You ensure safety when using web slings by selecting the right sling, inspecting it before each lift, applying proper lifting methods, and strictly following safety protocols.

Understanding how to use a web sling effectively is crucial, as neglecting these steps exposes you to risks such as broken stitching, burns, overloading, and chemical deterioration, as shown below:

Cause of Accident |

|---|

Broken stitching |

Perforations |

Burns |

Abrasion |

Cuts |

Overloading |

Improper storage and use |

Environmental conditions |

Chemical deterioration |

If you ignore safety guidelines, you may face increased repair costs, lost productivity, legal liabilities, and workplace accidents. Always follow manufacturer and OSHA instructions to protect yourself and your team.

Key Takeaways

Always inspect web slings before each use to identify any damage or wear that could compromise safety.

Choose the right sling type and hitch method based on the load’s weight, shape, and center of gravity to ensure stability.

Store web slings in a cool, dry place away from sunlight to prevent deterioration and extend their lifespan.

Train all team members on proper lifting techniques and safety protocols to minimize risks during operations.

Follow manufacturer and OSHA guidelines to maintain compliance and ensure safe lifting practices.

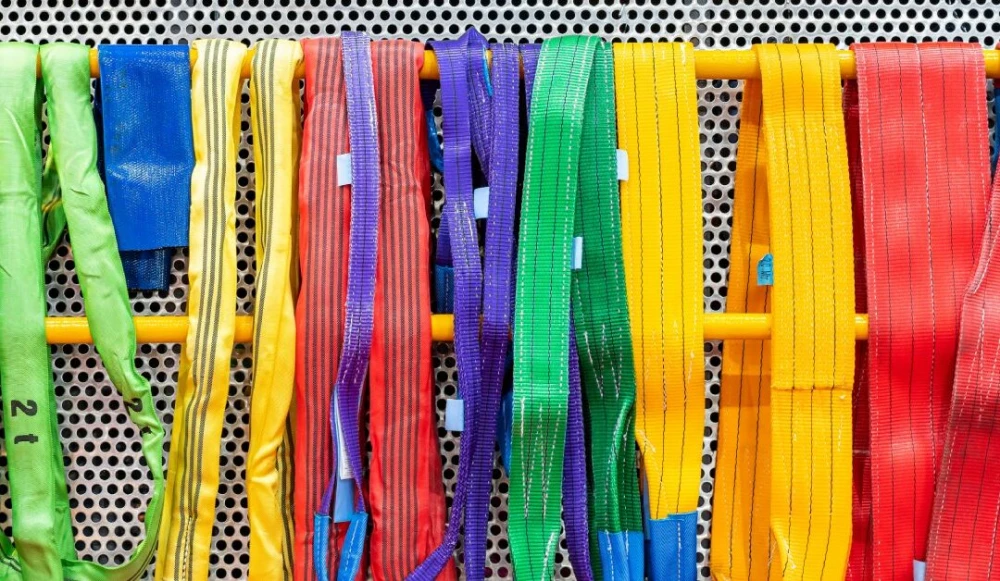

Choosing Web Slings for the Job

Assessing Load and Sling Type

You must start by evaluating the load you plan to lift. To choose the right web slings, follow these steps:

Determine the weight of your load. Always check that the sling’s working load limit (WLL) can handle it.

Examine the size and shape of the load. Irregular shapes may require special sling types or configurations.

Identify the center of gravity. This helps you balance the load and prevent tipping.

Locate attachment points. Make sure the sling can connect securely.

Decide on the type of lift and sling configuration. The method you use—vertical, choker, or basket—affects the sling’s capacity.

Select the sling material. Synthetic web slings work well for many lifting applications, especially when you need flexibility and protection for delicate surfaces.

Measure web sling length accurately to ensure proper fit and safe lifting.

Tip: Always read the sling tag for capacity and usage instructions before every lift.

Environmental and Application Factors

You need to consider the environment where you use web slings. Factors like temperature, moisture, and chemical exposure can impact performance. For example:

Chemical exposure, such as acids or alkalis, can weaken synthetic web slings.

