You face many choices when it comes to anchor chain selection for sailors. Understanding the types, grades, and materials helps you protect your vessel and ensure safe anchoring. As cruising sailors, you want confidence that your chain will perform in any condition.

Certified products from trusted brands like Powerful Machinery give you peace of mind, knowing your equipment meets the highest standards for reliability and safety.

Key Takeaways

Choose the right anchor chain type based on your vessel and anchoring conditions. Options include proof coil, BBB, high-test, and stainless steel chains.

Select a chain grade that matches your vessel’s requirements. Higher grades offer better strength and safety margins for demanding conditions.

Regularly inspect and maintain your anchor chain to prevent corrosion and ensure reliability. Clean it after use and store it properly.

Consider customization options for your anchor chain. Tailored lengths and link sizes can improve compatibility with your windlass and enhance safety.

Types of Anchor Chain

Choosing the right anchor chain is essential for safe and reliable anchoring. You will find several types of anchor chains available, each designed for specific marine conditions and vessel requirements. Powerful Machinery offers a full range of these chains, ensuring you have the best fit for your needs.

Proof Coil Chains

Proof coil chains use low-carbon steel and serve as a general-purpose option. You often see them on smaller boats or for temporary anchoring. These chains are not suitable for windlass use because of their longer link design and lower strength rating.

If you need a chain for light-duty tasks, proof coil chains provide a cost-effective solution.

Tip: Proof coil chains work well for non-critical applications but do not match the strength of other marine anchor chain types.

Chain Type | Material | Strength Comparison |

|---|---|---|

Proof Coil (G30) | Low Carbon Steel | Lower strength rating |

BBB Chains

BBB chains feature short, uniform links made from low-carbon steel. You will find them popular for small boats and windlass systems. Their compact design allows for smooth operation in windlasses and better storage in chain lockers.

BBB chains also offer higher strength than proof coil chains, making them suitable for more demanding anchoring situations.

Application Type | Description |

|---|---|

Anchoring for Small Boats | Provides safety and security in various marine conditions. |

Heavy-Duty Anchor Use | Handles extreme loads with a 100% chain rode. |

Commercial Shipping | Ideal for commercial ships and offshore applications due to high tensile strength. |

High-Test Chains

High-test chains, such as Grade 43, use high carbon steel and deliver twice the working load of proof coil or BBB chains of the same size. You benefit from increased strength without added weight, which allows you to store more chain in your locker.

Most modern windlass systems use high-test chains because of their superior performance and reliability.

High-test chains handle double the load of proof coil chains.

They are now the standard for many marine anchor chain applications.

Stainless Steel Chains

Stainless steel chains offer excellent corrosion resistance, making them ideal for harsh saltwater environments. You will appreciate their ease of cleaning and long-lasting shine.

Stainless steel chains resist rust better than galvanized chains, though they may fail suddenly without visible warning. For premium performance and aesthetics, stainless steel chains are a top choice.

Property | Stainless Steel Chains | Galvanized Chains |

|---|---|---|

Corrosion Resistance | High | Moderate |

Cleaning Ease | Easy | N/A |

Visual Wear | May fail suddenly | Shows deformation over time |

Stud Link and Studless Chains

Stud link chains include a bar (stud) across the center of each link, which increases strength and reduces deformation. You often see these chains on larger vessels and commercial ships.

Studless chains, on the other hand, offer greater flexibility and weight savings, making them easier to handle and ideal for smaller boats or where weight is a concern.

Chain Type | Strength | Flexibility | Weight Savings | Handling Ease |

|---|---|---|---|---|

Stud-Link | High | Moderate | Low | Moderate |

Studless | Moderate | High | High | High |

Note: Powerful Machinery supplies all major types of anchor chain, including stud link, studless, proof coil, BBB, and high-test chains, ensuring you find the right solution for your vessel.

Anchor Chain Selection for Sailors

Selecting the right anchor chain is a critical decision for every sailor. You must consider vessel size, anchoring conditions, and equipment compatibility.

Powerful Machinery offers certified anchor chains that meet international standards, giving you confidence in your choice. This section will guide you through the key factors for anchor chain selection for sailors.

Grade and Strength

You need to match the grade of anchor chain to your vessel’s requirements and anchoring environment. Grades of anchor chain determine the strength-to-weight ratio and working load limit. Choosing the correct grade ensures safety and optimal performance.

