Selecting the right clevis hook sizes for your job keeps your team and equipment safe. You must match the hook to your chain’s size and working load limit. For example, a 5/16″ Grade 70 chain, often used in industrial settings, supports up to 4,700 lbs and features a zinc-plated finish for durability:

Chain Size | Grade | Working Load Limit | Features |

|---|---|---|---|

5/16″ | 70 | 4,700 lbs | Zinc-plated, proof tested |

Powerful Machinery supplies certified clevis hooks trusted by professionals who demand reliability and safety in every lift.

Key Takeaways

Always match the clevis hook size to your chain size. This ensures a secure fit and prevents accidents during lifting.

Consider the working load limit (WLL) of both the hook and chain. Exceeding this limit can lead to equipment failure and serious injuries.

Select the appropriate hook type based on your application. Use grab hooks for stable lifting and slip hooks for added security.

Regularly inspect your clevis hooks for wear and damage. This practice helps maintain safety and extends the life of your equipment.

Consult manufacturer specifications and safety guidelines before use. This step ensures compliance and enhances operational safety.

Choosing Clevis Hook Sizes

Match Hook Size to Chain Size

You must select clevis hook sizes that fit your chain perfectly. Industry standards require you to match the hook size to the chain diameter for safe and efficient lifting. If you use a hook that is too large or too small, you risk unstable connections and unsafe loads.

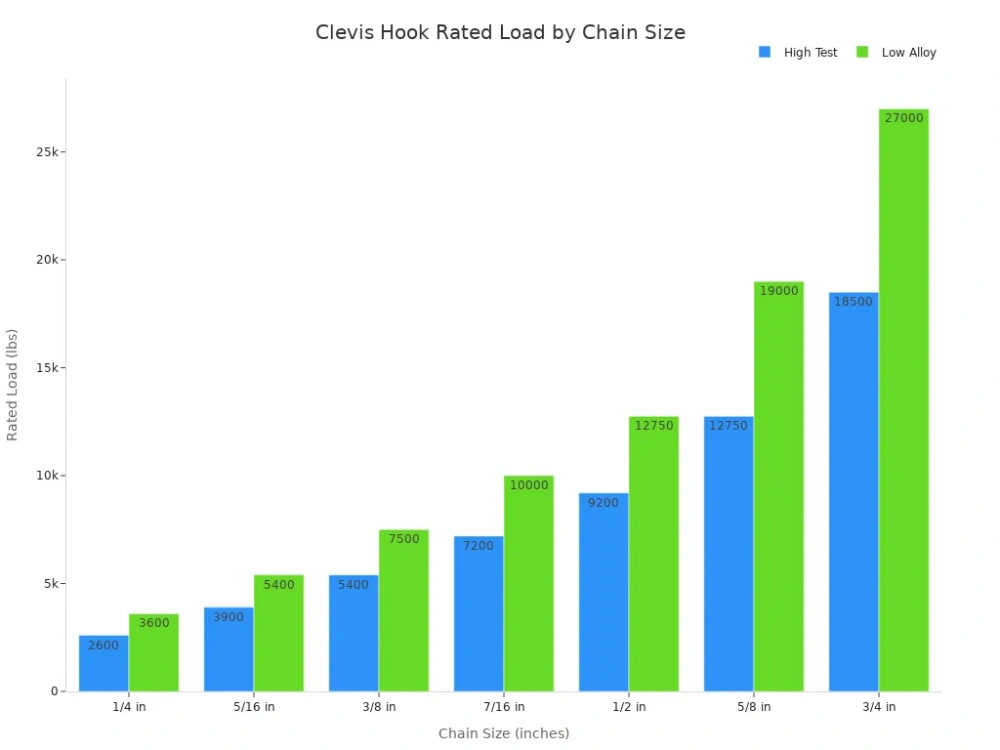

The following table shows recommended pairings for chain size and rated load:

Size of Chain Inches | Rated Load Lbs High Test | Rated Load Lbs. Low Alloy |

|---|---|---|

1/4 | 2600 | 3600 |

5/16 | 3900 | 5400 |

3/8 | 5400 | 7500 |

7/16 | 7200 | 10,000 |

1/2 | 9200 | 12,750 |

5/8 | 12,750 | 19,000 |

3/4 | 18,500 | 27,000 |

You should always check the manufacturer’s specifications for both the chain and the hook. Powerful Machinery provides detailed charts and diagrams for every product, making it easy for you to confirm compatibility.

