You want your lifting slings to last as long as possible while keeping your team safe. Most high-quality lifting slings, like those from Powerful Machinery, provide years of reliable service when you follow a disciplined Lifting Sling Lifespan and Maintenance routine.

Regular inspection and maintenance play a vital role in keeping your operation safe and efficient:

Inspections help you catch small problems before they lead to accidents.

Maintenance reduces hazards and creates a safer workplace.

Well-maintained lifting equipment works smoothly, which means fewer delays and higher productivity.

You can choose from several types of lifting slings, including chain, synthetic, wire rope, and metal mesh. Each type has its own typical lifespan, depending on how you use and care for it.

Key Takeaways

Regular inspections of lifting slings catch small issues before they lead to accidents, ensuring a safer workplace.

Understanding the typical lifespan of different sling types helps you plan for replacements and maintain safety.

Proper maintenance, including cleaning and storage, extends the life of your lifting slings and reduces downtime.

Always follow safety guidelines during lifting operations to protect yourself and your team from potential hazards.

Choose certified lifting slings from trusted suppliers like Powerful Machinery to ensure safety and compliance with industry standards.

Lifting Sling Lifespan and Maintenance

Typical Lifespans by Sling Type

You need to understand how long each type of lifting sling can serve you before replacement becomes necessary. The lifespan depends on the sling material and how you use it. The following table shows the typical lifespans for the most common sling types:

Type of Sling | Typical Lifespan |

|---|---|

Synthetic Slings | 2-5 years |

Wire Rope Slings | 5-10 years |

Chain Slings | 10 years or more |

Chain slings often last the longest. You can expect them to serve you for a decade or more with proper lifting sling lifespan and maintenance. Wire rope slings offer a solid balance between durability and flexibility, usually lasting up to ten years.

Synthetic slings, including round webbing and flat web slings, provide excellent load protection but typically need replacement after two to five years. Metal mesh slings are less common but can also deliver reliable performance when maintained correctly.

Powerful Machinery manufactures lifting slings that meet strict international standards. You benefit from products certified by ISO9001, ISO14001, TUV Rheinland, EURO CERT, OSHA, ASTM, China Classification Society, and Korean Register.

These certifications guarantee that your lifting equipment will perform safely and reliably throughout its expected lifespan. Powerful Machinery uses chemical analysis, dimensional verification, and proof-load testing to ensure every sling meets or exceeds industry requirements.

With over 20 years of experience, Powerful Machinery stands as a trusted partner for lifting sling lifespan and maintenance.

Factors Affecting Lifespan

Several factors can shorten or extend the life of your lifting slings. You must pay attention to these details to maximize safety and efficiency:

Environmental conditions play a major role. Extreme temperatures, exposure to chemicals, and abrasive surfaces can weaken sling fibers and accelerate aging.

Frequency of use matters. Regular lifting operations cause wear and tear, which shortens the lifespan. Infrequent use can help slings last longer, but only if you store and maintain them properly.

Load weight is critical. Exceeding the rated capacity puts excessive stress on the sling, compromising its structure and reducing its lifespan.

Proper lifting sling lifespan and maintenance routines, including regular inspections and cleaning, help you catch problems early and prevent premature failure.

Choosing certified lifting slings from Powerful Machinery ensures you start with products designed for durability and safety. Full certification to global standards means you can trust your equipment in demanding environments.

You must consider all these factors affecting rigging sling life expectancy when planning your lifting operations. By following best practices for lifting sling lifespan and maintenance, you protect your team and your investment. Reliable lifting slings keep your workflow smooth and your workplace safe.

Tip: Always check the manufacturer’s guidelines and certification labels before each lifting operation. This simple step helps you avoid costly mistakes and ensures your lifting sling’s lifespan and maintenance routine stays effective.

Types of Lifting Slings

You will find several main types of lifting slings in industrial settings. Each type offers unique advantages for different lifting tasks.

