You may encounter electric hoist troubleshooting challenges when your equipment stops functioning or exhibits unusual behavior. Always check for emergency procedures before you attempt to diagnose any problems.

If you notice the power supply is not connected, or suspect brake system issues, stop all operations and review safety protocols. Powerful Machinery’s reliable products help you work safely, but you should consult experts for complex repairs. Your focus on safety ensures efficient and secure lifting every time.

Key Takeaways

Always prioritize safety by disconnecting power and using lockout/tagout procedures before troubleshooting your electric chain hoist.

Wear appropriate personal protective equipment, including gloves, hard hats, and eye protection, to safeguard against potential hazards.

Perform regular visual inspections and maintenance checks to identify issues early and ensure the hoist operates safely and efficiently.

Use genuine parts from Powerful Machinery for repairs to maintain safety standards and prolong the life of your electric chain hoist.

Consult a certified technician for complex problems to ensure proper repairs and compliance with safety regulations.

Safety Precautions for Electric Hoist Troubleshooting

Before you begin any electric chain hoist troubleshooting, you must follow strict safety precautions. These steps protect you and your team from injury and prevent damage to your equipment.

Powerful Machinery’s electric chain hoists include advanced safety features, but you should always take extra care during inspection or repair.

Power Isolation and Lockout/Tagout

You must disconnect the power supply before you touch any part of the hoist. Use lockout/tagout procedures to make sure no one accidentally restores power while you work. Place warning tags and locks on the main switch. This step stops unexpected movement and electrical hazards.

Never skip this process, even for quick checks. Always verify that the hoist cannot operate before you begin troubleshooting.

Tip: Only trained personnel should perform lockout/tagout. If you feel unsure, ask for help from a qualified technician.

Personal Protective Equipment

Wearing the right personal protective equipment is a key part of safety precautions. You should always use:

Safety gloves

Hard hats

Eye protection

Steel-toed boots

These items protect you from electrical shock, falling objects, and sharp edges. Make sure your gear fits well and meets industry standards.

When to Call a Professional?

Some problems require expert attention. If you find complex electrical faults, damaged components, or issues you cannot identify, stop work and contact a certified technician. Powerful Machinery recommends professional service for repairs beyond basic troubleshooting. This approach keeps your hoist safe and reliable.

Follow these safety precautions every time you inspect or repair your electric chain hoist. You should also remember these industry rules:

Never operate a hoist with missing or unreadable safety labels.

Do not lift loads over people.

Never use the hoist to move or support people.

Only lift loads within the hoist’s rated capacity.

Make sure the chain or wire rope sits correctly in the sprockets or grooves.

Your commitment to safety ensures smooth operation and protects everyone on site.

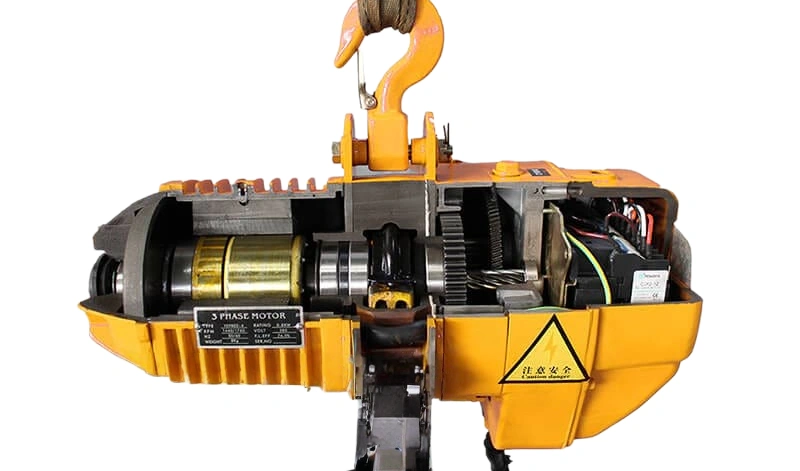

Electric Chain Hoist Components and Operation

Electric Chain Hoist Parts

You need to understand the main parts of an electric chain hoist to troubleshoot and maintain it effectively. Each component plays a critical role in safe and efficient lifting. Here are the essential parts and their functions:

Motor: Powers the hoist by converting electrical energy into mechanical force.

