The hoist sling chains assemblies market reached a market size of USD 4.7 billion in 2024, with projections estimating it will grow to USD 7.7 billion by 2030. Multiple growth drivers fuel this expansion, including industrialization, urbanization, and construction activity, alongside technological advancements and strict safety regulations.

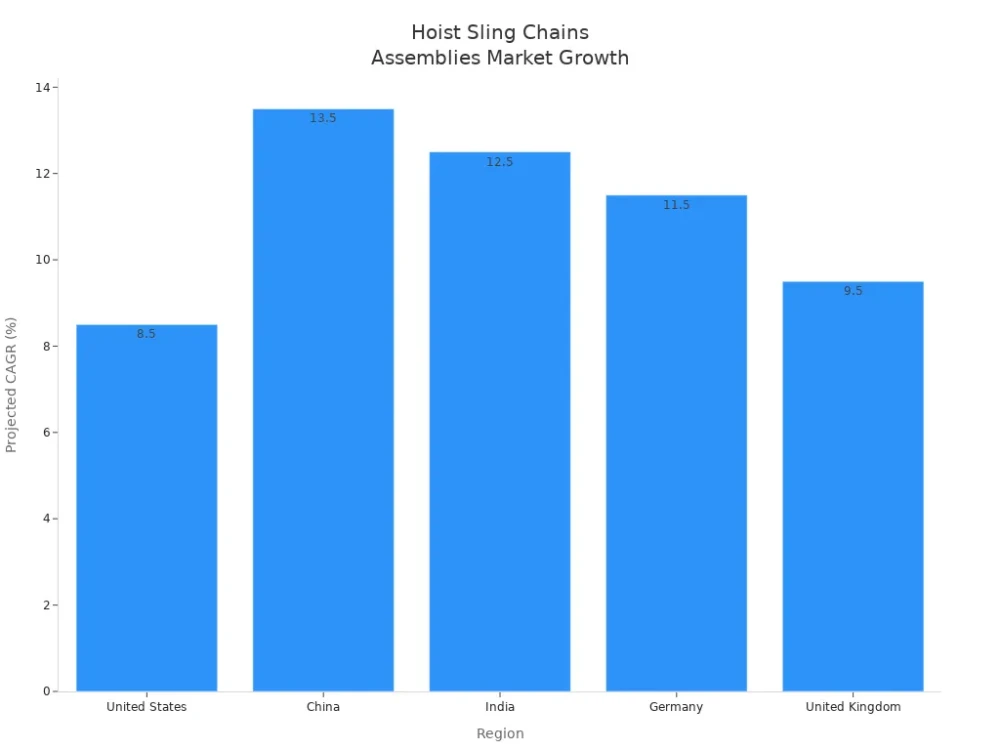

Key market segments span product types such as Chain Slings, Hooks and Shackles, and Lifting Hoists, with construction leading among end users. Automation, IoT integration, sustainability, and safety improvements shape current trends. Regional growth rates vary, as shown below:

Key Takeaways

The hoist sling chains assemblies market is projected to grow from USD 4.7 billion in 2024 to USD 7.7 billion by 2030, driven by industrialization and construction demand.

Technological advancements, such as IoT integration and automation, enhance operational efficiency and safety in lifting solutions.

Safety regulations, like OSHA and ASME standards, are crucial for market growth, ensuring compliance and reliability in lifting operations.

Asia Pacific leads the market due to rapid urbanization and infrastructure investments, while North America shows strong growth potential with a projected CAGR of 10.6% by 2025.

Customization and sustainability trends are shaping the future of the market, as companies focus on tailored solutions and eco-friendly materials.

Market Size & Forecasts

Current Market Value

The hoist sling chains assemblies market has shown remarkable expansion in recent years. In 2024, the market size reached 1.962 billion USD. This figure reflects a steady increase from previous years, driven by rising demand in construction, manufacturing, and logistics.

The market size and share have grown consistently, with the value in 2018 at 114 million USD and projected to reach 168.7 million USD by 2025. This upward trend highlights the robust nature of the industry.

Key points on current market value include:

The market was valued at 1.962 billion USD in 2024.

In 2018, the market size stood at 114 million USD.

By 2025, projections indicate a value of 168.7 million USD.

The market has experienced a compound annual growth rate of 5.5% from 2019 to 2025.

This consistent growth demonstrates the increasing reliance on advanced lifting solutions across multiple sectors.

