When you choose a shackle, your decision directly affects safety, performance, and working load limit. The right rigging shackle materials ensure your equipment meets both your operational needs and industry standards. Factors such as environment, load, and corrosion risk all play a role.

For example, different materials meet different safety standards and working loads, as shown below:

Shackle Material | Safe Working Load (SWL) | Standards Compliance |

|---|---|---|

Alloy Steel | Higher SWL | BS 3551 |

Higher Tensile Steel | Lower SWL | BS 3032 (withdrawn) |

Mild Steel | No standard for lifting | N/A |

Trust Powerful Machinery’s certified products and expertise to help you select the safest and most reliable solution for your application.

Key Takeaways

Choose the right shackle material based on your environment. For marine or high-humidity areas, opt for stainless steel or hot-dip galvanized shackles to resist corrosion.

Always verify the Working Load Limit (WLL) of shackles. Match the WLL to your lifting needs to ensure safety and prevent equipment failure.

Follow international safety standards when selecting shackles. Check for certifications from organizations like OSHA and ASME to ensure compliance and safety.

Regularly inspect shackles for wear and damage. Remove any shackles that show signs of corrosion or deformation to maintain safety during lifting operations.

Selection Factors

Choosing the right shackle starts with understanding the factors that impact performance and safety. You need to consider your environment, the load you plan to lift, and the safety standards that apply to your industry.

Environment & Corrosion

Your operating environment plays a major role in selecting rigging shackle materials. Humidity, temperature, and exposure to corrosive elements can weaken shackles over time.

In the marine and construction industries, high humidity and saltwater accelerate corrosion, which can compromise the integrity of your equipment. For example, seawater contains chloride ions and dissolved oxygen, both of which speed up corrosion.

Fast-moving water, pollution, and even microorganisms can make this worse.

Tip: For marine, offshore, or high-humidity applications, choose stainless steel or hot-dip galvanized shackles. These materials resist corrosion and last longer in harsh conditions.

Shackle Material | Safety Factor (SF) | Environmental Condition |

|---|---|---|

Grade 316 Stainless | 5:1 | Superior corrosion resistance |

Grade 304 Stainless | 5.5:1 | Chloride environments |

Marine/Offshore | ≥6:1 | DNV requirement |

Chemical Plants | 5:1 | Accounts for corrosion fatigue |

Regular inspections help, but prevention through material choice is key.

Load & WLL

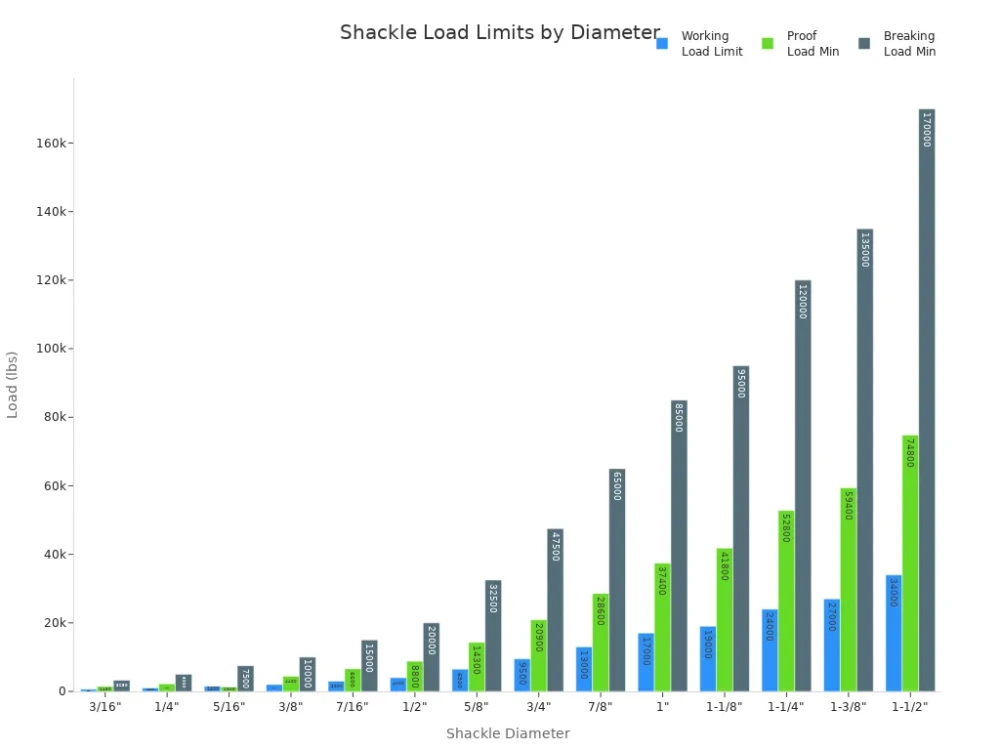

You must match the shackle’s working load limit (WLL) to your lifting needs. Each shackle comes with a marked WLL, which tells you the maximum safe load. Carbon steel shackles typically support loads from 1/3 to 55 metric tons, while alloy steel shackles can handle up to 85 tons.