Chain: Connects the load hook to the hoist body. Made from high-strength alloy steel for durability.

Load Hook: Attaches to the load and includes a safety latch to prevent accidental release.

Hoist Body or Frame: Houses the motor and gearbox. Designed to withstand heavy loads.

Gearbox: Reduces motor speed and increases torque for lifting.

Brake: Holds the load securely when not lifting.

Control Panel: Contains the electrical controls, including emergency stop and limit switches.

Chain Container: Stores unused chain and prevents tangling.

Push Button Pendant or Remote Control: Lets you operate the hoist from a safe distance.

Limit Switches: Stop the hoist automatically to prevent overtravel.

How Does an Electric Chain Hoist Work?

An electric chain hoist lifts and lowers heavy loads with precision and speed. You operate the hoist using a control pendant or remote. When you press the button, the motor activates and drives the gearbox. The gearbox transfers torque to the load chain, raising or lowering the hook.

The brake system holds the load in place when you stop lifting. Limit switches prevent the hook from moving too far. This system reduces manual effort and increases safety.

Here is a quick comparison between electric and manual chain hoists:

Feature | Electric Chain Hoist | Manual Chain Hoist |

|---|---|---|

Lifting Speed | Fast and consistent | Slow, depends on human effort |

Safety Features | Overload protection, emergency stop | Basic, relies on operator |

Operator Strain | Minimal | High |

Remote Operation | Yes | No |

Load Capacity | High, suitable for continuous use | Lower, limited by human strength |

Powerful Machinery Product Features

You benefit from advanced features when you choose Powerful Machinery’s electric chain hoist. These hoists use high-strength alloy chains for maximum durability. Overload protection systems keep your operations safe. The electromagnetic brake ensures secure stopping.

Each hoist meets international safety standards, including CE certification. You can select from single-phase or three-phase models, variable speed options, and low headroom designs. Powerful Machinery’s in-house manufacturing guarantees stable quality and fast delivery.

You also have access to technical support and genuine spare parts for long-term reliability.

Note: Powerful Machinery’s electric chain hoists are trusted by professionals in construction, marine, and industrial sectors worldwide.

Common Electric Hoist Troubleshooting Issues

When you work with electric chain hoists, you may face several common problems that can interrupt your workflow. Understanding these issues helps you perform electric hoist troubleshooting quickly and safely. Here are the most frequent malfunctions you might encounter:

Hoist Not Responding

If you notice the hook does not respond when you press the control pendant, check the power supply first. Power supply not connected, low voltage, or a faulty switch circuit often cause this issue. Sometimes, the hook moves in the wrong direction or the hook lowers but will not raise.

You may also find the hook raises but will not lower. These symptoms point to control circuit problems or mechanical issues. Always inspect the wiring and connections before moving to more complex troubleshooting.

Powerful Machinery offers technical support and genuine spare parts to help you resolve these issues efficiently.

Unusual Noise During Operation

Unusual noise during operation signals mechanical trouble. You might hear grinding, rattling, or squealing sounds. These noises often come from lack of lubrication, worn gears, or chain misalignment. If you ignore these sounds, you risk motor malfunction or gearbox oil leakage.

Lubricate the chain and inspect for wear as your first step.

Hoist Fails to Stop

A hoist fails to stop, or the hook does not stop promptly when the brake system or limit switches malfunction. This can lead to dangerous situations. Sometimes, contact welding of the contactor or brake wear causes the hook to fail to stop. Always check the brake and limit switches during troubleshooting hoists.

Chain Jamming or Slipping

Chain jamming or hoist slips after stopping usually result from improper chain installation, lack of lubrication, or brake adjustment issues. Inspect the load chain and adjust the brake settings. If you see gearbox oil leakage, address it immediately to prevent further damage.

