You must measure eye bolts with precision to ensure safe and proper installation. Accurate eyebolt measurement and selection protect your equipment and personnel.

Focus on key parameters such as load capacity, thread size, and eye diameter. Powerful Machinery’s Stainless Steel Eye Bolts provide certified strength and reliability for demanding environments. Review the most common parameters that affect safety and fit in the table below:

Parameter | Description |

|---|---|

Material | The quality and strength of the material (e.g., stainless steel, carbon steel) affect load capacity. |

Diameter | Larger diameter bolts generally handle heavier loads, impacting safety. |

Thread Length | A longer thread provides a more secure fit, enhancing the bolt’s capacity. |

Load Angle | The angle of load application affects effective capacity; ideally, it should be in line with the bolt. |

Safety Factors | Incorporating safety factors ensures the working load limit is lower than the breaking strength for safety. |

Key Takeaways

Always check the load capacity of eye bolts before installation. This ensures they can safely support the intended weight and prevents accidents.

Match the thread size of the eye bolt to the mounting surface for a secure fit. This step is crucial for maintaining strength and stability.

Measure the eye diameter accurately to ensure compatibility with ropes or chains. A proper fit prevents binding and wear on the eye bolt.

Select the right shank and thread length to ensure the eye bolt sits securely in the material. This helps distribute the load effectively and enhances safety.

Follow best practices during installation, such as tightening nuts securely and inspecting eye bolts regularly. These actions help prevent failures and extend the life of your equipment.

Key Measurements

Accurate eyebolt measurement and selection start with understanding the five most critical parameters. Each measurement ensures the eye bolt fits your application and meets safety requirements.

Powerful Machinery’s Stainless Steel Eye Bolts provide a reliable reference for these standards, as they are engineered for precision and certified for demanding environments.

Load Capacity

You must always check the load capacity before installing any eye bolt. The load capacity tells you the maximum weight the eye bolt can safely support. Manufacturers determine this value using strict international safety standards.

Loads should be applied in the plane of the eye, not at an angle.

Working load limits are based on a straight vertical lift with a safety factor of 5 to 1.

Angular lifts reduce the working load limit and require a properly seated shoulder pattern machinery eye bolt.

Eyebolts should be marked with a Working Load Limit valid for in-line pull, thread diameter, material identification symbol, manufacturer’s symbol, and CE mark.

Never exceed the working load limit. Exceeding the rated capacity can cause the eye bolt to bend or break, which may result in dropped loads and serious injury.

The surrounding structure could also be compromised. Powerful Machinery’s Stainless Steel Eye Bolts are clearly marked with their rated load and comply with DIN 580 and JIS 1168 standards, giving you confidence in every lift.

Thread Size

Thread size determines how securely the eye bolt fits into the mounting surface. You need to match the thread size to the hole or nut for a safe and stable connection.

Eye bolts use machine screw threads designed for secure threading in compatible nuts and surfaces. The thread diameter is crucial for compatibility and strength.

Eye Bolt Size | Diameter (mm) | Applications | Working Load Limit (tonnes) |

|---|---|---|---|

M10 | 10 | General construction, carpentry, DIY projects | 0.2 to 2 |

M12 | 12 | Construction, metal fabrication, industrial | 0.5 to 5 |

M16 | 16 | Heavy-duty lifting, securing beams, and rigging | 2 to 10 |

Powerful Machinery offers a wide range of thread sizes, from M6 to M20, ensuring you find the right fit for your project. Always verify the thread size during eyebolt measurement and selection to avoid mismatched or unsafe installations.

Eye Diameter

The eye diameter is the internal width of the loop at the top of the bolt. This measurement determines what size rope, chain, or hook you can use with the eye bolt. Measure the inside width at the widest point. A proper eye diameter ensures the hardware you attach moves freely and does not bind or wear the eye bolt.

Choosing the correct eye diameter is essential for both safety and functionality. Powerful Machinery’s Stainless Steel Eye Bolts feature precision-engineered eyes that accommodate a variety of rigging accessories, making them versatile for different lifting and securing tasks.

