You will notice a clear difference between eye bolts and screw eyes. Eye bolts feature a threaded shaft and a solid loop, making them suitable for heavy-duty lifting. Screw eyes have a pointed end and a loop, designed for lighter tasks. Choosing the right fastener impacts safety and efficiency in your project.

Type | Load Capacity | Applications | Safety Impact |

|---|---|---|---|

Eye Bolts | High | Heavy-duty lifting | Provides secure points for chains, ropes, or cables |

Screw Eyes | Low | Lighter applications | Less secure, suitable for non-critical uses |

Screw Eyes vs Eye Bolts is a critical comparison for anyone working in construction, marine, or industrial environments. Powerful Machinery offers certified eye bolts that ensure secure connections and reliable performance.

Key Takeaways

Eye bolts are designed for heavy-duty lifting. They feature a threaded shaft and a solid loop, making them suitable for securing heavy loads safely.

Screw eyes are ideal for lighter applications. Their pointed end allows for easy installation into wood or soft materials, making them perfect for hanging decorations or small fixtures.

Always match the fastener to your project’s load requirements. Using the correct type ensures safety and efficiency in your tasks.

Proper installation is crucial for both eye bolts and screw eyes. Follow the recommended steps to ensure secure and reliable connections.

Choose materials wisely. Stainless steel eye bolts offer high corrosion resistance, making them suitable for outdoor and marine environments.

Eye Bolt vs Eye Screw

Eye Bolt Overview

You will find that an eye bolt serves as a heavy-duty fastener designed for lifting and securing loads. The core design features a threaded shank and a solid circular eye at one end. This configuration provides a fixed attachment point for chains, ropes, or lifting equipment.

You can choose from several types, including standard eye bolts, shouldered eye bolts, screw eye bolts, and lifting eye bolts. Each type addresses specific load requirements and installation methods.

Load capacity stands out as a primary consideration. You must always match the rated load capacity of the eye bolt to the weight of your application.

Proper installation ensures safety. You should fasten the eye bolt securely and align it correctly to prevent failure.

Eye bolts come in a range of materials. You will see options such as standard steel, stainless steel, galvanized steel, and alloy steel. Stainless steel eye bolts, like those from Powerful Machinery, offer superior corrosion resistance and durability, making them ideal for marine and outdoor environments.

Powerful Machinery uses a meticulous manufacturing process to deliver high-performance eye bolts. The process begins with careful material selection, followed by precision cutting, forging, threading, and heat treatment.

Each eye bolt undergoes surface treatment for corrosion resistance and passes rigorous quality control checks. This attention to detail ensures you receive a product that meets international safety standards and performs reliably in demanding conditions.

Tip: Always inspect your eye bolt before use. Look for signs of wear or damage to maintain safety during lifting operations.

Screw Eye Overview

A screw eye, sometimes called an eye screw, is a versatile fastener for lighter-duty applications. You will notice its design includes a pointed end for direct installation into wood or other soft materials and a looped eye for attaching wires, ropes, or cables. Unlike an eye bolt, a screw eye does not require a pre-threaded hole or nut.

Design Feature | Description |

|---|---|

PRIMARY USE | Commonly used on gates, DIY projects, and light fixtures |

ROBUST DESIGN | Durable construction for reliability in various settings |

SEVERAL FINISHES/SIZES | Available in multiple finishes and sizes |

MATERIAL COMPOSITION | Steel screw eyes provide long-lasting strength |

WEATHER RESISTANCE | WeatherGuard finishes enhance durability in harsh conditions |

You can use a screw eye as a connection point for ropes, cables, or wires. Most commercial screw eyes use zinc-plated steel, which offers a smooth surface and some corrosion resistance.

You will find them in a variety of sizes and finishes to suit different needs. The installation process is simple. You twist the eye screw directly into the surface, making it a popular choice for quick, non-critical fastening tasks.

