When you start electric hoist oil leak repair, focus on safety and diagnosis first. You need to spot signs of oil leakage early, as these often indicate common failures or common causes of oil leaks. Always use certified replacement parts and follow manufacturer instructions to keep your equipment reliable.

Powerful Machinery stands for quality and safety, so their products support your repair efforts. Regular maintenance prevents electric hoist oil-leak repairs from becoming urgent. For standard use, inspect the hoist at least once a year. If you use it often, check every six months.

Seldom used means you should ask a technician about the best maintenance schedule. When you see signs of oil leakage or face common failures, seek professional help to avoid further issues. Maintenance routines prevent electric hoist oil-leak repairs from disrupting your operations.

Key Takeaways

Prioritize safety by using lockout/tagout procedures and wearing personal protective equipment (PPE) before starting any repair.

Regular inspections are crucial. Check your electric hoist at least once a year, or every six months for frequent use, to catch leaks early.

Use only certified replacement parts and follow manufacturer guidelines to ensure reliable repairs and maintain your warranty.

Document every step of the repair process, including inspections and findings, to track maintenance history and improve future repairs.

Consider the severity of damage when deciding to repair or replace your hoist. Frequent repairs may indicate it’s time for a new unit.

Safety Protocols for Electric Hoist Oil Leak Repair

When you repair an electric hoist oil leak, you must follow strict safety protocols. These protocols protect you, your team, and your equipment. Powerful Machinery designs every electric hoist to meet or exceed international safety standards.

The company holds certifications such as ISO9001, ISO14001, TUV Rheinland, and CSA. These certifications show a strong commitment to operational safety and reliability.

Lockout/Tagout and Power Isolation

Before you begin any repair, always use lockout/tagout procedures. This step prevents accidental startup and protects you from electric shock or motor malfunction. Disconnect the hoist from its power source. Place a lock and tag on the switch or breaker.

This action ensures no one can restore power until you finish the repair. You reduce the risk of injury and avoid further motor malfunction by isolating the equipment.

PPE and Work Area Preparation

Wear the right personal protective equipment (PPE) before you start. Use gloves, safety glasses, and steel-toed boots. These items shield you from oil, sharp edges, and falling parts.

Prepare your work area by clearing clutter and setting up barriers. Good lighting helps you address the specific leak source and spot hazards quickly. Keep a spill kit nearby to handle any oil that escapes during the repair.

Securing Loads and Environmental Safety

Never work on a hoist with a suspended load. Lower the load to the ground and secure it. Use certified supports if you must keep the load elevated. This step prevents accidents and protects everyone in the area.

Check for oil on the floor and clean it up to avoid slips. When you address the specific leak source, you also protect the environment by containing and disposing of oil properly.

Tip: Always document your safety steps. This habit builds a culture of safety and helps you track improvements over time.

Following these safety protocols ensures you can repair your electric hoist confidently and efficiently.

Electric Hoist Troubleshooting: Identifying Leakage

Cleaning and Visual Inspection

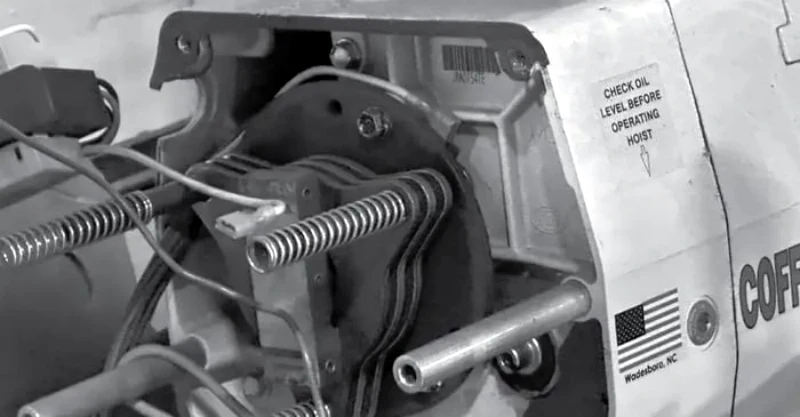

Start your electric hoist troubleshooting by cleaning the exterior of the hoist. Remove dust, oil, and debris with a lint-free cloth and a mild degreaser. This step helps you identify the leak source more accurately. Once the surface is clean, inspect all visible areas for signs of oil leakage.

