All chain hoists use the principle of mechanical advantage, achieved through gears and high-strength chains, to lift heavy loads with minimal effort. You rely on essential components like the load chain, gear train, brake system, and hook for safe and reliable lifting.

Powerful Machinery stands out as a trusted provider of certified solutions for demanding industries, ensuring you receive equipment built for strength and safety.

Key Takeaways

Chain hoists use mechanical advantage to lift heavy loads with less effort. This principle allows you to lift much heavier weights than you can pull.

The gear and chain system is crucial for effective lifting. It multiplies your input force, ensuring smooth and safe operation.

Choose the right chain hoist based on your load capacity needs. Always select a hoist with a capacity above your heaviest load for safety.

Regular maintenance and inspections are vital. Conduct daily checks and schedule professional servicing to extend the life of your hoist.

Understand the differences between manual and electric hoists. Manual hoists are ideal for occasional use, while electric hoists excel in speed and efficiency for frequent lifting tasks.

Mechanical Advantage in Chain Hoists

How Chain Hoists Multiply Force?

You rely on the mechanical advantage principle every time you operate a chain hoist. This principle allows you to lift loads that far exceed the force you apply. When you pull the hand chain, the gear system inside the hoist multiplies your input, making it possible to raise heavy objects with minimal effort.

Mechanical advantage is the ratio of output force to input force.

Chain hoists achieve this through a combination of load chain, hand chain gears, sprockets, and pulleys.

Gear reduction systems further increase the lifting power.

For example, a 5:1 mechanical advantage means you can lift a 500 kg load with only 100 kg of effort.

Powerful Machinery designs each chain hoist to maximize this force multiplication. You benefit from certified engineering that ensures consistent performance, whether you work in construction, manufacturing, or logistics.

Gear and Chain System Explained

The gear and chain system forms the core of every chain hoist. When you pull the hand chain, gears inside the hoist rotate and engage the load chain. This process multiplies your input force, allowing you to lift heavy loads smoothly and safely.

The gear train in Powerful Machinery’s chain hoists uses high-strength alloy steel for durability and precision. You experience reliable lifting action, even in demanding environments.

The load chain moves over sprockets, which distribute the force evenly. This design reduces wear and increases the lifespan of the hoist. You can trust the gear and chain system to deliver consistent results, whether you use manual or electric models.

Type of Hoist | Mechanism of Force Multiplication | Efficiency and Speed Differences |

|---|---|---|

Manual Chain Hoist | Utilizes human power and a system of gears to create a lifting force through mechanical advantage. | Slower lifting speed, dependent on operator effort. |

Electric Chain Hoist | Uses an electric motor to automate the lifting process, providing faster operation. | Higher efficiency and speed due to automation. |

Lifting Loads with Minimal Effort

You can lift heavy loads with minimal effort because the chain hoist does most of the work for you. Manual hoists require you to pull the hand chain, but the gear system multiplies your force. Electric hoists automate the process, reducing the need for manual labor and increasing speed.

Manual chain hoists rely on your physical effort, but the gear system makes lifting manageable.

Electric chain hoists use a motor to provide a consistent and powerful lifting force.

Both types can handle substantial weights, with manual models lifting to 20 tons and electric models managing even heavier loads.

Powerful Machinery’s certified chain hoists demonstrate reliability and efficiency in real-world applications:

Automated manufacturing lines use these hoists for precise lifting and positioning, improving production speed.

Construction sites depend on them for moving steel beams and equipment, enhancing safety and workflow.

Maintenance operations benefit from motorized hoists that reduce downtime and improve safety.

Warehousing and logistics teams use chain hoists to handle bulky goods, minimizing manual lifting injuries.

Heavy equipment assembly relies on chain hoists for the accurate positioning of large components.

You gain confidence knowing that Powerful Machinery’s chain hoists meet international safety standards and deliver dependable performance in every application.

Key Components of a Chain Hoist

Load Chain Material and Grades

You depend on the load chain for strength and safety during every lift. The material and grade of the chain directly affect the lifting capacity and durability of your chain hoist. Powerful Machinery uses high-tensile alloy steel chains, which meet strict international standards.

