If you want to know how to attach a hook to a chain safely, you need the right hook for the job—like a grab hook, slip hook, or a clevis hook. High-quality hooks, such as Powerful’s G80 and G100 options, keep your lifting secure on busy construction sites and in cargo yards.

Attach a Hook to a Chain Key Takeaways

- Choose the right hook for your lifting job. Options like G80 and G100 hooks provide strength and reliability.

- Inspect both the chain and hook before use. Look for signs of wear, corrosion, or damage to ensure safety.

- Secure the connection properly. Always check that the hook’s latch is closed and the chain is positioned correctly.

Tools for How to Attach a Hook to a Chain

Choosing the Right Lifting Hook

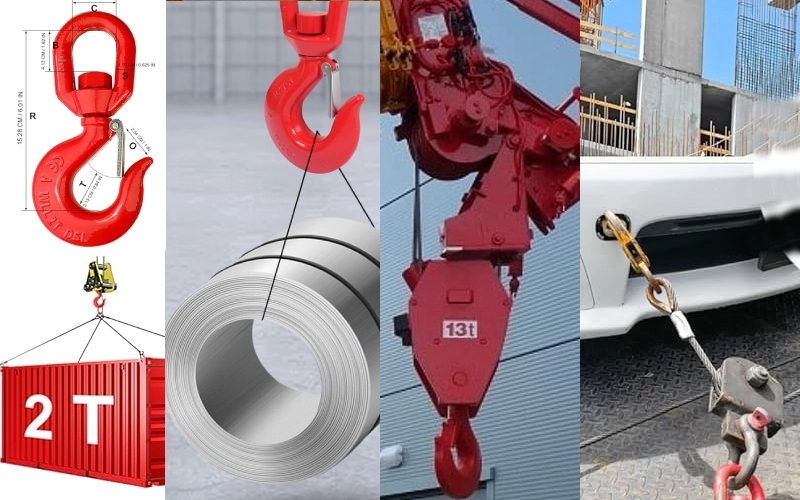

When you start a lifting job, picking the right hook is key. Powerful offers a full range of hooks, including clevis hooks, self-locking hooks, and the reliable eye hook. Each type fits different needs. For heavy-duty work, you want hooks that meet strict standards. G80 hooks are made from heat-treated alloy steel and work well for overhead lifting, even in tough marine or shock-load environments. G100 hooks give you about 25% more strength than G80, so you can use a smaller hook or chain for the same job. Self-locking hooks add extra safety because they stay closed under load. You’ll see these hooks in construction, shipbuilding, and manufacturing.

Selecting the Proper Chain

The chain you choose matters just as much as the hook. You want a chain that’s strong, durable, and safe. Here’s a quick look at what to consider:

| Factor | Description |

|---|---|

| Strength | Handles heavy loads with ease. |

| Durability | Stands up to wear, abrasion, and corrosion. |

| Safety | High-strength steel and gradual wear make it easy to spot issues early. |

| Maintenance | Needs only regular inspections, less upkeep than wire rope. |

| Cost-Efficiency | Lasts longer, saving you money over time. |

Powerful’s G80 and G100 chains are trusted in construction, marine, and manufacturing for these reasons.

Safety Gear

Don’t forget your safety gear. You’ll need gloves, safety glasses, and sometimes a hard hat. For the actual connection, use shackles, self-locking hooks, and hoist hooks. Powerful’s safety hooks have fail-safe designs that help prevent accidental disengagement. These features keep you and your team safe, especially when you’re working in heavy-duty environments.

Proper Way to Attach a Chain and Hook

Attaching a hook to a chain might look simple, but doing it the proper way keeps your team and your load safe. Let’s break down the steps so you can master how to attach a hook to a chain, whether you’re working in construction, agriculture, or transportation.

Inspecting Chain and Hook

Before you even think about connecting anything, you need to check your gear. This step is non-negotiable. You want to make sure both the chain and the hook are in top shape. Here’s a quick inspection checklist:

| Inspection Criteria | Description |

|---|---|

| Deformation | Look for any bending or warping of the hook. |

| Wear | Check for signs of wear that could affect strength. |

| Corrosion | Inspect for rust or other corrosion damage. |

| Nicks & Gouges | Find any cuts or gouges that may weaken the hook. |

| Latches | Make sure latches work properly. |

| Bolts & Pins | Check the condition of bolts and pins. |

| Markings | Verify all required markings are present. |

| Field Modifications | Watch for any modifications that may affect integrity. |

You should also look for these signs of wear or damage on your chain:

| Signs of Wear or Damage | Description |

|---|---|

| Kinks | Bends in the chain that disrupt its straightness. |

| Twists | Twisted links that can affect load distribution. |

| Cuts | Visible cuts that compromise the chain. |

| Nicks | Small notches that weaken the chain. |

| Corrosion | Rust or deterioration that affects strength. |

| Elongation | Stretched links beyond acceptable limits. |

Positioning and Connecting

Now you’re ready to connect. The proper way to attach a hook to a chain starts with positioning. You want to use the right hook for the job. Powerful’s G80 and G100 hooks meet strict industry standards, so you know you’re getting strength and reliability. The G80 hook is perfect for most heavy-duty lifting, while the G100 hook gives you even more load capacity.

