You play a critical role in keeping your workplace safe and efficient by prioritizing electric hoist maintenance. Regular inspections do more than prevent accidents—they help you avoid costly repairs, extend the operational life of your equipment, and keep your business running smoothly.

Relying on Powerful Machinery’s certified products ensures you meet industry standards and maintain the highest level of reliability.

Frequent inspections address minor issues before they escalate, reducing downtime.

Consistent servicing helps you avoid fines and legal liabilities due to non-compliance.

Reliable equipment performance supports your productivity every day.

Key Takeaways

Regular inspections of electric hoists prevent accidents and costly repairs, ensuring a safe and efficient workplace.

Follow a structured maintenance schedule, including daily, monthly, and annual checks, to extend the life of your hoist.

Use only certified tools and parts from Powerful Machinery to maintain safety and warranty coverage during repairs.

Keep detailed records of inspections and maintenance activities to support compliance with safety regulations.

Train operators thoroughly to recognize hazards and perform systematic inspections for safe hoist operation.

Electric Hoist Inspection Types

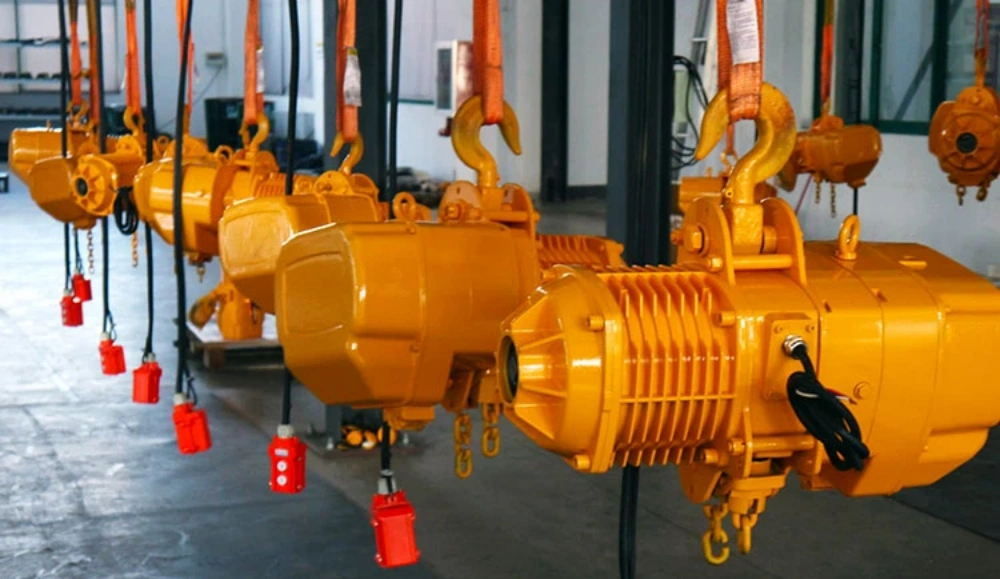

Powerful Machinery offers a comprehensive range of electric hoists, including electric chain hoists, wire rope hoists, and chain block hoists. Each model supports different lifting needs and environments, but all require regular inspections to ensure safe and reliable operation.

You must follow both manufacturer instructions and industry regulations for each inspection type. This approach helps you maintain compliance and extend the life of your equipment.

Tip: Consistent inspections help you catch small issues before they become major problems.

Here’s a quick overview of the main inspection types and their requirements:

Inspection Type | Frequency | Description | Key Requirements |

|---|---|---|---|

Daily | Daily | Basic checks for safe operation | Quick visual checks, no documentation required |

Monthly | Monthly | More thorough inspection | Includes checks of electrical components, safety devices, and alignment |

Annual | Annually | Comprehensive inspection | Must include structural checks, functional testing, and documentation of findings |

Daily Inspection Checklist

You should perform a daily inspection at the start of every shift. Look for obvious signs of wear or damage on the hoist, chain, wire rope, and hooks. Check for unusual noises or vibrations during operation. Make sure the controls respond correctly.

These quick visual and auditory checks do not require documentation, but they are essential for immediate safety.

Monthly Maintenance Checklist

Monthly inspections go beyond daily checks. Examine the hoist body, fasteners, and all electrical components for wear or damage. Test the alignment of the crane and runway.