Load Drift or Slippage

Load drift or slippage means the hook cannot hold the load securely. This often points to brake failure or motor malfunction. Check the braking system and ensure proper lubrication. If the hook fails to stop, stop using the hoist and follow the repair guide.

Control and Electrical Problems

Control and electrical problems include the hook not responding, the hook moving in the wrong direction, or the control pendant failing. Loose wiring, poor contacts, or common motor failures can cause these symptoms. Always check the control mechanism and wiring for possible solutions.

For persistent or complex issues, contact Powerful Machinery’s support team. You can access spare parts and expert advice to keep your electric chain hoist running smoothly.

Step-by-Step Electric Hoist Troubleshooting

When you face electric hoist troubleshooting, you need a clear and systematic approach. Follow these steps to diagnose and resolve issues with your electric chain hoist. Always keep your operating manual nearby and refer to it for model-specific instructions.

If you feel unsure at any stage, contact Powerful Machinery’s technical support for guidance.

Visual and Initial Checks

Start with a thorough visual inspection. Look for obvious signs of damage or wear. Examine the hoist body, load chain, hooks, and electrical cables. Check for loose bolts, missing safety labels, or oil leaks.

Make sure the chain sits correctly in the sprocket, and the hook latch works smoothly. If you see any broken or deformed parts, do not operate the hoist. Review the operating manual for the correct configuration and compare your findings.

Tip: A quick visual check can reveal many problems before you start deeper troubleshooting.

Electrical System Inspection

Move to the electrical system next. Use your operating manual to locate the main electrical components. Follow these steps for a safe and effective inspection:

Check for voltage at the hoist main line or branch circuit switch.

Inspect for blown fuses or tripped circuit breakers.

Test for electrical continuity in the wiring and connections.

Ensure the hoist operates at the correct voltage and frequency.

Verify that the brake functions properly and does not bind.

Replace any damaged wires or connectors. Look for signs of moisture or heat damage on circuit boards. If you find phase failure or open circuits, address these issues before continuing.

Always disconnect power before touching electrical parts. The operating manual provides wiring diagrams and troubleshooting charts for your reference.

Control Pendant and Limit Switch Testing

The control pendant and limit switches play a key role in safe operation. Use the following steps to test them:

Clear the area under the hoist and remove any load.

Run the hoist up and down with no load. Listen for strange noises.

The limit switch should stop the hoist before the hook block reaches the hoist body.

If the limit switch fails, remove the hoist from service immediately.

Lower the hook to test the lower limit switch in the same way.

Test limit switches regularly to prevent over-travel and avoid accidents. If you notice the hoist does not stop at the correct position, consult the operating manual for possible solutions or contact Powerful Machinery’s support team.

Mechanical and Brake Evaluation

Mechanical and brake issues can cause serious safety risks. Use your operating manual to identify the brake system and mechanical components. Watch for these symptoms:

Symptoms | Troubleshooting Steps |

|---|---|

Abnormal noises | Inspect the braking system for wear. Adjust or replace as needed. |

Overheating | Check for prolonged use. Make proper adjustments. |

Load drift or creep | Verify the hoist is not overloaded. Check the braking system for wear. |

Chain jamming or slipping | Inspect the load chain for damage. Ensure it is seated correctly in the sprocket. |

Abnormal brake noise, overheating, or sudden failure during lifting signal mechanical problems. Dirt, corrosion, or damaged gears can cause brakes to drag or slip. Clean and adjust the brake as described in the operating manual. If you cannot restore normal function, seek help from a certified technician.

Chain and Hook Assessment

Inspect the load chain and hook for wear, deformation, or cracks. The chain must move smoothly through the guide and sprocket. Lubricate the chain as recommended in the operating manual. Check the hook for a secure latch and proper alignment.

If you find chain jamming, slipping, or visible damage, replace the affected parts with genuine Powerful Machinery components. Preventative maintenance on these parts extends the life of your electric chain hoist.