Growth Projections

Industry forecasts suggest that the hoist sling chains assemblies market will continue its upward trajectory. Analysts expect the market to reach 2.862 billion USD by 2035. The following table summarizes the projected market size and CAGR over the next several years:

Year | Market Size (in billion USD) | CAGR (%) |

|---|---|---|

2023 | 2.5 | 4.0 |

2028 | 3.2 | 4.0 |

The market size and share are set to expand at a steady pace, with a forecast CAGR of 4.0% through 2028. This growth is fueled by ongoing investments in infrastructure, technological advancements, and the adoption of safer, more efficient lifting equipment.

The market outlook remains positive, with forecasts indicating sustained demand and innovation.

Regional Market Shares

Regional differences play a significant role in the market’s development. Asia Pacific leads the hoist sling chains assemblies market, supported by rapid urbanization and major investments in infrastructure.

North America also shows strong performance, with a projected CAGR of 10.6% by 2025. Asia Pacific is expected to maintain its leadership, with a CAGR of 9.4% by 2025.

Key regional insights:

North America: Projected CAGR of 10.6% by 2025.

Asia Pacific: Led the market in 2017 and continues to grow at a CAGR of 9.4%.

The APAC region benefits from economic development and large-scale construction projects, especially in countries like India.

Note: Regional market shares reflect differences in economic growth, urbanization, and infrastructure investment. These factors drive demand for advanced lifting solutions and contribute to the overall market size.

The market size and share across regions highlight the importance of local economic conditions and industry needs. As infrastructure projects expand, especially in the Asia Pacific, the market will likely see continued regional growth and diversification.

Market Drivers & Restraints

Industrial & Construction Demand

Industrialization and expansion in the construction sector continue to drive the hoist sling chains assemblies market. The construction sector relies on robust lifting solutions for infrastructure projects, manufacturing plants, and logistics hubs.

Demand estimates for sling chain assemblies remain high as industries seek reliable equipment for heavy-duty operations. The market benefits from ongoing investments in urban development and industrial facilities, which require advanced lifting products to ensure efficiency and safety.

Technology & Innovation

Technological advancements shape the market by introducing smart features and innovative materials. Companies now offer IoT-enabled hoist sling chains for real-time monitoring and predictive maintenance. These innovations improve operational reliability and reduce downtime.

The industry also explores new materials to enhance strength and durability, meeting the evolving needs of the construction sector and other demanding environments.

Safety & Compliance

Safety standards and regulatory compliance play a crucial role in market growth. Strict regulations, such as OSHA 1910.184 and ASME B30.9, set requirements for the fabrication, inspection, and testing of lifting slings. The table below highlights key safety regulations:

Regulation | Description |

|---|---|

OSHA 1910.184 | Governs the use, inspection, and removal criteria for lifting slings in general industry. |

ASME B30.9 | Guides the fabrication, marking, and testing of slings, including properties of different chain grades. |

Powerful Machinery demonstrates industry leadership by adhering to international safety standards and earning certifications from organizations such as ISO, TUV Rheinland, and OSHA. This commitment ensures product reliability and customer trust.

Sustainability Trends

Sustainability trends influence the market as companies respond to environmental concerns and regulatory initiatives. The table below summarizes emerging trends:

Trend/Response | Description |

|---|---|

Launch of Smart Hoist Sling Chains | Introduction of IoT-enabled hoist sling chains for real-time monitoring and predictive maintenance. |

Regulatory Compliance Initiatives | Companies are focusing on compliance with international safety and quality standards to enhance market credibility. |

Innovative Material Use | Development of hoist sling chains using advanced materials for increased strength and durability. |

Market Challenges

The hoist sling chains assemblies market faces several challenges. Price competition, supply chain dependency, and commodity risk impact profitability and stability. The table below outlines these challenges and mitigation strategies:

Challenge | Description | Mitigation Strategies |

|---|---|---|

Price Competition | Intense pricing pressures from established players and low-cost imports can erode margins. | Focus on product differentiation through advanced features, safety certifications, and brand reputation to justify premium pricing. |

Supply Chain Dependency | Reliance on specific raw materials or suppliers may cause disruptions. | Develop multi-vendor sourcing strategies, establish strategic inventory buffers, and explore local sourcing options. |

Commodity Risk | Fluctuations in raw material prices (e.g., steel alloys) impact cost structures. | Hedge raw material procurement, lock-in long-term supply contracts, and innovate with alternative materials where feasible. |

Companies that prioritize safety, innovation, and sustainability position themselves for long-term success in a competitive market.

Hoist Sling Chains Assemblies Market Segmentation

By Product Type

The hoist sling chains assemblies market features a diverse range of product types designed for specific lifting and handling tasks. Chain Slings stand out as a leading product, especially those manufactured by Powerful Machinery.

