Mechanical advantage plays a crucial role in every rigging system. You use it to lift heavier loads with less effort, which is essential in construction, marine, and industrial sectors. When you rely on block and tackle setups, you transform complex hauling systems into manageable tasks.

Statistics show that in 2023, over 2.6 million nonfatal workplace injuries and illnesses occurred in the U.S. Many injuries in these industries result from overexertion and poor lifting practices. Block and tackle systems, which offer mechanical advantage with pulleys, help reduce these risks and boost efficiency.

Feature | Description |

|---|---|

Mechanical Advantage | Reduces the force needed to lift heavy loads by distributing weight over multiple pulleys. |

Safety Improvement | Minimizes the risk of workplace injuries related to manual lifting. |

Operational Efficiency | Speeds up the process of moving heavy loads, reducing downtime, and increasing productivity. |

By choosing the right hauling systems, you improve both safety and productivity on the job.

Key Takeaways

Mechanical advantage allows you to lift heavy loads with less effort. Use pulleys to distribute weight and reduce the force needed.

Block and tackle systems improve workplace safety by minimizing the risk of injuries related to manual lifting. Always prioritize safety in lifting operations.

Count the number of rope segments in your pulley system to determine the mechanical advantage. More segments mean less force required to lift the load.

Choose high-quality pulleys to reduce friction and enhance efficiency. Quality equipment leads to safer and more effective lifting.

Regularly inspect your pulley systems for wear and damage. Maintenance ensures optimal performance and safety in lifting tasks.

Mechanical Advantage with Pulleys

What Is Mechanical Advantage?

You encounter mechanical advantage every time you use a tool to lift or move a heavy object. In lifting and rigging, mechanical advantage means you can move a load with less force than you would need using only your strength. This principle is vital for safety and efficiency in construction, marine, and industrial settings.

Mechanical advantage is the ratio of the force produced by a machine to the force applied to it. You can see how different organizations define it in the table below:

Source | Definition |

|---|---|

NFPA | A force created through mechanical means, including, but not limited to, a system of levers, gearing, or ropes and pulleys, usually creating an output force greater than the input force and expressed in terms of a ratio of output force to input force. |

Merriam Webster | The advantage gained by the use of a mechanism in transmitting force, specifically, the ratio of the force that performs the useful work of a machine to the force that is applied to the machine. |

You calculate mechanical advantage using a simple formula:

Source | Formula |

|---|---|

Legacy Grip | Mechanical Advantage = Load / Effort |

When you use a mechanical advantage system, you reduce the effort needed to lift a load. This concept is essential for professionals who want to work safely and efficiently.

Mechanical advantage with pulleys is critical in many real-world scenarios. You rely on these systems in:

Rescue operations, where you need to haul victims or equipment up steep inclines.

Industrial applications, such as cranes and hoists that lift heavy objects.

Construction, where tower cranes use pulley systems to move materials.

Conveyor systems, which transport heavy loads with less force.

Earthmoving equipment, including excavators and bulldozers.

Assembly line processes, where robots use mechanical advantage mechanisms for precise tasks.

How Pulleys Multiply Force?

You gain mechanical advantage by using pulleys to redirect and multiply force. A pulley is a simple machine that changes the direction of force and allows you to lift heavier weights than you could with your muscle strength alone.

When you set up a set of ropes and pulleys, you create a mechanical advantage system that makes lifting easier.

Pulleys work by distributing the load across multiple rope segments. The more segments you have supporting the load, the less force you need to apply. For example, if you use two wheels in your pulley system, you only need half the force to lift the same weight.

If you have a 100kg load supported by two rope segments, you only need to apply 500N of force to lift it.

Tip: Always count the number of rope segments supporting the load to determine your ideal mechanical advantage.

You can see how pulleys multiply force in these steps:

You set up a mechanical advantage system with pulleys.

You count the rope segments supporting the load.

You divide the total load by the number of segments to find the effort required.

Powerful Machinery’s Steel Rope Pulley and Pulley & Blocks are designed to help you maximize mechanical advantage with pulleys. The Steel Rope Pulley features a durable steel plate and cast sheave, making it ideal for light lifting operations.

The Pulley & Blocks product line offers single and double-sheave blocks, snatch blocks, and marine cargo blocks, all built for heavy-duty use. These products allow you to create efficient mechanical advantage systems for any lifting task.