Look for fresh oil stains, drips, or a sheen on the gearbox and surrounding components. Pay close attention to the area beneath the hoist, as oil often collects there. Powerful Machinery designs its electric hoist products for easy access, so you can perform these checks without disassembly.

Common Leak Points in Powerful Machinery Hoists

You need to know where leaks most often occur. The table below outlines typical locations, visual characteristics, and common causes of oil leakage in electric hoists:

Leak Source | Typical Location | Visual Characteristics | Common Cause |

|---|---|---|---|

Input/Output Shaft Seals | Where motor or drum shafts exit the gearbox | Oil spray pattern if the shaft rotates; drip below the shaft | Wear, contaminants, or improper installation |

Housing Gasket | Along the seam where gearbox halves meet | Slow weep or seep along seam or section | Gasket aging, improper bolt torque, surface flaws |

Fill/Drain Plugs | On the side or bottom of the gearbox casing | Slow drip from plug threads or head | Worn/missing seal washer, improper tightening |

Casing Crack | Near mounting points or high-stress areas | Fine line that weeps oil under load or temperature change | Impact, casting flaw, or material fatigue |

Use this table as a reference during your inspection. Powerful Machinery’s robust construction and precise assembly help minimize these risks, but regular checks remain essential.

Diagnostic Tools for Hard-to-Find Leaks

Sometimes, you may not spot the leakage right away. For advanced electric hoist troubleshooting, use specialized tools. UV dye mixed with oil can help you identify the leak source. Add the dye to the gearbox oil, run the hoist briefly, then use a UV flashlight to check for glowing traces.

This method highlights even the smallest leaks that visual inspection might miss. You can also use powder tracing or leak detection sprays for further troubleshooting. These tools make it easier to pinpoint the exact location of leakage, ensuring a thorough repair.

Tip: Always document your findings during electric hoist troubleshooting. Keeping records helps you track recurring issues and improve future maintenance.

Tools & Materials for Gearbox Oil Leakage Repair

When you repair gearbox oil leakage in an electric hoist, you need the right tools and materials. Using the correct equipment helps you address failures quickly and safely. Powerful Machinery recommends using only certified parts and following their guidelines for every repair.

Essential Tools and Safety Gear

You should gather all necessary tools before starting the repair. This preparation helps you avoid delays and reduces the risk of failures during the process. Here is a list of essential items:

A set of wrenches for removing bolts and fittings

Screwdrivers for opening covers and panels

An oil drain pan to catch old oil and prevent spills

Cleaning cloths or rags to wipe surfaces and remove debris

UV dye and a UV light for detecting hidden leaks

Fine white powder, such as talcum or chalk dust, to trace the source of gearbox oil leakage

Personal protective equipment (PPE), including gloves and safety glasses

Tip: Always keep your work area organized and well-lit to prevent accidents and spot failures early.

Replacement Parts and Sealants

You must use high-quality replacement parts and sealants to ensure a lasting repair. Powerful Machinery’s certified seal kits and gaskets fit their hoists perfectly and help prevent future gearbox oil leakage. For sealing, consider these options:

Check Seal™ 22 AB: A two-component epoxy sealant for flange gaskets and valve stems

Check Seal™ 357P: A non-curing sealant for high-temperature repairs

Check Seal™ 42: A fast-curing epoxy putty for quick fixes

Replacement seal kits designed for your specific hoist model

Always replace worn or damaged seals and gaskets to avoid repeated failures.

Using Manufacturer-Specified Components

You should always use manufacturer-specified components for repairs. Powerful Machinery’s certified parts meet strict quality standards and ensure your hoist operates safely after fixing gearbox oil leakage.

Using the correct parts reduces the risk of failures and extends the life of your equipment. Check your product manual for part numbers and installation instructions.

Note: Using non-certified parts can lead to more failures and may void your warranty.

Step-by-Step Guide to Electric Hoist Oil Leak Repair

You need a reliable step-by-step guide to address an oil leak in your electric hoist. This repair process ensures you restore your equipment’s performance and maintain safety standards.

Always consult your Powerful Machinery product manual for model-specific repair instructions and torque specifications. Document each step to track your work and support future maintenance.

Draining Oil and Disassembly

Start by draining the oil from your electric hoist before you begin any repair. This step prevents spills and allows you to inspect internal components safely. Follow these steps:

Place a drain pan underneath the gearbox to catch the oil.