Shank and Thread Length

Shank and thread length affect how deeply the eye bolt sits in the mounting surface and how much thread engages with the material. You measure the thread length as the part of the shank with threads, excluding the eye. The shank length includes the entire threaded portion and any part that extends beyond the eye.

Dimension | Description |

|---|---|

Thread length | The length of the threaded portion of the shank, excluding the eye. |

Shank length | The total length of the threaded shank, including the thread length and the portion that extends beyond the eye. |

Selecting the right shank and thread length ensures the eye bolt holds securely and distributes the load properly. Powerful Machinery’s eye bolts come in various lengths to match different material thicknesses and installation needs. Always include this step in your eyebolt measurement and selection process.

Overall Length

The overall length is the total distance from the top of the eye to the bottom of the shank. To measure this, place the eye bolt on a flat surface and use a ruler or caliper to measure from the highest point of the eye to the end of the threaded shank.

Identify the key elements: shank length, diameter, and eye diameter.

Measure the overall length from the top of the eye to the bottom of the shank.

This measurement helps you confirm the eye bolt will fit your application and not protrude too far or fall short. Powerful Machinery’s Stainless Steel Eye Bolts are manufactured to precise specifications, ensuring consistency and reliability in every application.

Tip: Always double-check all measurements before installation. Accurate eyebolt measurement and selection prevent costly mistakes and keep your team safe.

By following these guidelines and choosing certified products like Powerful Machinery’s Stainless Steel Eye Bolts, you ensure every lift meets the highest standards for safety and performance.

Eyebolt Measurement and Selection

Choosing the right eye bolt for your project requires careful attention to several factors. You must consider standard sizes, material, and grade, and application fit. Each step in eyebolt measurement and selection ensures your installation meets safety standards and performs reliably in demanding environments.

Standard Sizes

You will find that eye bolts come in a range of standard sizes. Selecting the correct size is essential for matching the load requirements and the hardware you plan to use. In the marine and construction industries, the most common sizes include:

Size | Description |

|---|---|

1/4″ | Commonly used for lighter loads |

5/16″ | Suitable for moderate loads |

3/8″ | Often used for heavier applications |

1/2″ | Ideal for substantial lifting tasks |

You should match the size to the expected load and the type of lift. For example, shouldered eye bolts work for both vertical and angular lifts, while non-shouldered eye bolts are only safe for vertical lifts. Always check the working load limits and avoid exceeding them.

Powerful Machinery’s Stainless Steel Eye Bolts are available in a wide range of sizes, making them suitable for everything from light-duty tasks to heavy lifting in industrial settings.

Eye bolts come in various types, such as regular, shoulder type, lag eye screw, forged, and stainless steel.

Shouldered eye bolts are versatile and safer for angular lifts.

Non-shouldered eye bolts should only be used for in-line or vertical lifts.

Material and Grade

The material and grade of an eye bolt directly affect its strength, durability, and safety rating. Stainless steel eye bolts offer superior corrosion resistance, making them ideal for outdoor, marine, and industrial environments.

You benefit from high strength and long-lasting performance, which reduces the need for frequent replacements.

Feature | Stainless Steel Eye Bolts | Carbon Steel Eye Bolts |

|---|---|---|

Corrosion Resistance | Superior, ideal for harsh conditions | Not specifically mentioned |

Strength | High strength suitable for heavy lifting | Not specified |

Longevity | Long-lasting, reduces the need for replacements | Not specified |

Ideal Environments | Outdoor, marine, industrial | Not specified |

Selecting the right grade is crucial. The grade indicates the material quality and strength. Higher-grade materials provide better strength and durability. You must choose the grade based on your load requirements to prevent failure.

Each eye bolt should display the manufacturer’s name, size, or rated load, and grade. Powerful Machinery’s Stainless Steel Eye Bolts comply with DIN 580 and JIS 1168 standards, ensuring you receive certified products designed for critical applications.

Note: The choice of material grade influences mechanical properties such as strength and resistance to deformation. Always select the appropriate grade for your lifting operations.