Key Principles and Trade-Offs

You must understand the basic physics behind mechanical advantage pulley systems to use them effectively. The main principle is that you trade force for distance. When you use a mechanical advantage system, you apply less force, but you must pull more rope to lift the load the same height.

If you double the number of pulleys, you halve the force needed, but you must pull twice as much rope.

The mechanical advantage increases as you add more pulleys, but friction also increases, which can reduce efficiency.

Component | Effect on Efficiency |

|---|---|

Base System Pulleys | Quality affects mechanical advantage |

Brake and Multiplier Pulley | Inefficiencies can arise from poor quality |

Additional Pulleys | Can increase mechanical advantage but may introduce friction losses |

You should choose high-quality pulleys to minimize friction and maximize efficiency. Powerful Machinery’s Steel Rope Pulley and Pulley & Blocks use robust materials and precision engineering to ensure smooth operation and reliable performance.

These products help you achieve the best possible mechanical advantage with pulleys while maintaining safety and durability.

When you design a mechanical advantage system, always consider the trade-off between force and distance. You gain mechanical advantage, but you must account for friction and efficiency. By selecting the right equipment and understanding these principles, you improve safety and productivity in your lifting operations.

Block and Tackle Systems

Types of Pulley Setups

You encounter several pulley setups in lifting operations. Each type offers unique benefits for mechanical advantage. The main categories include simple pulley systems, compound pulley systems, and complex pulley systems. The table below highlights their differences:

Pulley Type | Mechanical Advantage | Description |

|---|---|---|

Simple Pulley | 3:1 | All moving pulleys move in the same direction and speed as the load. A 100-pound pull raises a 300-pound load. |

Compound Pulley | 6:1 (3:1 + 2:1) | Combines simple systems to multiply the mechanical advantage. A 3:1 pulling on another 3:1 gives 9:1. |

Complex Pulley | 5:1 | More efficient than a simple system, requiring less rope to be pulled for the same load lift. |

Simple pulley systems work well for basic lifting tasks. Compound pulley systems combine multiple setups to increase lifting power. Complex pulley systems offer efficiency when you need to minimize rope movement.

You find these systems in many industries. For example, block and tackle setups are common in construction for lifting heavy materials. Compound pulley systems appear in cranes and ship rigging, while simple pulley systems are often used in basic hoists.

How a Block and Tackle Works?

A block and tackle system uses multiple pulleys to reduce the force you need to lift a load. You thread the rope through a series of pulleys, which distribute the weight and multiply your input force. Here is how the system functions:

The block and tackle system provides a 4:1 mechanical advantage, so you only need one-fourth the force to lift a load.

You use this setup in scenarios like lifting patients, extracting rescuers, or performing repeated work-at-height tasks.

The arrangement allows you to exert less force while still achieving the necessary lifting power.