Remove the drain plug and let the oil empty completely.

Dispose of the old oil properly. Check your local recycling rules for safe disposal.

Once you have drained the oil, begin disassembly. Remove the hoist covers and access panels using the correct tools. Keep all fasteners and small parts organized. Take photos or notes as you go to help with reassembly. This careful approach reduces the risk of mistakes during the repair process.

Tip: Label each part as you remove it. This habit makes reassembly faster and more accurate.

Replacing Seals, Gaskets, and Fittings

You must replace faulty seals and worn gaskets to stop the oil leak. Powerful Machinery recommends using only certified replacement parts for your electric hoist. The table below shows the most common types of seals and gaskets you may encounter during the repair:

Seal/Gasket Type | Description |

|---|---|

O-rings | Versatile seals used in static and dynamic applications, made from materials like silicone, nitrile, and Viton. |

Piston seals | Prevent fluid from bypassing the piston in hydraulic cylinders, crucial for maintaining pressure. |

Spiral wound gaskets | Suitable for high-pressure, high-temperature applications, made of metal and filler material layers. |

Polytetrafluoroethylene (PTFE) | Known for chemical resistance and low friction, used in aggressive fluid applications. |

Inspect each seal and gasket for signs of wear, cracks, or deformation. Remove damaged components and clean the surfaces before installing new ones. Always use the correct torque when tightening bolts to avoid damaging the new seals. Refer to your product manual for the recommended torque values.

Note: Using the wrong seal or improper installation can cause another oil leak. Double-check part numbers and installation steps.

Addressing Gearbox Cracks and Casing Damage

If you find cracks or damage in the gearbox casing during your inspection, you need to act quickly. Gearbox issues often show up as unusual noise or changes in the running status of your electric hoist.

Common causes include fatigue pitting in bearings or improper sealing, which can lead to oil leaks and performance problems.

Monitor the running status and listen for abnormal noise from the gearbox.

Check for visible cracks near mounting points or high-stress areas.

If you find a crack, stop using the hoist immediately and consult your Powerful Machinery manual for repair instructions.

Small cracks may be repaired with certified epoxy or sealant. For severe damage, you may need to replace the gearbox casing.

Regular maintenance and prompt repairs help prevent further damage and keep your electric hoist operating safely.

Cleaning and Surface Preparation

Proper cleaning and surface preparation are essential for a successful repair. You should remove all traces of old oil, dirt, and debris from the affected areas. Use specialized cleaning agents or soapy water to clean the surface of the electric hoist. Dry all parts thoroughly before installing new seals or gaskets.

A clean surface ensures that new seals adhere properly and prevent future oil leaks. Take your time with this step to avoid repeating the repair process.

Tip: Document your cleaning and preparation steps. Good records help you identify patterns and improve your maintenance routine.

By following this step-by-step guide, you can repair an oil leak in your electric hoist with confidence. Always use certified parts, follow manufacturer guidelines, and document your work for future reference.

Reassembly and Refilling After Leakage Repair

Proper Reassembly Techniques

You need to approach reassembly with care to prevent another oil leak. Begin by reviewing your notes and photos from disassembly. Align all components precisely. Tighten bolts in a cross-pattern to distribute pressure evenly. Use a torque wrench to match the manufacturer’s recommended settings.

This step helps you avoid over-tightening, which can damage seals or gaskets. If you skip these details, you risk causing a new oil leak or mechanical failure.

Tip: Organize your parts on a clean surface. This habit reduces the chance of missing small components during reassembly.

Lubrication and Oil Refilling

After you finish reassembly, refill the gearbox with the correct oil. Always use the oil type and grade specified in your Powerful Machinery manual. Using the wrong oil can lead to poor lubrication and increase the risk of another oil leak. Pour the oil slowly to avoid air pockets.

Check the oil level with the dipstick or sight glass. Do not overfill, as excess oil can escape through seals.

Steps for Oil Refilling:

Confirm all drain and fill plugs are secure.

Add oil gradually, checking the level as you go.

Wipe away any spills immediately.

Ensuring Seal Integrity

Before you return the hoist to service, inspect all seals and gaskets. Look for signs of seepage or drips around joints and fittings. Run the hoist briefly without a load to check for leaks.

If you see any oil leak, stop and recheck your work. Powerful Machinery recommends a final inspection to confirm seal integrity. This step ensures your repair will last and your equipment will operate safely.