Extreme temperatures may affect nylon or polyester slings. Always check the manufacturer’s temperature limits.

UV radiation can degrade web slings over time. Store them away from direct sunlight when not in use.

If you work in harsh or changing environments, inspect your slings more frequently and follow all safety guidelines.

Why Choose Powerful Machinery Web Slings?

Powerful Machinery web slings offer superior safety and reliability compared to generic brands. The table below highlights key advantages:

Metric | Powerful Machinery Web Slings | Generic Brands |

|---|---|---|

Reliability | Highest among HMPE fibers | Lower |

Fatigue Lifetime | 3x longer | Standard |

Rope Abrasion and Creep Lifetime | 4x longer | Standard |

Strength Retention at 70°C | Highest | Lower |

Service Life | Superior | Inferior |

Chance of Failure | Reduced | Higher |

You benefit from certified products that meet or exceed international standards. Always use compatible mechanical fittings and ensure they match or exceed the sling’s rated load.

Clean surfaces and remove sharp edges to prevent sling damage. Reading the sling tag and following manufacturer instructions keeps your lifting operations safe and efficient.

Inspecting Web Slings Before Use

Checking for Damage and Wear

You must inspect web slings before every lift. Look for visible signs of damage or wear that could compromise safety. Use this table to guide your inspection:

Type of Damage | Description |

|---|---|

Tensile Break | Frayed areas near failure points, often from overloading. |

Cut | Visible cuts in the webbing weaken the sling. |

Abrasion Damage | Worn spots from friction that reduce strength. |

Acid or Chemical Damage | Discoloration, brittleness, or deterioration from chemical exposure. |

Holes, Tears, Cuts | Openings that affect load-bearing capacity. |

Broken Stitching | Worn or missing stitching in load-bearing areas. |

Discoloration | Color changes from UV or chemical exposure, indicating possible weakening. |

Check both sides of the sling and all attachment points. Pay special attention to areas exposed to sunlight, as UV rays can reduce sling strength by up to 30% in one year. Store slings in a cool, dry, and dark place to prevent UV damage.

Understanding Sling Tags and Ratings

Always read the sling tag before use. The tag provides the Working Load Limit (WLL), which tells you the maximum load the sling can safely lift. The WLL is based on the sling’s minimum breaking strength and a safety factor.

Never exceed the WLL. If the tag is missing or unreadable, remove the sling from service. Regular inspections and following safety standards help you use web slings correctly.

When to Remove from Service?

Take web slings out of service if you find any of these issues:

Broken or worn stitching

Rips, snags, or crushed webbing

Missing or illegible tags

Cuts, abrasion, or damage to the edges

Weld splatter or embedded materials

Heat or flame damage

Knots or damaged eyes

Signs of UV degradation

OSHA requires you to inspect slings daily and keep records of inspections. In severe service conditions, inspect slings monthly or quarterly. Powerful Machinery provides certified web slings and supports your safety with clear inspection guidelines and documentation.

How to Use a Web Sling: Step-by-Step

Reading the Tag and Instructions

You must start every lift by reading the sling tag and reviewing the manufacturer’s instructions. The tag contains essential information that guides safe operation. Before you use web slings, check the following details:

Information Type | Details |

|---|---|

Manufacturer’s Name | Name or trademark of the manufacturer |

Manufacturer’s Code/Stock Number | Manufacturer’s code or stock number |

Rated Load | Rated load for at least one hitch type and the angle upon which it is based |

Type of Material | Type of synthetic material |

Number of Legs | Number of legs, if more than one |

You must confirm the rated load matches your lifting requirements. Inspect the safety label for material type, weight-bearing limit, sling angle, length, and inspection standard.

If the tag is missing or unreadable, remove the sling from service. Powerful Machinery provides clear, durable tags on all web slings to support safe lifting.

Tip: Always review the tag before each lift. This step helps you avoid overloading and ensures compliance with safety standards.

