If you wonder what angle is not recommended for eyebolts, always avoid using them at angles below 45°. You must keep loads as close to vertical or in line as possible to prevent dangerous stress.

Industry safety reports show that improperly installed lifting devices, including those set at wrong angles, cause about 25% of lifting accidents. The most common causes of eyebolt failures include:

Improper installations

Overload

Damaged synthetic slings

Stretched or bent links

Powerful Machinery provides only certified products to help you achieve safe, reliable lifting every time.

Key Takeaways

Always use eyebolts for vertical lifts at a 0° angle to ensure maximum safety and capacity.

Avoid using eyebolts at angles below 45°; doing so can reduce their load capacity by over 70%.

Inspect eyebolts before each use for damage or wear to prevent accidents and ensure safe lifting.

Only use shoulder eyebolts for angular lifts, and never exceed a 45° angle to maintain safety standards.

Follow manufacturer guidelines and industry standards to protect your team and equipment during lifting operations.

What Angle is Not Recommended for Eyebolts?

Vertical vs Angular Loading

When you use eyebolts for lifting, the direction of the load makes a critical difference. Vertical loading means you pull straight up, in line with the axis of the eyebolt. This is the safest and most effective way to use any lifting hardware.

Angular loading happens when you pull at an angle, not straight up. This introduces extra stress and can quickly reduce the strength of the eyebolt.

You should always check the type of load you apply. The table below shows how vertical and angular loads affect performance and safety:

Load Type | Description | Impact on Performance and Safety |

|---|---|---|

Tensile Loads | Forces applied along the axis of the bolt, pulling straight away. | Designed to handle these loads safely when lifting vertically. |

Angular Loads | Loads are applied at an angle, combining tensile and bending forces. | Must resist angular stresses; misalignment can lead to reduced capacity and increased risk. |

Load Angle Effect | As the load angle increases, the effective load decreases due to bending stress. | Beyond 45°, capacity can drop significantly, necessitating larger bolts or alternative hardware. |

You can see that vertical lifts keep the eyebolt strong and safe. Angular lifts, especially those below 45°, create bending forces that can cause the eyebolt to fail.

Why Angles Below 45° Are Unsafe?

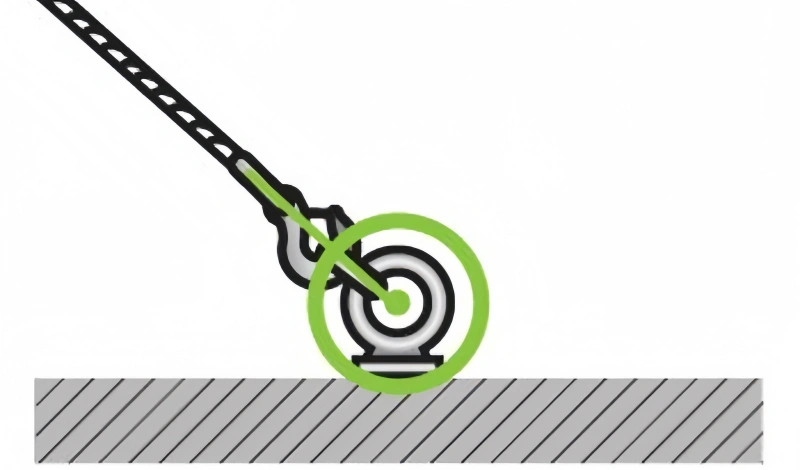

You may wonder what angle is not recommended for eyebolts. Industry standards and Powerful Machinery’s product guidelines both state that you should never use eyebolts at angles below 45°. This rule exists because the working load limit drops sharply as the angle increases.

The table below, based on international safety standards like ASME B30.26 and EN 1677, shows how much the load capacity decreases as the angle moves away from vertical:

Angle to Vertical | Reduction Factor |

|---|---|

Up to 15º | 0.63 |

Up to 30º | 0.4 |

Up to 45º | 0.25 |

If you use an eyebolt at a 45-degree angle, you only get about 25% of its rated capacity. At angles below 45°, the risk of failure becomes extreme. Safety organizations warn that angular pulls will significantly lower working load limits and should be avoided. The following points highlight the dangers:

The load capacity of an eyebolt decreases significantly when the loading angle is not vertical.