Inspect safety devices, such as limit switches and emergency stops, to confirm proper function. Only qualified personnel should perform these checks to meet manufacturer and regulatory standards.

Annual Safety Inspection

Annual inspections are the most comprehensive. You must include structural checks, functional testing, and sometimes partial disassembly. Document all findings in detail.

A qualified professional should conduct this inspection to ensure your hoist meets OSHA, ASME, and manufacturer requirements. This process helps you maintain a safe and compliant workplace year-round.

Preparing for Electric Hoist Maintenance

Before you begin any electric hoist maintenance, preparation is key. Proper planning helps you work safely and efficiently. You also ensure compliance with industry standards and manufacturer guidelines.

Powerful Machinery provides detailed manuals and support resources for every hoist model. Always reference these documents before starting your inspection or maintenance routine.

Tools and Documentation

You need the right tools and accurate records to perform effective maintenance. Start by assembling a dedicated kit. Include calipers, flashlights, feeler gauges, and the original manufacturer’s manual. These tools help you measure wear, check clearances, and follow step-by-step procedures.

Tip: Always use certified tools and parts from Powerful Machinery to maintain safety and warranty coverage.

Keep a detailed logbook for every inspection, repair, and maintenance activity. This record helps you track the hoist’s history and supports compliance with OSHA, ASME, and ISO standards. Regular inspections by qualified technicians add another layer of safety and reliability.

Safe Work Environment

A safe workspace protects you and your team. Clear the area around the hoist before starting any work. Use warning signs to alert others. De-energize the hoist and apply lockout/tagout procedures to prevent accidental operation.

Note: Never skip safety steps, even for quick checks. Safety protocols save lives.

Hoist Classification

Understanding your hoist’s classification is essential. Each hoist has a duty cycle and classification that determines how often you should inspect and maintain it. Review the manufacturer’s documentation to identify your hoist’s class. This knowledge helps you predict wear rates and set the right inspection schedule.

Remember: Powerful Machinery’s manuals provide clear guidance on hoist classification and maintenance intervals.

Electric Hoist Inspection: Step-by-Step Guide

A thorough electric hoist inspection ensures your equipment operates safely and efficiently. Use this maintenance checklist to guide your process, referencing Powerful Machinery’s manuals for model-specific details.

The following inspection checklist covers every critical point for electric hoists, including chain hoists, wire rope hoists, and chain block hoists.

Visual and Auditory Checks

Begin your electric hoist inspection with a visual and auditory assessment. Look for signs of motor overheating, such as excessive heat or a burning odor. Listen for abnormal noises, including buzzing, grinding, or high-pitched squealing.

These sounds often signal internal strain or failing bearings. Watch for load drift, which may indicate brake failure. Notice any rattling, clicking, or loud clunking, as these suggest loose components or gear damage.

Tip: Always trust your senses. Unusual sights, sounds, or smells mean you should stop and investigate before continuing.

Common indicators to watch for:

Motor overheating

Loss of power or slow lifting

Abnormal noises (buzzing, grinding, squealing)

Load drift after releasing controls

Brake engagement issues

Rattling, clicking, or clunking sounds

Chain and Wire Rope Inspection

Inspect the chain and wire rope for wear, damage, and stretched links. Check for corrosion, cracks, or foreign material. Examine end connections for deformation or wear. Powerful Machinery’s electric chain hoists and wire rope hoists use high-tensile materials, but you must still verify their integrity during every maintenance checklist.

Checklist for chain and wire rope:

Look for stretched or damaged links

Check for corrosion or cracks

Remove any foreign material

Inspect end connections for deformation

Confirm secure load attachment

Hook and Safety Latch

Hooks and safety latches play a vital role in load security. Use the inspection checklist below and refer to the table for specific criteria. Powerful Machinery’s chain block hoists feature forged hooks and robust safety latches for added protection.

Inspection Criteria | Description |

|---|---|

Deformation | Check for visible bending, twisting, or cracking; should not deviate by more than 5% from specs. |

Wear and Corrosion | Excessive wear or corrosion affecting more than 10% of the original dimensions indicates unsafe use. |

Nicks and Gouges | Any nick or gouge deep enough to fit a fingernail requires removal from service. |

Latches and Safety Devices | Ensure hook latches operate properly and bridge the throat securely when closed. |

A missing, bent, or broken safety latch makes the hoist unsafe.

