You play a critical role in workplace safety when you perform an ASME B30.10 hook inspection. Regular inspection helps you spot hazards such as cracks, deformation, or worn surfaces before they cause accidents.

Following ASME B30.10 standards allows you to meet compliance requirements and reduce injury risks. Each hook must meet strict asme criteria for locking and removal. Powerful Machinery supports your commitment to safety by delivering reliable hook solutions that meet top industry standards.

Key Takeaways

Regular hook inspections prevent accidents and ensure safety.

ASME B30.10 standards help meet compliance and reduce risks.

Inspect hooks based on usage: daily, weekly, or monthly.

Remove hooks with visible damage or missing markings.

Proper training and records improve safety and compliance.

ASME B30.10 Hook Inspection Standards

Scope and Purpose

You need to understand the scope and purpose of ASME B30.10 hook inspection before you start any crane work. The ASME B30.10 standards set clear requirements for the fabrication, attachment, use, inspection, and maintenance of every hook used in load handling.

These standards apply to hooks on cranes, hoists, and other lifting equipment. They help you meet OSHA and asme compliance requirements and keep your workplace safe.

ASME B30.10 includes provisions that apply to the fabrication, attachment, use, inspection, and maintenance of hooks used for load handling purposes, in conjunction with equipment described in other volumes of the B30 Standard.

You must follow these requirements to ensure every hook meets ASME and OSHA regulations. The standards also guide you on proper marking, rated load information, and removal criteria. By following ASME B30.10, you help prevent accidents and meet crane inspection requirements.

Why Inspection Matters?

You protect your team and equipment when you follow ASME B30.10 hook inspection procedures. Regular inspection helps you spot cracks, deformation, or wear before a hook fails. You must check each hook based on its service conditions and usage.

Regular inspections are mandated by ASME B30.10 standards to prevent equipment failure.

Inspection frequency is determined by the hook’s usage, service conditions, and load-handling activities.

Hooks showing signs of damage or wear must be removed from service to ensure safety.

Inspection intervals vary: Normal Service (Monthly), Heavy Service (Weekly to Monthly), Severe Service (Daily to Weekly).

Periodic inspections are required at least every 12 months, with more frequent checks for heavy and severe service conditions.

You must meet crane inspection requirements to comply with OSHA and ASME B30 standards. These requirements help you avoid costly downtime and injuries. When you follow ASME B30.10 and OSHA regulations, you show your commitment to safety and compliance.

Every hook inspection supports your goal of a safe and efficient operation.

Types of Hooks in ASME B30.10

Load-Bearing Hooks

You rely on load-bearing hooks for critical lifting operations. These hooks support the full weight of the load and must meet strict ASME B30.10 requirements. You encounter several types of hooks in your daily work:

Eye hooks provide a secure connection to wire rope slings or synthetic slings. You use them when you need a permanent attachment and a strong spliced connection.

Clevis hooks are designed for chain sling applications. You can quickly connect them to the last link of a chain sling, making them ideal for fast rigging.

Swivel hooks feature a rotating joint. You use these hooks to prevent twisting and ensure smooth handling during lifts.

Sorting and foundry hooks help you move irregular, bulky, or high-temperature loads. You see these hooks in scrap handling and demolition work.

Heavy-duty hooks are engineered for extreme environments. You depend on them in mining, offshore, steel mill, and heavy manufacturing settings.

You must always verify the working load limit for each hook. The hook’s bowl should seat the sling or shackle properly. In marine or corrosive environments, you select hooks with specialized coatings.

Non-Load-Bearing Hooks

You use non-load-bearing hooks for tasks that do not involve supporting the full weight of a load. These hooks help you organize rigging gear, secure tag lines, or manage slings during setup. You do not rely on these hooks for lifting, but you still inspect them for wear and damage.

Non-load-bearing hooks must remain in good condition to prevent accidents and maintain workplace safety.

Powerful Machinery Hook Solutions

You need reliable hook solutions that meet ASME B30.10 standards. Powerful Machinery offers a comprehensive range of certified hooks and lifting hooks, including Eye Grab Hook, Clevis Slip Hook, and Clevis Grab Hook.

You benefit from features such as high-strength forged steel construction, corrosion-resistant finishes, and compatibility with Grade 80 and Grade 100 chains. These hooks provide secure locking mechanisms and precision engineering for optimal load distribution.

You select the right types of hooks for your application, knowing that Powerful Machinery delivers safety and performance.

Tip: Always consult manufacturer guidelines when choosing a load hook for critical lifts. Use self-locking hooks when there is a risk of the load snagging or disengaging.

Hook Identification & Marking (ASME)

Manufacturer Markings

You must always check the markings on every hook before you use it. The asme standard requires that each hook display clear and permanent manufacturer markings. These markings help you identify the origin and trace the production of the hook.