Chain Slings

Chain slings use high-strength steel chains. You can rely on them for heavy-duty lifting, especially when you need to handle sharp-edged loads or work in high temperatures. Chain slings perform well in harsh environments and resist damage from rough materials.

Industry/Application | Key Features |

|---|---|

Construction | Handles heavy steel beams, concrete blocks, and pipes; adaptable for rough materials; performs well in harsh weather conditions. |

Manufacturing | Multi-leg slings for balancing loads; high working load limit; quick attachment and detachment. |

Mining and Quarry | Strong and corrosion-resistant; handles sharp-edged materials; high tensile strength for safety. |

Shipyards and Marine Industry | Reliable in wet environments; rust-resistant; easy to inspect and maintain; compatible with cranes. |

Transport and Logistics | Adjustable leg length; maintains grip during lifts; reduces accident risks. |

Powerful Machinery manufactures chain slings that meet strict international standards. You can trust their durability and safety in demanding industries.

Synthetic Slings (Round Webbing, Flat Web)

Synthetic slings include round webbing slings and flat web slings. These slings use materials like polyester, making them lightweight and flexible. You can use them for lifting loads with delicate surfaces or irregular shapes.

Round Webbing Sling: Powerful Machinery’s round webbing sling uses 100% polyester yarn. It features a non-load-bearing tubular sleeve for extra wear resistance and a PU-impregnated surface to block dirt. The color-coded system helps you identify load capacity quickly. These slings meet EN 1492-1, EN 1492-2, and CE certification standards.

Flat Web Sling: The flat web sling from Powerful Machinery meets ASME B30.9 standards. It offers reinforced eyes and wear pads for added durability. You can order custom lengths for your specific needs.

Note: Synthetic slings must have a visible tag with manufacturer details, material type, load capacity, and safety instructions. This ensures compliance and safe operation.

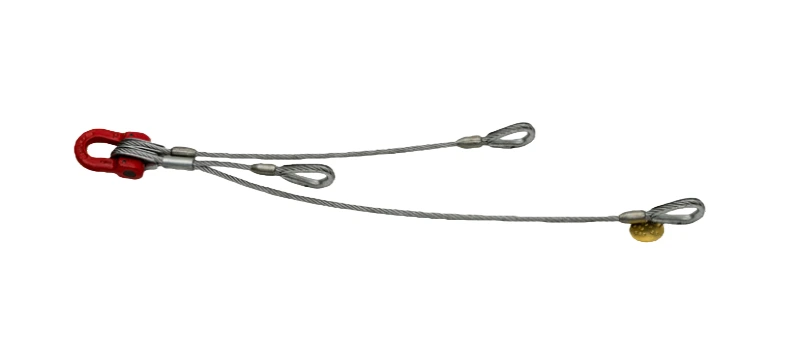

Wire Rope Slings

Wire rope slings use twisted steel wires. You can count on them for superior strength and long-term durability. These slings adapt to different load shapes and sizes, making them suitable for construction, marine, mining, and manufacturing.

Advantage/Use | Description |

|---|---|

Strength | Ideal for heavy-duty lifting. |

Durability | Withstands harsh conditions without losing integrity. |

Flexibility | Adapts to various load shapes and sizes. |

Versatility | Used in many industries, including construction and transportation. |

Safety | Certified for safety, providing peace of mind during lifting operations. |

Metal Mesh Slings

Metal mesh slings offer high strength and resist corrosion, abrasion, and cutting. You can use them for loads with sharp edges or in environments where other slings might wear out quickly.

Sling Type | Advantages | Disadvantages |

|---|---|---|

Metal Mesh Slings | High-strength, durable, resistant to corrosion, abrasion, and cutting. | Requires removal if one wire is broken; can be crushed. |

Powerful Machinery’s commitment to quality and safety means every sling meets or exceeds international standards. You receive reliable lifting solutions for every application.

Life Expectancy of a Rigging Sling

Understanding the life expectancy of a rigging sling helps you plan safe and efficient lifting operations. The lifespan of a lifting sling depends on several factors, including material quality, frequency of use, and environmental conditions.