The latch prevents slings or attachments from slipping off.

Proper latch function avoids load shifting and accidents.

Hoist Body and Frame

Examine the hoist body and frame for visible damage, such as cracks, dents, or corrosion. Powerful Machinery’s electric hoists feature durable aluminum shells and heat-treated gears, but regular inspection remains essential.

Verify that all bolts, nuts, and pins are secure. Check the pendant control for damage and test the emergency stop button.

Checklist for hoist body and frame:

Look for cracks, dents, or corrosion

Confirm hook safety latches are present and working

Inspect for twists or kinks in the load chain

Test the pendant control and the emergency stop

Operate the hoist through the full range of motion without a load

Suspension and Mounts

Inspect suspension points and mounting hardware. Ensure all fasteners are tight and free from corrosion. Powerful Machinery’s electric chain hoists and wire rope hoists use robust mounting systems for secure installation.

Note: Loose or damaged mounts can lead to catastrophic failure. Always check suspension integrity during every maintenance checklist.

Brake System Test

Test both the holding and controlled lowering brakes. Raise the load a few inches and apply the brakes. The holding brake should keep the load stationary when no power is applied.

The controlled lowering brake must prevent the load from accelerating during descent. Powerful Machinery’s chain block hoists feature double brake systems for enhanced safety.

Checklist for brake system:

Test holding brake with a suspended load

Verify controlled lowering brake during descent

Listen for proper brake engagement sounds

Inspect for excessive wear or slippage

Electrical Controls and Wiring

Check all electrical controls and wiring for damage or malfunction. Controls must be clearly marked and responsive. Emergency stop functions should operate correctly. Powerful Machinery’s electric hoists include 24V safety buttons and antiphase protectors for added protection.

Checklist for electrical controls:

Inspect control buttons for correct labeling and placement

Test the emergency stop function

Check wiring for damage or loose connections

Remove the hoist from service if any control malfunctions

Limit Switches

Limit switches prevent over-travel and protect your equipment. Diagnose any issues with the switch or wiring. Replace faulty switches with matching specifications. Test the system after replacement. Use a multimeter to check resistance and continuity.

Powerful Machinery’s electric hoists feature reliable limit switches for safe operation.

Checklist for limit switches:

Diagnose switch or wiring problems

Replace faulty switches

Test system for correct function

Inspect for physical damage

Use a multimeter for resistance and continuity

Adjust or realign switches as needed

Replace if tests fail or damage is present

Run the hoist through its full range of motions without a load. Test upper and lower limit switches to ensure they prevent over-travel.

Sprocket and Chain Guide

Inspect the sprocket and chain guide for wear, alignment, and lubrication. Powerful Machinery’s chain hoists use heat-treated alloy steel gears for durability.

Check for misalignment or excessive wear

Ensure proper lubrication

Remove debris or foreign material

Gearing and Oil

Check the gearing for signs of wear or damage. Inspect oil levels and quality in gearboxes. Powerful Machinery’s electric hoists feature modular designs for easy maintenance.

Look for worn or damaged gears

Verify oil levels and replace if contaminated

Ensure gearboxes are sealed and leak-free

Chain Container

Examine the chain container for cracks, deformation, or debris. A damaged container can affect chain movement and safety.

Inspect for physical damage

Remove any foreign objects

Confirm secure attachment to the hoist

Operational Test

Perform a final operational test to verify safe functioning. Run the hoist through its full range of motions, including lifting and lowering without a load. Listen for unusual noises.

Test upper and lower limit switches. Powerful Machinery’s electric hoists are designed for smooth, reliable operation, but you must confirm performance with every inspection checklist.

Test Type | Description |

|---|---|

Upper and Lower Limit Switch | Inspect the functionality of both limit switches before using the hoist. |

Operation Inspection | Test the operation of the hoist to ensure it does not exceed the limits and operates safely. |

Tip: Use this maintenance checklist for every electric hoist inspection. Consistent use of the inspection checklist helps you catch issues early and maintain compliance.

