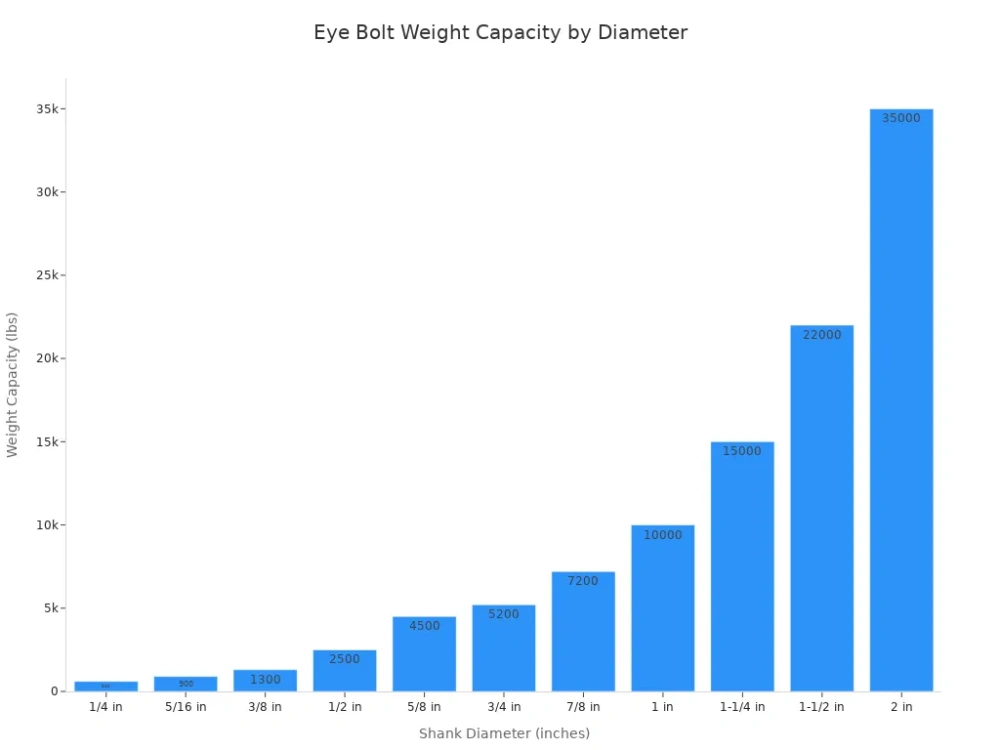

You need to know the eye bolt weight capacity before lifting heavy loads. The right eye bolt ensures safety and prevents accidents. Powerful Machinery provides certified lifting solutions trusted by professionals worldwide. You can check the weight capacity based on shank diameter using the table below.

Always review manufacturer specifications and factor in load angles, material, and environmental conditions. Stainless Steel Eye Bolts from Powerful Machinery offer extra strength and corrosion resistance for demanding jobs.

Shank Diameter (in) | Weight Capacity (lbs) |

|---|---|

1/4 | 600 |

5/16 | 900 |

3/8 | 1,300 |

1/2 | 2,500 |

5/8 | 4,500 |

3/4 | 5,200 |

7/8 | 7,200 |

1 | 10,000 |

1-1/4 | 15,000 |

1-1/2 | 22,000 |

2 | 35,000 |

Key Takeaways

Understand the weight capacity of eye bolts based on shank diameter. Larger diameters support heavier loads, so always refer to the manufacturer’s specifications.

Always check for manufacturer markings on eye bolts. These markings confirm the rated load and ensure compliance with safety standards.

Apply loads in a straight vertical direction to maximize weight capacity. Lifting at angles can significantly reduce the safe load limit.

Choose stainless steel eye bolts for better corrosion resistance, especially in marine or outdoor environments. They provide durability and safety in harsh conditions.

Regularly inspect eye bolts for wear and damage. Replace any that show signs of deterioration to maintain safety during lifting operations.

Eye Bolt Weight Capacity Table

Standard Shank Diameters

When you select an eye bolt, you must consider the shank diameter. The shank diameter directly affects the eye bolt weight capacity. Larger diameters support heavier loads.

The table below shows the typical weight capacity for standard shank diameters, referencing Powerful Machinery’s Stainless Steel Eye Bolts. Always check the manufacturer’s markings and certifications before use.