Note: Never use a hoist with a damaged chain or hook. Always follow the repair guide in your operating manual.

Testing After Repairs

After you complete repairs or adjustments, you must test the hoist before returning it to service. Follow these steps:

Conduct load testing according to regulatory standards for safety and reliability.

Use a test load between 100% and 125% of the rated capacity, unless your operating manual specifies otherwise.

Test all lifting and lowering functions. Verify the brake holds the load securely.

Prepare a written report of the load sustained and operations performed.

Make sure qualified personnel supervise or conduct the tests.

Testing ensures your electric chain hoists operate safely and efficiently. Keep all records as part of your preventative maintenance program. If you have questions, consult the operating manual or reach out to Powerful Machinery’s support team for assistance.

Your commitment to careful troubleshooting and regular maintenance keeps your equipment reliable and your workplace safe.

Electric Chain Hoist Inspection Checklist

Daily Visual Inspections

You should start each shift with a quick visual inspection of your electric chain hoist. This habit helps you spot problems before they become serious. Look for the following:

Condition of the hook and safety latch

Condition of the wire rope or chain

Proper legends and labels on all controls

Smooth operation of the bridge and trolley

Correct function of the hoist and limit switch

Check that the hoist load brake engages and releases as expected. Never use a hoist if you see cracks, bends, or other damage. Always make sure the total load, including rigging, does not exceed the rated capacity. Operate all controls and test the hoist load brake before lifting any load.

Weekly and Monthly Tests

You need to perform more detailed tests every week and month. These tests keep your equipment safe and reliable. Follow this checklist:

Inspect the hoist load brake for wear or unusual sounds.

Test the limit switch by raising the hook block slowly, then at full speed. The hoist must stop before the hook reaches the body.

Examine the chain or wire rope for signs of stretching or corrosion.

Check the operation of the control pendant and emergency stop.

Confirm that the hoist load brake holds the load securely during lifting and lowering.

OSHA and ASME standards require monthly inspections of all running ropes, hoist chains, end connections, and hooks. Powerful Machinery recommends you keep a record of each inspection.

Annual and Comprehensive Checks

You should schedule a full inspection of your electric chain hoist at least once a year. This process covers every part of the hoist, including the hoist load brake, gearbox, motor, and electrical system. Use the table below to guide your inspection schedule:

Inspection Type | Frequency |

|---|---|

Frequent Inspection | Weekly to Monthly |

Periodic Inspection | Monthly to Annually |

Older hoists, high-duty cycles, or harsh environments may require more frequent checks. Always follow Powerful Machinery’s guidelines for comprehensive inspections.

Maintenance Record Keeping

Keep detailed records of every inspection, test, and repair. Write down the date, findings, and actions taken. Note the condition of the hoist load brake each time. Good records help you track wear, plan maintenance, and prove compliance with safety standards.

Powerful Machinery provides maintenance log templates to help you organize your records. Accurate record keeping ensures your hoist load brake and other components stay in top condition.

Regular inspections and careful record keeping protect your team and extend the life of your electric chain hoist.

Electric Chain Hoist Maintenance

Lubrication and Cleaning

You must keep your electric chain hoist clean and well-lubricated to ensure safe and efficient operation. Regular lubrication of the load chain and moving parts prevents friction, rust, and wear.

Always follow the manufacturer’s recommendations for the type and frequency of lubricant. Use a damp towel to wipe down the hoist after each use. This simple step removes dust and debris that can cause damage.

Occasionally, wash the hoist with mild soap and water, but make sure it is completely dry before using it again. Proper lubrication and cleaning extend the lifespan of your equipment and help you avoid unexpected breakdowns.

Tip: Never use harsh chemicals or high-pressure water when cleaning your hoist. These can damage electrical components and protective coatings.

Load Testing and Adjustments

You should perform regular load testing and adjustments to maintain safety and performance. Daily checks before each use help you spot problems early. Monthly inspections allow you to examine the hoist’s components more thoroughly.