When you match the correct clevis hook sizes to your chain, you ensure a secure fit and reduce the risk of slippage during lifting or binding operations.

Tip: Always measure your chain diameter before selecting a hook. Even a small mismatch can compromise safety.

Consider Working Load Limit

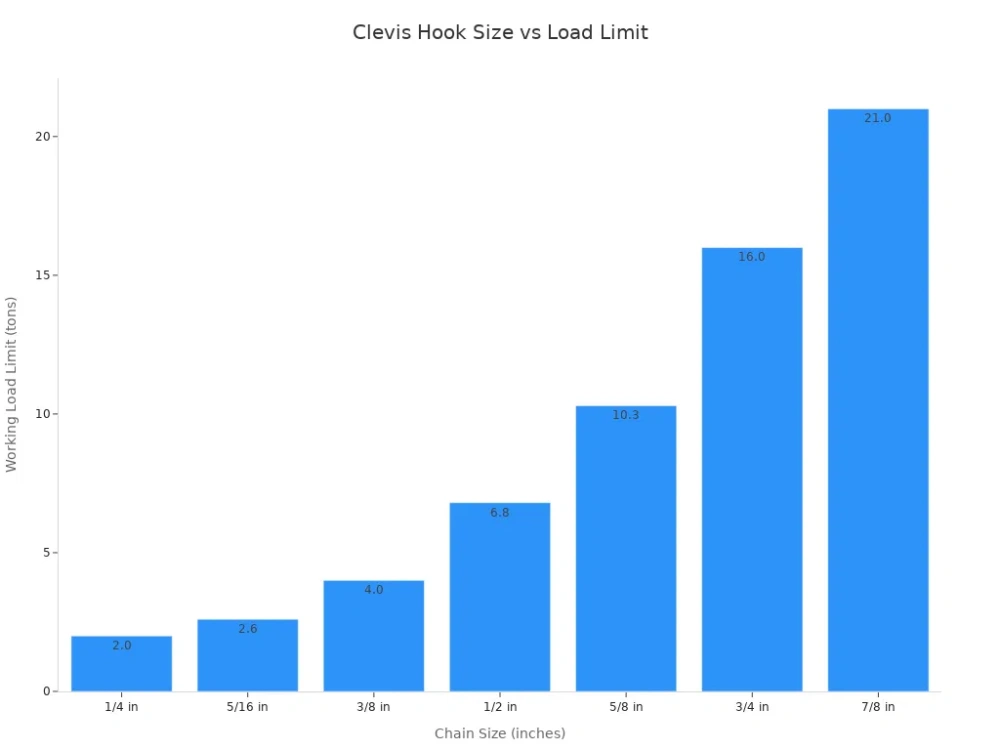

You must consider the working load limit (WLL) when choosing clevis hook sizes. The WLL tells you the maximum weight the hook and chain can safely support. If you exceed this limit, you risk equipment failure and serious injury. The table below lists common chain sizes and their corresponding working load limits:

Chain Size (in) | Working Load Limit (t) |

|---|---|

1/4 | 2.0 |

5/16 | 2.6 |

3/8 | 4.0 |

1/2 | 6.8 |

5/8 | 10.3 |

3/4 | 16.0 |

7/8 | 21.0 |

If you ignore the WLL, you put your team and equipment at risk. Catastrophic failures can lead to injuries or fatalities. Equipment that operates above its rated limit wears out faster and may fail unexpectedly.

