You ensure safely using bow shackles by selecting the correct type, inspecting each component for wear, and using certified products from Powerful Machinery. Always check alignment and avoid side loading, which can reduce strength by up to 50%.

Choose the right pin size and prevent twisting or uneven loads. Regular inspection and proper handling help you maintain bow shackles safety and prevent failures that result from misuse or material degradation.

Key Takeaways

Always inspect bow shackles for wear, corrosion, or damage before each use. Regular checks help prevent accidents and ensure safety.

Select the right type of bow shackle based on your application. Consider factors like working load limit, material, and environmental conditions.

Align the load correctly with the shackle’s axis to avoid side loading. This practice reduces the risk of failure and enhances safety.

Use certified shackles from trusted manufacturers like Powerful Machinery. Certified products ensure reliability and compliance with safety standards.

Replace any shackle that shows signs of damage, such as excessive wear or corrosion. Timely replacement is crucial for maintaining safety.

Bow Shackle Types

Main Components

A bow shackle consists of two main parts: the rounded body and the removable pin. The rounded shape, also called an Omega shape, allows you to connect multiple slings or chains from different directions. This design gives bow shackles greater flexibility than D-shackles, which have a straight, narrow profile.

The pin, which can be a screw or bolt type, secures the load and ensures a reliable connection. When you choose a bow shackle from Powerful Machinery, you get a product crafted for strength and durability, whether you select stainless steel shackles for marine use or heavy-duty shackles for construction.

Tip: Always check that the pin fits tightly and moves smoothly before use.

Types Overview

You will find several types of bow shackles in the lifting and rigging industry. Each type serves a specific purpose:

Synthetic Sling Shackles: Designed for use with synthetic slings, improving efficiency and safety.

Wide Body Shackles: Used with high-capacity slings to prevent kinking and extend service life.

Long Reach Shackles: Perfect for construction jobs that require extra reach.

Sheet Pile Shackles: Built for pulling sheet piling in heavy-duty projects.

Bow shackles stand out because they handle forces from multiple directions without losing strength. This makes them ideal for rigging tasks where you need to connect more than one sling or chain.

Feature | Bow Shackles | D-Shackles |

|---|---|---|

Shape | Rounded, ‘bow’ shape | ‘D’ shape |

Multi-directional Loading | Yes | Limited |

Load Distribution | Excellent | Less effective |

Use in Rigging | Multi-leg slings | Single attachments |

Identify and Match the Bow Types of Shackles

To select the right bow shackle for your job, you need to consider several criteria:

Criteria | Description |

|---|---|

Working Load Limit (WLL) | Maximum safe load for the shackle |

Size | Must fit your sling, chain, or rope |

Manufacturer’s Name | Ensures you use a trusted brand like Powerful Machinery |

Traceability Codes | Important for safety and compliance |

Material Type or Grade | Stainless steel or alloy steel for strength and corrosion resistance |

For temporary lifting, screw pin bow shackles offer quick and easy setup. For long-term or permanent installations, bolt-type shackles provide extra security. Powerful Machinery’s range includes both options, so you can match the right shackle to your application—whether you work in marine, construction, or cargo handling.

Note: Recent advancements include self-locking pins and anti-corrosive coatings, which you will find in Powerful Machinery’s latest shackle designs.

Selecting Bow Shackles

Working Load Limit

You must always check the Working Load Limit (WLL) before choosing bow shackles for any lifting or rigging task. The WLL tells you the maximum load a shackle can safely handle. Exceeding this limit can cause equipment failure, dropped loads, or even injuries. To ensure safety, follow these best practices:

Identify the WLL marked on each shackle.

Plan your rigging based on the lowest-rated component in your assembly.

Never exceed the WLL during operation.

The WLL helps prevent overloading and reduces the risk of catastrophic failure.

Using bow shackles without knowing their WLL can lead to serious accidents.

Powerful Machinery clearly marks the WLL on all its certified shackles, making it easy for you to select the right product for your needs.

Material and Certification

The material of your bow shackles affects both performance and safety. Stainless steel offers high strength and excellent corrosion resistance, making it ideal for marine and chemical environments.