By following this step-by-step guide, you ensure your electric hoists remain safe, reliable, and compliant. Powerful Machinery’s certified products and support resources help you maintain the highest standards in every inspection.

Electric Hoist Maintenance and Preventive Care

Regular electric hoist maintenance is essential for safe operation and long equipment life. Powerful Machinery recommends a proactive approach that combines cleaning, lubrication, and a structured maintenance schedule.

By following these steps, you reduce downtime, prevent costly repairs, and ensure your hoist performs at its best.

Cleaning Protocols

You should keep your electric hoist clean to prevent dust and grime from building up. Dirt on chains, ropes, and gears can cause stiffness and slow down your work. Use a soft brush or cloth to remove debris from all moving parts. Clean the hoist’s exterior monthly and after heavy use.

Pay special attention to the chain container and gear housing.

Tip: A clean hoist operates more smoothly and is less likely to develop mechanical issues.

Lubrication Guidelines

Lubrication is a key part of electric hoist maintenance. Apply specialized lubricating oil or grease to gears, bearings, and the load chain. This reduces friction and wear, helping your hoist run quietly and efficiently. Always follow the manufacturer’s guidelines for lubricant type and application frequency.

Lubricate the load chain regularly to prevent friction and wear.

Use only approved lubricants to avoid damaging components.

Wipe away excess oil to prevent attracting dust.

Preventive Maintenance Schedule

A structured preventive maintenance schedule keeps your hoist in top condition. You should perform daily, weekly, monthly, and annual checks. Here is a simple schedule to follow:

Interval | Task |

|---|---|

Daily | Inspect for visible damage, check cables, listen for odd noises |

Weekly | Lubricate moving parts, inspect hooks and chains |

Monthly | Clean exterior, check electrical connections, tighten fasteners |

Quarterly | Inspect control systems, replace worn parts |

Semi-Annual | Test brakes and limit switches, review safety devices |

Annual | Complete detailed inspection, update maintenance log |

By sticking to this routine, you extend your hoist’s lifespan and reduce the risk of unexpected breakdowns. Powerful Machinery’s durable products respond well to regular electric hoist maintenance, giving you reliable performance year after year.

Load Testing and Professional Service

Routine load testing ensures your electric chain hoist operates safely and meets all regulatory requirements. You must perform these tests regularly to verify that your equipment can handle its rated load without risk.

Powerful Machinery’s certified products support reliable performance and help you maintain compliance with industry standards.

Routine Load Testing

You should schedule routine load testing for every electric chain hoist in your facility. These tests confirm that your hoist can lift and lower loads safely. The following table outlines the main industry standards for routine load testing:

Standard | Description |

|---|---|

OSHA 1910.179(b)(3) and 1910.179(k)(2) | Load tests for modified or rerated cranes must use test loads up to 125% of the rated load unless the manufacturer specifies otherwise. Test reports must be available. |

ASME B30.2, B30.16, B30.17 | New, reinstalled, altered, repaired, and modified cranes and hoists require load testing before initial use with a test load of 100% to 125% of the rated load, covering all functions. |

CMAA Specification 78, section 4.7 | Load tests should occur at least once every four years at 100% load, with inspections before and after, and a written report kept for the equipment’s lifespan. |

You must document each test and keep records for regulatory audits. Routine load testing helps you identify issues early and maintain safe operation.

Post-Repair Testing

After servicing or repairs, you need to conduct post-repair load testing to confirm the electric chain hoist’s safety. This process verifies that all functions work correctly and that the hoist can handle its maximum rated load. The table below summarizes the requirements for post-repair testing:

Requirement | Details |

|---|---|

Regulatory Standards | Load testing must comply with regulatory standards for safety and reliability. |

Load Testing Percentage | Test loads should be between 100% and 125% of the rated load unless specified otherwise. |

Documentation | Prepare and file a written report of the load sustained and operations performed. |

Testing Functions | Test lifting and lowering functions and verify brake operation. |

Confirm the hoist can safely carry its maximum rated load after repairs. | |

Testing Method | Qualified personnel must conduct or supervise the tests. |

You must follow these steps to ensure your electric chain hoist meets all regulatory requirements after any servicing.

Qualified Personnel

You should always rely on qualified personnel for electric chain hoist inspections, maintenance, and professional servicing. Qualified individuals understand the operation, limitations, and hazards of the equipment.