Impact on Safety | Impact on Equipment Longevity |

|---|---|

Catastrophic failures can lead to injuries or fatalities. | Increased wear and tear significantly reduces lifespan. |

You should always select clevis hook sizes that meet or exceed your job’s load requirements. Powerful Machinery’s certified hooks display clear markings for WLL, helping you make informed decisions. You protect your crew and extend the life of your equipment when you respect these limits.

Note: Never guess the working load limit. Always verify the rating on both the hook and the chain before use.

Standard Clevis Hook Sizes and Applications

Size Ranges and Dimensions

You encounter a wide range of clevis hook sizes in the market. Each size fits specific chains and supports different load requirements. Manufacturers design hooks with precise dimensions to ensure safety and compatibility. You must select the correct size for your job to avoid accidents and equipment damage.

The table below shows common clevis hook sizes and their corresponding price points. These sizes represent industry standards and help you compare options for your project:

Size | Price |

|---|---|

9/32″ | $63.20 |

5/16″ | $63.20 |

3/8″ | $90.71 |

1/2″ | $150.44 |

5/8″ | $252.86 |

You see that smaller hooks, such as 9/32″ and 5/16″, work well for lighter loads and cost less. Larger hooks, like 1/2″ and 5/8″, support heavier loads and command higher prices. You should always check the manufacturer’s specifications for exact dimensions and working load limits before making a selection.

Tip: Measure your chain and review the hook’s throat opening and pin diameter. This step ensures a secure fit and safe operation.

Typical Uses by Industry

Clevis hook sizes play a vital role in many industries. You find specific sizes matched to unique applications, from towing to heavy lifting. The table below highlights how different industries use clevis hooks:

Industry/Application | Clevis Hook Size Usage |

|---|---|

Automotive Towing | Various sizes for towing applications |

Construction Cranes | Specific sizes for lifting heavy loads |

Boating (Rigging) | Sizes suitable for rigging and securing |

Off-Road Automotive Winches | Sizes designed for winching operations |

Aircraft | Specific sizes for securing loads |

Farming | Various sizes for agricultural uses |

You use smaller hooks for tasks like rigging on boats or securing loads in farming. Larger hooks serve construction cranes and aircraft, where you need maximum strength and reliability. You must choose the right size for your industry to maintain safety and efficiency.

Note: Always consult your industry’s safety guidelines and standards before selecting a clevis hook for critical applications.

Powerful Machinery Clevis Hooks Overview

Clevis Grab Hook Features

You get superior performance with Powerful Machinery Clevis Grab Hooks. These hooks use high-quality Grade 100 alloy steel, which gives you strength and reliability for demanding jobs. The patented Twist Lock design and secure latching mechanisms set them apart from standard hooks.

You can use these hooks for chain-to-chain connections, equipment safety, and vehicle stabilization. The table below shows how Powerful Machinery Clevis Grab Hooks compare to industry standards:

Feature | Powerful Machinery Clevis Grab Hooks | Industry Standards |

|---|---|---|

Material | High-quality Grade 100 alloy steel | Varies |

Design | Patented Twist Lock designs | Standard designs |

Latching Mechanism | Secure latching mechanisms | Varies |

Versatility | Chain-to-chain, equipment safety, vehicle stabilization | Limited applications |

You benefit from hooks that are designed for heavy-duty applications. The engineered clevis head minimizes mismatches between hook and chain. Replacement parts are always available, so you can keep your equipment running smoothly.

Clevis Slip Hook Features

Powerful Machinery Clevis Slip Hooks give you secure load handling with a closed design and a safety latch. This design prevents accidental unhooking and keeps your load secure. The table below highlights the differences between grab hooks and slip hooks:

Feature | Grab Hooks | Slip Hooks |

|---|---|---|

Design | Open design without a safety latch | Closed design with a safety latch |

Safety | No safety latch | Includes a safety latch |

Functionality | Grabs objects directly | Requires an inward force to release |

You can choose slip hooks when you need extra security for lifting or rigging. These hooks are proof-tested and certified for reliable performance. The tough powder coat finish protects them from harsh environments.