Galvanized steel provides moderate strength and is suitable for general use. Titanium is used in specialized industrial applications.

Material | Strength | Corrosion Resistance | Applications |

|---|---|---|---|

Stainless Steel | High | Excellent | Marine, chemical environments |

Titanium | High | Excellent | Industrial |

Galvanized Steel | Moderate | Moderate | General use |

You should also verify that your shackles meet industry certifications. Look for standards such as OSHA, ASME B30.26, RR-C-271, EN 13889, and AS 2741. Powerful Machinery’s products comply with these certifications, ensuring you get reliable and safe equipment for critical applications.

Application Fit

Select bow shackles that match your specific environment and task. For marine use, choose corrosion-resistant shackles that can withstand harsh conditions. In construction, pick shackles designed for heavy loads and compliance with safety standards.

Environmental factors like extreme temperatures or chemical exposure can affect shackle performance. Cold temperatures may make steel brittle, while chemicals can cause corrosion.

Environmental Factor | Effect on Shackles |

|---|---|

Extreme Temperatures | Can make steel brittle or reduce its strength. |

Chemically Active Environments | Can cause corrosion or sudden failure. |

Tip: Always consult the manufacturer for temperature limits and inspect shackles frequently in harsh environments.

By considering load, material, certification, and application, you ensure that your bow shackles deliver safe and reliable performance every time.

Bow Shackles Safety

Bow shackles safety starts with a disciplined approach to inspection, maintenance, and timely replacement. You protect your team and equipment by following industry standards and using certified products from Powerful Machinery. Let’s break down the essential steps for ensuring bow shackles safety in every application.

Inspection Steps

You must perform regular safety checks to maintain bow shackles safety. Each inspection helps you catch early signs of wear or damage before they become hazards. Follow these steps for a thorough inspection:

Check Pin and Body Identifications

Confirm that each shackle displays the manufacturer’s name and rated load limit. Missing or illegible markings mean the shackle is not safe for use.Inspect for Damage

Look for any elongation or wear that exceeds 10% of the original shape. This level of wear signals overloading and a loss of strength.Examine for Corrosion and Pitting

Scan the surface for rust, pitting, or other signs of corrosion. Even small areas of corrosion can weaken the shackle.Look for Other Deformations

Identify any bending, twisting, or cracking in the shackle body or pin. These deformations compromise the integrity of the shackle.Assess for Heat Damage

Check for discoloration or signs of heat exposure. Heat damage can reduce the strength of the metal.

You should also follow a schedule for safety checks based on usage and environment:

Type of Inspection | Frequency/Details |

|---|---|

Initial Inspection | When you purchase new shackles or after any repairs or alterations. |

Before Use Inspection | Every time before using a shackle; perform a visual check for distortions. |

Periodic Inventory Inspection | Annually, or more often if used in harsh conditions or high-frequency cycles. |

Tip: In high-use or harsh environments, increase the frequency of your safety checks to maintain bow shackles safety.

Maintenance Tips

Proper maintenance extends the life of your bow shackles and supports ongoing safety. Here are proven practices you should follow:

Conduct regular visual inspections for signs of wear, corrosion, or damage.

Ensure pins are always securely fastened before each use.

Store shackles indoors or in a dry area to prevent rust and dirt buildup.

Clean and lightly oil threads to block corrosion and ensure smooth operation.

Avoid dropping or knocking shackles, which can cause hidden damage.

Tag shackles used in harsh environments for early rotation and closer monitoring.

Never overload your shackles. Always stay within the rated working load limit.

Note: Powerful Machinery’s stainless steel shackles offer superior corrosion resistance, making them ideal for marine and industrial environments where maintenance is critical.

Replacement Guidelines

Knowing when to remove a shackle from service is a key part of bow shackles safety. Replace any shackle that shows the following signs:

Signs of Damage | Description |

|---|---|

Excessive Noise | Indicates potential failure in function. |

Misalignment | Suggests improper fitting or wear. |

Wear and Tear | Visible signs of degradation over time. |

Corrosion | Rust or deterioration of material integrity. |

Physical Distortions | Includes bending, twisting, or cracking. |

You should also remove a shackle from service if you notice:

Excessive pitting, corrosion, nicks, or gouges.

