Ensuring safety in your workplace starts with plate clamp inspection and maintenance. You protect your team and meet ASME B30.20 standards when you create a routine for checking and servicing your equipment.

Powerful Machinery’s Plate Clamps give you reliable performance during every lift, supporting efficient and secure materials handling.

Key Takeaways

Establish a routine for inspecting plate clamps before each use to ensure safety and compliance.

Understand the two main types of plate clamps: vertical for heavy lifting and horizontal for thin materials.

Follow ASME B30.20 standards for regular inspections, including every lift, frequent, and periodic checks.

Document all inspections and repairs to maintain compliance and track the history of each clamp.

Choose the right clamp for your lifting needs and always perform pre-use checks to ensure safe operation.

Plate Clamp Types and ASME B30.20 Standards

Plate Clamp Types Overview

You need reliable below-the-hook lifting devices for safe and efficient material handling. Powerful Machinery stands out as a trusted provider of certified plate lifting clamps, serving industries that demand strength and compliance. Plate clamps come in several types, each designed for specific lifting tasks.

The two main types are vertical and horizontal plate clamps.

Type of Plate Clamp | Description |

|---|---|

Vertical Plate Clamps | Used for lifting, turning, moving, or vertical transfer of sheet plates or fabrications. |

Horizontal Plate Clamps | Feature a pretension mechanism for horizontal lifting and transfer of non-sagging material. |

Horizontal plate clamps work best for thin or wide plates, spreading force uniformly to protect the material. Vertical plate clamps suit heavy or thick plates, providing stability during upright lifting. You should select the right clamp based on your application and the inspection standards required for your operation.

ASME B30.20 Compliance

You must follow ASME B30.20 standards when using below-the-hook lifting devices. These standards set inspection standards and operational requirements for plate clamps. Inspections include every lift inspection, frequent inspection, and periodic inspection.

Inspection Type | Description |

|---|---|

Every Lift Inspection | Visual examination before and during each use of the clamp. |

Frequent Inspection | Visual examinations at defined intervals based on service type (monthly, weekly, etc.). |

Periodic Inspection | Documented visual inspection at longer intervals (yearly, semiannually, etc.). |

Operational tests confirm that clamps work according to the manufacturer’s instructions. Load tests verify that clamps can handle 125% of their rated load. You need a maintenance program based on manufacturer recommendations, with inspections and repairs performed by qualified personnel.

Powerful Machinery’s Plate Lifting Clamp meets and often exceeds ASME B30.20 standards for below-the-hook lifting devices. Certified technicians inspect and test each clamp to ensure compliance. You benefit from robust design, secure locking mechanisms, and reliable performance.

Powerful Machinery’s commitment to safety and quality helps you maintain compliance with inspection standards and ASME B30.20 requirements.

Plate Clamp Inspection and Maintenance

Inspection Types and Intervals

You must establish a routine for plate clamp inspection and maintenance to ensure safety and compliance. ASME B30.20 outlines inspection requirements based on service conditions.

You should inspect clamps visually before each use and schedule frequent and periodic inspections according to the environment and workload.

Service Condition | Frequent Inspection Interval | Periodic Inspection Interval |

|---|---|---|

Normal service | Monthly | Yearly |

Heavy service | Weekly to monthly | Semiannually |

Severe service | Daily to weekly | Quarterly |

Special or infrequent service | As recommended by a qualified person | As recommended by a qualified person |

You need to perform an initial inspection before first use. Every lift requires a visual check. Frequent inspections depend on the level of service, ranging from daily to monthly.

Periodic inspections are more thorough and must be documented. Powerful Machinery recommends a periodic inspection every 12 months, with more frequent checks in severe conditions.

Plate Clamp Inspection Checklist

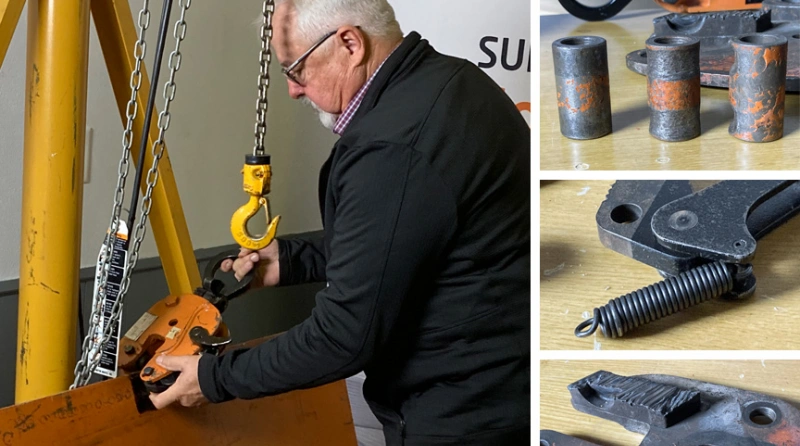

A comprehensive plate clamp inspection and maintenance program starts with a detailed checklist. You must inspect the exterior of a clamp and inspect the internal parts of the clamp to identify any issues. Use the following checklist to guide your process:

Loose bolts or fasteners

Cracked or worn gears, pulleys, sheaves, sprockets, bearings, chains, and belts

Structural deformation, cracks, excessive wear, or bends

Loose or missing guards, stops, or nameplates

Excessive wear of friction pads, linkages, and other mechanical parts

Excessive wear at hooking points and load support clevises or pins

Missing or illegible product safety labels

You should measure jaw opening and compare it to specifications. Inspect the cam and teeth for wear and measure tooth height. Check for clearances and signs of wear on pins and bushings. Verify fastener torque and locking features. Assess surface conditions for corrosion or damage.

Powerful Machinery’s plate lifting clamps feature secure locking mechanisms and proof-testing, which support safe operation and simplify inspection.

Tip: Always inspect the exterior of a clamp and inspect the internal parts of the clamp before each use. This habit helps you catch problems early and avoid equipment failure.

Inspection Criteria and Removal from Service

You must know when to remove a clamp from service to prevent accidents. The removal from service criteria include several key factors:

Criteria | Description |

|---|---|

Markings and Labeling | Must be clearly visible; unreadable information means the clamp cannot be safely used. |

Jaw and Cam Condition | Teeth must be sharp and complete; any damage reduces grip strength. |

Latch and Lock Mechanism | Should move freely and click securely; a weak spring indicates a problem. |

Clamp Body Condition | Must be free of cracks or bends; any distortion indicates overload or misuse. |

Fasteners and Hardware | All components must be secure and not visibly worn. |

Throat Measurement | If the base width exceeds the top, the clamp has been overloaded and must be replaced. |

If you find any of these issues, you must remove the clamp from service immediately. Repairs should use only original equipment manufacturer (OEM) parts. Document all repairs and inspections to maintain compliance.

Maintenance Program and Repairs

You need a maintenance program that supports the reliability and longevity of your clamps. Routine inspections help you spot wear, cracks, or rust before they become hazards. Lubricate moving parts to reduce friction and maintain functionality.

Replace worn components instead of the entire clamp to save costs and support sustainability. Always follow Powerful Machinery’s guidelines for cleaning and inspection intervals.

Record-keeping is essential for plate clamp inspection and maintenance. Keep detailed records of all inspections and repairs. This documentation helps you track the history of each clamp and ensures compliance with ASME B30.20 standards.

Best Practice | Description |

|---|---|

Documentation | Keeping detailed records of inspections and maintenance activities. |

Note: A well-managed maintenance program for clamps reduces downtime, increases safety, and extends the life of your equipment. You protect your investment and your team by following these best practices.

Plate Clamp Testing and Documentation

Operational and Load Testing

You must test plate clamps regularly to guarantee safe operation and compliance with ASME B30.20. Operational tests check the clamp’s basic functions, including the locking mechanism, jaw movement, and spring action.

You should activate the clamp and observe how the jaws grip and release the plate. If you notice any hesitation or irregular movement, you need to investigate further.

Load testing confirms that the clamp can handle its rated capacity. You should apply a test load equal to 125% of the clamp’s working load limit. For example, Powerful Machinery’s DFQ Turning Plate Lifting Clamp with a 10-ton rating must lift 12.5 tons during the test.

You must watch for signs of jaw wear, spring damage, or locking mechanism failure. Annual inspections by qualified professionals help you identify these issues early. You protect your team and equipment when you follow these testing procedures.

Tip: Always use certified technicians for annual inspections and load tests. This practice ensures your clamps meet safety standards and perform reliably.

Inspection and Test Records

You need to keep accurate records of all inspections and tests. Documentation supports compliance with ASME B30.20 and helps you track the history of each clamp. You should record the date, inspector’s name, findings, and any corrective actions taken.

This information proves that you maintain your equipment according to industry standards.

Annual inspections and certifications by qualified professionals are required.

Inspections must comply with ASME B30.20 standards for safety and performance.

Certified technicians identify issues such as jaw wear, spring damage, and locking mechanism failure.