At a 45-degree angle, the capacity can drop by over 70%.

Eyebolts are designed for vertical lifting, and any angle introduces side loading, which can lead to failure.

Manufacturers like Powerful Machinery provide clear guidelines for safe use. The table below summarizes the working load limits for different angles:

Angle from Vertical | Shoulder Eye Bolts WLL | Screw Eye Bolts WLL |

|---|---|---|

0° | 100% | 100% |

15° | 80% | NOT PERMITTED |

30° | 50% | NOT PERMITTED |

45° | 30% | NOT PERMITTED |

Beyond 45° | NOT PERMITTED | NOT PERMITTED |

Tip: Always calculate the angle of your lift before starting. If you cannot keep the load vertical, consider using alternative lifting hardware designed for angular pulls.

Powerful Machinery’s stainless steel eye bolts and eye nuts are engineered for safe, vertical lifting. These products meet international standards and provide full rated capacity when used in-line.

If you ask what angle is not recommended for eyebolts, remember that anything below 45° puts your operation at risk. Always follow manufacturer guidelines and industry standards to protect your team and your equipment.

Risks of Improper Eyebolt Angles

Reduced Strength and Failure

When you use eyebolts at improper angles, you put your equipment and team at risk. Eyebolts are designed to handle straight-line, vertical loads. If you pull at an angle, the force splits into vertical and horizontal components. The horizontal force tries to bend or shear the eyebolt, which can lead to sudden failure.

Eyebolts are designed for vertical lifting. As soon as you pull at an angle, the load rating drops fast, often by more than people expect. At 45°, the force splits into vertical and horizontal components, with the horizontal force trying to bend or shear the eyebolt.

You may see several types of mechanical failures when you ignore what angle is not recommended for eyebolts:

Bending of the eyebolt

Threads pulling out of the material

Breaking of the eyebolt due to excessive tension

For example, on a construction site, workers lifted a heavy steel beam using an eyebolt at a 60° angle. The eyebolt broke because of the increased tension, causing the load to drop and resulting in a serious injury. This incident shows the real dangers of using eyebolts at unsafe angles.

Safety Hazards in Lifting Operations

Improper eyebolt angles do not just damage equipment—they create serious safety hazards. You must align the bolt’s eye with the load. If you apply the load at an angle, you increase the chance of bending or breaking the bolt. The working load limit (WLL) is calculated for straight-line pulls.

Any angle reduces this limit and raises the risk of accidents.

Consider these hazards:

Dropped loads can injure workers or damage property.

Equipment failure can halt operations and cause costly delays.

Misaligned lifts can lead to unpredictable load movement.

You protect your team and your investment when you follow proper lifting practices. Always remember what angle is not recommended for eyebolts, and keep your lifts as close to vertical as possible.

Best Practices for Eyebolt Use

Recommended Lifting Angles

You must always use eyebolts in line with the load. The safest approach is a vertical lift, which means a 0° angle. This position allows you to use 100% of the rated Working Load Limit (WLL). If you need to lift at an angle, only use shoulder eyebolts and never exceed a 45° angle.

Lifting at angles greater than 45° is not permitted and puts your operation at risk.

Use vertical (0°) lifts whenever possible.

Only use shoulder eyebolts for angular lifts, and never go beyond 45°.

Avoid angular lifts with plain eyebolts.

Remember, angular lifts reduce the rated capacity of the eyebolt.

For lifts requiring angles, consider specialized hardware like safety swivel hoist rings.

Tip: Always plan your lift to keep the angle as close to vertical as possible. This practice protects both your equipment and your team.

Installation and Inspection Tips

Proper installation and regular inspection keep your lifting operations safe. Follow these steps to avoid common errors:

Check alignment. Make sure the eyebolt seats fully and aligns with the load direction.

Use washers on softer materials to prevent pull-through.

Tighten the eyebolt firmly, but do not over-tighten.

Thread the eyebolt by hand first to avoid cross-threading.

Inspect before each use. Look for bent or elongated eyes, worn threads, nicks, or corrosion.

Remove any eyebolt that shows signs of damage or lacks clear identification.

Never use eyebolts with visible wear or damage.