Shank Diameter (in) | Weight Capacity (lbs) | Markings Required |

|---|---|---|

1/4 | 600 | Manufacturer, Size, Grade |

5/16 | 900 | Manufacturer, Size, Grade |

3/8 | 1,300 | Manufacturer, Size, Grade |

1/2 | 2,500 | Manufacturer, Size, Grade |

5/8 | 4,500 | Manufacturer, Size, Grade |

3/4 | 5,200 | Manufacturer, Size, Grade |

7/8 | 7,200 | Manufacturer, Size, Grade |

1 | 10,000 | Manufacturer, Size, Grade |

1-1/4 | 15,000 | Manufacturer, Size, Grade |

1-1/2 | 22,000 | Manufacturer, Size, Grade |

2 | 35,000 | Manufacturer, Size, Grade |

Tip: Always verify that the eye bolt you choose displays the manufacturer’s name, the rated load, and the grade. These markings help you confirm the eye bolt weight capacity and ensure compliance with safety standards.

3/8 Eye Bolt Weight Capacity

A 3/8-inch eye bolt is a common choice for many lifting and rigging tasks. You can expect a standard 3/8-inch eye bolt to have a weight capacity of 1,300 pounds when used for a straight vertical lift.

Some manufacturers may rate a 3/8-inch steel eye bolt at around 650 pounds for vertical loading, depending on the material and design. The maximum weight capacity can decrease sharply if you apply the load at an angle.

The material also plays a role. Stainless steel eye bolts offer excellent corrosion resistance, which is ideal for marine or outdoor use. However, stainless steel versions may have a slightly lower weight capacity than carbon steel eye bolts.

Always check the manufacturer’s specifications for the exact maximum weight capacity.

3/8-inch eye bolt weight capacity (vertical lift): 1,300 lbs (standard)

3/8-inch steel eye bolt (vertical, straight pull): around 650 lbs (some manufacturers)

Stainless steel eye bolts: slightly lower weight capacity than carbon steel, but better corrosion resistance

Note: Never exceed the rated weight capacity. If you need to lift at an angle, reduce the load accordingly.

Eye Bolts in Wood

You may need to install eye bolts in wood for certain applications. The eye bolt weight capacity in wood depends on the wood type, the depth of installation, and the bolt size.

Hardwoods provide better holding strength than softwoods. You should always pre-drill a pilot hole to prevent splitting and ensure a secure fit. The maximum weight capacity in wood is usually lower than in steel or concrete, so always use caution and consult the manufacturer’s guidelines.

Use hardwood for a higher weight capacity.

Pre-drill pilot holes for best results.

Do not use eye bolts in wood for critical lifting unless the manufacturer approves it.

Lag Eye Bolts

Lag eye bolts have a screw thread designed for wood or masonry. You can use them for light to medium-duty applications. The eye bolt weight capacity for lag eye bolts depends on the length, diameter, and the material they are installed in.

Lag eye bolts are not suitable for heavy lifting or overhead loads unless specifically rated for such use. Always check the manufacturer’s rated capacity and never exceed it.

Lag eye bolts are best for anchoring in wood or masonry.

Not recommended for lifting heavy loads unless certified.

Screw Eye Bolts

Screw eye bolts are similar to lag eye bolts but often have a smaller diameter and are used for lighter loads. The safe working load for screw eye bolts depends on several factors:

Material and size of the eye bolt

Thread type and fit

Surface conditions (clean, rust-free, lubricated)

Application and load requirements (static or dynamic loads)

You should always follow the manufacturer’s recommendations for installation and use. The eye bolt weight capacity for screw eye bolts is usually much lower than for lifting eye bolts. Never use screw eye bolts for overhead lifting unless they are specifically rated and certified for that purpose.

Safety Reminder: Manufacturer ratings and certifications provide essential guidelines for safe use. Always ensure the working load limit is higher than your heaviest load. Inspect eye bolts regularly and follow all manufacturer instructions to prevent accidents.

Why Manufacturer Ratings and Certifications Matter?

Manufacturer ratings and certifications are critical for your safety. They tell you the exact eye bolt weight capacity and confirm that the product meets strict industry standards.

