When evaluating chain working load limit vs breaking strength, you’re looking at two crucial safety metrics that serve different purposes. The working load limit (WLL) indicates the maximum weight you can safely lift with a chain during everyday operations, ensuring reliable performance and safety.

In contrast, breaking strength represents the highest force a chain can withstand before it fails, reflecting the chain’s ultimate material capacity. Manufacturers, including Powerful Machinery, set the working load limit well below the breaking strength to provide a safety margin for regular use.

The breaking strength is determined by the chain’s material composition and rigorous testing procedures. Powerful Machinery’s certified lifting chains clearly display both the working load limit and breaking strength, giving you confidence in your equipment’s safety and reliability.

Aspect | Working Load Limit (WLL) | Breaking Strength |

|---|---|---|

Purpose | Safety limit for regular use | Absolute maximum force capacity |

Set by | Manufacturer | Material properties/testing |

Reflects | Safety, usability, and life of equipment | Material capabilities |

Key Takeaways

The working load limit (WLL) is the maximum weight a chain can safely lift during regular use. Always check this rating before lifting.

Breaking strength indicates the highest force a chain can withstand before failure. Use it only for comparison, not as a lifting guideline.

Manufacturers set the WLL significantly lower than the breaking strength to ensure safety. This safety margin protects against unexpected loads.

Regularly inspect chains for wear and damage. Remove any chain that shows signs of deterioration to maintain safety during lifting operations.

Always use certified chains with clear WLL markings. This practice helps prevent accidents and ensures compliance with safety standards.

Working Load Limit (WLL)

What Is Working Load Limit?

You need to understand the working load limit before you use any lifting equipment. The working load limit is the maximum weight a chain or rigging component can safely handle during regular use.

Safety standards like ASME and ISO define the working load limit rating as the highest load you can apply without risking failure. Manufacturers express the working load limit in pounds or kilograms.

You will see this rating marked on certified chains, including those from Powerful Machinery. The working load limit helps you avoid dangerous situations and keeps your lifting operations safe.

The working load limit rating is always lower than the breaking strength.

You must never exceed the working load limit during lifting or rigging.

The working load limit is a key safety guideline for all chains.

How WLL Is Determined?

Manufacturers use strict testing procedures to calculate WLL for each chain. Powerful Machinery’s Grade 80 and Grade 100 chains go through proof load testing. This test applies a load that is usually two times the working load limit rating.

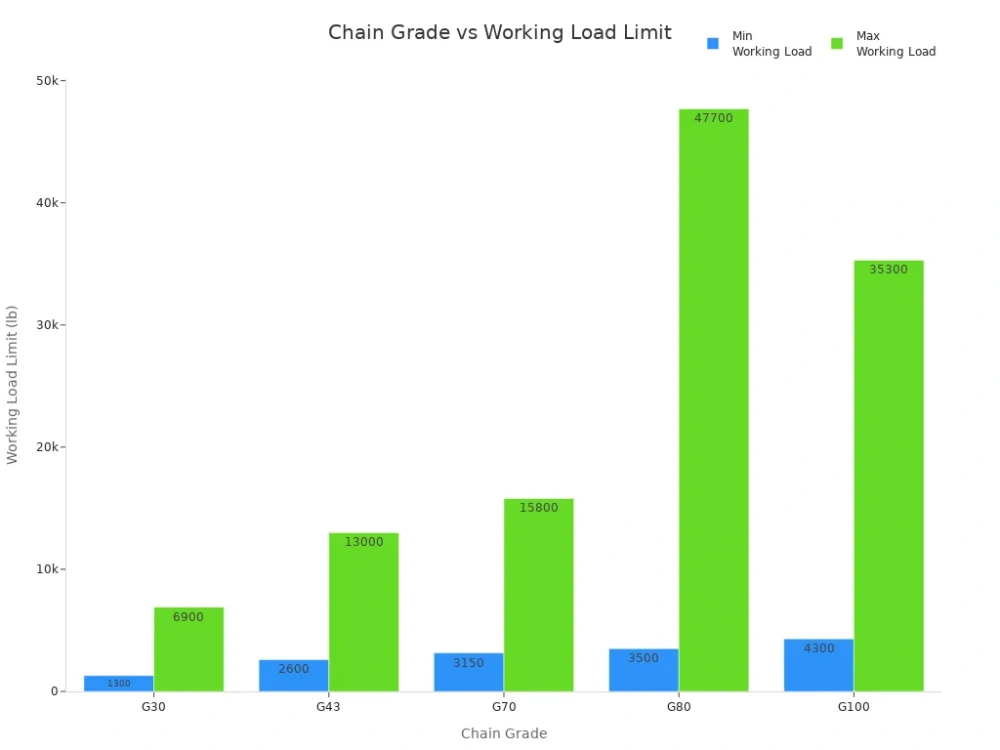

If the chain passes, it meets safety standards for real-world use. Grade 100 chains are about 25% stronger than Grade 80 chains. Both types have a minimum breaking load that is four times the working load limit. You can see the testing procedures in the table below:

Testing Procedure | Description |

|---|---|

Proof Load Testing | Applies a load of 1.1 to 2.5 times the working load limit rating to verify safety. |

Standards | Chains must meet ASME, OSHA, and ISO requirements. |

Purpose | Ensures chains can safely lift loads without damage. |

Why WLL Matters?

