You know that safety sits at the heart of every professional job. Reliable chains make safety a daily reality, not just a checkbox. Powerful Machinery’s certified chains help you meet safety standards with ease. These chains support safety by passing strict audits, aligning with global safety programs, and ensuring proper employee training.

You can count on them during safety checks and compliance reviews. Safety matters in every detail, from chain storage and maintenance to daily operations. When you focus on safety, you protect your team, your equipment, and your reputation. Make safety your habit, not your afterthought.

Key Takeaways

Choose the right chain type and grade for your job to ensure safety and efficiency. Consider factors like load capacity and environmental conditions.

Regularly clean and lubricate chains before storage to prevent rust and extend their lifespan. Follow a simple checklist for effective maintenance.

Store chains in a clean, dry area with good airflow. Proper organization and labeling help you quickly find the right chain when needed.

Conduct routine inspections to catch potential issues early. Check for wear, alignment, and lubrication to keep your chains running smoothly.

Avoid overloading chains and ensure proper handling to prevent accidents. Stick to manufacturer guidelines for safe operation.

Chain Selection and Suitability

Types and Grades of Chains

You face a lot of choices when picking the right chain for your job. Each type fits a different need. Roller chains work well for power transfer in machinery. Specialty chains handle tough environments.

Agricultural chains stand up to heavy impacts. Engineering class chains offer strength for conveyors. Leaf chains shine in lifting jobs.

Here’s a quick look at common types and grades:

Type of Chain | Description |

|---|---|

Roller Chain | Power transfer in machinery, including agricultural machines. |

Specialty Chain | Built for unique, heavy-duty applications. |

Agricultural Chain | Handles high-impact farming tasks. |

Engineering Class Chain | Superior strength for high-stress jobs like conveyors. |

Leaf Chain | High tensile strength for lifting. |

Grade | Description |

|---|---|

General-purpose, low-strength, light construction. | |

Stronger, used for towing and container securement. | |

Grade 70 | High strength, load securement, gold chromate finish. |

Overhead lifting, high-strength alloy. | |

Grade 100 | Construction and rigging, higher working load limit. |

Grade 120 | Ultra-premium, overhead lifting, 50% stronger than Grade 80. |

Materials and Finishes

You want your chain to last. Materials and finishes make a big difference. Stainless steel resists rust, especially Type 316 in saltwater. Galvanized steel works well outdoors. Black oxide finish reduces glare and suits general use.

Hot-dip galvanizing gives thick zinc protection.

Zinc-nickel coating boosts corrosion resistance.

Powder coating blocks moisture and chemicals.

Material | Corrosion Resistance | Suitable Environments |

|---|---|---|

Stainless Steel | Rust-resistant; Type 316 is best for saltwater | Marine, chloride-rich areas |

Galvanized Steel | Zinc coating for corrosion resistance | Outdoor, moist places |