The maximum proof load is usually twice the WLL, and the minimum breaking force is six times the WLL.

Each D shackle is marked with its WLL.

The maximum testing load is twice the working load.

Minimum breaking load is six times the WLL.

Selecting the right WLL ensures safety and prevents equipment failure.

Safety & Standards

You should always follow international safety standards when choosing shackles. Organizations like OSHA and ASME B30.26 set strict guidelines for design, manufacturing, and inspection. These standards protect you and your team by ensuring every shackle meets minimum safety requirements.

Powerful Machinery stands out by holding certifications from major classification societies and international bodies, including ISO and CE. This commitment to quality means you can trust their products to meet or exceed industry benchmarks.

Note: Always check for certifications and compliance before making your final selection.

Rigging Shackle Materials Overview

Selecting the right rigging shackle materials ensures your equipment performs reliably in every environment.

Powerful Machinery offers a comprehensive range of shackles, including stainless steel shackles and high-strength steel shackles, designed for diverse applications. You must understand the unique properties and advantages of each material before making your choice.

Carbon Steel

Carbon steel shackles deliver robust strength and toughness, making them a preferred choice for heavy-duty lifting and industrial operations. You will find these shackles in construction, transportation, and cargo handling, where high tensile strength is essential.

Carbon steel contains up to 2.1% carbon and lacks significant amounts of corrosion-resistant elements. This composition gives carbon steel shackles their impressive load-bearing capacity, but it also means they can rust when exposed to moisture.

Type of Steel | Key Elements and Composition | Properties |

|---|---|---|

Carbon Steel | High carbon content (up to 2.1%), no chromium | Strong, hard, prone to rust |

You should use carbon steel shackles in dry, controlled environments where corrosion risk is minimal. Powerful Machinery’s steel shackles feature drop-forged construction, ensuring maximum strength and durability for demanding tasks.

Tip: Regular inspection and proper storage extend the service life of carbon steel shackles in industrial settings.

Stainless Steel

Stainless steel shackles excel in environments where corrosion resistance is critical. You will benefit from their performance in marine, chemical processing, and outdoor applications.

Stainless steel contains at least 10.5% chromium, which forms a protective oxide layer that prevents rust and deterioration. Grades 304 and 316 offer superior resistance to moisture, saltwater, and chemicals.

Stainless steel shackles are ideal for marine and chemical processing environments.

The passive chromium oxide layer ensures longevity and reduces maintenance needs.

Marine-grade stainless steel, such as 316, withstands saltwater and high humidity.

Powerful Machinery’s stainless steel shackles provide secure connections for lifting and rigging in harsh conditions. You can rely on their certified quality and smooth finish for easy handling and installation.

Note: Choosing stainless steel shackles increases safety and reliability in demanding environments where equipment failure is not an option.

Alloy Steel

Alloy steel shackles combine the strength of carbon steel with enhanced mechanical properties from alloying elements like manganese, nickel, chromium, and molybdenum.

You should select alloy steel shackles for applications that require exceptional load-bearing capacity and resistance to extreme temperatures. These shackles are engineered for industries such as oil and gas, mining, and heavy construction.

Type of Steel | Key Elements and Composition | Properties |

|---|---|---|

Alloy Steel | Carbon steel + manganese, nickel, chromium, molybdenum | Superior strength-to-weight ratio, higher WLL, versatile |

Alloy steel shackles withstand extreme loads and harsh operating conditions.

The mechanical properties are enhanced by alloying elements, providing greater ductility and strength.

You can use alloy steel shackles in high-load, high-temperature, or impact-prone environments.

Powerful Machinery’s steel shackles meet international standards, ensuring safety and reliability for your most demanding projects.

Callout: Material selection is crucial for the performance and durability of rigging shackle materials. You should always match the shackle type to your specific environment and load requirements.

Powerful Machinery Product Insights

Stainless Steel Shackles

You need reliable rigging shackle materials when working in harsh or corrosive environments. Powerful Machinery’s stainless steel shackles deliver exceptional performance for marine, industrial, and construction applications.

These shackles use high-quality stainless steel, which resists rust and corrosion even in humid or salty conditions. You can trust their durability and strength for lifting, towing, and securing operations.

Take a look at the key features of stainless steel shackles from Powerful Machinery:

Feature | Description |

|---|---|

Material Quality | Made from high-quality stainless steel for durability and corrosion resistance. |

Load Capacity | Capable of lifting or securing up to 2000kg. |

Durability | Exceptionally durable, suitable for various lifting and safety operations. |

Corrosion Resistance | Designed to resist corrosion, even in humid or salty environments. |

Safety Features | Equipped with locking pins to prevent unintentional release. |

You benefit from products developed and tested in-house at Ketten Wälder GmbH. Powerful Machinery also tests these shackles at a Lloyd’s Register-certified laboratory to ensure maximum safety. You can find more details and specifications on the official stainless steel shackles product page.

