You rely on shackles to connect loads and equipment during lifting operations. A shackle is a strong metal connector that holds a critical weight. When you use shackles correctly, you protect people and property.

Mistakes can lead to accidents, injuries, or costly damage. The safe use of shackles in rigging starts with strict attention to safety and compliance. Powerful Machinery draws on years of experience to set industry standards for reliable hardware.

Key Takeaways

Always inspect shackles before use. A visual check helps identify damage and ensures safety.

Remove any damaged shackles immediately. Look for signs like cracks, corrosion, or missing markings.

Choose the right type and size of shackle for your load. Match shackles to the specific rigging application.

Use only manufacturer-approved pins with shackles. This maintains safety and integrity during lifting.

Plan each lift carefully. Understand how load angles affect the working load limit to prevent accidents.

Important Rules for Safe Shackle Use

You must follow important rules to ensure safe shackle use in every rigging operation. These rules of using shackles help prevent accidents, protect workers, and keep your lifting projects compliant with industry standards.

Powerful Machinery builds its reputation on safety and certified products, making these guidelines the foundation of every successful lift.

Inspect Shackles Before Use

Inspecting the shackles before use is a critical step in your daily routine. Industry standards require you to check each shackle before every lift. This process helps you spot any issues that could compromise safety.

You should perform an initial inspection when you purchase new shackles or after any repairs. Before each use, conduct a visual inspection to check for distortions or other visible problems.

Tip: Use a checklist to make sure you do not miss any steps during inspection.

Here is a quick overview of inspection types:

Inspection Type | Description |

|---|---|

Initial Inspection | Conducted by a designated person for new, altered, or repaired shackles. |

Daily Visual Inspection | Performed by you or a designated person before each use. |

Complete Inspection | Checks for any condition that may create a hazard. |

Regular inspection is one of the most important rules for safe shackle use. It ensures you catch problems early and avoid unsafe lifts.

Remove Damaged Shackles

You must remove any shackle that shows signs of damage. The rules of using shackles require you to look for specific defects during inspection. These include excessive corrosion, bent or twisted parts, cracks, or missing markings. If you find any of these issues, take the shackle out of service immediately.

Condition Number | Description |

|---|---|

1 | Physical size is reduced, making it unable to handle the rated load. |

2 | Excessive pitting, corrosion, nicks, or gouges. |

3 | Bent, twisted, distorted, stretched, elongated, cracked, or broken components. |

4 | Signs of heat damage, such as discoloration or weld spatter. |

5 | Missing or illegible manufacturer’s name, working load limit, or size. |

6 | Bent load pins or visibly damaged threads. |

By following these important rules, you help maintain a safe work environment. Powerful Machinery tests every shackle to meet or exceed ASME and OSHA standards, so you can trust the hardware you use.

Shackle Selection and Sizing

Choosing the correct type of shackle is essential for safe and efficient lifting. You need to select the right shackle for your specific rigging applications. Powerful Machinery offers a wide range of shackles, including stainless steel shackles, to meet the needs of various industries.

Types of Shackles

You will find several types of shackles designed for different tasks. The most common are bow shackles and D shackles. Bow shackles have a larger, rounded shape that allows for multiple connections and side loading.

D shackles, also called chain shackles, have a narrower profile and work best for straight-line pulls. Stainless steel shackles provide excellent corrosion resistance, making them ideal for marine or outdoor environments.

Powerful Machinery supplies both screw pin and bolt-type shackles, giving you flexibility for temporary or permanent installations.

Tip: Always match the shackle type to the load direction and connection points.

Sizing for Applications

You must size shackles correctly to ensure safety. The working load limit (WLL) must always meet or exceed the weight of your load. When you select shackles for use with wire rope or synthetic slings, consider these factors:

Wire Rope: Durable and strong, wire rope requires shackles with higher working load limits. You must ensure the shackle fits the rope diameter and does not pinch or damage the strands.