Black Oxide Finish | Moderate resistance, less glare | Low-risk environments |

Application Limits

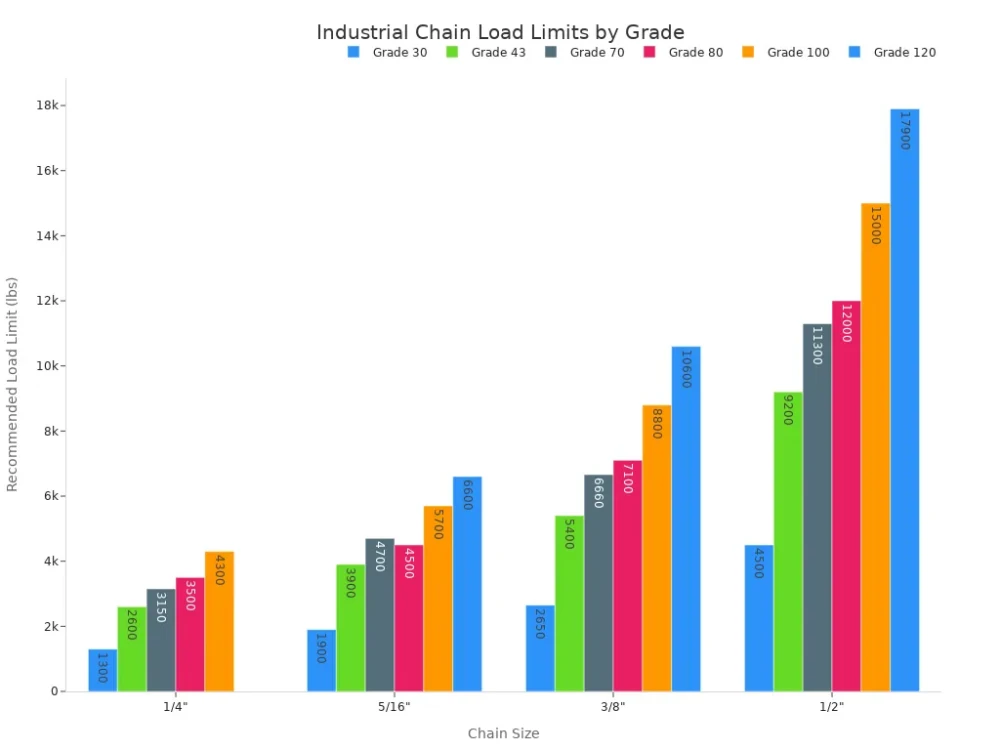

You need to match the chain to your load. Each grade and size has a specific working load limit.

Check out this chart for quick reference:

For example, Grade 30 suits light construction. Grade 43 works for towing. Grade 70 secures loads in transport. Grade 80 and above handles overhead lifting. Always check the load rating before you start.

Powerful Machinery Chain Features

Powerful Machinery chains stand out for their reliability and performance. You get high corrosion resistance with the G4 chain, perfect for marine use. The G43 chain meets ASTM and NACM standards, giving you confidence in towing, logging, and construction.

Tip: Always choose a chain that matches your load and environment. Powerful Machinery offers certified options for every job.

Chain Storage and Maintenance

Cleaning Before Storage

You want your chain to last as long as possible. Cleaning before storage is the first step in the chain storage and maintenance. Dirt, moisture, and chemicals can cause rust and weaken your chain. You should always clean your chain after use, especially if it’s been exposed to mud, saltwater, or chemicals.

Here’s a simple checklist for cleaning:

Wipe off dirt and debris with a clean cloth.

Wash the chain with mild soap and water if needed.

Dry the chain completely to prevent moisture buildup.

Lubricate the chain with a good grade of nondetergent petroleum base oil. This helps reduce wear and stops rust.

Label each chain by type, size, and date stored.

Keep all labels or markings on the packaging.

Lay the chain flat and flip it from time to time if not packaged.

Never stack chains if they are not packaged.

Store chains in a vibration-free area.

You should use the oldest chain first. This “first in, first out” method keeps your inventory fresh and safe. If you follow these steps, you’ll make chain storage and maintenance much easier.

Tip: Lubrication is key for proper load chain care. It protects the internal surfaces and keeps your chain working smoothly.

Storage Environment

The right environment makes a huge difference in chain storage and maintenance. Chains need a clean, dry place with steady temperature and humidity. Extreme temperatures can change the metal’s strength. Moisture causes rust and corrosion.

Corrosive environments, like coastal areas or places with chemicals, need chains with protective coatings or made from stainless steel.

Here’s what you should look for in a storage area:

Stable temperature, not too hot or cold.

Low humidity to prevent rust.

No exposure to chemicals or salt.

Good lighting for easy inspection.

If you store chains in wet or cold places, choose chains with enhanced toughness and corrosion resistance. Powerful Machinery’s chains, like the G80 and stainless steel options, are built for these tough environments. They meet international standards and last longer, even in harsh conditions.