You will usually find the manufacturer’s name or logo, the model number, and sometimes a serial number stamped or forged directly onto the hook body.

When you inspect a hook, look for these markings in a visible location. If you cannot find the manufacturer’s identification, you should not use the hook. Missing or illegible markings can mean the hook does not meet safety standards. You need to confirm that the hook comes from a trusted source.

Powerful Machinery ensures that all hooks carry proper identification, so you can trust their quality and traceability.

Tip: Always record the manufacturer markings in your inspection log. This practice helps you track the hook’s history and ensures compliance with your safety program.

Rated Load Info

You must also verify the rated load information on every hook. The asme guidelines require that each load hook display its rated load or working load limit (WLL). This marking tells you the maximum weight the hook can safely handle. You will find this information stamped or forged on the hook, often near the manufacturer’s mark.

Before you use a hook, check the rated load info and compare it to your lifting requirements. Never use a hook if the rated load marking is missing, unclear, or does not match your application. Using a hook without clear load information can lead to overloading and serious accidents.

Always match the hook’s rated load to your lifting task.

Remove any hook from service if the rated load info is missing or unreadable.

Use only hooks with clear, permanent markings for critical lifts.

You protect your team and equipment when you follow these identification and marking requirements. Proper hook markings support safe lifting and help you meet asme compliance every day.

ASME B30.10 Hook Inspection Intervals

Initial Inspection

You must perform an initial inspection before you use any hook for lifting operations. This step confirms that the hook meets all ASME B30.10 requirements and manufacturer specifications.

You check for visible defects, verify the rated load markings, and confirm the hook’s compatibility with your crane and rigging equipment. You also review the documentation to ensure the hook has passed all necessary tests and certifications.

Initial inspection procedures help you prevent accidents and ensure compliance with OSHA and asme standards.

Tip: Always compare the hook’s dimensions and markings with the manufacturer’s specifications during the initial inspection. This practice helps you avoid using non-compliant equipment.

Frequent Inspection

You need to conduct frequent inspections to maintain safety and meet ASME B30.10 hook inspection standards. Frequent inspections focus on identifying visible damage, wear, or deformation before each use or shift. Operators and foremen typically handle these checks.

You look for cracks, bent hooks, worn latch mechanisms, and signs of corrosion. You also verify that the hook rotates freely and the safety latch functions properly.

Here is a table showing industry best practices for frequent inspection intervals in high-use environments:

Inspection Type | Frequency |

|---|---|

Pre-use checks | Before each shift |

Routine inspections | Weekly or monthly |

Periodic inspections | Quarterly or annually |

You should inspect hooks before each use, schedule detailed inspections at least once a year, and increase inspection frequency in harsh environments. Frequent inspections help you catch problems early and reduce the risk of equipment failure.

Periodic Inspection

You must schedule periodic inspections to meet ASME B30.10 and OSHA crane inspection requirements. Periodic inspections are more comprehensive than frequent checks. You examine the hook’s internal components, measure throat opening, and test the safety latch under load.

You also inspect mounting hardware and verify all markings. You document the results and compare them to previous inspection reports.

Periodic inspections often occur every 12 months, but you may need to inspect more often if your crane operates in severe or heavy service conditions. You follow the annual comprehensive crane inspections schedule for overhead cranes and other critical equipment.

You use the overhead crane daily inspection checklist to supplement periodic checks and maintain compliance with B30.10 standards.

Note: In harsh environments, such as marine or chemical plants, you should inspect hooks every six months or quarterly. This practice helps you meet asme and osha regulations and extend equipment life.

Qualified Inspectors & Records

You must assign qualified inspectors to perform periodic and annual inspections. These inspectors have the training and experience to identify defects and evaluate hook integrity. You keep detailed records of all inspections, repairs, and certifications.

You maintain a hook history card or electronic record for each piece of equipment. You review previous inspection reports and update maintenance logs after each inspection.

Follow these recommended practices for maintaining inspection records:

Perform daily visual checks for damage, verify safety latch function, and inspect for cracks.

Conduct monthly inspections with full visual checks, measure throat opening, and test the safety latch under load.

Execute annual inspections with dimensional analysis, NDT testing, and certification updates.

You ensure that manufacturer specifications, previous inspection reports, and required certifications are available for reference. You keep all records current and accessible to meet ASME B30.10 and OSHA standards.

Tip: Accurate inspection records help you track equipment history, support compliance audits, and improve workplace safety.