Hooks for Grade 80/100 Chains

You must match your hooks, master links, and couplers to the same chain grade for safety. Powerful Machinery offers hooks made from Grade 100 alloy steel, which increases the working load limit by at least 25% compared to Grade 80.

The hooks feature a tough powder coat finish and are proof-tested for strength. Grade 100 chains work best for the heaviest loads, while Grade 80 chains suit most industrial lifting tasks.

Hooks, master links, and couplers must be rated and certified for the same chain grade.

Grade 100 chains are about 25% stronger than Grade 80 chains.

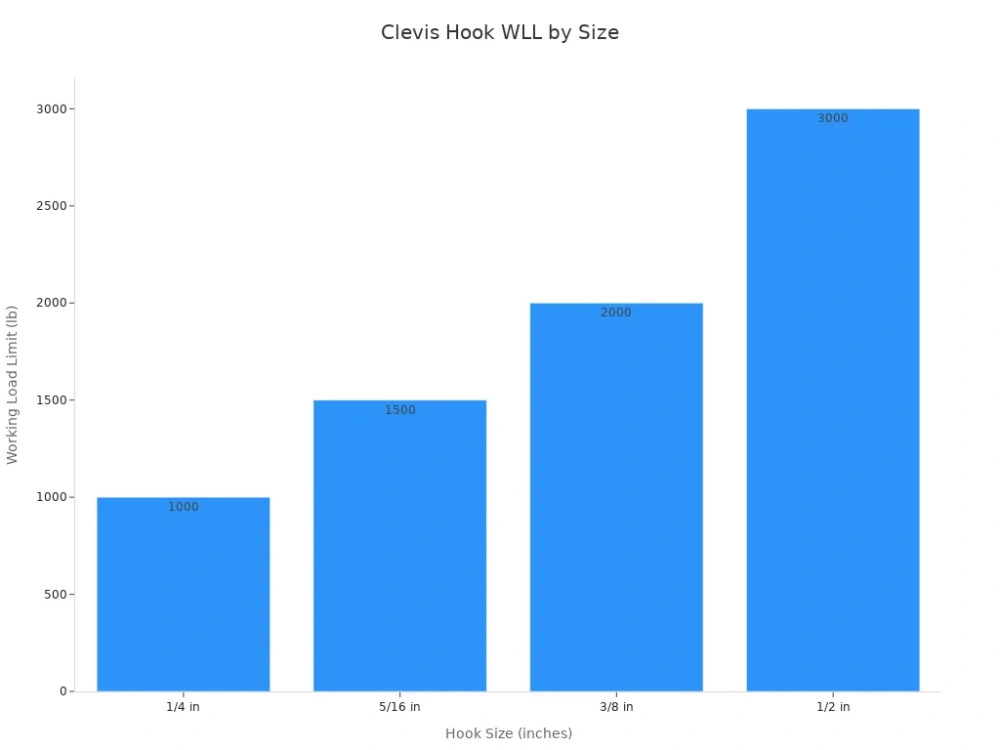

The table below shows some available sizes and working load limits:

Part # | Size (in) | WLL (lb) | Wt (lb) |

|---|---|---|---|

HKCS14SS | 1/4 | 1,000 | 0.57 |

HKCS516SS | 5/16 | 1,500 | 0.82 |

HKCS38SS | 3/8 | 2,000 | 1.14 |

HKCS12SS | 1/2 | 3,000 | 2.13 |

You can trust Powerful Machinery hooks because they hold top certifications for safety and quality. The table below lists two important certifications:

Certification Type | Description |

|---|---|

ISO 9001 | Quality management system certification |

LEEA | Membership in the Lifting Equipment Engineers Association |

When you select Powerful Machinery, you get clevis hook sizes that meet strict standards for durability, compatibility, and safety.