Record Type | Details to Include |

|---|---|

Inspection Log | Date, inspector, findings, actions |

Test Report | Load applied, results, technician |

Maintenance Record | Repairs, replacements, service dates |

You build a culture of safety when you document every inspection and test. Powerful Machinery recommends keeping digital and physical copies of all records. This habit helps you respond quickly to audits and ensures your plate clamps remain in top condition.

Use Plate Clamps Safely

Selection and Pre-Use Checks

Selecting the correct clamp for the job is essential for safe and efficient lifting. You should consider several factors before choosing a plate clamp:

Material hardness

Lift orientation (vertical, horizontal, or turning)

Jaw opening range

Thickness and surface condition of the plate

Working environment

The acronym “MAJEC” helps you remember key selection criteria: Material Hardness, Attitude of the lift, Jaw opening, Environment, and Confirmation through reading the manual and inspecting the clamp.

Powerful Machinery’s DFQ Turning Plate Lifting Clamp offers a range of jaw openings and working load limits from 1.5 to 20 tons. You can match the clamp’s specifications to your project requirements. Always confirm the clamp’s markings, including the working load limit and model number, before use.

Before each lift, perform these pre-use checks:

Inspect markings and labeling for clarity

Check jaw and cam condition for sharp, undamaged teeth

Test the latch and lock mechanism for smooth operation

Examine the clamp body for cracks, bends, or twists

Verify all fasteners and hardware are secure

Safe Lifting Techniques

You must use plate clamps safely to protect your team and equipment. Follow these steps for proper lifting:

Choose the right clamp for your application.

Position the clamp accurately, centering the plate within the jaws.

Lock a clamp closed before lifting to ensure a secure grip.

Lift the load smoothly, avoiding sudden movements.

Do not overload or underload a clamp; always stay within the rated capacity.

Do not lift over workers at any time.

Do not leave suspended loads unattended.

Tip: Consult a lifting equipment expert if you are unsure about clamp selection or operation.

Prohibited Actions

Certain actions can compromise safety and must be avoided when using plate clamps:

Action to Avoid When Using Plate Clamps | Reason |

|---|---|

Do not drag the load using the plate clamp | Dragging can damage the clamp and the load |

Do not overload or underload a clamp | Overloading leads to equipment failure; underloading may cause instability |

Do not lift over workers | Prevents serious injury in case of clamp failure |

Do not leave suspended loads unattended | Unattended loads pose a risk to everyone nearby |

Do not use damaged or uninspected clamps | Increases risk of accidents |

You must avoid using plate clamps, any shortcuts, or unsafe practices. Powerful Machinery’s commitment to safety and reliability ensures that every clamp meets strict standards, supporting your safe lifting operations.

Conclusion

You improve workplace safety when you follow a routine for plate clamp inspection and maintenance. Powerful Machinery’s Plate Lifting Clamp delivers proven reliability and safety.

Feature | Description |

|---|---|

Load Capacity | Tested to twice the weight limit for maximum safety. |

Certification | Meets ASME B30.20 and EU Directives with proof load certification. |

Traceability | Full inspection records and CE marking for compliance. |

You support safe lifting by choosing certified equipment and maintaining thorough records. Regular training and expert consultation help you meet industry benchmarks and reduce injury rates.

Blended learning options and scenario-based training keep your team prepared.

Experts provide specialized knowledge and rigorous inspection protocols.

Stay proactive with ongoing safety programs and expert advice to protect your team and assets.

FAQ

How do you choose the right clamps for your lifting needs?

You should match the clamps to the weight, size, and hardness of your steel plates. Always check the working load limit and jaw opening. Powerful Machinery offers clamps for a wide range of applications, ensuring you find the right clamps for every project.

How often should you inspect your clamps?

You must inspect clamps before every use. Schedule frequent and periodic inspections based on service conditions. Powerful Machinery recommends monthly checks for normal service and more frequent inspections for heavy or severe use. Regular inspection keeps your clamps safe and reliable.

What should you do if you find damage on your clamps?

Remove damaged clamps from service immediately. Do not attempt to repair clamps with non-original parts. Contact Powerful Machinery for guidance on proper repairs or replacement. Using damaged clamps increases the risk of accidents and equipment failure.

Can you use clamps for lifting more than one plate at a time?

You should use clamps to lift only one plate at a time. For multiple plates, use additional clamps or a lifting beam for stability. This practice ensures the clamps maintain a secure grip and prevent accidents during lifting operations.

How do you maintain your clamps for long-term performance?

Clean clamps after each use and lubricate moving parts regularly. Store clamps in a dry area to prevent rust. Keep detailed records of all inspections and maintenance. Following these steps extends the life of your clamps and supports safe lifting.