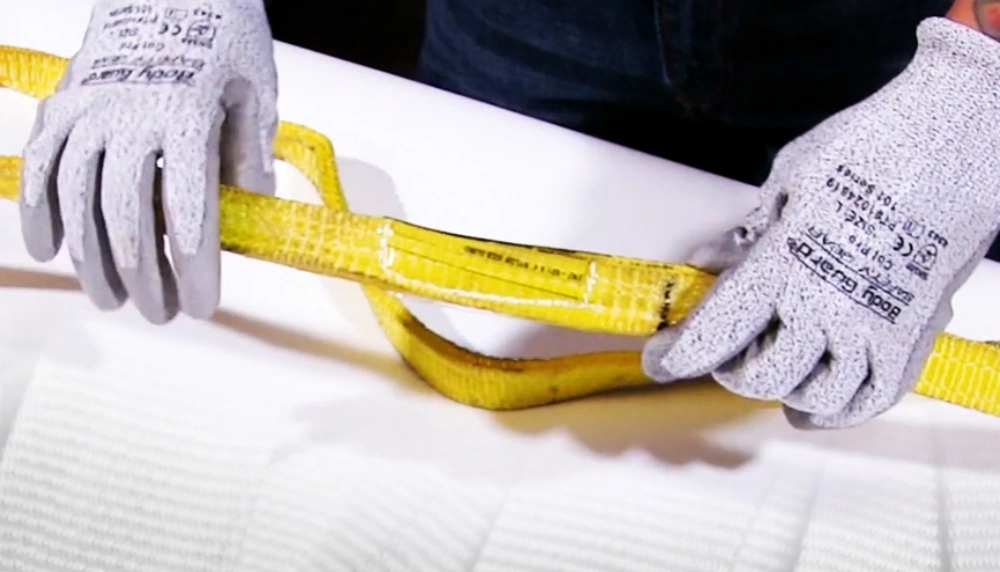

Proper Hitching and Rigging

You must select the correct hitch and rigging technique for your load. The hitch type affects stability and capacity. Here is a quick reference for common hitch types:

Hitch Type | Description | Key Points |

|---|---|---|

Basket Hitch | Loop the sling around the load for maximum stability. | Ideal for long or cylindrical objects; does not prevent rotation. |

Choker Hitch | Wrap the sling tightly around the load. | Reduces sling capacity; use cautiously. |

Bridle Hitch | Uses multiple slings to distribute weight for large objects. | Requires more setup time; enhances load stability and control. |

Single Vertical Hitch | Hangs the load directly below the hook. | Provides excellent control; only for easily balanced loads. |

You must protect web slings from sharp corners and abrasive surfaces. Use edge protectors or padding to prevent cuts and wear. Never twist or knot the sling to shorten it.

Always use shackles or safety latches for secure attachment. Avoid shock loading by lifting slowly and steadily. Powerful Machinery’s certified web slings come with detailed rigging instructions to help you select the right hitch and hardware.

Note: Do not pull slings from under the load. Lift the load fully before removing the sling.

Balancing and Securing Loads

You must balance and secure the load before lifting. Uneven weight distribution can cause tipping or accidents. Follow these steps to ensure stability:

Distribute weight evenly across the lifting points.

Adjust the sling or lifting device so the load sits centrally.

Place heavier items closer to the load’s backrest or support.

Tilt the lifting device slightly backward before raising the load to improve security.

You must know the weight and center of gravity of the load. Select the appropriate web slings and rigging equipment for each application. Powerful Machinery’s products include clear guidelines for load balancing and securing, helping you prevent accidents and maintain control.

Alert: Ignoring load control is a common mistake. Always confirm the load is stable before lifting.

Safe Lifting Practices

You must follow safe lifting practices to protect yourself and your crew. Here is a step-by-step guide on how to use a web sling safely:

Inspect all equipment daily and before each lift.

Confirm the load matches the rated capacity of your web slings and lifting gear.

Use the correct sling, hitch, and hardware for every application.

Train all operators and riggers thoroughly on how to use a web sling.

Plan each lift and review the process with your team.

Keep the area clear and never stand under a suspended load.

Mark and document all equipment for easy identification.

You must avoid standing or working under suspended loads. Crew training is essential for minimizing human error. Regular refresher sessions keep everyone updated on best practices and safety standards. Powerful Machinery supports your safety with certified products and comprehensive training resources.