Hook Removal Criteria (B30.10)

Visual Damage Signs

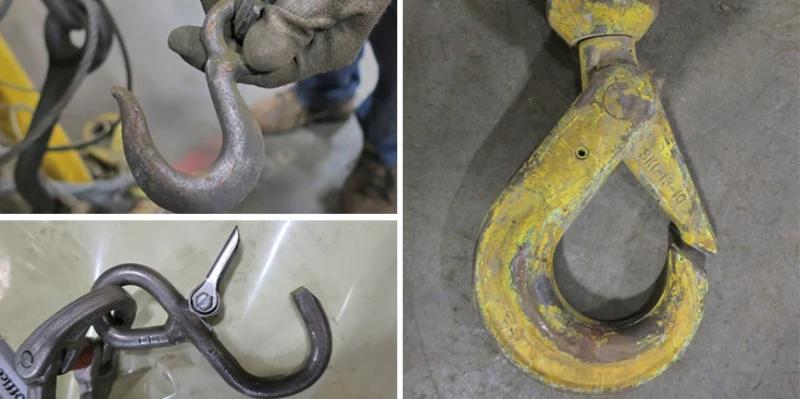

You must remove a hook from service if you see any visual damage that meets b30.10 criteria. Inspection helps you catch these problems before they lead to failure. Look for the following signs during every inspection:

Missing or illegible manufacturer’s identification

Missing or unreadable rated load marking

Excessive pitting or corrosion on the hook surface

Cracks, nicks, or gouges anywhere on the hook

Wear that exceeds 10% of the original section dimension or load pin

Visible bending or twisting of the hook body

Throat opening distortion greater than 5% or more than 1/4 inch (6mm)

Inability to lock for self-locking hooks

Latch that does not work or is missing

Damaged or malfunctioning hook attachment

Thread wear, damage, or corrosion on the shank or nuts

Evidence of heat exposure or unauthorized welding

Unauthorized alterations, such as drilling or grinding

You must not ignore these signs. Each one meets the ASME B30.10 criteria for immediate removal. You protect your team and equipment when you act quickly.

Tip: Always document any hook removal in your inspection records. This practice supports compliance and helps you track equipment history.

Functional Issues

You must also remove a hook if you find functional issues during inspection. The table below shows common problems and why they require removal:

Criteria for Removal | Description |

|---|---|

Corrosion or Pitting | Weakens the hook, especially if it exceeds 10% of the cross-section |

Cracks, Gauges, or Necks | Any visible cracks or deep marks threaten the hook’s integrity |

Bending or Twisting | Any deformation changes how the hook carries the load |

Throat Opening | If the opening increases by more than 5% or 1/4 inch |

Malfunctioning Hook Latches | Latch is missing or does not work properly |

Worn Threads | Threads on the shank or nuts show wear or corrosion |

Heat Damage | Signs of heat exposure or unauthorized welding |

You must follow these criteria to keep your lifting operations safe. Regular inspection and quick action help you meet asme and B30.10 standards. Never return a hook to service until you correct all issues or replace the hook.

Safety Best Practices for Hook Use

General Safety Guidelines

You must follow strict safety practices when using any hook in industrial environments. These guidelines help you maintain safe operation and meet OSHA requirements:

Inspect each hook at the start of every shift for visible damage.

Complete a thorough inspection at least once a year, adjusting frequency based on how often you use the equipment.

Tag every hook with its weight and working load limit (WLL).

Train all operators in safe usage and inspection procedures.

Always comply with OSHA and local regulations.

Never overload a hook or use one that shows signs of wear or damage.

Know the load before lifting and ensure all fittings match the sling’s break strength.

Keep all personnel clear of loads during lifting and while suspended.

Environmental Factors

You must consider environmental conditions when selecting and inspecting hooks. Certain environments increase risks for your equipment and team:

Coastal areas and chemical plants expose hooks to higher corrosion risks.

Outdoor work, humidity, and airborne pollutants can damage hook surfaces.

Salt-laden air and industrial chemicals speed up corrosion and weaken metal.

In high-humidity or saltwater environments, choose corrosion-resistant hooks, such as stainless steel or those with protective coatings.

Steel chain slings perform well up to 600º F, while synthetic slings work best from -40º F to 180º F.

Always consult manufacturer guidelines for hook selection and inspection intervals in extreme environments.

Latch Use

Proper latch use is essential for safety and OSHA compliance. The ASME B30.10 standard outlines different hook types and their latch requirements:

Type of Hook | Description |

|---|---|

Clevis Hook | Secure attachment with a clevis fitting |

Eye Hook | Loop for connecting to lifting devices |

Self-locking Eye Hook | Automatically locks to prevent accidental release |

Self-locking Clevis Hook | Clevis hook with automatic locking for added safety |

Select the right hook and latch type for your lifting needs. Always verify latch function before each lift.

Powerful Machinery Safety Features

You gain extra safety when you choose hooks from Powerful Machinery. These hooks feature advanced locking mechanisms and precision engineering. Automatic hook positioning systems use technology to reduce human error and improve alignment.