Ensure threads and receiving holes are clean.

Do not use non-shouldered eyebolts for side loading.

Powerful Machinery Product Advantages

Powerful Machinery’s stainless steel eye bolts and eye nuts deliver unmatched safety and reliability. These products meet or exceed international standards, including ISO9001, TUV Rheinland, OSHA, and ASTM. You benefit from:

Advantage | Description |

|---|---|

Higher Tensile Strength | Handles heavy-duty applications with confidence. |

Corrosion Resistance | Performs in marine and chemical environments without rust. |

Durability | Maintains integrity under stress and harsh weather. |

Low Maintenance | Offers a long lifespan with minimal upkeep. |

Certified lifting hardware reduces accidents, increases efficiency, and ensures your team works with confidence. Choose Powerful Machinery for products that set the standard in safety and performance.

Eyebolt Angle Myths and Misconceptions

Common Misunderstandings

You may hear many myths about eyebolt angles in lifting operations. Some people believe that any eyebolt can handle side loads or that the rated capacity remains unchanged at any angle. These ideas can put your team and equipment at risk. Eyebolts are not designed for side loading.

If you use them at angles below 45°, you expose the hardware to forces it cannot safely withstand.

A common misunderstanding is that shoulder eye bolts can always handle angular loads. In reality, only shoulder eye bolts can support angled lifts, and even then, you must never exceed a 45° angle. Plain eye bolts should only be used for vertical lifts.

Another myth is that increasing the size of the eyebolt will compensate for unsafe angles. This approach does not address the real issue. The angle of the load directly affects the working load limit, regardless of the eyebolt’s size.

Note: Believing that all eyebolts are suitable for any lifting angle can lead to dangerous mistakes. Always check the product specifications and guidelines before starting any lift.

Clarifying Manufacturer Guidelines

You must rely on manufacturer guidelines when selecting and installing eyebolts. Major manufacturers, including Powerful Machinery, provide clear instructions for safe use. Their guidance takes priority over general industry standards.

If a manufacturer states that their eyebolt cannot be used at a specific angle, you must follow that advice. Ignoring these instructions and relying only on standards like ASME can result in liability if an accident occurs.

Manufacturers emphasize their guidance over general standards.

Always verify the working load limits with the manufacturer before each use.

If the manufacturer restricts use at certain angles, do not attempt to use the eyebolt outside those limits.

Manufacturers design and test their products for specific applications. You protect your team and your operation when you follow these guidelines. Powerful Machinery’s certified stainless steel eye bolts and eye nuts come with detailed instructions to help you achieve safe, reliable lifts every time.

Conclusion

You must always use eyebolts for vertical or in-line pulls and avoid any angle below 45°. Industry safety reports show that using eyebolts at improper angles can reduce their capacity by up to 70%, especially with non-shouldered types.

Powerful Machinery remains committed to your safety by providing certified, reliable lifting solutions. To reduce risk, always:

Follow the manufacturer’s working load limits

Inspect hardware before each use

Train your team on proper installation and inspection

Choose certified products and best practices for every lifting operation.

FAQ

What is the safest angle for lifting with eyebolts?

You achieve maximum safety when you lift vertically, at a 0° angle. This position allows you to use the full rated capacity of the eyebolt. Always keep the load in line with the bolt’s axis.

Can you use plain eyebolts for angular lifts?

No. You should only use plain eyebolts for vertical lifts. Angular lifts with plain eyebolts can cause bending or failure. Always choose shoulder eyebolts for any lift that requires an angle.

How do you check if an eyebolt is safe to use?

Inspect the eyebolt for visible damage, corrosion, or worn threads. Make sure the identification markings are clear. Remove any hardware that shows signs of wear or does not meet manufacturer guidelines.

Do Powerful Machinery eye bolts meet international safety standards?

Yes. Powerful Machinery’s stainless steel eye bolts and eye nuts comply with major international standards, including ISO9001, TUV Rheinland, and OSHA. You can trust their certified products for reliable lifting operations.

What should you do if you must lift at an angle?

Use only shoulder eyebolts.

Never exceed a 45° angle.

Reduce the working load limit according to manufacturer instructions.

Consider using specialized lifting hardware for extreme angles.