Synthetic Slings: Lightweight and flexible, synthetic slings need shackles with smooth surfaces to prevent cutting or abrasion. Avoid using synthetic slings in high-temperature environments.

Common causes of shackle failure include overloading, wear and tear, improper use, and lack of inspection. Prevent these issues by inspecting shackles regularly, training your team, and following manufacturer guidelines.

Selecting the right shackle and sizing it properly reduces risk and increases the lifespan of your equipment. Powerful Machinery’s certified shackles help you achieve safe and reliable lifts every time.

Markings and Traceability on Shackles

Required Markings

You must check every shackle for clear and permanent markings before you use it. These markings help you trace the product back to its manufacturer and confirm that it meets industry standards. Look for the working load limit, size, and the manufacturer’s name or logo.

These details allow you to verify that the shackle matches your lifting guidelines and complies with safety standards.

Always compare the markings on your shackles with your project requirements. This step ensures you follow the correct guidelines and avoid using equipment that does not meet standards.

Shackles from Powerful Machinery display all required markings. You can trust these products to meet international standards for traceability and identification. Proper markings make it easy to confirm that your shackles are suitable for your lifting operation and align with your safety guidelines.

Actions for Illegible Markings

If you find a shackle with missing or illegible markings, you must act quickly. Illegible markings mean you cannot confirm the shackle’s compliance with standards or guidelines. Remove the shackle from service right away. Do not use it for any lifting operation. Replace it with a shackle that has clear, readable markings.

The following table shows recommended actions when you encounter illegible markings:

Action |

|---|

Replace the shackle immediately if the markings are illegible |

Remove from service any shackle that shows missing or illegible identification |

You protect your team and equipment when you follow these guidelines. Always rely on shackles that meet current standards and display clear markings. This practice supports safe lifting operations and keeps your workplace compliant with industry guidelines.

Working Load Limit (WLL) and Safe Use of Shackles in Rigging

Understanding WLL

You must always respect the working load limit when using shackles. The working load limit, or WLL, is the maximum load that a shackle can safely support during lifting operations. Manufacturers like Powerful Machinery test shackles to meet or exceed strict industry standards. This ensures you have confidence in the safe use of shackles in rigging.

Never exceed the WLL. If you ignore this rule, you risk serious consequences. For example:

In California, overloaded nylon slings failed, crushing a worker because the lift exceeded the rated capacity.

In Las Vegas, a hydraulic crane tipped over after the actual load weight was underestimated.

Both incidents caused major financial losses, lost workdays, and, tragically, loss of life.

You protect your team and equipment when you follow the safe use of shackles in rigging and always check the WLL before every lift. Always perform an inspection to confirm the shackle is in good condition and rated for your load.

