Galvanized Steel Wire Rope Manufacturer

Durable, corrosion-resistant galvanized wire ropes for lifting, rigging, and marine industries — supplied directly from our certified factory.

Technical Specifications of Galvanized Steel Rope Wire

We provide a full range of galvanized steel wire ropes in multiple constructions and diameters to meet diverse lifting and structural requirements.

| Construction | Core Type | Tensile Strength (MPA) | Common Applications |

|---|---|---|---|

| 1×7 | Steel Core | 1370- 1770 | Structural stays, guy wires |

| 1×19 | Steel Core | 1370- 1960 | Marine rigging, suspension |

| 6×7+FC | Fibre Core | 1570- 1960 | Light lifting, fencing |

| 6×7+IWS | Steel Strand Core | 1570- 1960 | Winch, general purpose |

| 6x9W+FC | Fibre Core | 1570- 1960 | Hoisting, agriculture |

| 6x9W+IWR | Wire Rope Core | 1570- 1960 | Marine hoists, winches |

| 6×19+FC | Fibre Core | 1570- 1960 | General lifting and rigging |

| 6×19+IWR | Wire Rope Core | 1570- 1960 | Cranes, elevators |

| 6×19+IWS | Wire Strand Core | 1570- 1960 | Construction, winches |

| 6×37+FC | Fibre Core | 1570- 1960 | Flexible hoisting rope |

| 6×37+IWR | Wire Rope Core | 1570- 1960 | Mining, cranes |

| 6×37+IWS | Wire Strand Core | 1570- 1960 | Heavy-duty applications |

| 6x19S+FC | Fibre Core | 1570- 1960 | General rigging |

| 6x19S+IWR | Wire Rope Core | 1570- 1960 | Cranes, winches |

| 6x19W+FC | Fibre Core | 1570- 1960 | Winching and pulling |

| 6x19W+IWR | Wire Rope Core | 1570- 1960 | Construction, lifting |

| 6x25Fi+FC | Fibre Core | 1570- 1960 | Elevator ropes, cranes |

| 6x25Fi+IWR | Wire Rope Core | 1570- 1960 | Hoisting, mining |

| 6x26SW+FC | Fibre Core | 1570- 1960 | General lifting |

| 6x26SW+IWR | Wire Rope Core | 1570- 1960 | Rigging and construction |

| 6x29Fi+FC | Fibre Core | 1570- 1960 | Hoisting, marine |

| 6x29Fi+IWR | Wire Rope Core | 1570- 1960 | Lifting, transportation |

| 6x31SW+FC | Fibre Core | 1570- 1960 | Winching, agriculture |

| 6x31SW+IWR | Wire Rope Core | 1570- 1960 | Construction cranes |

| 6x36SW+FC | Fibre Core | 1570- 1960 | Flexible hoisting use |

| 6x36SW+IWR | Wire Rope Core | 1570- 1960 | Marine and industrial use |

| 6x37S+FC | Fibre Core | 1570- 1960 | General lifting |

| 6x37S+IWR | Wire Rope Core | 1570- 1960 | Cranes, mining equipment |

| 6x41SW+FC | Fibre Core | 1570- 1960 | Hoisting, marine |

| 6x41SW+IWR | Wire Rope Core | 1570- 1960 | Lifting, rigging |

| 6x49SWS+FC | Fibre Core | 1570- 1960 | Flexible wire rope |

| 6x49SWS+IWR | Wire Rope Core | 1570- 1960 | Heavy-duty lifting |

| 6x55SWS+FC | Fibre Core | 1570- 1960 | Elevator, industrial use |

| 6x55SWS+IWR | Wire Rope Core | 1570- 1960 | Cranes, winches |