Schedule annual professional inspections and load tests to meet safety standards and detect hidden issues. These steps ensure your hoist operates reliably and remains a valuable asset in your workplace.

Spare Parts and Emergency Plans

You need to keep genuine spare parts on hand for quick repairs. Using original parts from Powerful Machinery ensures compatibility and safety. You should also have an emergency plan in place.

Make sure all operators know how to use the emergency stop button and understand the proper response steps. Regular drills and training sessions prepare your team for unexpected situations and reduce downtime.

Powerful Machinery Support

You can rely on Powerful Machinery for technical support, maintenance advice, and genuine spare parts. The company’s experts help you with preventative maintenance routines and troubleshooting.

Their support ensures your hoist stays in top condition and meets all safety requirements. Visit the official website for detailed guides and contact information.

Preventative maintenance protects your investment, extends equipment life, and keeps your workplace safe.

When to Seek Professional Hoist Repair?

Complex Electrical or Mechanical Failures

You must recognize when a problem goes beyond basic troubleshooting. Some issues require a certified professional. If you notice any of the following warning signs, stop using the hoist and call an expert:

Warning Sign | Implication |

|---|---|

Unusual noises | Underlying problems that need immediate attention |

Vibrations | Possible mechanical issues that could affect safety |

Changes in hoist performance | Signs that a professional inspection and repair are necessary |

Annual inspections by a professional service technician are crucial. Professionals can spot hidden issues that you might miss. They have the skills to make the right adjustments and repairs. You should never attempt repairs unless you have proper training. Unauthorized repairs can cause more damage and create unsafe conditions.

Certified Repairs and Warranty

You should always choose certified technicians for electric chain hoist repairs. These experts complete special training programs that include classroom lessons and hands-on practice. Their training covers safety checks, equipment inspection, load testing, and fall protection.

Certifications like the CMCO Chain Hoist Technician Certification show that a technician knows how to diagnose and repair hoists correctly. Certified repairs also help you meet OSHA and ASME safety standards.

When you use Powerful Machinery’s certified repair services, you protect your warranty and ensure your equipment stays reliable.

Only certified professionals should handle complex repairs. This keeps your hoist safe and your warranty valid.

Importance of OEM Parts

You should always use original equipment manufacturer (OEM) parts for repairs. OEM parts from Powerful Machinery fit your hoist perfectly and meet all safety standards. Using non-original parts can lead to poor performance and safety risks. Genuine parts help your hoist last longer and reduce downtime.

Powerful Machinery provides a full range of spare parts and technical support to keep your equipment running smoothly.

Trusting certified technicians and genuine parts ensures the best performance and safety for your electric chain hoist.

Conclusion

You ensure safe and efficient electric chain hoist operation by following a systematic troubleshooting process and regular maintenance schedule.

Maintain detailed records of inspections and repairs.

Replace worn parts promptly.

Use proper lubrication and safety gear.

Consult the manufacturer’s manual for every procedure.

Regular inspections and quick troubleshooting reduce downtime, prevent accidents, and protect your investment. Rely on Powerful Machinery’s resources and expert support for reliable performance and peace of mind.

FAQ

What should you do if your electric chain hoist stops working suddenly?

First, check the power supply and control pendant. Inspect for blown fuses or tripped breakers. If you cannot find the cause, contact Powerful Machinery’s technical support for guidance.

How often should you lubricate the load chain?

You should lubricate the load chain weekly or after every 40 hours of use. Always use the lubricant recommended in your operating manual for best results.

Can you replace hoist parts with non-original components?

You should only use genuine Powerful Machinery parts. Non-original components may not fit correctly or meet safety standards. Using genuine parts ensures reliable performance and protects your warranty.

Where can you find technical support for Powerful Machinery electric chain hoists?

You can visit Powerful Machinery’s official website for technical guides, spare parts, and expert support. The support team helps you solve problems quickly and safely.