Note: Always follow Powerful Machinery’s guidelines for oil selection and maintenance. Using certified products protects your investment and supports long-term reliability.

Testing & Monitoring Post-Repair

After you complete an oil leak repair on your electric hoist, you must test and monitor the equipment before returning it to service. This process ensures your repair holds up under real-world conditions and supports long-term reliability.

Powerful Machinery recommends a graduated approach to testing and ongoing monitoring as part of your maintenance program.

No-Load and Load Testing

You should begin with a no-load test. Run the hoist through its full range of motion without any load attached. Test both lifting and lowering functions. Listen for unusual noises that may signal internal problems. Activate the upper and lower limit switches to confirm they stop the chain at the correct points.

Next, conduct a static load test. Attach a test load equal to 125% of the hoist’s rated capacity. Lift the load just off the ground and hold it steady for 10 to 20 seconds. Watch for any signs of structural deformation or brake slippage.

Finish with a dynamic load test. Reduce the test load to 110% of the rated capacity. Operate the hoist through its full range of motions. Check for smooth operation, proper brake function, and responsive controls. These steps help you verify the effectiveness of your repair and ensure safe operation.

Inspecting for Recurring Leaks

You need to monitor your electric hoist for recurring oil leaks after repair. A comprehensive maintenance schedule includes daily, frequent, and periodic inspections. The table below outlines recommended inspection types and frequencies:

Inspection Type | Frequency | Purpose |

|---|---|---|

Daily Inspection | Before each shift | Identify obvious defects and ensure immediate operational safety. |

Frequent Inspection | Monthly to quarterly | More thorough visual and operational inspection to uncover developing issues. |

Periodic Inspection | Annually | In-depth inspection may involve partial disassembly to measure wear. |

Daily inspections help you spot immediate problems. Frequent inspections, performed monthly or quarterly by trained personnel, uncover developing issues.

Periodic inspections, typically done annually, assess the overall condition and address potential leaks before they become safety risks. Consistent monitoring is a key part of your maintenance strategy.

Maintenance Record Updates

You should update your maintenance records after every repair and inspection. Document the date, type of test performed, findings, and any corrective actions taken. Accurate records help you track the history of your electric hoist and identify patterns in failures or leaks.

This habit supports compliance with safety standards and improves future maintenance planning. Powerful Machinery recommends keeping detailed logs as part of your ongoing maintenance program.

Tip: Use a digital logbook or maintenance management software to streamline recordkeeping and ensure easy access to your hoist’s service history.

Regular testing and monitoring, combined with thorough maintenance documentation, protect your investment and support safe, reliable operation.

Preventing Future Electric Hoist Oil Leaks

Regular Inspection Schedules

You can reduce the risk of oil leaks by following a strict inspection schedule. Regular inspections help you catch problems early and keep your electric hoist running smoothly.

Powerful Machinery designs its products for durability and low maintenance needs, but you still need to check key areas often. Use the table below to guide your preventative maintenance routine:

Inspection Item | Action Required |

|---|---|

Signs of leaks in hydraulic systems | Inspect hoses and connections |

Fluid levels in reservoirs | Check fluid levels |

Wet spots or drips | Look for wet spots |

Integrity of seals | Ensure all seals are intact |

Immediate repairs | Repair any leaks found immediately |

Set up a calendar for regular inspections. Daily checks help you spot leaks or wear before they become serious. Monthly and annual inspections let you measure seal integrity and fluid levels. This schedule supports prevention and keeps your equipment safe.

Tip: Document every inspection and repair. Good records make future maintenance easier and help you track patterns.

Proper Oil Levels and Fluid Selection

Maintaining the correct oil level is essential for preventing future oil leaks. You should always use the oil type and viscosity recommended by Powerful Machinery. The right fluid protects your gearbox and seals from wear. The table below shows which viscosity index works best for different temperature ranges:

Temperature Range | Recommended Viscosity Index |

|---|---|

-20°C to 40°C | VI 90-110 (mineral oils) |

Below -20°C | VI 130+ (synthetics) |

For low-speed operation, use ISO VG 220-320 oils or NLGI Grade 2 grease. These fluids contain anti-wear or extreme pressure additives. For high-speed operation, select ISO VG 32-68 oils with a high viscosity index.