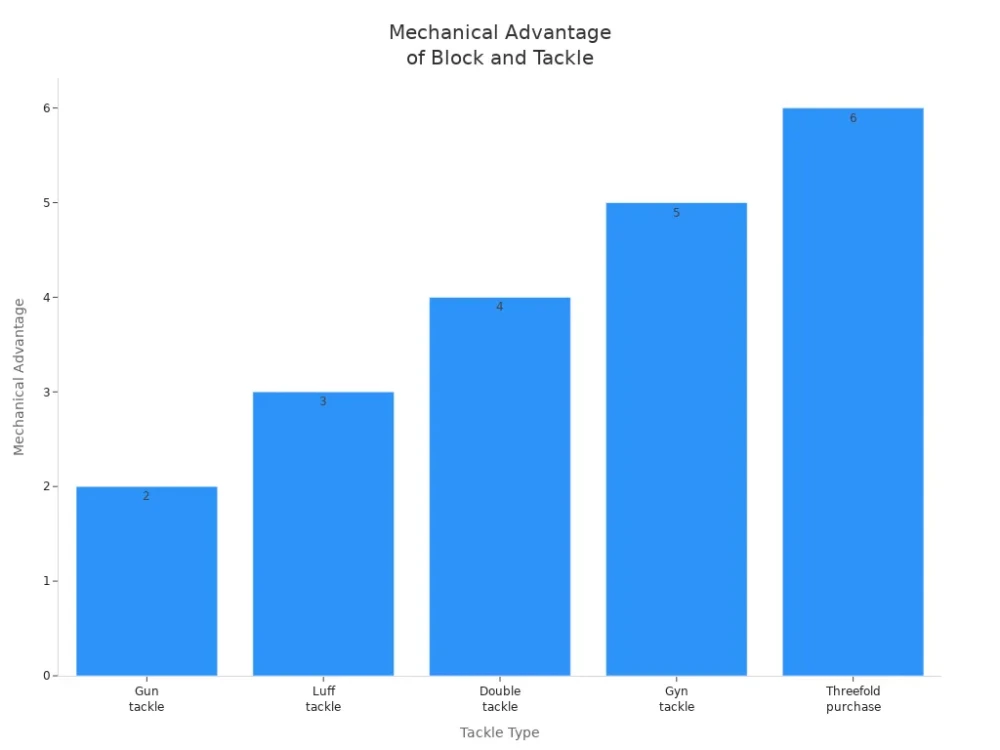

You can see the typical mechanical advantages for standard block and tackle configurations in the table below:

Tackle Type | Mechanical Advantage |

|---|---|

Gun tackle | 2 |

Luff tackle | 3 |

Double tackle | 4 |

Gyn tackle | 5 |

Threefold purchase | 6 |

You achieve greater lifting efficiency by selecting the right configuration for your application.

Powerful Machinery Product Features

When you choose Powerful Machinery’s Pulley & Blocks, you gain access to equipment designed for durability and performance. These products use stamped steel for enhanced strength and a powder-coated finish for corrosion resistance.

You benefit from ISO9001 and CE certifications, which ensure quality and safety. These blocks guide wire ropes and cables smoothly, making them ideal for lifting and rigging tasks in demanding environments.

Feature | Description |

|---|---|

Material | Stamped steel for enhanced durability |

Finish | Powder-coated for corrosion resistance |

Certifications | ISO9001 and CE certified for quality and safety |

Applications | Ideal for guiding wire ropes and cables in lifting and rigging tasks |

You can rely on Powerful Machinery’s Pulley & Blocks for robust construction and versatile use across construction, marine, and industrial projects. These features help you achieve safe, efficient, and reliable lifting operations every time.

Calculating Mechanical Advantage

Counting Rope Legs

You can calculate the mechanical advantage in a block and tackle system by counting the rope legs that support the load. This method gives you a quick and reliable way to determine how much force you need to lift an object. Follow these steps:

Identify the weight of the object you want to lift.

Determine the force required to raise the object.

Divide the weight of the object by the force you apply to find the mechanical advantage.

Measure the length of the rope you pull and the distance the object moves.

Divide the rope length by the distance the object rises to confirm the mechanical advantage.

Count the number of rope legs between the pulleys. This number equals the mechanical advantage.

Tip: If you see four rope legs supporting the load, you have a mechanical advantage of 4. You only need one-fourth the force to lift the object.

For example, you use Powerful Machinery’s Steel Rope Pulley to lift a 600 kg load. If your block and tackle system has three rope legs supporting the load, you only need to apply 200 kg of force. This method helps you plan safe lifting operations and select the right pulley system for your project.

The T-Method

The T-Method offers another way to calculate mechanical advantage, especially in more complex pulley systems. You follow the tension through each part of the system to find the total force at the load. Here is how you use the T-Method:

Start with “1” tension at the point where you pull on the rope.

Trace the tension through each pulley and component.

At each pulley, the tension entering and exiting remains equal.

At the pulley eye, add the tensions from ropes entering and exiting.

When tensions join, add the values together.

The final tension value at the load gives you the mechanical advantage.

Advantages | Limitations |

|---|---|

Versatile for simple and compound systems | Struggles with more complex configurations |

Requires only basic addition | Assumes frictionless pulleys and 180-degree turns |

You can use the T-Method with Powerful Machinery’s Pulley & Blocks to design efficient lifting setups. For instance, if you set up a double sheave block and trace the tension, you find a mechanical advantage of 4. This method helps you visualize force distribution and confirm your calculations.

Real-World Efficiency

You must consider real-world factors when you calculate mechanical advantage. Friction plays a major role in the efficiency of block and tackle systems. As you add more pulleys, friction in the pulley shafts increases and can lower the system’s efficiency.

The type of bearings in the pulleys affects friction levels.

Different load conditions change how friction impacts performance.

Sintered bronze impregnated bearings, such as Oilite, release lubricant under high pressure. These bearings work well in low-speed, high-load applications and help maintain efficiency in block and tackle systems.