These slings offer multiple configurations, including single, double, triple, and quadruple leg designs. The following table outlines the main product type segments and their typical applications:

Grade | Product Type | Application | Common Use |

|---|---|---|---|

Grade 80 | One-Leg Sling | Single leg lifting, load distribution | Construction, general lifting, rigging |

Grade 80 | Four-Leg Sling | Four-point lifting, balanced load handling | Heavy-duty lifting, large loads |

Grade 100 | Round Binding Sling | Securing loads, flexible for various shapes | Binding irregular objects |

Grade 100 | Round Sling | General-purpose lifting, flexible load handling | Standard loads, general lifting |

Grade 100 | Three-Leg Sling | Stability for complex loads | Large, irregular loads |

Grade 100 | Two-Leg Sling | Even load distribution, medium-duty tasks | Construction, industrial lifting |

Grade 100 | Four-Leg Sling | Heavy-duty lifting, optimal load distribution | Mining, heavy construction, industrial tasks |

Powerful Machinery’s Chain Slings provide reliability and adaptability, making them a preferred choice across segments.

By Capacity & Material

Capacity and material selection play a critical role in the performance and adoption of sling chain assemblies. Manufacturers focus on three main factors:

Material durability ensures resistance to wear, corrosion, and fatigue, which improves safety and efficiency.

Load capacity determines the maximum weight the sling chain assemblies can handle, meeting strict safety standards.

Design flexibility allows compatibility with various hoist types and supports customization for unique lifting requirements.

Powerful Machinery offers chain slings in Grade 80 and Grade 100, providing options for different market sizes and heavy-duty applications.

By End-User Industry

The market serves a wide range of industries, each with specific equipment needs. Construction remains a dominant segment, requiring robust sling chain assemblies for infrastructure and building projects.

Manufacturing, shipping, and mining also rely on these products for safe and efficient material handling. Powerful Machinery customizes chain slings to meet the demands of each industry, ensuring optimal performance and safety.

By Region

Regional segments influence the market size and product demand. Asia Pacific leads in adoption due to rapid industrial growth and large-scale construction projects. North America and Europe follow, driven by advanced safety standards and technological innovation.

Other regions, including Latin America and the Middle East, show increasing demand for sling chain assemblies as infrastructure expands.

Note: Versatility and customization options make chain slings suitable for diverse industries and regions, supporting growth in the hoist sling chains assemblies market.

Market Trends

Automation & IoT

Automation and IoT continue to transform the hoist sling chains assemblies market. Manufacturers now integrate robotic-assisted lifting and remote operation capabilities, which improve safety in hazardous environments.

Industry 4.0 trends drive the use of data analytics and machine learning, optimizing operational efficiency and predictive maintenance. The following table highlights the impact of automation and IoT:

Aspect | Description |

|---|---|

Automation Integration | Robotic-assisted lifting and remote operation capabilities enhance safety in hazardous environments. |

Industry 4.0 Trends | Data analytics and machine learning optimize operational efficiency and predictive maintenance. |

Cost Savings | Improved lifecycle management leads to significant cost reductions. |

IoT-enabled chains allow for real-time monitoring of load conditions. Innovations in smart technology reduce downtime and workplace accidents by up to 30%. Powerful Machinery incorporates these advancements into its product type offerings, delivering reliable lifting solutions for construction and industrial sectors.

Eco-Friendly Materials

The market is witnessing a shift toward sustainable and eco-friendly materials in hoist sling chain assemblies. Buyers increasingly prefer products that meet environmental standards, which enhances brand loyalty and influences purchasing decisions.

Powerful Machinery responds to this trend by offering product type options that use advanced materials, supporting growth and sustainability in the market.

Safety & Traceability

Safety and traceability remain top priorities for manufacturers and end users. Companies implement digital inspection tools to support predictive maintenance strategies. Compliance with safety protocols increases industry-wide standardization.

Smart lifting solutions enhance reliability and safety in operations through load monitoring.

Advancement Type | Description |

|---|---|

Digital Inspection Tools | Support predictive maintenance strategies. |

Compliance with Safety Protocols | Increases industry-wide standardization. |

Smart Lifting Solutions | Enhances reliability and safety in operations through load monitoring. |

Powerful Machinery’s product range meets strict safety requirements, ensuring traceability and confidence for customers in construction and other demanding industries.

Custom Solutions

Customization drives innovation in the hoist sling chains assemblies market. Manufacturers design product type options to meet unique lifting needs across various sectors. Powerful Machinery excels in delivering tailored solutions, offering chain slings in multiple configurations and grades.