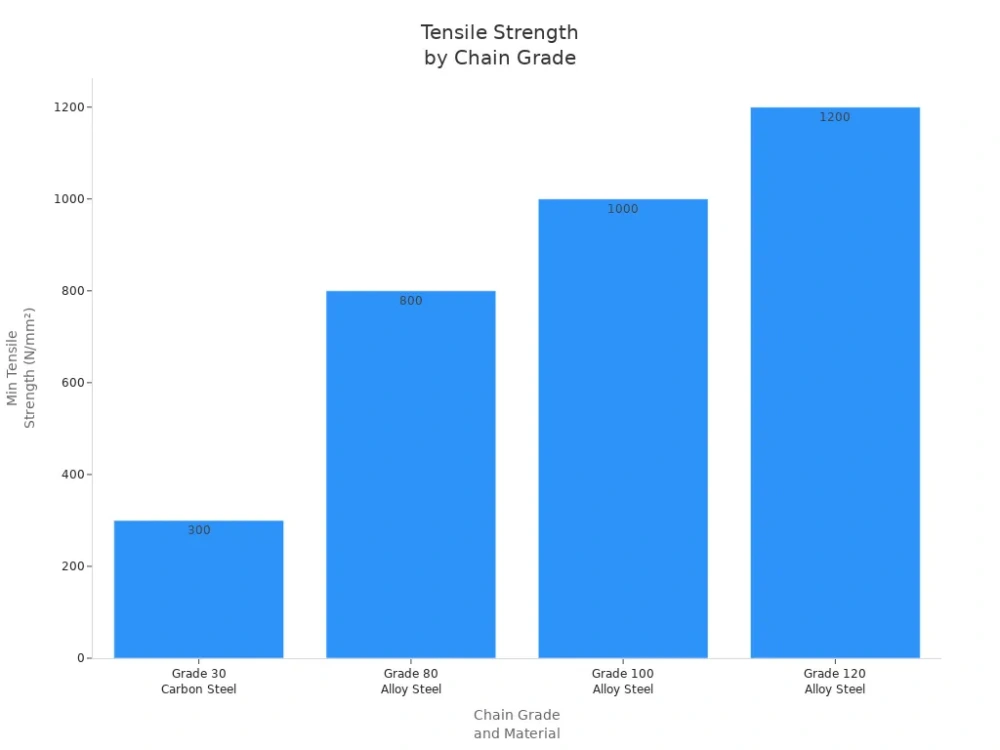

The table below shows how different grades impact performance:

Chain Grade | Material Type | Minimum Tensile Strength (N/mm²) | Lifting Capacity Impact |

|---|---|---|---|

Grade 30 | Carbon Steel | 300 | Suitable for hand chains but not for overhead lifting in harsh environments. |

Grade 80 | Alloy Steel | 800 | Widely used for overhead lifting; resilient to extreme heat. |

Grade 100 | Alloy Steel | 1000 | 25% higher strength-to-weight ratio than Grade 80, suitable for heavy-duty tasks. |

Grade 120 | Alloy Steel | 1200 | Superior strength-to-weight ratio but higher production costs; less commonly used. |

Stainless Steel | Stainless Steel | Varies | Excellent wear and corrosion resistance, ideal for harsh environments. |

Gear Train and Force Multiplication

The gear train is the heart of your chain hoist. It multiplies your input force, making heavy lifting possible.

The gear train is arguably the most critical system within any chain hoist. It is the engine of force multiplication, the component that directly provides the mechanical advantage needed for lifting.

Without the gear train, an operator would have to pull with a force equal to the load’s weight, which defeats the purpose of the hoist. Its design and construction are central to the hoist’s capacity, smoothness of operation, and longevity.

Powerful Machinery designs gear trains with multiple stages, compounding the force multiplication. You get smooth operation and long service life.

Brake System for Safe Load Retention

You trust the brake system to hold loads securely. Powerful Machinery equips each chain hoist with a self-setting brake that engages automatically. The brake system meets strict safety requirements:

Requirement | Specification |

|---|---|

Self-setting brake | Engages directly on the motor shaft or gear train |

Holding brake torque | Provides at least 125% of full load hoisting torque |

Automatic application | Activates when power is removed |

Wear adjustment | Allows for compensation as brake surfaces wear |

Smooth surfaces | Ensures reliable contact and minimal wear |

These features ensure your load stays in place, even during power loss or emergencies.

Hooks and Suspension Features

Hooks and suspension points connect your load to the hoist. Powerful Machinery uses forged steel hooks with safety latches. You benefit from products certified to CE and ISO9001:2000 standards, which guarantee reliability in critical industries.

Forged steel construction for strength

Safety latches to prevent accidental release

Certified to international standards

Protective Casing and Durability

You need a chain hoist that withstands harsh environments. Powerful Machinery uses heat-treated load plates and case-hardened internal parts. The protective casing offers IP65 protection, making the hoist dustproof and resistant to water jets.

Compact, robust design for outdoor and dusty sites

Safety factor of at least 8 for the load chain, reducing wear and extending service life

You can rely on these key components to deliver safe, efficient lifting in any environment.