Here’s how to attach a hook to a chain step by step:

- Choose the right hook: Decide if you need a clevis, slip, or eye hook. For extra safety, a self-locking hook is a great choice. The eye hook is popular for its secure fit and easy inspection.

- Select the correct chain: Make sure the chain matches the hook’s grade and size. G80 and G100 chains work best with their matching hooks.

- Position the hook: Place the hook so the load will sit in the bowl or saddle, not on the tip. This keeps the load centered and prevents side or tip loading, which can weaken the connection.

- Attach the chain: Insert the last link of the chain into the hook’s opening. If you’re using an eye hook, thread the chain through the eye and secure it with a shackle or pin if needed.

- Check the angle: Use the right hitch for your load—vertical, choker, or basket. Each method affects how much weight you can safely lift. For example:

- Vertical Hitch: Good for stable, balanced loads.

- Choker Hitch: Wraps around the load for better control, but reduces lifting capacity.

- Basket Hitch: Distributes weight across two points, great for long or awkward loads.

Note: Always keep your hands and body clear from between the hook and the load. Never force a chain into a hook that doesn’t fit.

Securing the Connection

Once you’ve connected the hook and chain, you need to make sure the connection is secure. This is where Powerful’s self-locking hooks shine. These hooks automatically close and lock under load, so you don’t have to worry about accidental detachment. The latch mechanism gives you peace of mind, especially in high-risk environments like construction sites or offshore platforms.

Here’s what you should do to secure the connection:

- Double-check that the hook’s latch is fully closed and engaged.

- Make sure the chain sits properly in the hook’s bowl, not on the tip or side.

- For eye hooks, confirm that any pins or shackles are tight and undamaged.

- Avoid shock loading—lift slowly and steadily to prevent sudden jerks.

- Visually verify the connection before lifting. If you’re working with multiple sling legs or angles greater than 45°, use a collector ring for added safety.

Common Mistakes to Avoid:

- Using the wrong size or type of hook for your chain.

- Attaching the hook at an incorrect angle.

- Failing to check that the latch is closed.

- Ignoring signs of wear or damage.

- Not following the manufacturer’s instructions.

The proper way to attach a hook to a chain always includes a final check. Industry standards like ASME B30.20 and BTH-1 require you to inspect, mark, and maintain your lifting gear. Powerful’s G80 and G100 hooks, with their forged steel construction and self-locking features, help you meet these standards and keep your operation safe.

Best Practice:

Get basic rigging training if you’re new to lifting. Certified Rigger Level I courses teach you how to attach a chain and hook safely and spot potential hazards before they become problems.

No matter if you’re in agriculture, construction, or transportation, following these steps and using high-quality hooks like Powerful’s G80 or G100 eye hook will help you master how to attach a hook to a chain the right way—every time.

Lifting Hooks and Safety Hooks: Industry-Specific Connection and Fixing Methods

Construction Industry

In construction, every second counts and safety can’t be compromised. That’s why clevis hooks with safety latches are the standard choice. Their pin-and-cotter design makes them quick to attach, while the latch prevents materials from slipping out mid-lift. From our experience supplying crane contractors, workers prefer clevis hooks because they save time without cutting corners on safety. In fact, OSHA’s Subpart CC specifically stresses secure rigging, and clevis hooks check all the boxes. On a busy site, reliability is everything.

Shipping & Marine Industry

Ports and offshore platforms are some of the toughest places for lifting equipment. Chains can easily twist when moving shipping containers or heavy gear. That’s why swivel hooks with eye connections are so popular here. The swivel allows free rotation, reducing dangerous stress on the chain. We’ve seen operators rely on them daily to keep container lifts smooth and safe. According to EN 1677 standards, swivel hooks are tested for alignment under load—something absolutely necessary when waves or ship movement are involved.

Mining Industry

Mining doesn’t forgive weak equipment. Shock loads, abrasive dust, and massive machinery demand rugged solutions. Here, welded safety hooks prove their worth. Once welded to the chain, there’s no risk of tampering or accidental detachment. Many of our mining clients in Australia and South Africa insist on welded hooks because downtime underground can cost thousands per hour. Backed by ASME B30.10 guidelines for lifting hooks, these heavy-duty solutions have consistently shown they can handle the extremes of mining.