Key Differences

When you compare screw eyes vs eye bolts, you will see several important distinctions in design, function, and application. The table below highlights the main differences:

Feature | Eye Bolt | Eye Screw |

|---|---|---|

Purpose | Heavy-duty fastener for lifting and securing loads | Lightweight applications, like hanging items |

Installation Process | Requires a pre-threaded hole or nut, uses washers | Screws directly into surfaces without pre-drilling |

Size and Load Capacity | Larger, higher load capacity, various sizes | Smaller, lower weight capacity, fewer sizes |

Material | Durable materials like stainless steel | Often made from softer materials like plastic or zinc-plated steel |

Applications | Used in marine equipment, crane operation | Best for DIY projects like hanging decorations |

You should select an eye bolt when your project demands strength, reliability, and compliance with safety standards.

Powerful Machinery’s stainless steel eye bolts provide the durability and load capacity required for construction, marine, and industrial environments. If you need a fastener for lighter tasks, such as hanging planters or securing small items, an eye screw offers a quick and easy solution.

The debate of screw eyes vs eye bolts centers on safety and performance. You must consider the load, installation method, and environment before making your choice. Screw eyes vs eye bolts is not just a matter of preference; it is a decision that impacts the integrity of your project.

Powerful Machinery’s expertise in manufacturing ensures that every eye bolt meets the highest standards, giving you confidence in critical applications.

You will notice that screw eyes vs eye bolts also differ in material options and finishes. Eye bolts often use stainless steel or alloy steel for maximum strength, while screw eyes typically use zinc-plated steel for general use.

When you evaluate screw eyes vs eye bolts, always match the fastener to your specific requirements for safety and efficiency.

Design and Installation

Eye Bolt Design & Installation

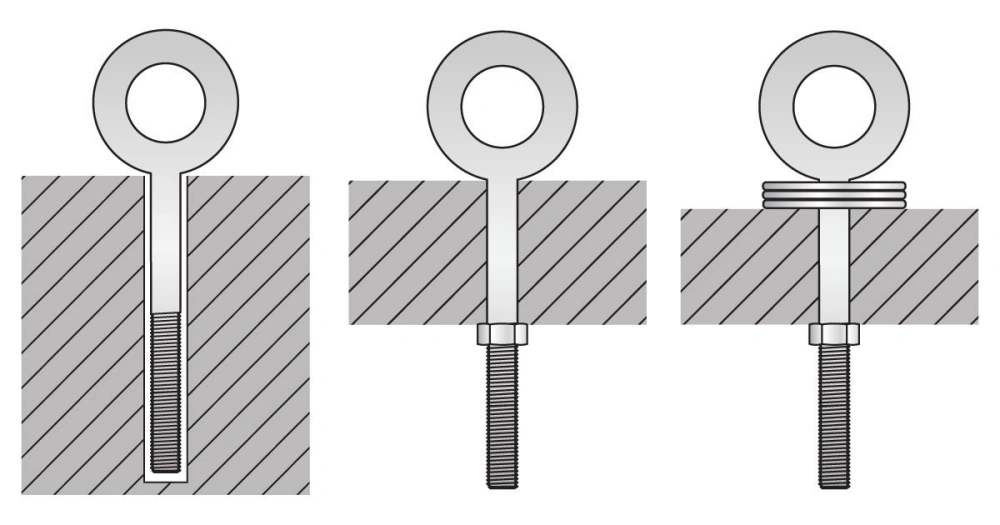

You will notice that an eye bolt features a solid loop and a threaded shaft, engineered for strength and reliability. Powerful Machinery’s Stainless Steel Eye Bolts stand out due to their high-quality stainless steel construction, sharp tapered points, and lag screw threads.

These features make installation straightforward and secure, even in demanding environments.

Feature | Benefit |

|---|---|

Sharp, tapered points | Easy screwing into wood |

Lag screw threads | Strong, secure attachment |

High-quality stainless steel | Durability in harsh conditions |

When you prepare for installation, you should follow these steps:

Select the right eye bolt for your load and surface.