Certified eye bolts from Powerful Machinery display the manufacturer’s name, the rated load, and the grade. These markings help you identify the correct product for your application and avoid dangerous mistakes.

Manufacturer ratings and certifications set the working load limit and performance requirements.

Always choose eye bolts with clear markings and documentation.

Proper inspection and adherence to specifications prevent equipment failure and accidents.

By following these guidelines and choosing certified products like Powerful Machinery’s Stainless Steel Eye Bolts, you ensure the highest level of safety and reliability for every lifting task.

Load Angles and Safety

Angle Reductions

When you lift a load with an eye bolt, the angle of the pull has a major impact on safety. Eye bolts are strongest when you apply the load straight up, in a vertical direction.

As the angle increases, the weight capacity drops sharply. You must always check the angle before lifting.

Here is a table showing how much the weight capacity reduces as the angle increases:

Angle (Degrees) | Weight Capacity Reduction |

|---|---|

15° | 20% |

30° | 35% |

45° | 70% |

For example, if you use an eye bolt rated for 1,000 lbs at a 45-degree angle, the safe load drops to just 300 lbs. You should always plan your lift to keep the angle as close to vertical as possible.

Tip: Never guess the safe load. Always use the reduction percentages to calculate the true working load limit for your setup.

Unsafe Angles

You face serious risks if you use eye bolts at unsafe angles. The following practices can lead to dangerous situations:

Load alignment matters. Always apply the load in line with the lift and parallel to the eye axis. This prevents bending or breaking of the bolt.

Avoid slinging between eyebolts. Running a sling from one eye bolt to another creates an angular force, which can greatly reduce the working load limit.

Prevent shock loading. Sudden changes in load direction or rapid acceleration increase tension and can cause the eye bolt to fail.

You must inspect your setup and avoid these unsafe practices to protect both your equipment and your team.

Hoist Rings vs Eye Bolts

You should consider hoist rings when your lift requires angles or load manipulation. Hoist rings can pivot and swivel, so they maintain their full rated working load limit at any angle. Eye bolts lose much of their capacity when you lift at an angle, making them unsafe for anything other than straight, vertical loads.

Choose hoist rings in these situations:

You need to lift at an angle or rotate the load.

The load direction may change during the lift.

You want to prevent lateral stress or deformation.

You need to maintain the full working load limit, even at extreme angles.

A 45-degree lift angle can reduce an eye bolt’s capacity by over 70%. Hoist rings align with the direction of pull, keeping your lift safe and efficient. For complex lifts, always select hoist rings to ensure the highest level of safety.

Choosing Eye Bolts

Measuring Shank Diameter

Selecting the right eye bolts starts with accurate measurement of the shank diameter. You need to ensure a proper fit for both safety and performance. Follow these steps to measure the shank diameter:

Select a caliper that is calibrated for precise readings.

Hold the eye bolt so the caliper jaws can fully enclose the shank.

Read the measurement displayed on the caliper. For threaded eye bolts, measure the major (outer) diameter, which is the widest part of the thread.

Accurate measurement helps you match the eye bolts to your application and ensures you meet the rated capacity for your lifting needs.

Product Features

Powerful Machinery’s Stainless Steel Eye Bolts stand out due to their advanced engineering and robust construction. You benefit from features that enhance both safety and efficiency. The table below highlights what sets these eye bolts apart from standard models:

Feature | Description |

|---|---|

High Tensile Strength | Handles substantial loads and strains, ideal for demanding uses. |

Corrosion Resistance | Prevents rust and damage, perfect for marine and outdoor environments. |

Easy Installation | Allows for quick assembly with standard tools, saving time and effort. |

Accurate Threading | Ensures a snug fit, maintaining security and safety in every setup. |

These features make eye bolts from Powerful Machinery a reliable choice for construction, marine, and industrial projects.

Safety Certifications

When you choose eye bolts for lifting, you must verify compliance with international safety standards. Certified products guarantee performance and reduce risk. The following table lists key certifications relevant to lifting applications:

Certification/Standard | Description |

|---|---|

B.S. 4278 | Standard for eye bolts in lifting applications. |

EN 1677 | Specifies requirements for lifting points, ensuring safety and reliability. |

ASME B30.26 | Covers requirements for hoist rings, ensuring proof testing and safety markings. |

Many leading products, including those from Powerful Machinery, comply with standards such as ASME B18.15 and DIN 580. These standards define technical specifications for eye bolts, including thread size, shank length, eye diameter, and material grade. Compliance ensures safe and effective use in lifting operations.