You must pay close attention to the working load limit rating every time you use lifting chains. Exceeding the working load limit can cause equipment failure, injuries, or even fatalities. Safety reports show that overloaded chains and slings have led to serious accidents and financial losses.

Following the working load limit rating prevents accidents and extends the life of your chains. Powerful Machinery marks each chain with a clear, permanent working load limit rating. You can easily identify the safe load for each chain and avoid mistakes. Always check the working load limit before you start any lifting job.

Tip: Always use chains with certified working load limit ratings and never exceed the marked value. This simple step keeps your team safe and your equipment reliable.

Breaking Strength

What Is Breaking Strength?

You need to know what breaking strength means before you select a chain for lifting or rigging. Breaking strength is the maximum force or weight a chain can withstand before it fails or breaks. Standards organizations use this definition to set safety requirements for industrial chains.

When you look at a chain’s specifications, you see the breaking strength rating listed as a key metric. This rating helps you understand the chain’s ultimate capacity, but you should never use it as your working guideline.

Breaking strength shows the chain’s absolute limit.

You must always use the working load limit for safe lifting, not the breaking strength.

Breaking strength helps you compare different chains for heavy-duty jobs.

How is Breaking Strength Measured?

Manufacturers use laboratory tests to measure breaking strength. You see two main methods:

Proof tests apply tension to the chain without causing damage. These tests check the construction and workmanship.

Break tests pull the chain until it fails. These tests show the chain’s ultimate breaking strength, but they are destructive and not used for routine checks.

Powerful Machinery uses an in-house testing bed to verify breaking strength. The testing bed pulls chains to their breaking strengths, simulating real-world conditions. Technicians set the working load limit and breaking strength before each test. This process ensures every chain meets or exceeds safety standards.

Breaking Strength in Powerful Machinery Chains

When you compare breaking strength and working load limit, you see important differences in safety and performance.

Aspect | Breaking Strength | Working Load Limit (WLL) |

|---|---|---|

Definition | Maximum force or weight before failure | Maximum weight or force with a safety margin |

Margin for Error | No margin for error | Includes a safety net by dividing the breaking strength by one-third |

Purpose | Determines if a product can safely hold cargo | Ensures safety during use by accounting for unknown strains and stresses |

International standards set minimum breaking load requirements for lifting chains. Powerful Machinery’s Grade 80 and Grade 100 chains meet or exceed these standards.

Chain Grade | Minimum Breaking Strength | Working Load Limit (WLL) |

|---|---|---|

Grade 80 | 8,000 lbs | 2,000 lbs |

Grade 100 | 10,000 lbs | 2,500 lbs |

You can trust Powerful Machinery chains because each product undergoes strict testing. The minimum breaking load for every chain is much higher than the working load limit. This safety margin protects you during lifting operations. Always check the breaking strength rating and use the working load limit for safe lifting.

Chain Working Load Limit vs Breaking Strength

Key Differences

When you compare the chain working load limit vs breaking strength, you see two numbers that serve different purposes. The working load limit tells you the maximum weight you can safely lift during normal operations.

Breaking strength shows the ultimate point of failure, which is the highest force a chain can handle before it breaks. You should always use the working load limit for daily lifting tasks, not the breaking strength.

Here are the main differences:

Working load limit is the safe working load for regular use.

Breaking strength is the force at which the chain reaches the ultimate point of failure.

WLL is always set lower than the breaking strength to protect you from unexpected loads.

SWL and WLL mean the same thing. Both refer to the safe working load.

Breaking strength helps you compare chains for heavy-duty jobs, but you should never use it as your lifting guideline.

You can see these differences in the table below:

Concept | Description |

|---|---|

Working Load Limit (WLL) | The maximum load that equipment can safely handle during normal use, marked by the manufacturer. |

Minimum Breaking Load (MBL) | The load at which the equipment will fail, providing a threshold for safety. |

Factor of Safety | A margin that accounts for unexpected loads, wear and tear, and operational variances, ensuring safety. |

When you look at Powerful Machinery’s chains, you find both the working load limit and breaking strength clearly marked. This helps you choose the right chain for your job and avoid mistakes.

Safety Factors

You need to understand why manufacturers set the working load limit much lower than the breaking strength. The safety factor is the ratio between breaking strength and WLL. This margin protects you from sudden shocks, wear, and unpredictable forces.

Most lifting chains use a safety factor of 3 to 5. For example, if a chain’s breaking strength is 9,000 lbs, the working load limit might be 3,000 lbs. This means you have a buffer zone before the chain reaches its ultimate point of failure.

Safety Factor | Description |

|---|---|

3 | Minimum capacity for normal use |

5 | Required minimum by OSHA for general-purpose lifting equipment |

International safety standards like ASME B30.9 and EN 818 require manufacturers to follow strict rules for chain working load limit vs breaking strength. These standards define the relationship between WLL and breaking strength, making sure you have a safe working load for every lifting job.