Inspect the mounting surface to confirm it is flat and strong.

Drill and tap a hole that matches the bolt’s diameter if you work with metal.

Install the eye bolt by hand-tightening and ensuring proper alignment.

Test the connection to verify stability.

Tip: Always check that the shoulder of the eye bolt sits flush against the surface for maximum safety.

You must ensure the load aligns with the eye bolt to prevent side loading. For untapped through-holes, use longer shoulder eye bolts and confirm full contact with the surface. Powerful Machinery’s products simplify installation methods and provide peace of mind in critical lifting tasks.

Screw Eye Design & Installation

A screw eye, also known as an eye screw, offers a practical solution for lighter loads. You will find that installation methods differ from those of an eye bolt. The screw eye has a pointed end and a loop, making it ideal for wood and other soft materials.

To install a screw eye, you should:

Drill a pilot hole to prevent splitting.

Start the screw eye by hand.

Use a drill-driver with an open hook for efficient installation.

You can apply a small amount of super glue to the tip of the screw eye to prevent it from twisting out. For best results, use an awl to open the pilot hole slightly before inserting the screw eye. These installation methods help you achieve a secure fit and reduce the risk of material damage.

Note: Eye screws require less alignment than eye bolts, but you should always confirm the pilot hole size matches the screw eye diameter.

You will see that screw eyes are suitable for hanging decorations, securing wires, or light fixtures. Their simple installation makes them a popular choice for quick projects.

Load Capacity & Materials

Strength Comparison

When you select a fastener, you must consider its strength and load capacity. Eye bolts deliver high strength and can handle heavy loads, especially when you use forged steel models. According to ASTM A 489, forged eye bolts have rated capacities for in-line pulls.

These ratings apply to carbon steel eye bolts at temperatures between 30°F and 275°F. You must ensure the correct engagement length in the base material to achieve the rated load capacity.

Forged steel eye bolts provide the highest strength for lifting and securing.

Stainless steel eye bolts offer reliable strength, but their load ratings are generally lower than forged steel.

Screw eyes are suitable for lighter loads and do not meet the same capacity standards as eye bolts.

Always match the load capacity of your fastener to the weight of your application. Never exceed the rated capacity to maintain safety.

Material | Load Rating Comparison | Corrosion Resistance | Manufacturing Process |

|---|---|---|---|

Stainless Steel | Generally lower | Better | Investment cast |

Forged Steel | Typically higher | Lower | Forged |

You will find that grade 5 steel eye bolts can handle more load than standard mild steel. Stainless steel provides better corrosion resistance, but you should use forged steel when maximum strength is required.

Material Options

The materials of the eye bolt or screw eye affect both durability and corrosion resistance. Stainless steel stands out for its high corrosion resistance, making it ideal for marine and outdoor use. Zinc-plated high-carbon steel offers moderate corrosion resistance and works well for general applications.

Material Type | Durability Aspect |

|---|---|

Stainless Steel | High corrosion resistance |

Zinc-Plated High-Carbon Steel | Moderate corrosion resistance |

For the best performance in harsh environments, you should choose stainless steel 316. This material resists salt water and chlorine, making it perfect for marine projects. Stainless steel 18-8 also provides strong corrosion resistance for general hardware use.

Hot-dipped galvanized steel gives very good protection due to its thick coating. Zinc-plated steel offers moderate resistance and suits indoor or dry conditions.

Tip: For outdoor or marine applications, always select a fastener with high corrosion resistance to ensure long-term strength and safety.

Powerful Machinery’s certified stainless steel eye bolts meet international standards and deliver reliable load capacity, strength, and durability. You can trust these products for demanding lifting and rigging tasks in any environment.

Applications & Selection Guide

Typical Uses

You will find that eye bolts and screw eyes serve a wide range of applications across industries. Eye bolts act as a heavy-duty fastener in construction projects, marine environments, and industrial settings.