Chain Grade | Strength-to-Weight Ratio | Typical WLL (% of Breaking Strength) | Best For |

|---|---|---|---|

Proof Coil (G30) | Standard | ~25% | General-purpose use on smaller boats; budget-conscious users |

BBB (G30) | Standard | ~25% | Recreational boats with windlass |

High Test (HT/G43) | High | ~33% | Performance boats, cruisers, and weight-sensitive applications |

G70 (Transport) | Very High | ~33% | Industrial transport; rarely needed for anchoring |

Tip: For most recreational sailors, high test chains (HT/G43) offer the best balance of strength and weight. Always check the working load limit and ensure it exceeds the maximum expected load for your vessel.

Material: Galvanized vs Stainless

Material selection impacts durability, maintenance, and cost. You will find two main options: galvanized steel and stainless steel.

Feature | Galvanized Steel | Stainless Steel |

|---|---|---|

Cost | More affordable | More expensive |

Corrosion Resistance | Needs regular maintenance; re-galvanizing | Superior resistance; lasts longer |

Durability | Strong, but needs upkeep | Can be brittle; high-quality required |

Maintenance | Regular washing and re-galvanizing | Less maintenance, but careful selection |

Galvanized chains are cost-effective and widely used. You must perform regular maintenance, especially in saltwater.

Stainless steel chains resist corrosion and require less upkeep. You should select high-quality stainless steel to avoid brittleness.

Note: Powerful Machinery supplies both galvanized and stainless steel anchor chains, ensuring you find the right material for your anchoring needs.

Size and Calibration

Proper sizing and calibration are essential for safe and smooth operation. The chain must match your vessel’s weight and the windlass gypsy.

Calibration ensures the chain fits your windlass and prevents jamming.

International standards like DIN766 and ISO4565 specify link dimensions for compatibility.

Larger vessels require thicker chains to handle greater strain.

Always check that the chain’s link shape and size match your windlass specifications.

Chain Material | Properties | Compatibility Considerations |

|---|---|---|

Galvanized Steel | Common choice, various materials and sizes | Generally compatible with most windlasses |

Stainless Steel | Superior corrosion resistance, more expensive | Must meet ISO standards to avoid compatibility issues |

The shape and calibration of each link are crucial. Mismatched chains can cause jamming or damage to your windlass.

Chain Length

Chain length directly affects anchoring security. You must calculate the correct length based on water depth, weather, and vessel size. Using the right scope (ratio of chain length to water depth) ensures a secure hold.

Total Depth (Water + 5ft Freeboard) | Scope (Calm) | Required Chain (Calm) | Scope (Stormy) | Required Chain (Stormy) |

|---|---|---|---|---|

15 feet | 7:1 | 105 feet | 10:1 | 150 feet |

25 feet | 7:1 | 175 feet | 10:1 | 250 feet |

35 feet | 7:1 | 245 feet | 10:1 | 350 feet |

50 feet | 7:1 | 350 feet | 10:1 | 500 feet |

In calm weather, use a 7:1 scope. In stormy conditions, increase to 10:1.

Strong winds and currents require longer chains for a lower pull angle.

Always plan for the highest expected tide to avoid running short.

Tip: Insufficient chain reduces holding power and increases the risk of dragging. Excessive chain can be difficult to manage, especially in shallow water.

When you follow these guidelines for anchor chain selection for sailors, you ensure safety, reliability, and peace of mind. Powerful Machinery’s certified anchor chains provide the quality and compatibility you need for every voyage.

Anchor Chain Features and Specifications

Corrosion Resistance

You need an anchor chain that stands up to harsh marine environments. Powerful Machinery uses high-grade steel and advanced coatings to protect your chain from rust and abrasion. Galvanized coatings provide a soft zinc layer that shields the steel underneath.

This zinc layer, combined with zinc/iron alloy coatings, increases durability against saltwater and UV exposure. After shot blasting, marine-grade coatings or galvanization further extend the life of your anchor chain. You can trust these protective layers to keep your equipment reliable, even in demanding conditions.

Regular rinsing and inspection help maintain corrosion resistance and ensure long-term performance.