| 6×12+7FC | Fibre Core | 1570- 1770 | Construction rigging |

| 6×24+7FC | Fibre Core | 1570- 1770 | Light lifting |

| 8x25Fi+FC | Fibre Core | 1570- 1960 | High-flex applications |

| 8x25Fi+IWR | Wire Rope Core | 1570- 1960 | Mining, cranes |

| 8x26SW+FC | Fibre Core | 1570- 1960 | Winching |

| 8x26SW+IWR | Wire Rope Core | 1570- 1960 | Construction |

| 8x31SW+FC | Fibre Core | 1570- 1960 | Lifting machinery |

| 8x31SW+IWR | Wire Rope Core | 1570- 1960 | Heavy industry |

| 8x36SW+FC | Fibre Core | 1570- 1960 | Marine equipment |

| 8x36SW+IWR | Wire Rope Core | 1570- 1960 | Cranes |

| 8x41SW+FC | Fibre Core | 1570- 1960 | General lifting |

| 8x41SW+IWR | Wire Rope Core | 1570- 1960 | Construction |

| 8x49SWS+FC | Fibre Core | 1570- 1960 | Hoisting ropes |

| 8x49SWS+IWR | Wire Rope Core | 1570- 1960 | Mining, cranes |

| 8x55SWS+FC | Fibre Core | 1570- 1960 | Elevator, marine |

| 8x55SWS+IWR | Wire Rope Core | 1570- 1960 | Industrial lifting |

| 18×7+FC | Fibre Core | 1570- 1960 | Rotation-resistant, cranes |

| 18×7+IWR | Wire Rope Core | 1570- 1960 | Hoisting, elevators |

| 18×19+FC | Fibre Core | 1570- 1960 | Rotation-resistant applications |

| 18×19+IWR | Wire Rope Core | 1570- 1960 | Tower cranes, lifts |

What Is Galvanized Steel Wire Rope?

Galvanized steel wire rope is composed of high-carbon steel strands with a protective zinc coating. This process enhances corrosion resistance and provides exceptional strength for industrial use.

Our galvanized wire ropes are widely applied in cranes, winches, construction hoists, and marine projects.

Each rope undergoes precise stranding and uniform galvanization to ensure long-term performance even in harsh outdoor conditions.

Applications of Galvanized Steel Rope Wire

Galvanized steel wire ropes are widely used across construction, marine, mining, and industrial sectors. Their corrosion resistance, high tensile strength, and long service life make them a reliable solution for both lifting and structural purposes.

Lifting and Hoisting Equipment

Galvanized steel wire ropes are essential in cranes, hoists, and elevators, where they provide durable and safe lifting performance. From construction cranes and shipyard winches to mining hoists, these ropes withstand repeated stress, heavy loads, and harsh outdoor conditions without losing strength.

Recommended Construction: 6×19+IWR, 6x36SW+FC, 8x25Fi+IWR

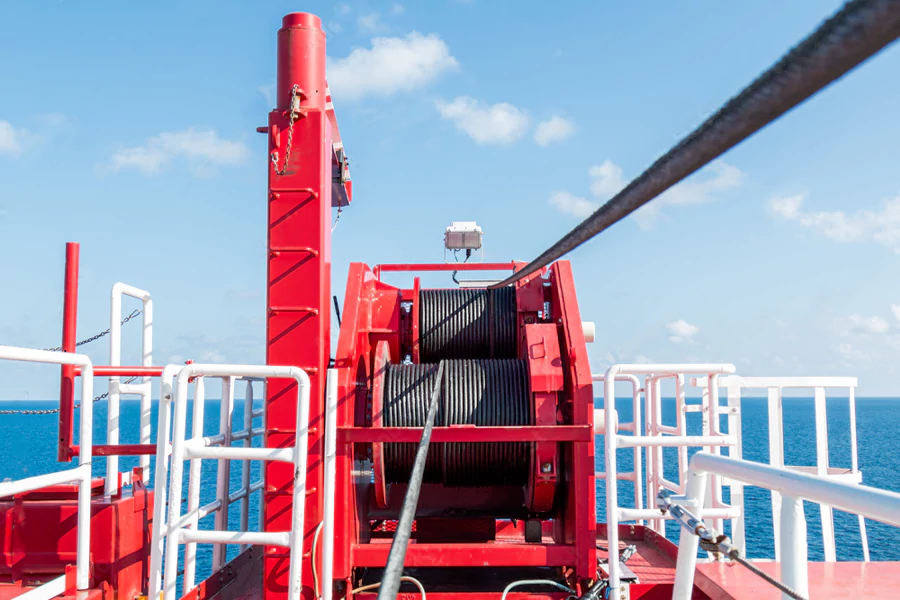

Marine and Offshore Applications

In marine environments, galvanized ropes are used for mooring, towing, and anchor lines. Their zinc coating offers superior protection against saltwater corrosion, ensuring reliability for ships, docks, and offshore platforms.