You often use them for suspending overhead structures, attaching chains or ropes, and rigging applications. The table below highlights some of the most common applications for eye bolts:

Application Type | Description |

|---|---|

Lifting and Rigging | Eye bolts serve as secure attachment points for lifting equipment, enabling the lifting of heavy loads. |

Securing Loads | They provide anchor points for securing devices during transportation, preventing load movement. |

Construction and Building | Used for anchoring scaffolding, securing safety nets, and providing attachment points for hoists. |

Marine Applications | Made from corrosion-resistant materials, they secure equipment and attach lines to boats and ships. |

Screw eyes, on the other hand, excel in lighter-duty applications. You can use them for hanging and securing objects in wood or drywall, such as picture frames, mirrors, and small shelves.

Many DIY projects and home improvement tasks rely on screw eyes for creating hanging points for curtains, planters, and decorative elements. Outdoor and indoor applications include hanging garden ornaments, bird feeders, and lights.

How to Choose?

Selecting the right fastener depends on your specific application. You should always consider the load requirements, installation surface, and environment. For heavy-duty needs, such as lifting, securing loads, or use in marine and construction projects, choose an eye bolt made from stainless steel.

Powerful Machinery’s Stainless Steel Eye Bolts provide the strength and corrosion resistance required for demanding applications.

When you select an eye bolt for load-bearing applications, check if you need a shouldered or non-shouldered type. Shouldered eye bolts offer more versatility and safety, especially for angled lifts.

Non-shouldered eye bolts work best for vertical lifts only. Always account for the angle of the sling, as the weight capacity decreases with increased angle. Make sure the eye bolt is secured against rotation during lifting.

For lighter applications, such as hanging decorations or small fixtures, screw eyes provide a quick and easy solution. You can install them directly into wood or drywall without special tools. Always match the fastener to your application to ensure safety and efficiency.

Tip: For any application involving lifting or securing heavy loads, always use a certified heavy-duty fastener like Powerful Machinery’s Stainless Steel Eye Bolts to guarantee safety and reliability.

Conclusion

You can see clear differences between screw eyes and eye bolts. The table below highlights these distinctions:

Feature | Screw Eye | Eye Bolt |

|---|---|---|

Design and Structure | Small, screw-like fastener with a loop | Larger, bolt-like fastener with a circular eyelet |

Installation | Rotates into pre-drilled hole; lighter loads | Threads into pre-tapped hole or uses nuts; heavier loads |

Load Capacity | Lower, for lightweight tasks | Higher, for heavy-duty use |

Applications | Hanging small items, DIY projects | Lifting, securing machinery, and construction |

To ensure safety and efficiency, always:

Check weight capacity and material stability.

Use proper tools and wear safety gear.

Select certified eye bolts with clear markings for critical projects.

Powerful Machinery’s Stainless Steel Eye Bolts deliver durability, reliability, and compliance with international standards, making them the best choice for demanding applications.

FAQ

What is the main difference between an eye bolt and a screw eye?

You will see that an eye bolt has a threaded shaft for heavy-duty loads. A screw eye features a pointed end for lighter tasks. Eye bolts suit lifting and rigging. Screw eyes work best for hanging or securing small items.

Can you use eye bolts outdoors or in marine environments?

You can use stainless steel eye bolts outdoors and in marine settings. Powerful Machinery’s stainless steel eye bolts resist corrosion and rust, making them ideal for harsh environments.

Tip: Always choose certified stainless steel for maximum durability.

How do you install an eye bolt correctly?

You should drill a hole matching the bolt’s diameter. Insert the eye bolt and tighten it securely. Make sure the shoulder sits flush against the surface. Test the connection before use.

Step | Action | Purpose |

|---|---|---|

1 | Drill hole | Fit bolt |

2 | Insert bolt | Secure |

3 | Tighten | Ensure safety |

What load can a screw eye handle?

You will find that screw eyes handle light loads only. They suit hanging decorations, small fixtures, or wires. Never use screw eyes for lifting or securing heavy objects.

Note: Always check the manufacturer’s rating before use.