They may work under the supervision of a certified operator. Maintenance and repair tasks require personnel who meet the definition of a qualified person for each job.

Familiarity with equipment operation and hazards

Direct supervision by a qualified operator when necessary

Maintenance and repair performed by qualified personnel

Professional servicing by trained experts ensures your electric chain hoist remains safe, reliable, and compliant with all regulatory standards.

Tip: Rely on Powerful Machinery’s certified products and professional servicing to maintain safety and regulatory compliance for every electric chain hoist in your operation.

Documentation and Compliance

You must keep thorough documentation and record-keeping for every electric hoist in your facility. This practice supports compliance with OSHA, ASME, and ISO standards.

Accurate records help you prove that regular hoist inspections and routine inspections occur as required. Powerful Machinery’s certified products meet international standards, making it easier for you to maintain compliance.

Maintenance Logbook

A well-structured maintenance logbook is essential for documentation and record-keeping. You should include the following details for each entry:

Date of Action: Record when you performed the work.

Description of Work: Note what you did, such as “Lubricated load chain” or “Inspected brake.”

Parts Used: List any replacement parts and their part numbers.

Findings: Document any deficiencies, even if you corrected them.

Technician’s Name/Signature: Identify who completed the work.

This logbook helps you track regular hoist inspections and supports compliance during audits.

Reporting and Tag-Out

You need to follow best practices for reporting and tagging out electric hoists during inspection and maintenance. Always check for tags that indicate a hoist is out of service before you begin work. Make sure all nameplates and safety labels are present and easy to read.

During routine inspections, focus on components like wire ropes and electrical connections. Keep a detailed record of all inspections and note any signs of damage. Report abnormalities to your maintenance team immediately.

Tip: Tagging out unsafe equipment prevents accidents and ensures only qualified personnel perform repairs.

Regulatory Standards

You must understand the regulatory standards that apply to electric hoist inspection and maintenance. Powerful Machinery’s products hold certifications that meet these standards, supporting your compliance efforts. The table below summarizes key standards:

Standard | Description |

|---|---|

ISO 4301-1 | Defines duty cycles and service conditions for lifting appliances. |

ISO 9001 | Ensures manufacturing consistency for reliable electrical system integration. |

IEC 60204-32 | Outlines electrical safety requirements, including emergency stop circuits. |

IEC 60038 | Provides standard voltages for equipment design. |

EN 14492-2 | Includes overload protection and emergency lowering device provisions. |

ASME B30.16 | Covers safety devices and operational practices for overhead hoists. |

NFPA 70 (NEC) | Specifies wiring and grounding requirements to mitigate electrical hazards. |

You should keep documentation for each inspection, including the date, inspector’s name and signature, hoist serial number, and records of deficiencies and corrective actions. This approach ensures you meet all compliance requirements and maintain a safe workplace.

Training and Safety Best Practices

Operator Training

You need proper training to operate electric hoists safely and efficiently. Training programs teach you how to perform a daily visual inspection, recognize hazards, and follow systematic inspection routines. Many organizations offer specialized courses for hoist operators. The table below shows several options:

Training Program | Description | Target Audience |

|---|---|---|

Bluedrop USA | Comprehensive hoist operator training tailored to operational needs. | Defense, Homeland Security, SAR Teams, Fire Departments, Law Enforcement, Windfarms |

JET Tools | Safety training focusing on OSHA and ASME standards, including hands-on instruction. | General hoist operators and maintenance staff |

DSM Hoist | Customized training classes for hoist operation, maintenance, and rigging. | Facility-specific personnel |

Crane1 | Tailored training addressing specific workplace needs and load handling. | Operators and personnel involved in load movement |

You should complete a training course before using any electric hoist. Training helps you understand preventive measures and the importance of a daily visual inspection. Powerful Machinery recommends ongoing education to keep your skills current and your workplace safe.