Recommended Constructions: 6×37+IWR, 8x41SW+IWR

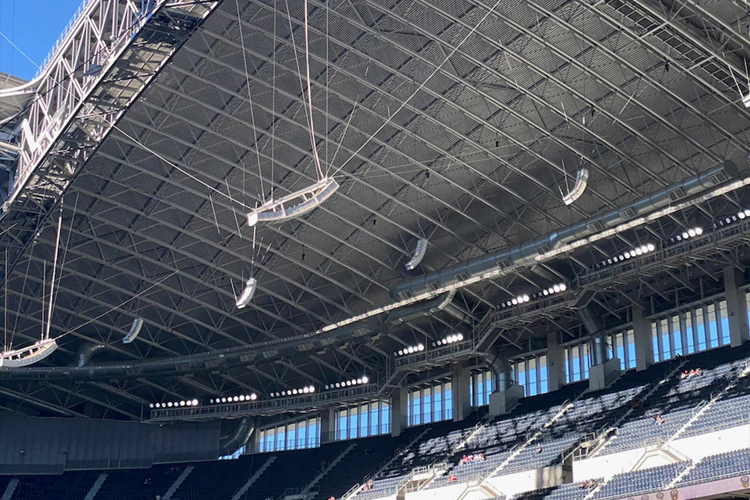

Structural and Architectural Uses

Galvanized wire ropes serve as support cables in bridges, stadium roofs, and tension structures. They combine strength with flexibility, maintaining structural integrity under dynamic loads and environmental exposure.

Industrial and Mining Operations

In mining, manufacturing, and processing plants, galvanized ropes are used for conveyors, elevators, and winches, where long-term fatigue resistance is crucial.

Recommended Constructions: 6x26SW+IWR, 8x31SW+IWR

Why Choose Our Factory

As a leading galvanized steel wire rope manufacturer with over 20 years of experience, we ensure each product meets international standards and delivers exceptional performance for industrial, construction, and marine applications.

We operate multiple ISO-certified production lines, capable of manufacturing galvanized, stainless steel, and ungalvanized wire ropes ranging from 0.5 mm to 60 mm in diameter. Each rope is precisely stranded and lubricated for maximum durability, flexibility, and load-bearing capacity.

Our factory holds major global certifications, including ISO 9001, CE, Lloyd’s Register (LR), DNV-GL, ABS, BV, and CCS, ensuring compliance with the most demanding international standards and marine classifications.

With exports to over 80 countries across Europe, North America, the Middle East, and Southeast Asia, we combine advanced manufacturing, efficient logistics, and large inventory capacity to guarantee short lead times and on-time delivery for every order.

Quality Assurance & Standards

All our galvanized steel wire ropes strictly comply with EN 12385 and ISO 2408 international standards, ensuring consistency, safety, and long service life.

Each batch undergoes tensile strength, torsion, zinc coating thickness, and bend fatigue tests to verify mechanical integrity and corrosion resistance.

We maintain full traceability from raw material selection to final inspection, guaranteeing every rope delivers reliable performance under demanding industrial, construction, and marine conditions.

Packaging & Delivery

Our galvanized steel wire ropes are packed on wooden reels or coils with waterproof wrapping. Custom labels and export pallets are available. We deliver from major Chinese ports such as Qingdao and Shanghai.

FAQs of Galvanized Steel Rope Wire

What is galvanized steel wire rope used for?

Galvanized steel wire rope is widely used in construction, lifting, marine, and industrial applications where both high tensile strength and corrosion resistance are required.

It serves in cranes, hoists, winches, elevators, cable barriers, guy wires, and structural supports.

The zinc coating protects the rope from rust and moisture, making it ideal for outdoor or marine environments such as ports, bridges, and ships. It is also used for security cables and mechanical pulling systems in factories and infrastructure projects.

Can I order custom diameters or coatings?

Yes. We offer custom manufacturing according to your technical requirements. You can specify the diameter (0.5 mm to 60 mm), construction (e.g., 6×19, 6×37, 7×19, etc.), core type (FC or IWRC), and surface treatment.

In addition to standard hot-dip galvanized finishes, we also provide PVC or nylon coating, vinyl coating, and bright or ungalvanized finishes for specific applications.

Our engineering team can help you select the most suitable configuration based on your load requirements, operating environment, and budget.

How is the price calculated?

The price of galvanized steel wire rope depends on several key factors:

- Diameter and construction (e.g., 6×19, 6×37, 7×19, etc.)

- Material grade (carbon content and wire quality)

- Surface finish (galvanized, vinyl coated, stainless steel, etc.)

- Order quantity and packaging type (coil, reel, drum)

- Delivery terms (FOB, CIF, or EXW)

For bulk orders, we offer factory-direct pricing with volume discounts. You can send us your specifications or drawings, and our sales team will provide a detailed quotation within 24 hours.

What’s the HS code for galvanized wire rope?

The HS Code for galvanized steel wire rope is typically 7312.10, which covers “Stranded wire, ropes and cables, of iron or steel, not electrically insulated.”

However, the exact code may vary slightly depending on the rope construction and coating type according to your country’s customs regulations.

We include the correct HS code and certificate of origin (CO/FORM E) with all shipments to ensure smooth customs clearance and export documentation.

Request a Quote

Looking for a trusted galvanized steel wire rope supplier? Contact us today for bulk orders and customized solutions.