When you use certified products from Powerful Machinery, you start with slings designed for maximum durability and safety.

What Impacts Rigging Sling Lifespan?

You influence the life expectancy of a rigging sling every time you use, inspect, or store it. The following factors play the biggest roles:

Polyester slings can serve you for a single use or up to five years, depending on how you use and maintain them.

Regular inspections and proper care extend the rigging sling’s lifespan and reduce the risk of unexpected failure.

Alternating between slings helps distribute wear and prolongs service life.

The table below summarizes the main factors that impact the life expectancy of a rigging sling:

Factor | Description |

|---|---|

Quality of Material | High-quality materials like polyester and nylon enhance durability and lifespan. |

Frequency of Use | Increased usage leads to faster wear; alternating slings can extend lifespan. |

Environmental Conditions | Extreme conditions can degrade slings; frequent inspections are necessary in harsh environments. |

Inspection and Maintenance | Regular checks and proper care significantly increase the longevity of rigging slings. |

Powerful Machinery’s certified lifting slings use premium materials and advanced manufacturing processes. You benefit from products that withstand demanding environments and deliver consistent performance throughout their expected lifespan.

Do Lifting Slings Expire?

You might wonder if lifting slings have a set expiration date. Current regulations do not require manufacturers to specify a maximum service life or expiration date for lifting slings. Instead, you must focus on the actual condition of the sling and follow recommended inspection and maintenance routines.

Manufacturers may suggest a service life for safety, but standards emphasize proper use and care over a fixed timeline.

By following best practices and using certified equipment, you maximize the life expectancy of a rigging sling and ensure safe lifting operations. Always inspect your slings before use and retire any that show signs of damage or excessive wear.

Powerful Machinery’s commitment to quality gives you confidence in the rigging sling’s lifespan, even in the toughest working conditions.

Inspection and Maintenance Checklist

Initial Inspection

You must conduct an initial inspection before you use any new lifting slings. This step ensures your equipment meets all safety and performance requirements. You should also inspect any sling that has been altered, repaired, or returned to service after removal.

Check the sling immediately upon receiving it from the manufacturer.

Verify the identification tag. Make sure it matches your order and displays the correct rated capacity, material type, and manufacturer details.

Confirm that the rated capacity aligns with your project’s lifting requirements.

Inspect the sling for visible defects, such as cuts, abrasions, broken wires, or chemical damage.

Review the documentation and certifications provided by Powerful Machinery. These documents confirm compliance with international standards.

Tip: Never skip the initial inspection. Early detection of defects prevents accidents and extends the service life of your lifting equipment.

Frequent and Periodic Inspections

You need to inspect lifting slings regularly to ensure ongoing safety and reliability. The frequency of these inspections depends on how often you use the slings and the severity of the working conditions.

Inspection Type | Frequency | Key Points to Consider |

|---|---|---|

Initial Inspection | Before the slings go into service | Verify identification, check for defects |

Daily Inspection | Before each use | Visual check for damage, defects, or deformities |

Normal Service | Annually | Frequency of use, severity of service conditions |

Severe Service | Monthly to Quarterly | Nature of lifts, experience with similar slings |

Periodic Inspection | Every 12 months (minimum) | Documented inspections required, records to be maintained |

Perform a visual inspection before each use. Look for signs of wear, cuts, broken wires, corrosion, or chemical exposure.

Document periodic inspections at least once every 12 months. Keep records of all findings and actions taken.

Increase inspection frequency if you use slings in severe service conditions, such as extreme temperatures or heavy loads.

Assign a competent person to conduct inspections, as required by OSHA and ASME standards.

Note: Regulatory standards require daily and periodic inspections. OSHA enforces these rules and refers to ASME and ANSI standards for detailed procedures.

Maintenance Best Practices

You can extend the lifespan of your lifting slings by following best practices for rigging sling maintenance. Properly maintain your equipment to ensure safety and reduce downtime.