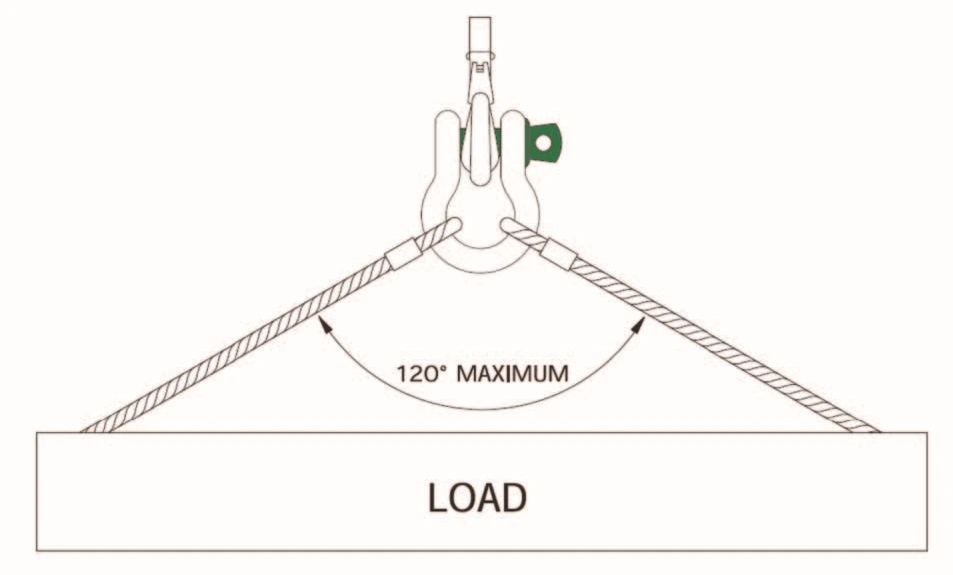

Effects of Loading Angles

The angle at which you apply a load to a shackle affects its WLL. Shackles are designed for straight-line pulls. When you introduce side loading or angles, the WLL decreases. This can lead to shackle failure even if the load appears to be within the rated limit.

Loading Angle (Degrees) | Percentage of WLL Available |

|---|---|

0 (Straight Line) | 100% |

45 | 70% |

90 | 50% |

You must avoid side loading whenever possible. If your rigging setup requires an angle, choose a shackle with a higher WLL to compensate. Always use the safe use of shackles in rigging by planning your lifts and understanding how angles impact the load. This practice keeps your lifting operations safe and compliant.

Proper Attachment Techniques for Shackles

Centering Loads

You must always center the load in the bow of the shackle. Shackles work best when you apply force in a straight line. This method allows the shackle to handle its maximum capacity. If you place the load off-center or at an angle, you risk side loading.

Side loading can reduce the working load limit by up to 50% or more. This reduction creates a serious safety hazard.

Tip: Always check that the load sits directly in the center of the shackle bow before lifting.

Here are key best practices for centering loads:

Place the load in the center of the shackle bow.

Avoid attaching multiple sling legs to the pin.

Never apply force at an angle.

Inspect the setup to confirm the load is not pulling to one side.

Best Practice | Description |

|---|---|

Center Load | Ensure the load is centered in the bow of the shackle to prevent side loading. |

Avoid Side Loading | Do not attach multiple sling legs to the pin. Side loading reduces capacity. |

When you follow these steps, you protect your team and equipment from unexpected failures.

Correct Connections

You must use the correct connection method for every lift. Always attach the shackle so the pin connects to the lifting device, and the bow connects to the load. This setup helps distribute force evenly. If you use multiple slings, connect them to the bow, not the pin. The pin is not designed to handle side loads from multiple sling legs.

Tighten the shackle pin securely by hand.

Do not use makeshift tools or force the pin.

Double-check that the pin is fully engaged and seated.

Use only manufacturer-approved pins for replacements.

Note: Proper connections prevent accidental disengagement and keep the load stable during lifting.

By following these attachment techniques, you ensure safe, efficient, and compliant lifting operations every time.

Securing Shackle Pins

Manufacturer Pins Only

You must always use the original manufacturer’s pin with your shackle. The pin and the shackle body are designed and tested as a matched set. Substituting a pin from another source can weaken the connection and create a serious safety risk.

When you use only manufacturer-approved pins, you maintain the integrity of your rigging hardware.

Tip: Keep spare manufacturer pins on hand for quick replacement if you lose or damage one during operations.

Never attempt to modify or fabricate a replacement pin. Even small differences in size or thread pitch can cause the pin to fail under load.

Powerful Machinery shackles come with precision-engineered pins that fit perfectly and meet all safety standards. This attention to detail helps you avoid unexpected failures and ensures every lift meets compliance requirements.

Pin Engagement

Proper pin engagement is essential for securing a load safely. Always screw the pin in fully by hand until it seats firmly against the shackle body. Do not use tools to overtighten, as this can damage the threads or make removal difficult later.

After tightening, check that the pin does not protrude or wobble. A loose or partially engaged pin can work itself free during lifting, leading to dropped loads or equipment damage.