Step-by-Step Guide to Selecting Clevis Hook Sizes

Choosing the right clevis hook sizes for your job requires a systematic approach. You must consider the chain size and grade, load requirements, hook type, and safety standards. Follow these steps to ensure a secure and efficient lifting operation.

Identify Chain Size and Grade

Start by identifying the exact size and grade of your chain. This step is essential because the hook must match the chain for safe operation. Use the following methods to determine your chain’s specifications:

Check for the size stamped on the side of the chain plate.

Clean off any dirt or grease to reveal the markings.

Measure the overall width of the chain.

Measure the diameter and width of the roller.

Measure the thickness of the plate.

Measure the overall height of the chain.

Identify the pin of your chain.

Measure the distance from the center of one pin to the center of the next pin.

You can refer to the table below to understand the different chain grades and their applications:

Grade | Description | Suitable for Overhead Lifting? |

|---|---|---|

Grade 30 | Low-carbon steel chains and hooks for light-duty applications. | No |

Grade 43 | Used in towing and logging, meets higher performance criteria. | No |

Grade 70 | Heat-treated carbon steel, stronger than Grade 43, is used for towing. | No |

Grade 80 | Heat-treated alloy steel, minimum grade approved by ASME for lifting. | Yes |

Grade 100 | High-grade alloy steel, stronger than Grade 80, is commonly used for lifting. | Yes |

Grade 120 | Premium chains and hooks offer even higher strength than Grade 100. | Yes |

Tip: Always confirm the chain grade before selecting a hook. Using the wrong grade can compromise safety and performance.

Determine Load Requirements

Next, calculate the load requirements for your lifting or rigging scenario. You must know the total weight, including any attachments or below-the-hook devices. Use these steps to ensure accuracy:

Determine the weight of the load and all additional items.

Choose the appropriate sling style and hitch type.

Calculate the sling angle to understand the forces involved.

Inspect all rigging equipment before use.

Lift the load slightly to check for stability.

Consider environmental factors such as wind or friction.

Proper load calculation prevents equipment failure and accidents. Underestimating load requirements can result in equipment failure, accidents, or injuries. You protect your team and equipment by always verifying the working load limit of both the chain and the hook.

Note: Safety considerations are crucial. Proper load distribution extends the life of your rigging equipment and ensures compliance with industry standards.

Select Hook Type: Grab vs. Slip

You must choose the correct hook type for your application. Grab hooks and slip hooks serve different purposes and offer unique safety features. Review the table below to compare their characteristics:

Feature | Grab Hooks | Slip Hooks |

|---|---|---|

Design | Open design allows for quick attachment | Closed design with a safety latch |

Safety | No safety latch, less secure | Safety latch prevents accidental release |

Application | Used in stable lifting situations | Ideal for dynamic environments where loads shift |

Load Security | Designed to grab a specific link in the chain | Ensures load remains attached under strain |

You should select grab hooks for stable lifting or load binding, where the chain will not move. Choose slip hooks when you need extra security, especially in dynamic environments where loads may shift.

Powerful Machinery offers both types, including Clevis Grab Hooks for chain shortening and Clevis Slip Hooks with safety latches for secure load handling.

Factor | Clevis Hook | Slip Hook |

|---|---|---|

Design | Open, no safety latch | Closed, has a safety latch |

Use Case | Frequent hooking/unhooking | Lifting or securing loads safely |

Load Capacity | Varies with chain size and grade | Varies with chain size and grade |

Environmental Suitability | Depends on the material used | Needs to resist rust/corrosion |

Safety Features | None | The safety latch prevents the load from slipping off |

Compatibility | Must match chain size | Must match chain size |

Tip: Always match the hook type to your job’s requirements. For example, use a Clevis Slip Hook from Powerful Machinery for overhead lifting where a safety latch is required.

Check Compatibility and Safety

Before you begin any lifting operation, check the compatibility and safety of your selected hook and chain. Follow these guidelines:

Ensure the hook size matches the chain diameter and grade.

Verify that the working load limit of the hook meets or exceeds your load requirements.