Organization and Airflow

Organization helps you find the right chain fast and keeps your workspace safe. You should label every chain and keep them sorted by type and size. Use shelves or racks to keep chains off the floor. Make sure chains are easy to reach and inspect.

Proper airflow is just as important in chain storage and maintenance. Stale air can cause temperature differences and hot spots, even if the thermostat looks fine. Good ventilation keeps every chain at the right temperature and humidity. This stops rust and keeps your chains in top shape.

Note: Sufficient airflow management in your storage area ensures every chain stays stable and fresh. Poor airflow can lead to uneven cooling and hidden damage.

Powerful Machinery Storage Solutions

Powerful Machinery knows how important chain storage and maintenance are for your business. Their chains are designed for durability and easy care. You get chains that resist corrosion, handle tough environments, and meet strict safety standards.

Powerful Machinery recommends storing chains in clean, dry areas with proper labeling and organization. Their certified chains make chain storage and maintenance simple and reliable.

If you want to upgrade your storage, check out Powerful Machinery’s solutions. You’ll find racks, labeling systems, and corrosion-resistant chains that fit your needs. With these products, you can keep your chains safe, organized, and ready for action.

Cold Storage Management

Importance of Cold Storage

You know how crucial safety is when you handle temperature-sensitive products. Cold storage management keeps your chains strong and reliable, especially in cold storage warehouses. If you ignore the importance of cold storage, you risk chain failure and equipment breakdown.

Chains exposed to fluctuating temperatures can lose their strength and become unsafe. You need cold storage management to protect your investment and keep your team safe.

When you store chains with temperature-sensitive products, you must think about safety every step of the way. Cold storage warehouses rely on steady temperature to prevent corrosion and damage. If you don’t manage temperature, you might face equipment malfunction, breakdown, or even theft.

Human error and poor training can also lead to cold chain breaches. You want to avoid these risks and keep your chains ready for action.

Temperature Control

Temperature control systems play a huge role in cold storage management. You need to monitor temperature in cold storage warehouses to keep chains and temperature-sensitive products safe. If the temperature drops too low or rises too high, chains can become brittle or corrode.

You should check the temperature regularly and use alarms to catch problems early.

Here’s a quick table to help you manage temperature in cold storage warehouses:

Temperature Range | Chain Condition | Safety Risk |

|---|---|---|

Below freezing | Brittle, risk of breaking | High |

0°C to 10°C | Stable, less corrosion | Low |

Above 10°C | Increased corrosion | Moderate |

Tip: Always use strong shelving that supports heavy chains and is easy to clean. Nonporous surfaces help keep pathogens away.

Preventing Corrosion

Corrosion is a big threat in cold storage management. You want to keep chains free from rust, especially when storing temperature-sensitive products. Use polymer or stainless steel shelving in cold storage warehouses to prevent rust. Make sure shelving is strong and easy to clean.

Nonporous surfaces help stop pathogens from building up.

You should inspect chains often for signs of corrosion. If you see rust, clean and lubricate the chain right away. Good cold storage management means you keep chains dry, organized, and protected from temperature swings. You lower safety risks and keep your chains working longer.

Note: Regular training helps your team avoid mistakes and keeps cold storage management running smoothly.

Maintenance and Inspection

Inspection Frequency

You want your electric chain hoists to run smoothly and avoid unexpected breakdowns. Regular maintenance and inspections keep your equipment safe and reliable. Check out this table for recommended inspection schedules:

Source | Inspection Type | Frequency |

|---|---|---|

OSHA 1915.112 | Visual Inspection | Before use |

OSHA 1915.112 | Thorough Inspection | Every 3 months |

OSHA 1910.184 | Thorough Inspection | At least once every year |

ASME Guidelines | Normal Service | Yearly |

ASME Guidelines | Severe Service | Monthly to Quarterly |

ASME Guidelines | Special Service | As recommended |

You should always inspect your electric chain hoists before each use. Schedule thorough maintenance every three months, and increase the frequency if you use your hoists in harsh conditions.