Inspect slings routinely. Identify and address potential issues early, including hardware and attachment points.

Clean slings with mild soap and water. Dry them thoroughly before storage to prevent mold, rust, or fiber degradation.

Store slings in a clean, dry, and well-ventilated area. Keep them away from direct sunlight, chemicals, and sharp objects.

Always respect the rated load capacity. Never exceed the limits specified on the identification tag.

Train your team in proper handling techniques and best practices for rigging. Well-trained workers help you properly maintain your lifting equipment.

Use only certified slings that meet OSHA, ASME, and ANSI standards. Powerful Machinery provides full documentation and certification for every product.

Keep detailed records of all inspections, maintenance activities, and sling retirements. Good documentation supports compliance and helps you track equipment history.

Alert: Never attempt to repair damaged slings. Remove them from service immediately and replace them with certified equipment.

By following these best practices for rigging sling maintenance, you protect your team and your investment. Properly maintain your lifting slings to ensure safe, efficient, and compliant lifting operations every day.

When to Retire Lifting Slings?

Knowing when to retire lifting slings protects your team and keeps your operation safe. You must recognize clear retirement indicators for each sling type and act quickly when you spot damage.

Retirement Criteria by Sling Type

You should follow industry-accepted criteria to decide when to remove a sling from service. The table below outlines common retirement indicators for different sling types:

Condition | Description |

|---|---|

Broken wires | Ten broken wires in one rope lay for strand-laid slings; five in one strand for single-part slings. |

Distortion | Kinking, crushing, or other damage that distorts the rope structure. |

Heat damage | Metallic discoloration or loss of internal lubricant due to heat exposure. |

Damaged end attachments | Cracked or bent end fittings from wear or damage. |

Bent hooks | Throat openings exceeding 5% of normal size. |

Corrosion | Severe corrosion causing pitting or binding of wires. |

Pulled eye splices | Evidence of slippage or serious damage in eye splices. |

Unbalance | Damage from kinks that distort the sling’s structure. |

Kinks | Permanent strand distortion from improper handling. |

Doglegs | Permanent bends from improper use; severe cases require removal from service. |

Powerful Machinery follows OSHA and ASME standards for retiring damaged slings. You benefit from regular inspections and detailed documentation for every sling in your inventory.

Signs of Damage and Replacement

You must act immediately when you notice any sign of damage. Remove the sling from service and replace it with certified equipment. Look for these common signs:

Cuts, tears, or abrasions on the sling surface.

Broken or damaged stitching.

Deformation or corrosion in hooks and rings.

Unusual twisting or knotting.

Visible inner threads or fibers.

Quick visual scans reveal obvious damage, such as cuts or abrasions.

Alert: Even a small cut or exposed inner thread means the sling is unsafe for lifting. Do not attempt repairs. Replace the sling right away.

Powerful Machinery trains technicians to recognize damage and maintain strict safety standards. You can trust their products to meet global requirements for lifting safety and timely retirement.

Storage and Protection Tips

Proper Storage Practices

You must store your slings correctly to prevent premature wear and damage. Good storage habits keep your equipment safe and ready for every lifting job. Follow these best practices:

Store slings in a clean, dry, and temperature-controlled area.

Hang or lay slings flat on racks or hooks to avoid tangling or crushing.

Keep slings off the ground to prevent moisture absorption and damage from vehicles.

Organize slings in lockers or rigging boxes to shield them from dirt and sunlight.

Choose a cool, dark space to maintain sling strength and flexibility.

Avoid exposure to direct sunlight, rain, or extreme temperatures, which can weaken materials.

Powerful Machinery’s round webbing slings feature PU-impregnation, which helps block dirt and moisture. The color-coded system allows you to identify load capacity at a glance, reducing the risk of overload and making storage organization easier. These features help you maintain your slings in top condition.

Tip: Always inspect slings before storing them. Clean off any dirt or chemicals to extend their service life.

