You need precise chain measurements to ensure safety, compatibility, and optimal performance in demanding environments. Accurate sizing protects your equipment during lifting, marine, and transport operations. Powerful Machinery’s certified products help you achieve reliable results every time.

Focus on three critical measurements: wire diameter, pitch, and inner width. Chain Measurement and Cutting require attention to detail and the right tools. You gain confidence by following proven methods and international standards.

Key Takeaways

Accurate chain measurements are crucial for safety and performance. Focus on wire diameter, pitch, and inner width to ensure compatibility.

Use the right tools, like calipers and chain wear indicators, for precise measurements. This helps avoid errors and ensures reliable results.

Follow a step-by-step guide for measuring the chain. Clean the chain, measure at multiple points, and compare with manufacturer specs to confirm accuracy.

Regular inspections and detailed record-keeping enhance safety and reliability. Document every inspection to track changes and maintain compliance.

Always verify chain measurements against manufacturer specifications. This step prevents unexpected failures and ensures optimal performance.

How to Measurea Chain?

Key Chain Measurements

You need to focus on three main dimensions when you measure a chain for any application. These measurements ensure compatibility, safety, and performance. International standards like DIN 766 and ISO define these dimensions clearly. Here are the most important ones:

Wire Diameter: This is the thickness of the metal wire used to form each link. It determines the chain’s strength and load capacity.

Pitch: The pitch is the distance from the center of one link to the center of the next. It affects how the chain fits with sprockets or pulleys.

Inner Width: This is the space between the inner sides of a link. It ensures the chain fits properly onto equipment.

You should also consider other dimensions for mechanical systems. The table below shows which measurements matter most for compatibility with sprockets and pulleys:

Dimension | Description |

|---|---|

Pitch | The distance between the centers of two consecutive pins affects the type of sprocket used. |

Roller Diameter | The size of the cylinder that contacts the sprocket teeth helps to distribute load and minimize wear. |

Inner Width | The distance between the two inner plates ensures a proper fit onto the sprocket. |

Pin Diameter | The thickness of the pins connecting the chain links is crucial for the chain’s strength. |

Plate Thickness | Thicker plates provide greater mechanical strength for heavy-duty applications. |

Plate Height | Impacts load capacity and resistance to tension. |

Pin Length | Ensures the chain has the correct width for the intended system. |

Powerful Machinery’s certified chains meet strict ISO and DIN standards. You can trust their dimensional accuracy, strength, and wear resistance for demanding jobs.

Tools for Accurate Measurement

You need the right tools to measure chain dimensions precisely. Using a suitable tool for measuring helps you avoid errors and ensures reliable results. Here are the most common tools used in industrial settings:

Calipers: These provide high accuracy for measuring wire diameter, inner width, and pitch.

Chain Wear Measuring Tools: These help you check for elongation and wear.

Chain Wear Indicator Guides: These offer a quick way to assess chain condition.

Roller Diameter Wear Gages: These measure the size of rollers for chains with rollers.

Width Measuring Tools: These check the internal and external widths of links.

Calipers and vernier gauges are popular choices. Calipers can measure with an accuracy of up to 0.02mm. However, you must position them carefully, as even small errors can affect your readings.

Many professionals find it helpful to use a new chain as a reference when checking for wear. This method can be more reliable than relying only on tools.

Tip: Always measure away from welds, coatings, or damaged areas. This gives you the most accurate measurements.

Step-by-Step Guide to Measure Chain

You can follow these steps to measure the chain accurately and avoid common mistakes:

Clean the chain. Remove dirt, grease, or wax that could affect your measurements.

Use a caliper to measure the wire diameter. Take readings at several points along the chain, avoiding welds and worn spots.

Measure the inner width. Place the caliper’s jaws between the inner sides of a link.

Measure the pitch. For standard chains, measure from the center of one link to the center of the next along the chain’s length.

For roller chains, measure the roller diameter and pin diameter if needed.

Compare your measurements with the manufacturer’s catalog or standard tables. This confirms you have the correct chain size.

If you work with weldless chains, include any twists in your measurements.

Note: Chains do not wear evenly. Measure in multiple spots and avoid the quick link area. Tension the chain before measuring, and never measure a freshly waxed or slack chain.

Powerful Machinery’s chains undergo strict dimensional checks and quality assurance. Their products conform to ISO 9001 and DIN standards, with length tolerances restricted to 1/6 of the DIN limit.

You benefit from chains with excellent wear resistance and breaking strength, making them ideal for lifting, marine, and transport applications.