Follow these best practices for pin engagement:

Inspect the threads for dirt or damage before installation.

Insert the pin straight and avoid cross-threading.

Tighten the pin by hand until it is snug.

For bolt-type shackles, secure the nut and cotter pin as required.

Step | Action |

|---|---|

1 | Inspect threads and pins for cleanliness |

2 | Insert and hand-tighten the pin |

3 | Confirm full engagement and security |

By following these steps, you help prevent accidents and ensure the shackle remains secure throughout the lift. Proper pin engagement is a key part of securing a load and maintaining a safe work environment.

Environmental Considerations for Shackles

Temperature and Chemicals

You must always consider the environment when selecting and using shackles. Extreme temperatures can affect the strength and performance of your rigging hardware. Most shackles operate safely between -40 degrees Fahrenheit and 400 degrees Fahrenheit.

If you expect to work outside these limits, consult the manufacturer for specific recommendations. Exposure to temperatures beyond this range can reduce the shackle’s load capacity or cause material failure.

Chemical exposure also poses a significant risk. In marine environments, saltwater accelerates corrosion, leading to pitting and rust. Chemicals in industrial settings can degrade the metal, reducing the shackle’s integrity and strength. To address these challenges, choose shackles made from corrosion-resistant materials.

Stainless steel shackles from Powerful Machinery offer excellent resistance to rust and corrosion. They perform reliably in marine, offshore, and food industry applications, maintaining their integrity over time.

Tip: Always follow temperature and chemically active environment guidelines to ensure your shackles remain safe and effective.

Environmental Factor | Impact on Shackles | Recommended Solution |

|---|---|---|

Extreme Temperatures | Reduced strength or failure | Use within the rated temperature range |

Chemical Exposure | Corrosion, pitting, loss of strength | Use stainless steel or galvanized shackles |

Shock Loading

Shock loading happens when a sudden force strikes your rigging system. This can occur if you drop a load or make abrupt movements during lifting. Shock loading places excessive stress on shackles, which can lead to unexpected failure.

To avoid shock loading, follow these best practices:

Use proper rigging techniques to prevent dropping loads.

Train your team to recognize and avoid sudden movements.

Inspect your equipment regularly for signs of damage.

Always follow the manufacturer’s rated capacities.

Plan each lift carefully to avoid sudden stops or impacts.

By understanding environmental factors and following these guidelines, you protect your team and extend the life of your rigging equipment.

Removing and Replacing Shackles

Criteria for Removal

You must know when to remove a shackle from service to maintain safety in your lifting operations. The ASME B30.26 standards outline clear criteria for shackle removal. If you spot any of these issues during inspection, take the shackle out of service immediately. Never ignore these warning signs.

Cracks, bends, or twists in the shackle body or pin

Excessive wear, corrosion, or pitting

Distorted, stretched, or elongated components

Missing or illegible manufacturer markings

Evidence of heat damage, such as discoloration or weld spatter

Damaged threads or bent pins

Tip: Always document the removal of any shackle and notify your supervisor. This practice helps you track equipment and maintain compliance with safety standards.

A shackle that fails any of these criteria cannot guarantee safe lifting. You protect your team and equipment by acting quickly and decisively.

No Repairs or Modifications

You must never attempt to repair or modify a damaged shackle. Repairs can weaken the metal and compromise the integrity of the hardware. Modifications, such as welding or bending, change the original design and void manufacturer certifications.

Only use shackles that meet all safety standards and retain their original structure.

Action | Acceptable? |

|---|---|

Welding a cracked shackle | ❌ |

Straightening a bent pin | ❌ |

Replacing with the manufacturer’s pin | ✅ |

Using an original, unmodified shackle | ✅ |

Note: Always replace damaged shackles with certified products from trusted suppliers like Powerful Machinery. You ensure every lift meets industry standards and keeps your workplace safe.