Inspect hooks for any signs of bending, wear, or damage. Do not use bent or sprung hooks.

Confirm that hooks display clear markings for size, grade, and working load limit.

Follow OSHA and ASME standards. Apply loads to the throat of the hook to prevent overstressing.

Train all users in proper selection, inspection, and safe operating practices.

Powerful Machinery’s clevis hooks meet strict international standards, including ISO and ASME certifications. You can trust these products for durability, traceability, and reliable performance in demanding environments.

Alert: Always follow the manufacturer’s recommendations for safe working loads. If you cannot find the rating, have the hook tested to twice its intended load before use. Regular inspections are mandatory for ongoing safety.

By following these steps, you ensure that your clevis hook sizes are appropriate for your chain, load, and application. This approach protects your team, equipment, and reputation.

Clevis Hook Sizes Comparison Table

Quick Reference Chart

When you select a clevis hook, you need a quick way to compare sizes, chain compatibility, and working load limits. This chart gives you a clear overview of Powerful Machinery’s most popular clevis hook sizes. You can use it to match the right hook to your chain and ensure you meet your job’s safety requirements.

Hook Size (in) | Compatible Chain Size (in) | Working Load Limit (lbs) | Shank Dia. (in) | Head Dia. (in) | Head Height (in) | Hole Dia. (in) | Pin Length (in) | Cotter Pin Size (in) |

|---|---|---|---|---|---|---|---|---|

1/4 | 1/4 – 5/16 | 5,700 | 0.248 | 0.380 | 0.100 | 0.210 | 0.770 | 1/16 |

5/16 | 5/16 | 5,700 | 0.311 | 0.440 | 0.100 | 0.260 | 0.940 | 3/32 |

3/8 | 3/8 | 8,800 | 0.373 | 0.510 | 0.130 | 0.330 | 1.060 | 3/32 |

1/2 | 1/2 | 15,000 | 0.496 | 0.630 | 0.160 | 0.440 | 1.360 | 1/8 |

5/8 | 5/8 | 22,600 | — | — | — | — | — | — |

Tip: Always check both the hook and chain markings before use. Matching the correct size and grade helps you avoid dangerous mismatches.

You can see that as the hook size increases, the working load limit also rises. For example, a 1/4-inch or 5/16-inch hook supports up to 5,700 lbs, while a 5/8-inch hook can handle 22,600 lbs. The table also lists key dimensions, such as shank diameter and pin length, so you can confirm a secure fit with your chain.

You can use this chart as a quick reference when selecting hooks for lifting, rigging, or load securement. Powerful Machinery provides hooks with clear markings and precise engineering, so you can trust your equipment in every application.

Note: If you need more detailed measurements, refer to the manufacturer’s technical datasheets or contact Powerful Machinery for expert guidance.

Safety and Inspection Tips

Material and Grade Considerations

You need to pay close attention to the material and grade of your clevis hooks. The right combination ensures both safety and performance in demanding environments. Manufacturers use several materials and grades for different applications:

High-quality steel: Grade 43 hooks work well for heavy-duty jobs.

Forged steel: Grade 70 hooks provide secure towing and load binding.

European-made alloy: Grade 100 hooks excel in overhead lifting.

The grade of your hook directly affects its strength and safety. For example, Grade 70 hooks use high-strength forged steel and often include a spring-loaded safety latch. These hooks can handle working loads up to 9,000 lbs for binding and tie-downs.

Some Grade 70 hooks, made from forged alloy steel, support up to 11,300 lbs for cargo securement. Grade 100 hooks, constructed from alloy steel, offer a working load limit at least 25% higher than Grade 80. You should always match the hook grade to your job’s requirements.

Material Grade | Working Load Limit | Construction | Application |

|---|---|---|---|

Grade 70 | 9,000–11,300 lbs | Forged/high-strength steel | Binding, tie-downs, cargo |

Grade 100 | 25% higher than Grade 80 | Alloy steel | Robust lifting tasks |

Tip: Always check the markings on your hook. The grade and material type must match your chain and application.