By following these steps and using the right tools, you ensure your measurements are accurate. This helps you select the right chain for your needs and maintain safety in every operation.

Chain Measurement and Cutting Tips

How to Measure Lifting Chain?

You must approach chain measurement and cutting for lifting chains with extra care. Lifting chains require strict adherence to standards because they support heavy loads overhead. You should always check the chain link size, wire diameter, and pitch.

These measurements help you confirm the chain’s grade and compatibility with lifting hardware.

Here is a comparison of lifting chains and general-purpose chains:

Aspect | Lifting Chains | General-Purpose Chains |

|---|---|---|

Strength | Graded based on ultimate breaking strength | Used for less critical applications |

Material Specifications | Subject to specific safety standards | No specific safety standards required |

Intended Applications | Designed for overhead lifting | Suitable for various non-critical uses |

You should only use certified lifting chains, such as those from Powerful Machinery, which meet ISO and DIN requirements. These standards ensure the chain links have the correct dimensions and strength for safe lifting.

How to Measure Marine Anchor Chain?

Chain measurement and cutting for marine anchor chains must follow international maritime standards. You need to measure the chain link size, wire diameter, and pitch, just as you would for lifting chains.

However, you must also consider the effects of corrosion and marine exposure, which can change the actual dimensions over time.

Key standards for marine anchor chain include:

Standard Name | Description |

|---|---|

ISO 1704 | Provides guidelines for the design, manufacturing, and testing of anchor chains. |

EN 818-2 | Sets forth safety, strength, and testing requirements for marine anchor chains. |

API 2F | Focuses on anchor chains for offshore platforms, ensuring reliability under extreme conditions. |

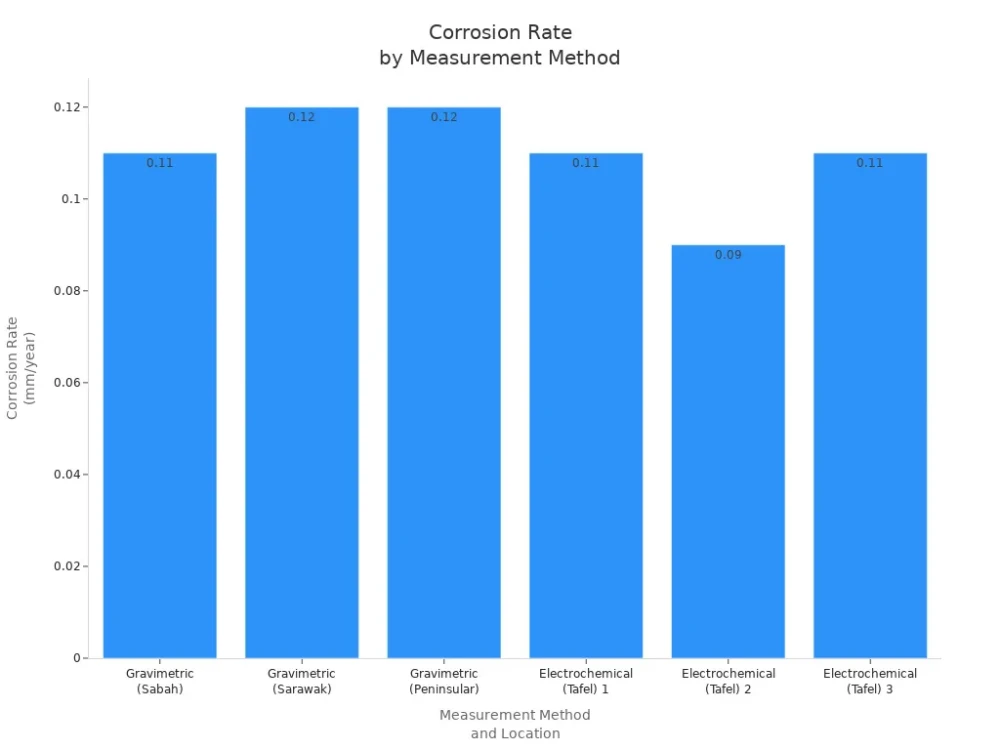

You should always check for corrosion before you measure. Corrosion can reduce the chain link size and affect safety. The chart below shows how corrosion rates can vary by location and method:

You should use calipers for the best way to measure the chain and compare your results to ISO 1704 or EN 818-2 standards.

How to Cut Chain?

You must follow a careful process for chain measurement and cutting to maintain safety and chain integrity. Here is a step-by-step guide for how to cut a chain:

Inspect the chain and select the correct cutting method based on the chain link size and material.