Their commitment to customization ensures that each product matches specific operational requirements, supporting efficiency and safety for every application.

Note: The integration of automation, eco-friendly materials, advanced safety features, and custom solutions shapes the future of the hoist sling chains assemblies market. Companies that prioritize these trends position themselves for continued growth and leadership.

Competitive Landscape

Leading Companies

The hoist sling chains assemblies market features several prominent companies that set industry standards for quality and reliability. These organizations have built strong reputations through consistent performance and adherence to safety regulations.

PowerFul Machinery

Lift-All

Lift-It Mfg. Inc.

Mazzella Companies

Dyneema

Rigging Warehouse

Certified Slings & Supply

Holloway

Powerful Machinery stands out for its extensive product range, global certifications, and trusted customer relationships. The company’s commitment to safety and innovation has earned recognition across the market.

Partnerships & M&A

Strategic partnerships and mergers shape the competitive landscape in this industry. Leading companies often collaborate to expand their market reach and enhance product offerings.

These alliances allow organizations to share technology, improve safety standards, and respond quickly to changing market demands. Mergers and acquisitions also help established players strengthen their positions and enter new regions.

Product Innovation

Innovation drives growth in the hoist sling chains assemblies market. Companies invest in research and development to introduce advanced products that meet evolving industry needs.

Columbus McKinnon’s battery-powered hoist received the 2024 Product of the Year award from Material Handling Product News.

PowerFul Machinery continues to develop high-performance chain slings and lifting solutions, focusing on customization and safety.

These advancements improve operational efficiency and support the industry’s commitment to safety.

Entry Barriers

New competitors face significant challenges when entering the market. Strict safety standards and regulatory compliance requirements favor established companies with proven track records. New entrants must invest heavily in certification processes and adapt to evolving regulations.

These barriers make it difficult for newcomers to compete with industry leaders who already possess recognized certifications and trusted products.

Note: Companies that prioritize safety, innovation, and strategic partnerships maintain strong positions in the market and continue to drive industry progress.

Regional Analysis

North America

North America leads in technological innovation within the hoist sling chains assemblies market. Companies in this region invest in smart lifting technologies, including load monitoring sensors and wireless communication systems. Manufacturers prefer lightweight, high-strength alloy chains to improve efficiency.

Sustainability trends influence purchasing decisions, with a growing focus on eco-friendly materials and modular sling designs. These modular systems allow for quick replacement and help reduce waste.

The market faces challenges such as fluctuating raw material costs, supply chain disruptions, and a shortage of skilled labor. Compliance with diverse safety and regulatory standards adds complexity to operations.

Integration of smart lifting technologies

Preference for lightweight, high-strength alloys

Focus on eco-friendly materials

Adoption of modular sling designs

Europe

Europe maintains a strong position in the global market due to its advanced manufacturing capabilities and strict safety regulations. Companies in this region prioritize product quality and compliance with international standards. The regional construction sector drives demand for reliable lifting solutions.

European manufacturers invest in research and development to create innovative products that meet evolving industry needs. Sustainability remains a key focus, with many firms adopting recycled materials and energy-efficient production methods.

Asia-Pacific

Asia-Pacific dominates the market in terms of volume and growth rate. Rapid urbanization and infrastructure development fuel demand for hoist sling chain assemblies. Countries like China and India invest heavily in the regional construction sector, leading to increased adoption of advanced lifting solutions.

Manufacturers in this region offer a wide range of products to meet diverse industry requirements. The market benefits from competitive pricing and large-scale production capabilities.

LAMEA

LAMEA (Latin America, the Middle East, and Africa) shows steady growth in the hoist sling chains assemblies market. Infrastructure expansion and industrialization drive demand across these regions. Companies focus on improving product quality and meeting international safety standards.

The market in LAMEA faces challenges related to supply chain logistics and regulatory compliance, but ongoing investments in construction and manufacturing support continued growth.

Opportunities & Challenges

Growth Opportunities

The hoist sling chains assemblies market offers several promising growth opportunities for both new and established players. Companies can focus on safety and compliance, which remain the main drivers of demand. Regulatory frameworks and internal safety requirements push organizations to invest in certified products.

Migration to higher-grade alloys and optimized designs improves ergonomics and reduces fatigue injuries for workers. Digital identification and fleet intelligence give operators better visibility, allowing for proactive maintenance and fewer jobsite delays.

Specialized materials that resist corrosion and extreme conditions extend the service life of chain assemblies. Configurable products for complex load paths help improve control and sustain uptime. Aftermarket services, such as rapid recertification and technician training, provide competitive advantages.