Tip: Always follow manufacturer and OSHA guidelines. Proper training and planning prevent accidents and ensure efficient lifting operations.

You now know how to use a web sling safely. By reading the tag, selecting the right hitch, balancing the load, and following safe lifting practices, you protect your team and equipment. Powerful Machinery’s certified web slings and expert support help you achieve reliable, accident-free lifts.

Web Sling Care and Maintenance

Cleaning and Storage

You must keep web slings clean and properly stored to maintain their strength and reliability. After each use, clean your slings with mild soap and water to remove dirt and contaminants. Avoid harsh chemicals, as these can weaken the webbing material.

To prevent damage and extend the lifespan of your slings, follow these storage tips:

Store slings in a dry, clean area to avoid moisture-related issues.

Protect slings from direct sunlight, which can degrade the material.

Hang slings on racks or coil them neatly to prevent kinks and tangles.

Keep slings away from sharp edges or abrasive surfaces.

Proper cleaning and storage help you avoid premature wear and keep your lifting equipment ready for safe use.

Regular Maintenance

You should inspect web slings regularly to ensure safe lifting operations. The frequency of inspection depends on your work environment:

Work Condition | Inspection Frequency |

|---|---|

Normal Work Conditions | Annual inspection |

Severe Work Conditions | Monthly or quarterly |

Special Work Conditions | Consult a Qualified Person |

Keep your slings clean and free of debris. Use edge protection to prevent cuts and abrasions during use. Store slings in a well-ventilated area, away from sunlight.

Record-keeping is also important. Track your maintenance and inspections with a simple log:

Record-Keeping Practice | Description |

|---|---|

Inspection Dates | Log the dates of each inspection |

Findings | Document any issues found during inspections |

Actions Taken | Record cleaning, repairs, or replacements |

Extending Sling Life with Powerful Machinery

You can extend the life of your web slings by choosing high-quality products and following proper care routines. Powerful Machinery designs web slings to meet strict international standards, ensuring durability and safety.

You receive clear maintenance guidelines and support, making it easier to keep your lifting gear in top condition. With certified products and expert advice, you reduce the risk of failure and maximize the service life of your equipment.

When you invest in Powerful Machinery, you invest in long-term safety and performance for all your lifting needs.

Conclusion

You can ensure safe web sling operations by following these essential steps:

Inspect slings before every use.

Choose the correct sling and hitch for each lift.

Store slings properly and avoid twisting or knotting.

Train your team on proper handling and keep clear of the load path.

Schedule regular professional inspections.

Manufacturer and OSHA guidelines require you to use only qualified personnel and conduct routine inspections. When you select certified web slings from Powerful Machinery, you gain these advantages:

Benefit | Description |

|---|---|

Safety Standards | Slings meet strict safety standards for demanding applications. |

Durability | Reliable performance reduces replacement needs. |

Non-Corrosive | Resistant to corrosion for outdoor and wet environments. |

Gentle on Loads | Soft material protects delicate surfaces. |

Cost-Efficiency | Long-term savings through durability and reusability. |

Prioritize safety and trust Powerful Machinery for your lifting needs.

FAQ

What are the main advantages of synthetic web slings?

You gain flexibility, lightweight handling, and protection for delicate loads with synthetic web slings. These slings resist corrosion and suit many lifting applications. You also benefit from easy inspection and storage.

How do you measure web sling length correctly?

You measure web sling length from the bearing point of one end fitting to the bearing point of the other. Always use a straight line. Accurate measurement ensures safe and efficient lifting.

Can you use synthetic web slings for all lifting applications?

You can use synthetic web slings for most lifting applications, especially when you need to protect sensitive surfaces. For extreme temperatures or sharp edges, you should consult the manufacturer for guidance.

How often should you inspect your web slings?

You should inspect your web slings before every use. For severe or special conditions, increase inspection frequency. Regular checks help you spot damage early and prevent accidents.

What should you do if you find damage during inspection?

You must remove the sling from service immediately. Do not attempt repairs yourself. Replace damaged slings to maintain safety in all lifting operations.