your chains for peace of mind.

Can you customize alloy steel chains for special projects?

Yes, you can request custom sizes, grades, and finishes. Powerful Machinery works with you to design chains that fit your unique application.

Choose your preferred material, link size, and coating.

Get expert advice for your project needs.

How fast can you expect delivery?

You benefit from fast delivery times. Powerful Machinery maintains efficient logistics and inventory systems. Most standard orders ship quickly.

Order Type | Estimated Delivery Time |

|---|---|

Standard Chains | 7–15 days |

Custom Orders | 15–30 days |

How do you maintain alloy steel chains for long life?

You should inspect chains before each use. Clean them regularly and store them in a dry place. Lubricate moving parts to prevent rust.

Note: Replace chains that show signs of wear or damage to ensure safety.