Tip: Choose stainless steel shackles for environments where corrosion resistance and long-term reliability are essential.

Steel Shackles

You require steel shackles that meet strict safety standards for heavy-duty lifting and rigging. Powerful Machinery’s steel shackles provide robust strength and versatility for construction, shipping, and logistics.

Each shackle undergoes rigorous static and dynamic testing to guarantee reliability. The working load limit (WLL) is clearly marked on every certified shackle, so you always know the maximum safe lifting capacity.

Consider these important points about Powerful Machinery’s steel shackles:

The working load limit (WLL) represents the maximum weight or force the shackle can safely handle.

WLL is calculated by dividing the breaking strength by a safety factor. For example, a shackle with a breaking strength of 10,000 pounds and a safety factor of 5:1 has a WLL of 2,000 pounds.

Powerful Machinery shackles meet international standards and provide peace of mind for demanding projects.

You can explore the full range of steel shackles and their specifications on the official shackles product page.

Note: Always select rigging shackle materials that match your environment and load requirements to ensure safety and efficiency.

Comparison & Checklist

Quick Reference Table

Selecting the right shackle material requires you to compare performance, durability, and safety. You can use the table below to quickly assess how carbon steel shackles, stainless steel shackles, and alloy steel shackles perform under standardized testing and real-world conditions.

Material | Typical WLL Range | Corrosion Resistance | Strength (Testing) | Best Use Cases |

|---|---|---|---|---|

Carbon Steel Shackles | 1–12 tons | Moderate | Grade A: 6x WLL, Grade B: up to 12 tons | Construction, dry environments |

Stainless Steel Shackles | 1–10 tons | Excellent | Ongoing testing, high resistance | Marine, chemical, outdoor |

Alloy Steel Shackles | 2–24+ tons | Good | Twice the strength of Grade A (testing) | Heavy lifting, extreme loads |

During testing, carbon steel shackles show reliable performance in dry, controlled settings. Stainless steel shackles excel in corrosion resistance, especially after repeated testing in marine environments.

Alloy steel shackles consistently outperform others in strength-based testing, making them ideal for demanding industrial applications.

Note: Side loading during testing reduces shackle strength by up to 50%. Always align the load for maximum safety.

Selection Checklist

You can ensure safe and effective shackle selection by following this checklist:

Verify Working Load Limit (WLL): Confirm the WLL matches your lifting needs. Carbon steel shackles offer a wide range, but always check the rating after testing.

Choose the Correct Shape: Select a bow or D shape based on your application.

Inspect Condition: Look for wear, cracks, deformation, or corrosion. Remove shackles with more than 10% wear or any visible damage.

Check Markings: Ensure all shackles are clearly marked, certified, and traceable.

Routine Inspections: Schedule inspections based on service conditions. For normal use, inspect yearly. For severe conditions, inspect monthly or quarterly.

Review Pin and Body: Examine for heat damage, proper fit, and closure.

Consult Manufacturer Specifications: Always refer to manufacturer data and international safety standards before use.

🛠️ Tip: Replace any shackle that fails inspection or shows signs of damage during testing. Proper selection and regular testing extend the lifespan of your rigging equipment.

Conclusion

You improve safety and efficiency when you match shackle material to your environment and lifting needs. Always consult manufacturer specifications and follow safety standards to avoid common mistakes, such as mixing pins or using the wrong shackle type.

Choose carbon steel for general lifting, alloy steel for heavy-duty jobs, and stainless steel for corrosive settings.

Inspect shackles regularly and remove any with damage or unclear markings.

Rely on Powerful Machinery’s certified products to ensure reliable rigging and long-term performance.

FAQ

What is the difference between carbon steel and stainless steel shackles?

Carbon steel shackles offer high strength for dry environments. Stainless steel shackles resist corrosion and work best in marine or chemical settings.

Tip: Choose stainless steel if you expect moisture or salt exposure.

How do I know which shackle size to use?

You should match the shackle size to your load requirements. Always check the Working Load Limit (WLL) marked on the shackle.

For heavy loads, select a larger shackle with a higher WLL.

Can I use shackles in saltwater environments?

Yes, you can use shackles in saltwater. Stainless steel shackles provide the best corrosion resistance for marine applications.

Regularly rinse and inspect shackles to maintain safety.

How often should I inspect my shackles?

Inspect shackles before each use. For harsh environments, increase inspection frequency.

Look for cracks, deformation, or corrosion.

Remove damaged shackles immediately.

Are the Powerful Machinery shackles certified for international standards?

Yes, Powerful Machinery shackles meet major international standards, including ISO and CE.

You can trust their certifications for safety and reliability in demanding industries.