Protection from Environmental Hazards

Environmental hazards can shorten the lifespan of your slings. You need to protect your equipment from moisture, chemicals, and UV exposure. The table below outlines common hazards and how you can guard against them:

Hazard Type | Description | Protection Measures |

|---|---|---|

Moisture | Causes corrosion of wire rope slings, weakening structural integrity. | Store in dry areas, use stainless or galvanized ropes in marine environments. |

Chemicals | Degrades synthetic and wire rope slings, compromising load capacity. | Store away from chemicals, clean immediately if exposed. |

UV Exposure | Degrades synthetic fibers, leading to brittleness and reduced flexibility. | Store indoors, use UV-resistant slings, and rotate equipment usage. |

You should always store slings in clean, dry environments away from chemicals. If a sling comes into contact with corrosive substances, clean it right away. For outdoor applications, use slings made from UV-resistant materials.

Powerful Machinery’s slings offer enhanced wear resistance and clear capacity markings, so you can trust their durability even in tough conditions.

Alert: Discard any sling that shows signs of discoloration, brittleness, or fiber damage. These are signs of environmental degradation and can lead to failure during lifting.

Choosing Quality Slings and Supplier

Selecting the Right Sling

When you select a sling for your lifting operation, you must consider several important factors. Each job has unique requirements, so choosing the right type of lifting sling ensures safety and efficiency. Start by evaluating the load and the environment. The following table helps you compare key factors:

Factor | Description |

|---|---|

Load Characteristics | Assess the weight, size, shape, and fragility of the load. Sharp edges may require special protection. |

Environmental Conditions | Think about exposure to water, chemicals, UV light, or high heat. These can affect sling performance. |

Hitch Type | Decide on the lifting configuration—vertical, choker, or basket. This impacts capacity and suitability. |

Frequency of Use | Frequent lifting calls for durable slings. Occasional lifts may benefit from lighter synthetic options. |

Load Weight & Safety Factors | Always check the Working Load Limit (WLL) and consider how the angle and hitch affect capacity. |

Regulatory Compliance | Make sure your sling meets OSHA, ASME, and other safety standards. |

Protective Accessories | Use corner protectors or sleeves for sharp or abrasive loads. |

Tip: Always know the weight and delicacy of your load. Identify the center of gravity and use the right sling for sharp or irregular objects.

By carefully reviewing these factors, you can make informed decisions when choosing the right type of lifting sling for your application.

Importance of Supplier Certification

You should always partner with a supplier who meets strict industry standards. Certified suppliers provide slings that have passed rigorous testing and comply with safety regulations. This reduces downtime, prevents accidents, and extends the life of your equipment.

Powerful Machinery stands out as a trusted supplier. You benefit from a wide range of certifications, including:

Certification Name |

|---|

ISO9001 |

ISO14001 |

TUV Rheinland |

EURO CERT |

EAC |

Geprüfte Sicherheit |

OSHA |

ASTM |

China Classification Society |

Korean Register |

You also gain access to custom solutions. Powerful Machinery’s in-house engineers design lifting products tailored to your needs. The logistics team manages global shipping and documentation, ensuring smooth delivery and compliance.

Note: Certified lifting slings guarantee that you meet OSHA, ASME, and ANSI standards. Always request product testing documentation and technical support from your supplier.

Choosing a certified supplier like Powerful Machinery gives you peace of mind. You know your lifting equipment will perform safely and reliably, no matter the challenge.

Worker Training and Safety Protocols

Training for Inspection and Maintenance

You play a critical role in maintaining safe lifting operations. Proper training ensures you can inspect and care for lifting slings with confidence. You should invest time in learning the correct inspection techniques and maintenance routines.

Training helps you recognize early signs of wear and damage, which prevents accidents and extends equipment life.

You need to understand the importance of routine inspections before every lift.

Cleaning routines and appropriate storage practices help you keep slings in top condition.

You should complete lifting equipment training to gain essential skills.