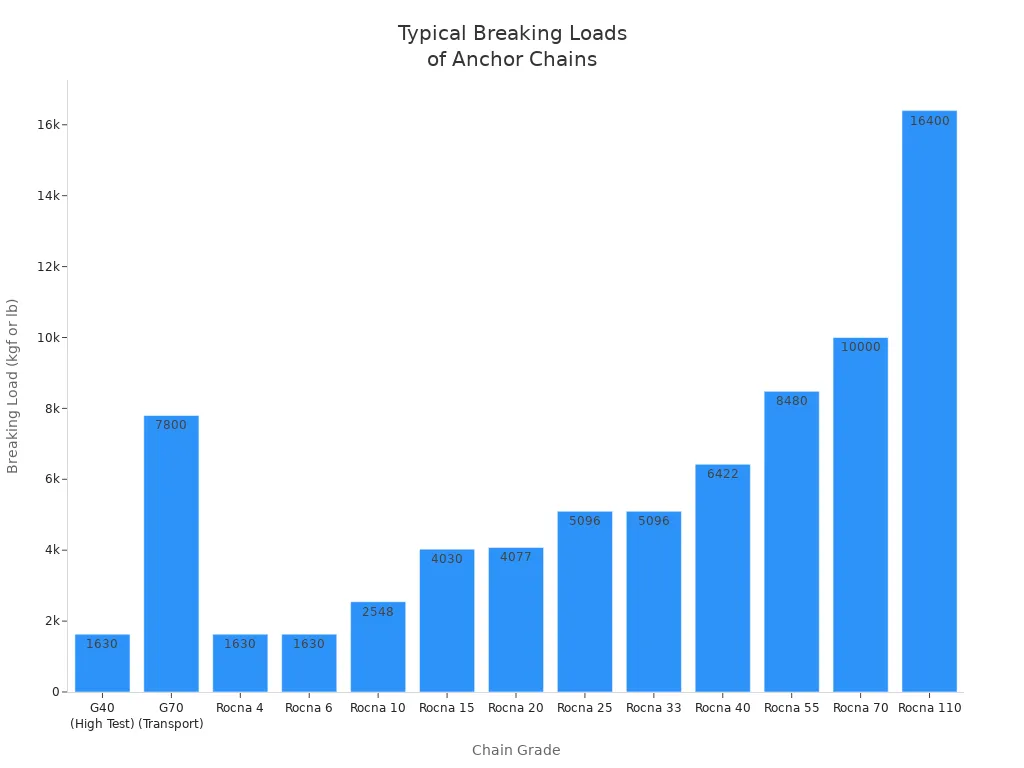

Breaking Load and Durability

You want an anchor chain that delivers strength and reliability. Powerful Machinery designs each chain to meet strict standards for breaking load and durability. The working load limit tells you the maximum safe load for your chain. Always choose a chain with a working load limit that matches or exceeds your vessel’s needs.

Chain Grade | Typical Working Load Limit (WLL) | Typical Breaking Load |

|---|---|---|

G40 (High Test) | 400 kgf | 1630 kgf |

G70 (Transport) | 2600 lb | 7800 lb |

Rocna 4 | 400 kgf | 1630 kgf |

Rocna 6 | 400 kgf | 1630 kgf |

Rocna 10 | 630 kgf | 2548 kgf |

Rocna 15 | 800 kgf | 4030 kgf |

Rocna 20 | 1000 kgf | 4077 kgf |

Rocna 25 | 1250 kgf | 5096 kgf |

Rocna 33 | 1250 kgf | 5096 kgf |

Rocna 40 | 1600 kgf | 6422 kgf |

Rocna 55 | 2120 kgf | 8480 kgf |

Rocna 70 | 2500 kgf | 10000 kgf |

Rocna 110 | 4100 kgf | 16400 kgf |

You can see that higher-grade chains offer greater strength and safety margins. This durability ensures your anchor chain performs under heavy loads and tough conditions.

Customization Options

Powerful Machinery gives you flexibility with strong customization capabilities. You can request non-standard link dimensions or special surface treatments to fit your vessel’s unique requirements. Many clients return for repeat orders, showing high satisfaction with these tailored solutions.

Custom link sizes for special windlass or anchor setups

Special coatings for extra corrosion resistance

Personalized chain lengths for different vessel types

You can rely on Powerful Machinery to deliver anchor chain solutions that match your exact needs.

Manufacturer Reputation and Certification

Powerful Machinery Brand

You want to trust your anchor chain supplier. Powerful Machinery stands out as a global leader in the marine industry. The company has built a reputation for reliability, on-time delivery, and customer satisfaction. Many clients choose Powerful Machinery for their high reorder rate and consistent performance.