You maintain a safe rigging environment by removing, not repairing, any shackle that shows signs of damage. Rely on certified replacements to support your lifting operations.

Application-Specific Shackle Choices

Temporary vs. Permanent Use

You must select the right shackle type for each rigging scenario. Screw pin shackles work best for temporary lifting tasks. You can connect and disconnect them quickly, which saves time during frequent equipment changes.

However, screw pin shackles do not suit permanent or long-term installations. The pin may loosen if exposed to vibration or rotation.

Bolt-type shackles provide a more secure connection for permanent or semi-permanent setups. The bolt, nut, and cotter pin design prevents accidental loosening, even when the shackle faces rotational forces.

You do not need to retighten these shackles during extended use. Powerful Machinery offers both screw pin and bolt-type shackles, so you can match your choice to the demands of your project.

Tip: Always review your lifting plan before choosing between screw pin and bolt-type shackles. Select the option that matches the duration and safety needs of your operation.

Key factors to consider:

Screw pin shackles: Fast installation and removal, ideal for short-term or temporary rigging.

Bolt-type shackles: Secure, reliable, and suitable for permanent or semi-permanent applications.

Load Suspension

When using shackles for load suspension, you must follow strict practices to ensure safety and stability. Proper load securing starts with a thorough inspection and the correct choice of shackle for the job. Always center the load on the bow and make sure the pin is properly seated.

Best Practice | Description |

|---|---|

Check for damage or wear before each lift. | |

Select the Right Shackle for the Job | Match the shackle type to your lifting requirements. |

The Pin Must Be Properly Seated | Ensure the pin is fully engaged and secure. |

Center the Load on the Bow | Apply the load in a straight line, centered on the shackle’s bow. |

Make Proper Sling and Hardware Connections | Confirm all connections are correct and secure. |

Account for Sling Angles | Understand that multi-leg slings increase force on the shackle. |

Never Replace the Original Pin | Use only the manufacturer’s original pin for load securing. |

Avoid Extreme Temperatures and Chemical Exposure | Protect shackles from harsh environments. |

Always Respect the Working Load Limit (WLL) | Never exceed the rated capacity marked on the shackle. |

You should never use a shackle with a damaged pin or deformed body. Avoid pulling at an angle, as this can open the shackle legs and cause failure. Remove any shackle from service if it shows signs of repair or modification. By following these practices, you ensure safe and reliable lifting operations every time.

Conclusion

You protect your team and equipment when you consistently apply all nine shackle safety rules. Choosing certified shackles from Powerful Machinery ensures reliability and compliance on every lift. Stay current with best practices by following these steps:

Pre-plan each lift with your crew.

Use proper rigging techniques.

Train all operators regularly.

Keep rigging handbooks and equipment accessible.

Stop and report any safety concerns.

Prevent injuries by planning for equipment failure.

Communicate clearly with hand signals.

Stay informed and prioritize safety in every operation.

FAQ

What is the most important step before using a shackle in rigging?

You must inspect before every use. A visual inspection helps you spot cracks, corrosion, or other damage. This step ensures your rigging hardware meets safety standards and prevents accidents.

How do OSHA standards and ASME standards affect shackle selection?

You must choose shackles that comply with OSHA standards and ASME standards. These regulations set minimum requirements for design, rating, and testing. Following them keeps your rigging operations safe and compliant.

Why is the rating on a shackle important?

The rating shows the maximum load the shackle can safely handle. You must never exceed this rating. Using shackles within their rated capacity protects your team and equipment during rigging.

Can I use the same shackle for every rigging job?

No. Each rigging job has unique requirements. You must select shackles based on load, environment, and application. Always match the shackle type and size to your specific needs.

What should I do if I find damage during a visual inspection?

Remove the shackle from service immediately. Damaged shackles do not meet safety standards. Replace them with certified hardware to maintain safe rigging operations.