What to Check?

During routine inspections, focus on these key points:

Inspecting hooks for cracks or wear

Check sprocket alignment and chain channel smoothness

Adjust the slack side sag of the chain

Improve lubrication conditions

Look for chain elongation or distortion

Examine safety mechanisms and hoist load indicators

Don’t forget to check for proper lubrication. This step helps prevent unexpected breakdowns and keeps your electric chain hoists working at peak operational efficiency.

Compliance Standards

You need to follow safety standards for maintenance. Operators must use standard operating procedures and keep maintenance logs. Document every inspection and calibration.

Train your team to spot risks and report any issues. Use a validated system for maintenance records. Always review changes to your maintenance process and keep records for audits.

Compliance Considerations | Documentation Requirements | Risk Management |

|---|---|---|

Follow SOPs for cleaning and maintenance | Keep logs and records | Train staff to spot risks |

Align schedules with regulatory guidelines | Use validated systems | Assess risks with FMEA |

Validate and calibrate equipment | Document every check | Conduct root cause analysis |

Removal Criteria

Remove a chain from service if you see:

Missing or unreadable tags

Cracks, excessive wear, or corrosion

Stretched, bent, or twisted links

Heat damage or binding

Any condition that affects chain integrity

Never use a chain that fails these checks. Ignoring warning signs or exceeding hoist load capacity can lead to serious accidents.

Powerful Machinery Maintenance Support

Powerful Machinery supports you with maintenance resources and technical help. You get preventative care tips, real-time inventory tracking, and advanced technology for electric chain hoists. Their team helps you shift from reactive to proactive maintenance.

This approach reduces costly breakdowns and boosts reliability. You can count on their expertise to avoid common maintenance mistakes and keep your hoists safe.

Tip: Overlooking regular inspections can lead to unexpected breakdowns. Stick to your maintenance schedule and follow all maintenance procedure tips for your electric chain hoists.

Damage Prevention

Overloading and Shock Loading

You might think pushing your chains a little harder will get the job done faster. Overloading is one of the main reasons chains fail in industrial settings. When you use chains above their rated capacity, you risk expanding pin holes and causing pin fractures or link separations.

High starting torque, jams, or sudden load changes can bend pins, crack plates, or even snap chains. Mining and crushing operations often see these problems because chains face tough conditions. If you want to avoid costly replacements and downtime, always stick to the manufacturer’s load limits.

Misuse and Impacts

Misusing chains or handling them incorrectly can lead to serious accidents. Overloading hand chain blocks, skipping inspections, or installing equipment the wrong way all increase the risk of failure.

Neglecting maintenance makes chains wear out faster, which can cause breakdowns during lifting. You should always check your hoist for damage before use, secure it properly, and follow the manufacturer’s instructions. Regular maintenance keeps your equipment safe and reliable.

Overloading

Inadequate inspection

Incorrect installation

Neglecting maintenance

Incorrect rigging

These mistakes can compromise chain integrity and put you and your team at risk.

Chemical Exposure

Certain chemicals can damage chains quickly. You need to watch out for substances like methyl isocyanate, hydrogen iodide, methyl mercaptan, iron pentacarbonyl, nitrogen dioxide, phosphine, sulfur trioxide, and toluene 2,4-diisocyanate.

If your chains work near these chemicals, develop health and safety plans, use proper protective equipment, and set up decontamination procedures. Medical surveillance helps keep exposed workers safe.

Environmental Factors

Humidity and temperature changes can weaken chains over time. High humidity above 60% leads to hydrolysis and encourages microbial growth. Temperature swings speed up chemical reactions and can double the shelf life of sensitive products if managed well.

Moisture causes oxidative degradation and destabilizes chains. You should store chains in areas with controlled temperature and humidity to keep them strong.

Powerful Machinery Safety Tips

Powerful Machinery wants you to stay safe. Here are some tips:

Know where the emergency stop is.