Gather your tools. Use pliers, hacksaws, or bolt cutters for different chain types. Always wear gloves and eye protection.

Secure the chain on a stable surface or clamp it to prevent movement during the cut.

Cut or open the chain links with the appropriate tool. Work slowly to avoid jagged edges.

Smooth any sharp edges with a metal file or sandpaper after you cut.

After you cut, inspect the chain for wear or damage. Clean your tools to prevent buildup. This process ensures your chain measurement and cutting results meet safety standards.

Powerful Machinery uses high-grade alloy steel and stainless steel for all chain links. Their products offer excellent durability and versatility for lifting, marine, and transport applications. You can trust their chains for every chain measurement and cutting task.

Ensuring Compatibility and Avoiding Mistakes

Double-Check Manufacturer Specs

You must always verify your chain measurements against the manufacturer’s specifications, especially for critical applications. This step protects your operation from unexpected failures and ensures the chain performs as intended.

Powerful Machinery provides detailed technical data for every certified chain, making it easy for you to confirm compatibility.

Aerospace components operate in environments where failure is not an option. A single defective part can compromise an entire mission, endanger lives, or result in catastrophic financial losses.

You should treat every lifting, marine, or transport application with the same level of caution. Always compare your measurements to the official specs before installation or replacement.

Common Measurement Errors

You can avoid costly mistakes by understanding the most frequent errors in chain measurement. Measuring near welds, ignoring wear, or using the wrong tools can lead to inaccurate results. Chains often experience wear and deformation, which affects their true dimensions.

Key Findings | Description |

|---|---|

Wear Estimation | The conventional mass-spring model tends to overestimate wear, while a modified three-dimensional link model provides more accurate estimates of wear amount in relation to chain diameter measurements. |

You should measure away from welds and worn areas. Use calibrated tools and inspect multiple points along the chain. Replace chains that show signs of excessive wear or deformation.

Regular Inspection and Record Keeping

You maintain safety and reliability by inspecting chains regularly and keeping detailed records. Powerful Machinery follows industry-leading practices for chain inspection and documentation.

Maintain accurate inspection records to meet certification requirements.

Ensure dated inspection reports are accessible to authorized personnel.

Implement a long-range inspection program that documents the examination of ropes or chains removed from service.

Record every inspection, cleaning, lubrication, repair, and test in a logbook or digital system.

Include details such as date, type of inspection, findings, actions taken, and technician’s name.

Conduct visual inspections for obvious signs of wear, corrosion, or damage.

Use non-destructive testing methods, such as ultrasonic testing, to detect hidden flaws.

Document each inspection thoroughly so you can track changes over time.

Schedule professional assessments annually or biannually, depending on your initial findings.

You build a safer workplace and extend the life of your chains by following these best practices. Powerful Machinery’s commitment to safety and reliability ensures you receive products that meet or exceed industry benchmarks.

Conclusion

You achieve accurate chain measurement and safe cutting by following proven steps, using precise tools, and adhering to international standards. Certified, high-quality chains from Powerful Machinery deliver reliability and reduce long-term costs.

Regular inspections and maintenance protect your operations. Use the checklist below to maintain safety and performance. When in doubt, consult industry experts or manufacturers for guidance.

Inspection Type | Frequency | Description |

|---|---|---|

Initial Inspection | Before initial use | Ensures compliance with standards |

Frequent Inspection | Weekly to monthly | Visual check for proper operation |

Periodic Inspection | Monthly to annually | Detailed examination by competent personnel |

Hoists Not in Service | After inactivity | Inspection before returning to service |

Inspection Records | Ongoing | Maintain dated reports for accountability |

FAQ

How do you choose the right chain grade for lifting?

You should check the load requirements and safety standards for your application. Powerful Machinery offers G80 and G100 grades for heavy lifting. Always verify the chain’s certification and match it to your lifting hardware.

What tools do you need for accurate chain measurement?

You need calipers or vernier gauges for precise measurement. Use chain wear indicators for quick checks. Always measure away from welds or damaged areas for best results.

Can you use Powerful Machinery chains outdoors?

Yes. Powerful Machinery chains use alloy steel and stainless steel. These materials resist corrosion and wear. You can use them for outdoor lifting, marine, and transport applications.

How often should you inspect your chains?

You should inspect chains before each use and schedule periodic inspections monthly or annually. Keep detailed records of every inspection to maintain safety and meet certification requirements.

Where can you find technical specifications for Powerful Machinery chains?

Visit Powerful Machinery’s official website for detailed product specifications, certifications, and technical support. You can also contact their team for custom solutions.