C-type hooks include adjustable lifting eyes for better balance and stability. Each hook comes equipped with safety latches to minimize the risk of load disengagement. These features help you meet OSHA standards and ensure safe operation for every lift.

Compliance & Equipment Longevity

Training & Programs

You need effective training programs to meet crane inspection requirements and ensure proper hook use. OSHA and ASME require you to train your team in safe lifting techniques. These programs help you recognize hazards, handle emergencies, and select the right hook for each job.

You gain confidence and competence through hands-on practice and real-world scenarios. Many organizations offer customized training at your site or remotely, making it easy to meet compliance requirements and keep your team prepared.

Training covers safe lifting and rigging practices.

You learn to inspect hooks and identify criteria for removal.

Programs include hazard recognition and emergency response.

Customized options fit your operational needs.

Third-Party Inspections

You benefit from third-party inspections by gaining unbiased evaluations of your hook and crane equipment. These inspections bring specialized expertise and help you meet regulatory compliance. Third-party inspectors check your hooks against ASME and OSHA regulations, ensuring you meet all criteria and requirements.

This process reduces risk, supports quality assurance, and builds customer confidence. You also avoid costly penalties and improve efficiency by catching issues early.

Note: Third-party inspections add transparency and help you maintain high safety standards across your operation.

Ongoing Education

You must keep your knowledge current to maintain compliance and reduce incidents. Ongoing education includes regular refresher courses, safety drills, and cross-training. You learn to spot signs of hook wear or damage and understand the latest criteria for removal.

Sharing lessons from industry incidents helps you prevent future problems. Using simulators and specialized training keeps your skills sharp and your team ready for any challenge.

Regular training improves awareness of hook safety procedures.

Refresher courses ensure you retain critical inspection skills.

Learning from real incidents promotes a strong safety culture.

Powerful Machinery Support

You can rely on Powerful Machinery to support your compliance programs and equipment longevity. The company meets international standards and holds certifications such as ISO, ASME, CE, EN13001-3-5:2016, and ANSI. These certifications prove the reliability and safety of every hook.

Customers worldwide trust Powerful Machinery for consistent quality and support. You benefit from expert guidance, certified products, and positive testimonials from industry leaders.

Certification/Standard | Description |

|---|---|

ISO | International Organization for Standardization, ensuring quality and safety. |

ASME | American Society of Mechanical Engineers is recognized for safety standards. |

CE | Conformité Européenne, compliance with European safety standards. |

EN13001-3-5:2016 | European standard for cranes and lifting equipment. |

ANSI | American National Standards Institute, safety and performance in North America. |

Tip: Choose certified hooks and follow all inspection requirements to maximize equipment life and meet compliance requirements.

Conclusion

You strengthen workplace safety and compliance when you follow ASME B30.10 hook inspection standards. Powerful Machinery provides certified hook solutions that meet asme and OSHA requirements, supporting your equipment longevity.

Regular inspection, ongoing training, and third-party reviews help you avoid costly downtime and ensure every hook performs reliably. Use the table below to guide your inspection program and keep your b30.10 compliance on track:

Inspection Type | Requirements |

|---|---|

Initial Inspection | Required for new, altered, modified, or repaired rigging equipment before first use. |

Frequent Inspection | Conducted daily or before each shift; no formal documentation required. |

Periodic Inspection | Comprehensive evaluations at regular intervals; formal documentation is required for certain items. |

Compliance | Adherence to OSHA and ASME standards is critical to avoid fines and ensure safety. |

Take action by reviewing your current hook inspection process, updating your training, and scheduling third-party evaluations for your equipment.

FAQ

What is the main purpose of ASME B30.10 in crane operations?

You use ASME B30.10 to set clear standards for every crane hook. This standard guides you on proper inspection, maintenance, and removal. It helps you prevent accidents and ensures your crane equipment meets safety requirements.

How often should you perform an inspection on crane hooks?

You must inspect crane hooks before each shift and after any incident. Schedule frequent inspections for daily crane use. Plan periodic inspection at least once a year. Increase inspection frequency if your crane operates in harsh environments.

What signs indicate a crane hook needs removal from service?

You remove a crane hook if you see cracks, excessive wear, or a bent shape during inspection. Missing markings or a malfunctioning latch also require removal. Always follow ASME B30.10 removal criteria for every crane inspection.

Who should perform crane hook inspection?

Qualified inspectors must handle periodic inspections. You can performa daily visual inspection before crane use. For annual or complex inspection, rely on trained professionals who understand ASME B30.10 and crane safety standards.

Why is documentation important for crane hook inspection?

You keep detailed inspection records to track crane hook history. Documentation helps you prove compliance with ASME B30.10. It also supports audits and improves your crane safety program.