Polyurea-thickened greases work well for demanding environments. Always monitor for stick-slip motion and conduct regular oil analysis.

Note: Using the correct oil and keeping levels within the recommended range will extend the life of your hoist and support preventative maintenance.

Storage and Environmental Care

Proper storage and environmental care play a big role in prevention. Store your electric hoist in a clean, dry area. Protect it from moisture, dust, and temperature extremes. Cover the hoist when not in use. Make sure the storage area has good ventilation. These steps help you avoid corrosion and seal damage.

You should also keep the work area clean during operation. Remove oil spills quickly and dispose of waste oil according to local regulations. This practice supports preventative maintenance tips and keeps your equipment in top condition.

Callout: Prevention starts with small habits. Clean storage and regular inspections help you avoid costly repairs and downtime.

By following these preventative maintenance tips, you can focus on preventing future oil leaks and keep your Powerful Machinery electric hoist reliable for years.

Repair or Replace: Decision-Making for Powerful Machinery Hoists

Assessing Damage Severity

You need to start by evaluating the condition of your electric hoist. Look for signs of severe wear, repeated oil leaks, or structural damage. If you notice cracks in the gearbox, frequent breakdowns, or if the hoist has reached the end of its service life, you should consider more than just a simple repair.

Minor issues, such as worn seals or gaskets, often require straightforward fixes. However, major problems like casing fractures or persistent leaks may signal that the equipment is no longer reliable.

When to Replace vs Repair?

Making the right decision between repair and replacement saves you time and money. Use the table below to compare your options:

Consideration | Repairing Existing Hoist | Replacing with New Hoist |

|---|---|---|

Initial Costs | Lower if repairable | Higher for new equipment |

Long-term Maintenance Costs | It can be high with frequent repairs | Lower due to new components |

Energy Efficiency | May not improve | Improved with new models |

Safety Features | Limited to current features | Enhanced with the latest technology |

Total Cost of Ownership (TCO) | High if repairs are frequent | Lower with reduced maintenance needs |

If the cost of repair approaches or exceeds the value of your electric hoist, replacement is the better choice. New hoists offer advanced safety features, better energy efficiency, and lower long-term maintenance costs. You also benefit from improved warranties and customer support.

Tip: Always factor in the age of your equipment. If your electric hoist is near the end of its expected lifespan, replacement ensures greater reliability.

Consulting Powerful Machinery Professionals

You do not have to make this decision alone. Powerful Machinery offers a full range of support services to help you choose the best path. You can access on-site repair, 24/7 emergency service, and even send your equipment for quick evaluation and return.

The team can inspect your electric hoist, provide expert advice, and recommend whether to repair or replace. Their certified technicians ensure your equipment meets all safety and performance standards.

Note: Rely on Powerful Machinery’s certified service for peace of mind and long-term value.

Conclusion

You protect your equipment and team when you follow a safety-first, step-by-step approach to electric hoist oil leak repair. Using Powerful Machinery’s certified parts ensures long-term reliability because genuine components fit perfectly and last longer.

Proactive maintenance extends the lifespan of your hoist and reduces unexpected failures. Keep detailed records of every inspection and repair. This habit helps you spot recurring issues and plan preventive maintenance.

When you consult professionals for complex problems, you support safe, reliable operation for years to come.

FAQ

What causes oil leaks in electric hoists?

You often see oil leaks due to worn seals, damaged gaskets, or loose fittings. High operating temperatures and improper maintenance can also lead to leaks. Regular inspections help you catch these issues early.

Can you use any oil for refilling the gearbox?

You must use the oil type and viscosity recommended by Powerful Machinery. Using the wrong oil can cause poor lubrication, increase wear, and lead to more leaks. Always check your product manual for specifications.

How often should you inspect your electric hoist for oil leaks?

You should inspect your electric hoist before each use for visible leaks. Schedule monthly and annual inspections for a thorough check. Frequent inspections help you prevent major failures and extend equipment life.

What should you do if you find a crack in the gearbox casing?

Stop using the hoist immediately. Contact a certified Powerful Machinery technician for assessment. Small cracks may require epoxy repair, but severe damage often means you need to replace the casing for safety.

Does repairing an oil leak void your warranty?

Note: If you use certified parts and follow Powerful Machinery’s repair guidelines, you keep your warranty valid. Using non-certified components or improper repair methods may void your warranty.