Application Fit

Proper application fit is vital for safety and performance. You need to consider the type of eye bolt, the angle of lift, and the nature of the load. Shouldered eye bolts provide versatility and safety for both vertical and angular lifts.

Non-shouldered eye bolts are restricted to vertical lifts only. If your application involves rotating loads, use swivel eye bolts instead of standard eye bolts.

Eye bolt type: Shouldered eye bolts are safer and more versatile.

Angle of lift: Lifting at an angle requires careful selection and adherence to manufacturer guidelines.

Load rotation: Standard eye bolts are not designed for rotating loads; use swivel eye bolts for these situations.

For collar eyebolts, reduce the working load when used at an angle:

Up to 15º: Use 0.63 of the rated load.

Up to 30º: Use 0.4 of the rated load.

Up to 45º: Use 0.25 of the rated load.

Industry standards such as DIN 580 and JIS 1168 guide you in selecting the right eye bolt for your application. These standards specify material properties, load capacities, and correct usage, ensuring safety in lifting operations.

Powerful Machinery’s Stainless Steel Eye Bolts meet these standards and offer reliable performance in harsh environments, including marine, construction, and industrial settings.

Tip: Always refer to the manufacturer’s recommendations and international standards during eyebolt measurement and selection. This practice helps you avoid common mistakes, such as exceeding rated capacity or using the wrong type of eye bolt for the lift.

By following these guidelines, you ensure that your eyebolt measurement and selection process results in safe, efficient, and long-lasting installations. Powerful Machinery’s certified products provide peace of mind and superior performance for every application.

Additional Considerations

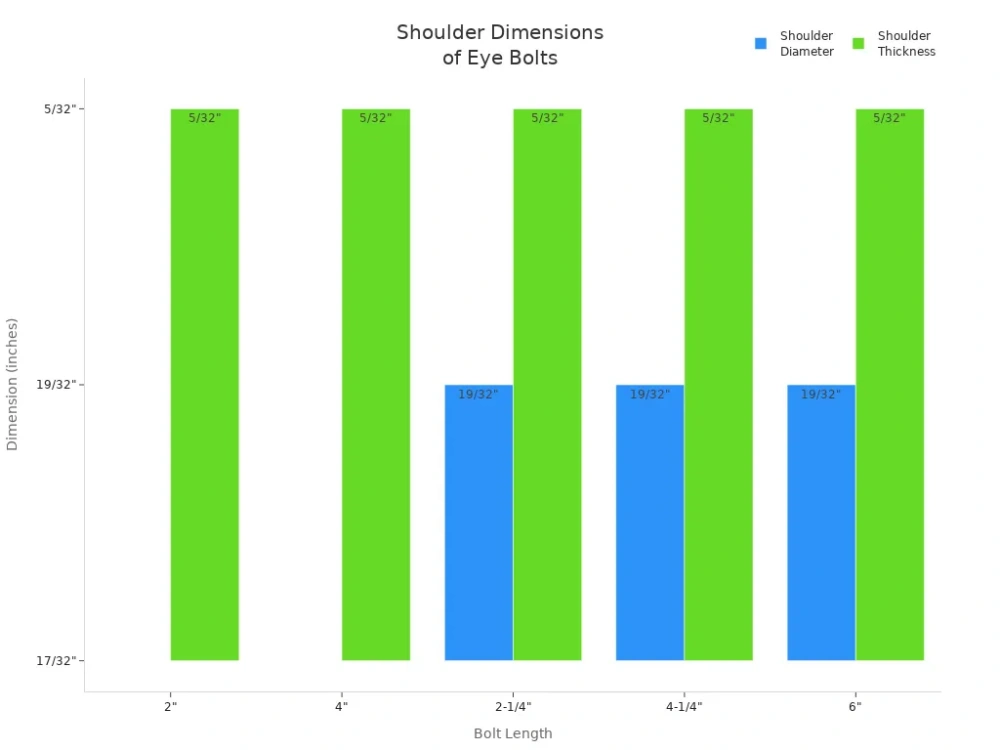

Shoulder Dimensions

You must pay close attention to shoulder dimensions when selecting eye bolts for lifting applications. The shoulder provides critical reinforcement, especially during angular lifts. Proper shoulder size ensures the load distributes evenly and reduces the risk of bolt failure.