Oil & Gas Industry

Offshore rigs and drilling sites demand precision under harsh conditions. The winning combination here is swivel safety hooks paired with coupling links. This setup allows flexibility in rigging while keeping everything firmly locked. In our collaborations with oilfield service providers, we’ve seen how these connections meet API RP 2D offshore crane standards. When wave motion and wind put unpredictable stress on equipment, operators trust safety hooks with coupling links to keep loads secure.

Manufacturing & Warehousing

In manufacturing plants and warehouses, the environment may be calmer, but the need for consistency is just as high. Eye hooks and latch hooks dominate here, especially with hoists and overhead cranes. Eye hooks offer a strong, semi-permanent connection, while latch hooks give that extra security to prevent accidental release. Many of our industrial clients report fewer workplace incidents after switching to certified latch hooks, aligning with ISO 7597 requirements for lifting appliances. In this sector, it’s about efficiency and safety working hand in hand.

Check Security After You Attach a Chain

Visual and Manual Inspection

After you attach the hook to the chain, you need to make sure everything is secure before you start lifting or moving anything. Start with a visual check. Look at every link in the chain for signs of wear, rust, or stretching. If you see any damage, take the chain out of service right away. Next, give the chain a gentle tug. This helps you feel if the connection is tight or if something might slip. Always check that the hook’s latch is closed and working. For hooks like Powerful’s G80 and G100, the self-locking feature should snap shut when you apply a load. This keeps the load from slipping out the wrong way.

You should also check all bolts and pins for tightness. If you find any defects that go past safe limits, remove the hook from service. Document what you find and any fixes you make. In places like manufacturing plants or rail yards, these steps can prevent accidents and keep your team safe.

Tip: Measure the reach from the top of the master link to the bottom of the hook. If you notice any binding or loss of clearance, you might have overloaded the chain the wrong way.

Common Mistakes to Avoid

Many people make simple mistakes that can lead to big problems. Here are a few to watch out for:

- Skipping the inspection step or rushing through it.

- Using a hook or chain that does not meet the right standard, like mixing a G80 hook with a lower-grade chain.

- Forgetting to check if the latch is fully closed.

- Ignoring signs of wear or stretch.

- Not giving the chain a tug before use.

Powerful’s safety features, like self-locking hooks and safety latches, help prevent loads from slipping out. These features give you extra peace of mind, especially when you work in busy environments.

| Feature | How It Helps You Stay Safe |

|---|---|

| Safety latch on hook | Stops loads from slipping out |

| Self-locking mechanism | Prevents accidental opening under load |

| Under hook accessories | Distributes weight and adds stability |

If you follow these steps and avoid the wrong way of connecting or inspecting your gear, you can trust your lifting setup every time.

When you attach a hook to a chain, follow these steps for safety and reliability:

- Pick the right hook, like a G80 or G100.

- Inspect your chain and hook before every use.

- Secure the connection and check the latch.

- Keep up with regular inspections.

| Benefit | Description |

|---|---|

| Enhanced Safety | Regular checks catch problems early and prevent accidents. |

| Cost Savings | Early fixes save money and extend equipment life. |

| Compliance with Standards | Inspections help you meet safety rules and protect your team. |

High-quality hooks from Powerful give you peace of mind and help your chain setup last longer.

FAQ

What is the difference between a G80 hook and a G100 hook?

G80 hooks handle heavy loads. G100 hooks give you more strength for the same size. You get better performance with G100 in tough jobs.

How do you know if your hook meets the right standard?

Check the markings on your hook. You should see G80 or G100 stamped on it. This tells you the hook meets safety standards.

Can you use Powerful hooks outdoors?

Yes, you can use Powerful hooks outside. The high-grade alloy steel resists rust and stands up to tough weather.

Can I mix different grades of chain and hook (e.g., G80 chain with a G100 hook)?

No. Mixing grades reduces overall strength and violates safety standards. Always match the chain and hook grade for safe lifting operations.

Conclusion

Attaching a hook to a chain may look straightforward, but doing it the proper way makes all the difference in safety, reliability, and efficiency. From choosing the right grade of hook (G80 or G100) to inspecting every link in your chain, each step ensures that your lifting operation runs smoothly without accidents. Using certified, high-quality hooks with features like self-locking mechanisms and safety latches helps you meet industry standards while protecting your crew and equipment.

Whether you’re working in construction, shipping, mining, oil & gas, or manufacturing, the rules remain the same: pick the right hardware, inspect before every lift, and secure the connection properly. These habits don’t just prevent costly downtime—they also save lives. With Powerful’s G80 and G100 hooks and chains, you get peace of mind knowing that every lift is backed by strength, durability, and safety you can trust.