Bent, twisted, distorted, or cracked load-bearing components.

Indications of heat damage, such as discoloration or weld splatter.

Missing or illegible manufacturer’s name or trademark.

Incomplete pin engagement or excessive thread damage.

Any evidence of unauthorized welding or repairs.

A reduction in any dimension by more than 10% from the original size.

If you ever doubt the integrity of a shackle, replace it immediately. Bow shackles safety depends on your commitment to these guidelines and your willingness to act quickly when you spot a problem.

Remember: Regular inspection, proper maintenance, and timely replacement are the foundation of bow shackles safety. Powerful Machinery’s certified products make it easier for you to uphold these standards in every lifting operation.

How to Use a Bow Shackle?

Load Alignment

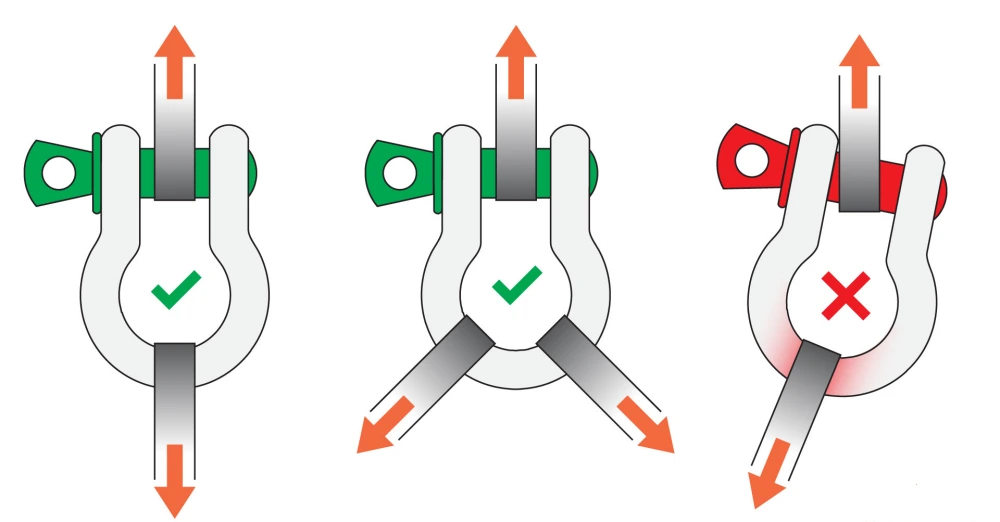

You must align the load correctly when using a bow shackle. Proper alignment ensures the shackle carries the load along its centerline, which prevents dangerous side loading and reduces the risk of failure. Follow these steps for safe load alignment:

Select the right type of bow shackle for your application, making sure it meets the Working Load Limit.

Position the shackle so the load pulls straight along the axis of the shackle body.

For multi-leg slings, check the angle between the sling legs. Keep this angle at or below 120 degrees to avoid overloading the shackle.

Place all sling legs in the bow, not on the pin, to distribute the load evenly.

Use a loose spacer on the pin if needed to prevent eccentric loading, but never modify the shackle.

Tighten the pin fully and ensure it seats properly in the shackle eye.

Tip: Bow shackles are designed for loads aligned with their axis. Side loading introduces extra stress and can cause the shackle to fail.

Pin Security

Securing the pin is essential for safe lifting. You have several pin options, each suited for different environments:

Screw pin bow shackles allow quick attachment and removal. Always tighten the pin by hand and check that it is fully engaged before lifting.

Safety pin bow shackles feature a locking mechanism that prevents accidental loosening. Use these in high-risk or long-term applications.

Bolt-type shackles provide the highest level of security. They prevent unintentional unthreading and meet ASME standards for overhead lifting.

Powerful Machinery’s bow shackles include advanced pin retention features. These keep the pin secure and prevent accidental disengagement, even in demanding conditions.

Note: Always use the correct pin for your application. Never replace a lost pin with a makeshift substitute.