Shoulder eye bolts handle side loads much better than plain eye bolts, which only support vertical lifting. This design helps maintain the structural integrity of the bolt under challenging conditions.

Here is a table showing key shoulder dimensions for common eye bolt sizes:

Length (B) | Outside Eye Diameter (C) | Inside Eye Diameter (D) | Overall Length (E) | Shoulder Diameter (H) | Shoulder Thickness (G) | Thread Length (F) |

|---|---|---|---|---|---|---|

2″ | 1″ | 1/2″ | 3-3/8″ | 17/32″ | 5/32″ | 1-1/2″ |

4″ | 1″ | 1/2″ | 5-3/8″ | 17/32″ | 5/32″ | 2″ |

2-1/4″ | 1-1/4″ | 5/8″ | 3-15/16″ | 19/32″ | 5/32″ | 1-1/2″ |

4-1/4″ | 1-1/4″ | 5/8″ | 5-15/16″ | 19/32″ | 5/32″ | 2-1/2″ |

6″ | 1-1/4″ | 5/8″ | 7-11/16″ | 19/32″ | 5/32″ | 3″ |

Safety and Installation

You can maximize safety and performance by following best practices during installation. Always select the correct type of eye bolt for your lifting needs. Misalignment or improper threading can weaken the bolt and increase the risk of failure. Follow these essential safety tips:

Never undercut an eye bolt to seat the shoulder against the load.

Countersink the receiving hole or use washers to seat the shoulder properly.

Screw the eye bolt down completely for a secure fit.

Tighten nuts securely against the load.

Inspect eye bolts regularly for wear, nicks, or cracks.

Remove any unmarked or damaged eye bolts from service.

Keep threads on both the shank and receiving hole clean.

Never repair or reshape an eye bolt by welding, heating, or bending.

Do not exceed the specified load limits.

For proper installation, orient the eye bolt in line with the slings to avoid bending. Use pack washers to ensure firm contact between the eye bolt and the load surface.

Always torque the nut so it makes full contact with the surface. Powerful Machinery’s Stainless Steel Eye Bolts are engineered for reliability and meet strict international standards, giving you confidence in every lift.

Regular inspections and correct installation help prevent accidents and extend the life of your lifting equipment.

Conclusion

You ensure workplace safety and equipment reliability when you measure and select eye bolts accurately. Certified products like Powerful Machinery’s Stainless Steel Eye Bolts deliver proven performance in safety-critical applications.

International standards support your efforts by providing clear guidelines and rigorous quality control:

Aspect | Contribution to Safety and Reliability |

|---|---|

Load Capacities | Handle specified weights safely |

Quality Control | Prevent failures during use |

Usage Instructions | Minimize risks of improper use |

Always review product specifications and standards before installation. Your attention to detail protects your team and your investment.

FAQ

How do you measure the thread size of an eye bolt?

You measure the thread size by using a caliper to check the diameter of the threaded section. Match this measurement to the corresponding metric or imperial size. Always verify the thread pitch for compatibility with your application.

Can you use stainless steel eye bolts outdoors?

Yes, you can use stainless steel eye bolts outdoors. Their corrosion resistance makes them ideal for marine, construction, and industrial environments. Powerful Machinery’s Stainless Steel Eye Bolts maintain strength and reliability even in harsh weather conditions.

What standards should you check before selecting an eye bolt?

You should check for compliance with international standards such as DIN 580 and JIS 1168. These standards ensure the eye bolt meets strict safety and performance requirements. Powerful Machinery’s products meet or exceed these certifications.

How often should you inspect eye bolts for safety?

You should inspect eye bolts before each use. Look for signs of wear, corrosion, or deformation. Remove any damaged or unmarked eye bolts from service immediately to maintain workplace safety.