When you use Powerful Machinery’s Steel Rope Pulley or Pulley & Blocks, you benefit from precision engineering and high-quality materials. These products minimize friction and maximize mechanical advantage.

You can create a mechanical advantage system that lifts heavy loads safely and efficiently, even in demanding environments.

Note: Always inspect your pulley system for wear and proper lubrication. Regular maintenance ensures you maintain optimal mechanical advantage and safety.

You improve your lifting operations by understanding how to calculate mechanical advantage and account for real-world efficiency. Powerful Machinery’s products give you the reliability and performance you need to create a mechanical advantage in every project.

Applications and Safety

Sailing, Rescue, and Tree Rigging

You see block and tackle systems in action across many industries. In sailing, you use them to adjust sails and control rigging with precision. Rescue teams rely on block and tackle setups to lift injured people or heavy equipment safely.

Arborists use these systems for tree rigging, allowing controlled lowering or lifting of branches. The table below highlights common applications and their benefits:

System Type | Description | Benefits | Drawbacks |

|---|---|---|---|

Simple Purchase | A single line runs through the system, purchase ratio by rope passes. | Simple to rig, easy to use, good for small adjustments | Needs more lines for higher purchase, limited by pulley count |

Compound Purchase | Combines simple systems for a higher purchase ratio. | Doubles purchase without a doubling line needed | More complex to rig and manage |

You choose the right block and tackle setup based on your task, whether you need quick adjustments or maximum lifting power.

Anchor Points and Progress Capture

You must always secure your block and tackle system to a strong anchor point. Anchor strength is critical for safety. The table below shows recommended standards:

Type of Anchor | Required Strength | Safety Factor |

|---|---|---|

Non-certified anchors | 5,000 pounds | N/A |

Certified anchors | 2:1 safety factor (max arrest force) | N/A |

Fall restraint anchors | 3,000 pounds | N/A |

Anchorage points | Twice the expected load | N/A |

Anchors should support users from 130 to 310 pounds.

For fall arrest, anchors must support twice the maximum arrest force.

For work positioning, anchors must support twice the expected force.

Progress capture devices add another layer of safety. These pulleys manage loads during ascent and descent, preventing accidental slippage. You gain reliability and efficiency, especially in demanding vertical work.

Choosing the Right Pulley System

You need to consider several factors when selecting a block and tackle system:

Type of pulley: Choose steel for heavy loads and harsh environments.

Pulley diameter: Larger diameters increase cable life.

Bearing type: Bronze bushings offer durability for industrial use.

Powerful Machinery’s Steel Rope Pulley and Pulley & Blocks meet these needs. You benefit from robust construction, corrosion resistance, and compliance with strict safety standards.

These products support heavy lifting, direction changes, and load distribution in construction, marine, and industrial settings. You can select from various sizes and load capacities to match your project requirements, ensuring safe and efficient lifting every time.

Conclusion

You improve workplace safety and efficiency when you understand mechanical advantage and block and tackle systems. The table below highlights how different sectors benefit from these principles:

Sector | Application Description |

|---|---|

Industrial and Manufacturing | Utilizes cranes, hoists, and forklifts to lift heavy objects, enhancing productivity and reducing worker strain. |

Architecture and Construction | Employs tower cranes with pulley systems for lifting materials, improving safety, and reducing effort. |

Automotive Industry | Uses leverage in braking systems to convert foot pressure into braking force, enhancing vehicle safety. |

Powerful Machinery’s products deliver reliability and durability for demanding projects.

You can explore resources like block and tackle kits, wire rope pulley blocks, and custom crane sheaves for advanced solutions. Practice regular gear inspections, minimize friction, and continue learning to optimize your lifting operations.

FAQ

What is the main benefit of using a block and tackle system?

You reduce the force needed to lift heavy loads. Block and tackle systems distribute weight across multiple pulleys, making lifting safer and more efficient in construction, marine, and industrial applications.

How do I choose the right pulley for my project?

You should consider load weight, rope diameter, and environmental conditions. Powerful Machinery offers steel rope pulleys and blocks in various sizes and finishes to match your specific lifting requirements.

How often should I inspect my pulley system?

You should inspect your pulley system before each use. Look for signs of wear, corrosion, or damage. Regular maintenance ensures safety and extends the life of your equipment.

Can I use Powerful Machinery pulleys outdoors?

Yes. Powerful Machinery’s pulleys feature corrosion-resistant finishes and robust construction. You can use them in outdoor environments, including marine and construction sites, with confidence.