Always check for clear markings and documentation before using any eye bolts. Certified products help you maintain safety and meet industry requirements.

Environmental Considerations

Cold Weather Use

You must consider temperature extremes when selecting eye bolts for your project. Cold weather can affect the strength and safety of different materials. For example, carbon steel eye bolts may lose strength at lower temperatures, while alloy steel performs better in the cold.

The table below shows the recommended temperature ranges for common eye bolt materials:

Eyebolt Type | Minimum Temperature | Maximum Temperature |

|---|---|---|

Alloy Steel | -40°F (-40°C) | 400°F (204°C) |

Carbon Steel | 30°F (-1°C) | 275°F (135°C) |

Stainless steel eye bolts, such as those from Powerful Machinery, offer excellent performance in low temperatures. DIN580 stainless steel eye bolts remain impact-resistant even in extreme cold. You can rely on them for safety and durability, even when temperatures drop well below freezing.

Tip: Always check the material rating before using eye bolts in cold environments. Stainless steel is a safe choice for extreme conditions.

Material Limitations

Environmental factors like humidity, saltwater, and chemicals can shorten the life of standard eye bolts. In marine or outdoor settings, metals face constant exposure to corrosive elements. Stainless steel and aluminum resist corrosion better than other materials, making them ideal for harsh environments.

Type of Eye Bolt | Corrosion Resistance | Suitable Environments |

|---|---|---|

Galvanized Eye Bolts | Moderate | General, moist conditions |

Stainless Steel Eye Bolts | High | Marine, outdoor, chemical applications |

Stainless steel resists rust due to its chromium content.

It keeps its corrosion resistance even if scratched.

Grade 316 stainless steel is best for marine use because it withstands ocean mist and high chloride levels.

Humidity and chemicals can damage regular steel fasteners, but stainless steel stands up to these challenges.

You should always inspect your eye bolts for wear, cracks, or corrosion. Rinse them with fresh water after saltwater exposure. Keep them clean and ensure proper installation.

By choosing Powerful Machinery’s Stainless Steel Eye Bolts, you get superior corrosion resistance and long-lasting performance, even in the toughest environments.

Conclusion

You must understand eye bolt weight capacity, load angles, and environmental factors to ensure safe lifting. Always consult manufacturer specifications and select certified products, such as Powerful Machinery’s Stainless Steel Eye Bolts. Follow this general guide to minimize risks:

Inspect eye bolts before each use and replace any that show wear or damage.

Confirm the working load limit matches your application.

Apply loads in line with the eye axis and avoid unsafe angles.

Document maintenance and train your team on proper installation.

Common Mistake | Why It Matters |

|---|---|

Overtightening bolts | Reduces strength and may cause failure |

Ignoring inspections | Increases the risk of accidents |

Reach out to experts for advice on complex projects. Prioritize safety in every lift.

FAQ

What factors affect the weight capacity of an eye bolt?

You must consider shank diameter, material, installation method, and load angle. Each factor changes the weight capacity. Always check the manufacturer’s guide for the rated capacity. Never guess the weight capacity for your application.

How do I determine the correct eye bolt capacity for my project?

Start with the manufacturer’s guide. Match the weight capacity to your load. Consider the angle and environment. Always select an eye bolt with a higher capacity than your maximum load. This approach ensures safety and reliability.

Can I use the same weight capacity for angled lifts?

No, you cannot. Angled lifts reduce the capacity of the eye bolt. Always use the reduction percentages from the guide. For example, a 45-degree angle can lower the weight capacity by up to 70%. Never exceed the adjusted capacity.

Why is it important to follow the manufacturer’s guide for weight capacity?

The manufacturer’s guide provides tested and certified capacity ratings. You protect your team and equipment by following these limits. Ignoring the guide can lead to failure, injury, or property damage. Always trust the certified weight capacity.

Do stainless steel eye bolts have the same capacity as carbon steel?

Stainless steel eye bolts offer excellent corrosion resistance. Their weight capacity may differ from carbon steel. Always check the manufacturer’s guide for the exact capacity. Never assume the capacity is the same for different materials.