Chain assemblies excel in specific conditions, even as they compete with synthetics and wire rope. Supply chain resilience and vertical integration help companies manage risks and stabilize product availability. Hardware innovation enhances field safety and reduces misapplication risks.

Guided online configurators make product selection easier and improve documentation accuracy.

Safety and compliance drive demand

Higher-grade alloys and optimized geometry improve ergonomics

Digital identification supports proactive maintenance

Specialized materials extend service life

Configurability for complex load paths increases uptime

Aftermarket services differentiate suppliers

Chain assemblies excel in specific conditions

Supply chain resilience stabilizes availability

Hardware innovation boosts field safety

Online configurators improve selection cycles

Industry Challenges

The market faces several pressing challenges that impact growth and profitability. Fluctuating raw material costs, especially for steel and alloys, affect margins and pricing strategies. A shortage of skilled labor in manufacturing and assembly limits production capacity and can reduce product quality.

Compliance with strict safety and regulatory standards leads to higher production costs and longer lead times. Companies must address these issues to remain competitive and meet the evolving needs of the industry.

Fluctuating raw material costs affect profitability

Shortage of skilled labor impacts production and quality

Compliance with safety standards increases costs and lead times

Companies that invest in innovation, training, and supply chain management position themselves to overcome these challenges and capture new opportunities in the market.

Future Outlook

Market Projections

Analysts expect the hoist sling chains assemblies market to maintain a positive trajectory over the next decade. The forecast indicates steady expansion, driven by ongoing investments in infrastructure and industrial automation.

Asia-Pacific will likely remain the largest contributor, supported by rapid urbanization and manufacturing growth. North America and Europe will continue to adopt advanced lifting solutions, focusing on safety and sustainability.

Companies such as Powerful Machinery plan to introduce new products that meet evolving industry standards. The market will benefit from digital transformation, with smart technologies improving operational efficiency and safety. The following table summarizes projected regional contributions:

Region | Projected Share (%) | Key Drivers |

|---|---|---|

Asia-Pacific | 45 | Urbanization, manufacturing |

North America | 30 | Technology, safety |

Europe | 20 | Compliance, innovation |

LAMEA | 5 | Infrastructure, expansion |

Note: The forecast highlights the importance of innovation and compliance in shaping the future outlook for the industry.

Strategic Insights

Industry leaders recognize several strategies that will shape the future outlook of the market. Companies should invest in research and development to create safer and more efficient products. Customization will remain essential, as clients demand solutions tailored to specific lifting needs.

Digitalization offers opportunities for predictive maintenance and real-time monitoring, reducing downtime and improving safety. Sustainability initiatives, such as using eco-friendly materials, will enhance brand reputation and meet regulatory requirements.

Strategic partnerships and global certifications will help companies expand into new regions and build customer trust.

Invest in R&D for advanced lifting solutions

Offer customization for diverse industry needs

Adopt digital tools for maintenance and monitoring

Prioritize sustainability and eco-friendly materials

Pursue certifications and strategic partnerships

Industry players who embrace these strategies will position themselves for long-term success in the hoist sling chains assemblies market.

Conclusion

The market continues to expand, with market size and growth driven by industrial demand, innovation, and strict safety standards. Companies focus on safety and compliance to meet evolving needs. Industry leaders invest in smart technologies and expand into new regions.

They prioritize safety and customization to improve efficiency.

The future outlook remains positive, with ongoing advancements and a strong commitment to safety shaping the industry’s direction.

FAQ

What are the main types of hoist sling chain assemblies?

Manufacturers offer several types, including single-leg, double-leg, triple-leg, and quadruple-leg chain slings. Each type suits different lifting tasks. Powerful Machinery provides custom configurations to meet specific industry requirements.

How do companies ensure safety and compliance?

Companies follow international standards like ISO9001 and OSHA. Powerful Machinery tests every product and holds certifications from TUV Rheinland and EURO CERT. Regular inspections and documentation support safe operations.

Which industries use chain slings most frequently?

Chain slings serve the construction, manufacturing, shipping, and mining industries. These sectors require reliable lifting solutions for heavy loads and harsh environments. Powerful Machinery supplies certified products to meet these demands.

Can chain slings be customized for unique applications?

Yes. Manufacturers like Powerful Machinery offer customization in length, grade, and attachments. Clients receive tailored solutions for specific lifting needs, improving efficiency and safety.

What advantages do Grade 80 and Grade 100 chain slings provide?

Grade 80 and Grade 100 chain slings deliver high strength and durability. They resist wear and corrosion, making them ideal for demanding tasks. Users benefit from increased load capacity and longer service life.