You can see how Powerful Machinery compares to other leading manufacturers in the table below:

Metric | Qingdao Powerful Machinery | Other Leading Manufacturers |

|---|---|---|

Reorder Rate | 31% | Moderate (20%+) |

On-Time Delivery | 100% | Varies |

Revenue Volume | $650K+ | Varies |

Powerful Machinery’s commitment to excellence ensures you receive a high quality chain for every application.

International Standards

You need anchor chains that meet strict international standards. Powerful Machinery manufactures products that comply with recognized global benchmarks. These standards guarantee safety and performance for your vessel.

ISO 20438:2017 – Ships and Marine Technology-Offshore Mooring Chains

Chains that meet these standards give you confidence in demanding marine environments.

Quality Assurance

You rely on rigorous quality assurance to keep your vessel safe. Powerful Machinery uses advanced testing and inspection methods throughout the production process.

Quality foundries apply stringent testing to ensure material properties.

Assessments include cyclic loading and resistance to corrosion.

Rigorous source inspection involves batch sampling, UT volumetric examination, and visual checks.

Advanced metallographic testing evaluates grain size and phase composition for durability.

These steps help identify defects and confirm that every chain meets high standards. You can trust that each anchor chain will perform reliably, even in harsh marine conditions.

Anchor Chain Maintenance

Proper anchor chain maintenance keeps your vessel secure and extends the life of your equipment. You should follow a regular schedule for inspection, cleaning, and safe handling to prevent unexpected failures and ensure reliable performance.

Inspection Tips

You need to inspect your anchor chain regularly to catch early signs of wear or damage. Powerful Machinery recommends the following routine:

Perform daily quick checks during deck operations. Look for obvious damage or abnormalities.

Conduct monthly inspections of visible chain segments. Focus on signs of wear, rust, or deformation.

Complete a thorough annual survey. Pull the entire chain on deck and use non-destructive testing methods to check for hidden issues.

Tip: Pay special attention to the D-shackle, taper pin, and windlass brake. These areas often show the first signs of technical problems.

Cleaning and Storage

Cleaning and storing your anchor chain properly helps prevent corrosion and keeps it ready for use. After each use, especially in saltwater, rinse the chain thoroughly with fresh water. Make sure to clean all links, including hard-to-reach areas.

Apply a marine-grade lubricant or corrosion inhibitor after cleaning.

Store the anchor chain in a dry, well-ventilated area.

Use moisture absorbers like silica gel to keep the environment dry.

Coil and secure the chain to prevent tangling and allow air circulation.

Regular cleaning and proper storage are essential parts of anchor chain maintenance.

Safety Practices

You must follow safety practices when handling and maintaining your anchor chain. Always inspect the rode, windlass, and all connecting hardware for wear or damage. Grease and reassemble detachable links to prevent rust and ensure smooth operation.

Clean the entire rode, anchor, and chain with mild soap and water.

Check for bent or damaged parts and replace them if needed.

Monitor your vessel while at anchor and ensure enough room for swinging.

Remember, anchor chain maintenance not only protects your equipment but also ensures the safety of everyone on board.

Conclusion

You ensure safety on your vessel by following a clear process for anchor chain selection and care. Regularly inspect for corrosion, bent links, and worn contact points. Clean and re-galvanize as needed. Use this checklist for best results:

Measure chain diameter and link dimensions.

Confirm compatibility with your windlass.

Choose the right grade for your vessel.

Replace damaged components promptly.

Certified anchor chains from trusted brands like Powerful Machinery undergo rigorous testing, giving you confidence in every voyage.

Maintenance Task | Monthly | Seasonally | Annually | As Needed |

|---|---|---|---|---|

Visual chain inspection | X | |||

Rinse the chain with fresh water | X | |||

Inspect the anchor for damage | X | |||

Replace worn components | X |

FAQ

What material should you choose for your anchor chain?

You should select high-grade steel for strength and durability. Galvanized steel resists corrosion and fits most budgets. Stainless steel offers superior corrosion resistance and a polished look for premium vessels.

How often should you inspect your anchor chain?

You need to inspect your anchor chain before every voyage. Monthly checks help you spot wear or rust early. Annual inspections ensure long-term safety and performance.

Can you customize anchor chain length and size?

Yes, Powerful Machinery lets you customize chain length, link size, and coatings. You can request specifications that match your vessel and anchoring needs.

Tip: Custom chains improve compatibility and safety for unique setups.

How do you maintain your anchor chain?

You should rinse your chain with fresh water after each use. Store it in a dry, ventilated area. Apply marine-grade lubricant to prevent rust and extend service life.