Safety Features

Modern electric hoists include advanced safety features that protect you and your team. These features support preventive maintenance and reduce the risk of accidents. The table below highlights important safety features found in high-quality hoists:

Safety Feature | Description |

|---|---|

Real-time Monitoring Systems | Provides immediate feedback on equipment status, alerts to potential issues like overheating or excessive load. |

Automated Limit Switches and Sensors | Prevents over-travel and detects hazardous conditions, enhancing reliability and safety. |

Training Simulators | Offers immersive training experiences to prepare operators for emergencies without real risks. |

Remote Operation Capabilities | Allows operation from a distance, reducing injury risk in hazardous environments. |

You should always check that these safety features work during every systematic inspection. Powerful Machinery’s electric hoists include many of these protections, helping you maintain a safe environment.

Manufacturer Support

You benefit from manufacturer support when you use Powerful Machinery’s products. Support services include technical inspections, genuine replacement parts, and expert supervision. The table below outlines how manufacturer support improves safety and reliability:

Service Type | Benefits |

|---|---|

Mechanical and electrical upgrades | Increased system performance, operational functionality, and safety, improved reliability |

Training | Training in a safe environment, a more productive workforce, and increased job satisfaction |

Technical inspections/audits | Minimize production losses, detection of safety hazards,and increase safety and reliability |

Genuine replacement parts | Ensures safety features are properly functioning, promotes maintenance in the safest way |

Expert supervision | Performs installations in the safest way possible, saving time and resources |

You can access manuals, training materials, and technical support directly from Powerful Machinery. These resources help you perform systematic inspection and preventive maintenance with confidence. Rely on manufacturer support to keep your equipment running safely and efficiently.

Post-Inspection Actions

Repair or Replace

After you complete your electric hoist inspection, you must decide whether to repair or replace the equipment. Using Powerful Machinery-certified parts for all repairs ensures safety and maintains warranty coverage. You should consider several criteria before making your decision:

Repeated failures: If your hoist breaks down often or needs frequent part replacements, replacement may offer better reliability.

Unavailable replacement parts: When you cannot source the required parts, downtime increases. In this case, replacing the hoist is the best option.

Excessive repair costs: If the cost to repair your hoist exceeds 50% to 60% of the price of a new unit, replacement provides better long-term value.

Inspector recommendation: Qualified inspectors may find hidden issues. If they advise replacement due to safety or performance concerns, you should follow their guidance.

Tip: Always use genuine Powerful Machinery-certified parts for repairs. This practice keeps your equipment compliant and ensures optimal performance.

Returning to Service

Once you finish repairs or replacements, you must follow a structured process to safely return your electric hoist to service. Only qualified personnel should perform these steps and give final approval.

Disconnect the hoist from its power source before starting any work.

Secure the hoist and load to prevent movement during repairs.

Replace or repair components such as motors, chains, brakes, electrical wiring, or gears following manufacturer guidelines.

Reassemble the hoist, ensuring all connections are tight and covers are in place.

Test the hoist with a light load first. Check for proper alignment, smooth operation, and correct brake function.

Reconnect the power and perform a full operational test, including limit switches and emergency stops.

Document all actions in your maintenance logbook.

Note: Final approval must come from a qualified technician. This step guarantees your hoist meets safety standards and is ready for reliable operation.

Conclusion

Regular electric hoist inspection and maintenance give you many advantages. You spot minor issues early, prevent costly breakdowns, and keep your team safe. You also meet government standards and improve your equipment’s efficiency.

Identify problems before they disrupt production

Maintain compliance for safety and operational efficiency

Enhance workplace safety and boost productivity

Trust Powerful Machinery’s certified products and support. Use the maintenance checklist, keep detailed records, and ensure your hoists deliver reliable performance every day.

FAQ

What is the recommended frequency for electric hoist inspections?

You should inspect your electric hoist daily for visible damage and monthly for deeper checks. Schedule a comprehensive annual inspection by a qualified technician to ensure safety and compliance.

How do you know when to replace an electric hoist?

You need to replace your hoist if you notice repeated failures, excessive wear, or if repair costs exceed half the price of a new unit. Always follow the advice of a qualified inspector.

Can you use any replacement part for repairs?

Use only Powerful Machinery-certified parts for repairs. Genuine components maintain safety, warranty coverage, and ensure your hoist meets regulatory standards.

What safety features should you check during inspection?

Check for working limit switches, emergency stop buttons, overload protection, and secure safety latches. Powerful Machinery hoists include advanced safety features to protect you and your team.