Passing certification exams demonstrates your competence and readiness for the job.

Your employer will evaluate your skills before you operate any equipment.

Regular refresher courses keep you updated on new equipment and safety protocols.

A culture of continuous learning encourages you to take ownership of your safety and seek improvement.

Powerful Machinery supports your training by providing resources and guidance for proper certification. Their commitment to safety ensures you have the knowledge and skills needed for every lift.

Tip: Well-trained workers reduce risks and improve overall workplace safety. Make training a priority for your team.

Safe Usage Guidelines

You must follow strict safety guidelines every time you use lifting slings. These rules protect you and your coworkers from injury and equipment failure. Review the essential safety commandments below:

Commandment | Description |

|---|---|

Inspect Before Every Lift | Always inspect your rigging slings before each use. If you spot damage, remove the sling from service immediately. |

Never Alter or Modify Slings | Don’t tie knots, add bolts, or use makeshift devices to change the length or configuration of a sling. These shortcuts compromise strength and safety. |

Keep Sling Legs Straight | Prevent kinks in the sling legs. Kinking reduces the load-carrying capacity and creates unpredictable tension points. |

Stay Within Rated Capacity | Know your lifting sling’s rated working load limit (WLL) and never exceed it. Consider sling angle and hitch type in every calculation. |

Balance Basket Hitches Correctly | Balance the load evenly when using a basket hitch. Unbalanced loads can shift mid-lift and create serious hazards. |

Secure Every Connection | Attach slings properly to both the load and lifting hook. Unsecured connections cause instability and increase the risk of failure. |

Protect Against Sharp Edges | Use edge guards or padding where slings contact sharp corners. This prevents cutting and abrasion on both synthetic and wire rope slings. |

Clear the Lift Zone | Remove all obstructions from the lift area. A clean, clear path reduces the risk of snags or mid-lift interference. |

Keep Personnel Out of the Danger Zone | Make sure no one stands under or near a suspended load. Maintain clear communication and visual awareness at all times. |

Use Tools, Not Hands, to Position Slings | Never place your hands or fingers between the sling and the load while tightening or tensioning. Use rigging tools to guide and position instead. |

Avoid Shock Loads | Always lift slowly and evenly. Quick, jerking movements—or shock loading—can overstress the lifting sling and cause catastrophic failure. |

Never Drag or Yank Slings | Lift the load fully before removing the sling. Dragging a sling from under a load can cause internal damage that isn’t always visible. |

Alert: Following these guidelines helps you prevent accidents and maintain a safe lifting environment.

Conclusion

You protect your team and your business when you prioritize regular inspection, proper maintenance, and timely retirement of lifting slings. Routine checks reduce accidents, meet legal requirements, and help you avoid costly repairs. Timely maintenance extends service life and keeps your lifting operations efficient.

Choose Powerful Machinery for certified solutions that support your safety and compliance every day.

Regular inspections identify hidden faults before they become hazards.

Maintenance and timely retirement ensure reliable performance and legal compliance.

FAQ

How often should you inspect lifting slings?

You should inspect lifting slings before each use and perform a thorough inspection at least once every 12 months. Increase inspection frequency if you work in harsh environments or use slings heavily.

Can you repair a damaged lifting sling?

You must not repair damaged lifting slings. Remove them from service immediately and replace them with certified equipment. Repairs can compromise safety and violate industry standards.

What is the best way to store lifting slings?

Store lifting slings in a clean, dry, and well-ventilated area. Hang them on racks or hooks to prevent tangling. Keep slings away from direct sunlight, chemicals, and moisture.

How do you identify the working load limit (WLL) of a sling?

Check the identification tag attached to the sling. The tag displays the working load limit, manufacturer details, and material type. Always verify this information before lifting.

Why choose Powerful Machinery for lifting slings?

Powerful Machinery provides certified lifting slings that meet global safety standards. You benefit from durable products, expert support, and custom solutions for your lifting needs.