Manual vs Electric Chain Hoist Types

Manual Chain Hoist Operation

You operate a manual chain hoist by pulling the hand chain, which turns the gears and lifts the load. This type of hoist does not require electricity, making it ideal for locations without power access. You benefit from its simplicity and reliability.

Manual chain hoists from Powerful Machinery feature robust construction and precise control, allowing you to position heavy loads safely. You often use a manual chain hoist in workshops, maintenance areas, or construction sites where you need to lift or pull loads occasionally.

You control the lifting speed and movement directly.

Manual chain hoists work well for lighter tasks and infrequent use.

You can use them in remote or outdoor environments.

Electric Chain Hoist Features

An electric chain hoist uses a motor to lift and lower loads quickly and smoothly. You operate it with minimal physical effort, often using a remote control or pendant. Powerful Machinery’s electric chain hoist models offer advanced safety features, including automatic brakes and overload protection.

You gain precise control over lifting, which reduces the risk of accidents and physical strain.

Electric chain hoists lift heavy loads at a much faster rate than manual chain hoists.

You experience enhanced efficiency and productivity, especially in busy or high-volume environments.

These hoists often include variable speed controls for safe and accurate positioning.

Tip: Electric chain hoists reduce operator fatigue and improve workplace safety by minimizing manual effort.

Comparing Input Methods and Applications

You choose between manual and electric chain hoists based on your work environment and how often you need to lift loads. The table below highlights the main differences:

Type of Hoist | Common Applications | Advantages |

|---|---|---|

Manual Chain Hoist | Workshops, maintenance, construction sites, areas without electricity | Simple, reliable, easy to use, precise control, no power needed |

Electric Chain Hoist | Factories, warehouses, production lines, repetitive lifting tasks | Fast, efficient, high lifting capacity, reduces strain, and advanced safety features |

You select an electric chain hoist for frequent or continuous lifting tasks, as it handles repetitive work efficiently.

Manual chain hoists suit occasional lifting or environments where speed is not critical.

Electric chain hoists outperform manual chain hoists in speed, load capacity, and safety, making them the preferred choice for demanding industrial applications.

Choosing Chain Hoist Load Capacity and Safety

Determining Load Capacity Needs

You must select a chain hoist with the right load capacity for your lifting tasks. Start by calculating the maximum weight of the loads you plan to lift. Always choose a hoist with a capacity slightly above your heaviest loads to ensure safe operation and prevent equipment strain.

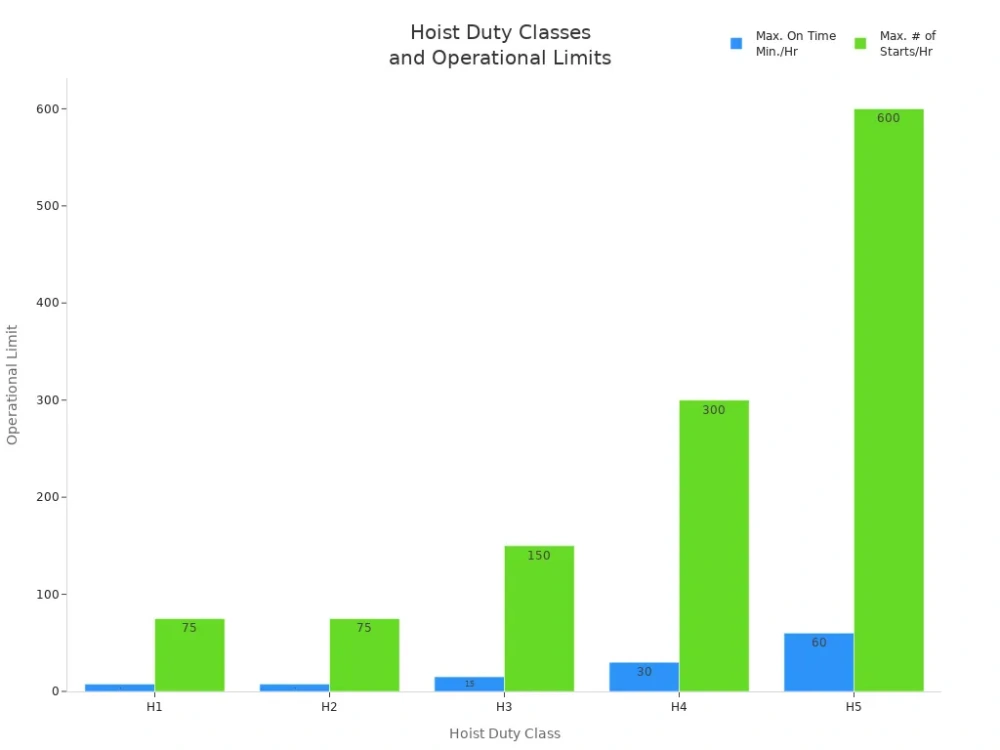

Consider the duty class of your application, as this affects how often and how long you will lift loads. The table below helps you match your needs to the correct hoist duty:

Hoist Duty | Applications | Max. On Time Min./Hr | Max. # of Starts/Hr |

|---|---|---|---|

H1 | Infrequent handling, loads frequently approach capacity | 7.5 min. (12.5%) | 75 |

H2 | Randomly distributed loads, infrequently rated loads | 7.5 min. (12.5%) | 75 |

H3 | Randomly distributed loads and utilization | 15 min. (25%) | 150 |

H4 | High volume handling, loads near rated capacity | 30 min. (50%) | 300 |

H5 | Cab operated, frequent heavy loads | 60 min. (100%) | 600 |

Selection Criteria for Chain Hoists

When choosing a chain hoist from Powerful Machinery, follow these steps for high-efficiency lifting:

Calculate the maximum load weight for your lifting tasks.

Measure the required lift height, including any extra clearance.

Assess how often you will lift loads to determine the right duty cycle.

Ensure the hoist meets all relevant safety standards.

Select a hoist with a capacity buffer above your maximum loads to avoid overloading.

Understand headroom requirements, as this affects lift height.

Tip: Always match the hoist’s load capacity and safety features to your specific application for reliable heavy lifting.

Maintenance and Inspection Guidelines

You protect your investment and ensure safe operation by following a strict maintenance schedule. Conduct a regular inspection before each use to check for visible wear or damage. Schedule monthly inspections of the hoist’s framework and controls.

Arrange for a qualified technician to perform a comprehensive inspection at least once a year. In high-usage environments, add extra inspections every six months.

Maintenance Type | Frequency |

|---|---|

Daily Checks | Before each use |

Monthly Inspections | Once a month |

Professional Servicing | At least once a year |

Additional Inspections | Every six months (high usage) |

Note: Regular inspection and proper maintenance extend the life of your hoist and reduce the risk of failure during heavy lifting.

Safe Operation and Common Mistakes

You must follow best practices for safe operation. Never modify the hoist or exceed its load capacity. Avoid twisting the chain or pulling too fast, as these actions can damage internal safety mechanisms. Always inspect your hoist before lifting loads and operate it steadily to prevent the chain from coming off the gear.

Common mistakes to avoid:

Overloading the hoist with heavy loads

Twisting the chain or hoist during operation

Skipping regular inspection and maintenance

Lubricating the brake incorrectly can cause brake failure

Operator training is essential. You should complete accredited courses, understand load calculations, use personal protective equipment, and know emergency procedures. Powerful Machinery provides chain hoists with advanced safety features, ensuring you can handle all lifting tasks with confidence.

Conclusion

You rely on the mechanical advantage of gears and high-strength chains to lift heavy loads safely and efficiently. Understanding each component and choosing the right chain hoist ensures reliable performance in your operations.

Powerful Machinery delivers certified solutions that prioritize quality, safety, and durability. Regular maintenance and strict safety standards keep your equipment running smoothly and protect your team.

Long-Term Benefit | Description |

|---|---|

Enhanced Safety | Fewer accidents and load failures |

Increased Equipment Lifespan | Less wear, fewer replacements |

Operational Efficiency | Reduced downtime, consistent productivity |

Regulatory Compliance | Meets OSHA, ASME, and ANSI standards |

FAQ

What is the main difference between manual hoists and electric hoists?

You operate manual hoists by hand, using a chain to lift loads. Electric hoists use a motor to lift and lower loads quickly. You choose electric hoists for frequent or heavy-duty lifting. Manual hoists work best for occasional or remote tasks.

How do you ensure the safe operation of hoists?

You inspect hoists before each use. You never exceed the rated load. You keep the load balanced and avoid sudden movements. You follow the manufacturer’s instructions. You schedule regular maintenance for all hoists, including electric hoists, to prevent accidents.

What industries use hoists most often?

You find hoists in construction, manufacturing, warehousing, marine, and transportation. These industries rely on hoists for lifting heavy materials, equipment, and cargo. Electric hoists improve efficiency in busy environments. Hoists support safe and reliable operations across many sectors.

How often should you maintain or inspect hoists?

You check hoists daily for visible damage. You perform monthly inspections for wear and alignment. You schedule professional servicing at least once a year. For electric hoists, you add extra checks for electrical components. Regular maintenance extends the life of your hoists.

Can you use hoists outdoors or in harsh environments?

You can use hoists outdoors if they have protective casings and corrosion-resistant chains. Electric hoists with weatherproof features handle harsh conditions. You always check the manufacturer’s specifications. Hoists from trusted brands offer durability for demanding environments.