Maintenance and Inspection Guidelines

You must inspect your clevis hooks regularly to maintain safety. Start each use by checking for visible signs of wear, cracks, or deformation. Look for bent hooks, worn latches, or missing pins. If you find any damage, remove the hook from service immediately.

Follow these steps for routine maintenance:

Clean hooks after each use to remove dirt and debris.

Lubricate moving parts, such as safety latches, to prevent rust.

Store hooks in a dry, protected area.

Check that all markings remain clear and readable.

Replace any hook that fails inspection or shows excessive wear.

Alert: Never use a hook that shows signs of damage or excessive wear. Regular inspections help prevent accidents and extend the life of your equipment.

By following these guidelines, you ensure your clevis hooks remain reliable and safe for every job.

Final Checklist for Clevis Hook Selection

Before you start your next lifting or rigging job, use this final checklist to confirm you have chosen the right clevis hook. This step helps you avoid costly mistakes and keeps your team safe.

Confirm Size and Type

You must double-check the size and type of your clevis hook. This ensures a secure fit and reliable performance.

Measure your chain diameter. Match it to the hook size listed in the manufacturer’s chart.

Check the working load limit (WLL). Make sure the hook’s WLL meets or exceeds your load requirements.

Select the correct hook type. Use grab hooks for chain shortening and load binding. Choose slip hooks for secure lifting with a safety latch.

Inspect the hook’s throat opening and pin diameter. Confirm these dimensions fit your chain.

Look for clear markings. The hook should display its size, grade, and WLL.

Tip: Always keep a copy of the manufacturer’s sizing chart nearby. This helps you verify compatibility quickly.

Review Certifications and Safety

You need to confirm that your clevis hook meets all relevant safety standards and certifications. This step protects your operation and ensures compliance.

Check for certifications. Look for ISO, ASME, or LEEA markings on the hook or packaging.

Inspect for visible damage. Do not use hooks with cracks, bends, or worn latches.

Verify traceability. Certified hooks from Powerful Machinery include batch numbers for quality tracking.

Review inspection records. Make sure the hook has passed recent safety checks.

Train your team. Ensure everyone understands proper hook selection and inspection procedures.

Safety Feature | What to Look For |

|---|---|

Certification Markings | ISO, ASME, LEEA, or equivalent |

Condition | No cracks, bends, or wear |

Traceability | Batch or serial number present |

Alert: Never use a hook if you cannot confirm its certification or if it fails inspection. Your safety depends on it.

By following this checklist, you guarantee that your clevis hook selection supports both safety and efficiency on every job.

Conclusion

You now know how to choose the right clevis hook sizes for your job. Always match your hook and chain, check the working load limit, and follow safety guidelines. Use the checklist before every project to avoid mistakes.

Powerful Machinery’s certified products help you work with confidence. Inspect your hooks often and review product specifications to keep your team and equipment safe.

FAQ

What is the difference between a grab hook and a slip hook?

A grab hook holds a chain link securely for load binding or shortening. A slip hook features a safety latch and allows the chain to move, making it ideal for lifting or securing loads.

How do you measure the correct clevis hook size for your chain?

Measure the diameter of your chain link. Match this measurement to the hook size listed in the manufacturer’s chart. Always check both the chain and hook markings for compatibility.

Can you use a clevis hook for overhead lifting?

You can use a clevis hook for overhead lifting if it matches the chain grade and displays proper certifications. Grade 80 or 100 hooks are suitable for lifting. Always verify the working load limit.

How often should you inspect your clevis hooks?

Inspect your clevis hooks before each use. Look for cracks, bends, or worn latches. Remove damaged hooks immediately. Regular inspections help prevent accidents and extend equipment life.

What certifications should you look for on clevis hooks?

Look for certifications such as ISO, ASME, or LEEA. Certified hooks display batch numbers for traceability. These markings ensure your hook meets international safety and quality standards.