Connection Methods

Proper connection methods help you achieve safe and efficient lifting. When attaching a bow shackle to slings, chains, or other equipment, follow these guidelines:

Place multiple sling legs in the bow, not on the pin. This ensures even load distribution and prevents pin damage.

When connecting two shackles, use a bow-to-bow or bow-to-pin connection. Avoid connecting pin-to-pin, as this can create dangerous point loads.

Use bolt-type shackles for overhead lifting or when you need extra load stability.

Check that all components are compatible in size and strength. The rounded shape of a bow shackle accommodates multi-leg sling connections and side loading, but always reduce the Working Load Limit if the load is not in-line.

Connection Rule | Why It Matters |

|---|---|

Sling legs in bow, not pin | Prevents pin overload and sling damage |

Bow-to-bow or bow-to-pin | Distributes force safely, avoids point loading |

Use bolt-type for overhead | Prevents accidental unthreading, meets safety standards |

Check compatibility | Ensures safe, reliable lifting |

Always inspect the connection before lifting. A secure and compatible setup prevents accidents and equipment failure.

Avoiding Common Mistakes

Many lifting accidents result from avoidable mistakes. You can prevent these by following best practices and using features built into Powerful Machinery’s bow shackles.

Inspect every bow shackle before use. Look for wear, cracks, or deformation.

Choose the correct shackle for the job. Using the wrong type can lead to overloading and breakage.

Avoid sudden jerks or drops. Rapid acceleration or deceleration can stress the shackle and cause failure.

Never force a shackle into position. If it does not fit, select a larger size.

Do not side load a round pin shackle. Always align the load with the shackle’s axis.

Attach sling legs to the bow, not the pin, to prevent long-term damage.

Make sure all connections are correct. Incorrect connections can overload the pin and cause it to break.

Remove any damaged or unsafe equipment from service immediately.

Design Feature | Benefit |

|---|---|

Load Distribution | Reduces risk of deformation by spreading force evenly |

Pin Retention | Prevents accidental pin movement or loss |

Alignment | Maintains correct load path, reducing wear and tear |

Safety Enhancement | Minimizes risk of dropped loads or accidental disengagement |

Powerful Machinery’s bow shackles include features that support proper usage and help you avoid common errors. These design elements improve safety and reliability in every lift.

By following these steps and using certified equipment, you ensure the proper usage of bow shackles in any lifting or rigging operation.

Conclusion

To use bow shackles safely, you should always follow these best practices:

Avoid side loading by keeping the load in line with the shackle’s axis.

Never exceed the working load limit.

Inspect shackles for wear, corrosion, or damage before every use.

Use proper techniques for load alignment and pin security.

Choose certified, high-quality shackles for reliable performance.

Benefit | Description |

|---|---|

Regular Inspections | Check for wear or damage before every use. |

Safety and Accident Prevention | Prevent accidents during lifting operations. |

Compliance with Standards | Ensure safety and success by following manufacturer guidelines. |

Regular inspection and strict adherence to guidelines help you achieve risk-free lifting every time.

FAQ

What is the main difference between bow shackles and D-shackles?

You will notice that bow shackles have a rounded shape, which allows for multi-directional loading. D-shackles have a straight profile and work best for single-line pulls. Choose bow shackles when you need flexibility in your rigging setup.

How do you know if a shackle is safe to use?

You should inspect the shackle for visible damage, corrosion, or deformation. Always check that the manufacturer’s markings and load ratings are clear. If you find any issues, replace the shackle immediately to ensure safety.

Can you use bow shackles in marine environments?

Yes, you can use bow shackles in marine environments. Stainless steel models resist corrosion from saltwater. Always select shackles designed for marine use and inspect them regularly for signs of rust or wear.

How often should you inspect your shackles?

You should inspect your shackles before every use. For shackles used in harsh or high-frequency environments, increase inspection frequency. Regular checks help you catch problems early and prevent accidents.

What should you do if a shackle pin does not fit properly?

You must never force a pin into place. Select a shackle with the correct size and type of pin. Using the wrong pin can cause failure during lifting operations.