Term | Definition | Purpose |

|---|---|---|

Working Load Limit (WLL) | The maximum load the manufacturer authorizes for the equipment during normal use. | Operational Safety |

Minimum Breaking Load (MBL) | The minimum force at which the equipment is expected to fail, based on destructive testing. | Design & Engineering |

Safety Factor (SF) | The ratio of the Minimum Breaking Load to the Working Load Limit (MBL / WLL). | Risk Mitigation |

The safety factor ensures that your chain will not reach the ultimate point of failure during normal use. You can trust Powerful Machinery’s chains because the company follows all major international standards. The engineering team works with accredited bodies to test and certify every product.

You get chains that meet OSHA, ASME, ISO, and EN requirements. Each chain displays its working load limit and breaking strength, so you know exactly how much weight you can lift safely.

Note: Always use the working load limit for your lifting operations. Never use breaking strength as your guideline. The safety factor protects you and your team from accidents.

You should remember that the chain working load limit vs breaking strength is not just a technical detail. It is a critical safety rule. The working load limit gives you a safe working load for every job.

The breaking strength shows the ultimate point of failure, but you must never reach it. Powerful Machinery’s certified chains help you work safely and confidently every day.

Using WLL in Practice

Identifying WLL on Chains

You must identify the working load limit before you use any chain for lifting. Manufacturers like Powerful Machinery mark each chain with a tag or stamp that shows the WLL, grade, diameter, and serial number. You will find these markings on Grade 80 and Grade 100 lifting chains.

The tag also lists the maximum weight and safe working load for each configuration. If a chain does not have an identity tag, you should not use it for lifting.

Always check for clear markings and certification stamps. Powerful Machinery’s chains display all required information, making it easy for you to confirm the WLL and breaking strength.

Breaking Strength (lbs) | Safety Factor | Working Load Limit (WLL) (lbs) |

|---|---|---|

24,000 | 3:1 | 8,000 |

Best Practices for Safe Use

You need to follow best practices to keep lifting operations safe. Start by knowing the WLL and breaking strength of every chain you use. Inspect chains before each use for signs of wear, corrosion, or deformation. Store chains in a dry, clean place to prevent rust.

Train your team to understand WLL and safe working load guidelines. Use the right chain for the job. For example, Grade 80 and Grade 100 chains from Powerful Machinery are designed for overhead lifting and heavy-duty tasks.

Grade 30 Proof Coil Chain is suitable for towing and securing cargo, but not for lifting. Never exceed the maximum weight listed on the tag.

Tip: Always select chains with certified WLL ratings and check the tag before every lift.

Common Mistakes to Avoid

You must avoid common mistakes when using WLL data. Ignoring the working load limit can lead to accidents and equipment damage. Misreading charts or lifting radius may cause you to overload a chain.

Using chains without proper inspection increases the risk of failure, even if you stay below the maximum weight. Worn or damaged chains compromise the breaking strength and safe working load.

Remove any chain from service if you see cuts, rust, or deformation. Never use Grade 30 Proof Coil Chain for overhead lifting. Always match the chain grade and WLL to your task.

Feature | Grade 30 Proof Coil Chain | Grade 80 Lifting Chain |

|---|---|---|

Material | Low-carbon steel | Alloy steel |

Strength | Lower tensile strength, suitable for light-duty applications | High tensile strength, ideal for heavy lifting |

Applications | General-purpose, agricultural, light towing | Hoisting, cranes, and industrial lifting operations |

Durability | Less durable, not designed for heavy loads | Fatigue-resistant, designed for frequent loading |

Cost | Generally inexpensive | Higher cost due to strength and durability |

Note: Regular inspections and proper training help you maintain the breaking strength and WLL of your chains.

Conclusion

You now see the clear difference between the working load limit and breaking strength. Always use the working load limit as your safe guideline. This practice keeps you within legal and safety standards.

Proper planning and organization help you stay safe during lifting operations.

Following the working load limit prevents overload and reduces accident risks.

Certified chains, like those from Powerful Machinery, meet strict safety standards.

Understanding the working load limit and breaking strength lowers the chance of equipment failure.

Regular inspections and compliance with the working load limit protect your team and workplace.

FAQ

What happens if you exceed the working load limit?

You risk chain failure, equipment damage, or serious injury. Always follow the marked working load limit. Exceeding it can cause sudden breaks, even if the chain looks strong.

How do you find the working load limit on a Powerful Machinery chain?

Look for the stamped tag or marking on the chain. You will see the WLL, grade, and size clearly displayed. Never use a chain without this information.

Can you use breaking strength as your lifting guideline?

No, you should never use breaking strength for lifting. Always use the working load limit. The breaking strength only shows the chain’s maximum capacity before failure, not the safe working load.

What is the difference between Grade 30 and Grade 80/100 chains?

Chain Grade | Use Case | Overhead Lifting |

|---|---|---|

Grade 30 | Towing, securing cargo | ❌ Not allowed |

Grade 80/100 | Lifting, hoisting, rigging | ✅ Approved |