Store fuel safely and keep fire extinguishers nearby.

Stay in the cab and keep your seatbelt fastened during a rollover.

Train in first aid and know evacuation routes.

Report incidents and near-misses.

Follow shutdown checklists and keep up with maintenance.

Tip: Safety starts with you. Take these steps every day to protect your team and your equipment.

Quick Reference Checklist

Selection Steps

Choosing the right chain for your job keeps your team safe and your equipment running. Here’s a simple way to make smart choices:

Figure out what you need. Think about the weight, speed, and environment.

Pick the chain type that matches your job. Roller chains work for machines. Leaf chains lift heavy loads.

Check the chain material. Stainless steel resists rust. Alloy steel handles tough jobs.

Make sure the chain can handle your load. Look at the strength and working limit.

Maintenance plan. Choose chains that are easy to inspect and lubricate.

Ask experts or suppliers for advice if you’re unsure.

Test the chain before you use it. Make sure it fits your equipment and handles the weight.

Tip: Always match the chain to your job and environment. Testing before use helps you avoid surprises.

Storage Steps

Storing chains the right way helps them last longer. Here’s what you should do:

Clean chains after every use. Remove dirt and moisture.

Dry chains completely before storing.

Lubricate chains to prevent rust.

Label each chain with type, size, and date.

Store chains flat or on racks. Avoid stacking loose chains.

Keep chains in a dry, stable environment with good airflow.

Inspection Steps

Regular inspections catch problems early. Use this table to guide your checks:

Inspection Step | What to Do |

|---|---|

Measure Pitch | Use a gauge to check the distance between roller pins. |

Examine Roller Diameter | Measure rollers at different spots for wear. |

Check for Elongation | Measure several links to spot stretching. |

Lubrication | Make sure chains are oiled as the manufacturer recommends. |

Note: Early detection of wear keeps your chains safe and reliable.

Damage Prevention Steps

You can prevent chain damage with a few smart habits:

Inspect and align chains and sprockets often.

Use chains built for your load. Never overload.

Pick corrosion-resistant chains for harsh areas. Clean and lubricate them regularly.

Keep the chain tension correct. Check it often.

Replace worn or cracked links before they fail.

Set up a maintenance schedule for lubrication, alignment, and replacements.

Safety starts with daily care. Stick to these steps to keep your chains strong.

Conclusion

You boost safety and extend chain life when you follow a solid chain storage and maintenance checklist. Regular inspections and cleaning help you spot hidden damage and prevent corrosion.

Storing chains the right way keeps them ready for action. Powerful Machinery stands by you with certified products and expert support. Want more guidance? The website offers helpful resources:

Feature | Description |

|---|---|

Detailed Product Pages | Find specs, pricing, and downloadable guides. |

Resource Center | Access catalogs, datasheets, and case studies. |

FAQs | Get answers to common questions about products and shipping. |

Keep reviewing your process and stay ahead with best practices.

FAQ

How often should you inspect your chains?

You should check your chains before every use. Schedule a thorough inspection every three months. If you work in harsh conditions, increase the frequency. Regular checks help you catch problems early and keep your team safe.

What is the best way to store chains?

Store your chains in a clean, dry place. Use racks or shelves to keep them off the floor. Label each chain by type and date. Good airflow and stable temperature help prevent rust and damage.

Can you use Powerful Machinery chains outdoors?

Yes, you can use Powerful Machinery chains outdoors. Their chains use high-quality alloy steel or stainless steel. These materials resist corrosion and handle tough weather. Just remember to clean and lubricate them after outdoor use.

What should you do if you find rust on a chain?

Spot rust? Clean the chain right away. Use a wire brush and mild cleaner. Dry it completely and apply lubricant. If you see deep pitting or cracks, remove the chain from service.

How do you choose the right chain for your job?

Check your load weight and environment.

Pick the right chain grade and material.

Ask your supplier for advice if you feel unsure.

Test the chain before using it.