A shank hook is a strong, curved metal tool designed to connect and lift heavy loads safely. You often see these hooks in construction, marine, and industrial settings.

Many people ask what is shank hook is because it plays a vital role in both fishing and heavy-duty rigging. Powerful Machinery provides high-quality shank hooks that you can trust for demanding lifting jobs.

Key Takeaways

A shank hook is essential for safely connecting and lifting heavy loads in various industries, including construction and fishing.

Choose the right type of shank hook based on your specific needs, such as short, long, or offset shank designs for optimal performance.

Always inspect shank hooks for wear and damage before use to ensure safety and compliance with industry standards.

Select hooks made from high-quality materials like carbon or alloy steel for durability and strength in demanding environments.

Utilize shank hooks with safety features, such as latches, to prevent accidental load release during lifting operations.

What is Shank Hook?

Definition

You may wonder what is shank hook is and why it matters in different industries. In fishing, a shank hook refers to the straight part of the hook that connects the eyelet to the bend. The length and shape of the shank affect how you present bait and how easily you can remove the hook from a fish.

In industrial and lifting applications, a shank hook is a forged metal hook with a straight or slightly curved shank. You use it to attach chains, slings, or ropes for lifting heavy loads.

The table below shows the main types of shank hooks and their uses in fishing:

Type of Shank Hook | Description |

|---|---|

Standard Shank | Hooks with shanks that are half of the wire length from the eyelet to the bend, versatile for all-around fishing applications. |

Long Shank | Hooks with shanks greater than half the wire length, offering a larger surface area to protect against bite-offs and facilitate catch and release. |

Short Shank | Hooks with shanks less than half of the total wire length, popular for creating natural action with live bait and soft plastics. |

In lifting and rigging, when you ask what is shank hook, you refer to a hook designed for secure load handling. These hooks must meet strict safety standards and often include features like safety latches and identification codes.

Structure

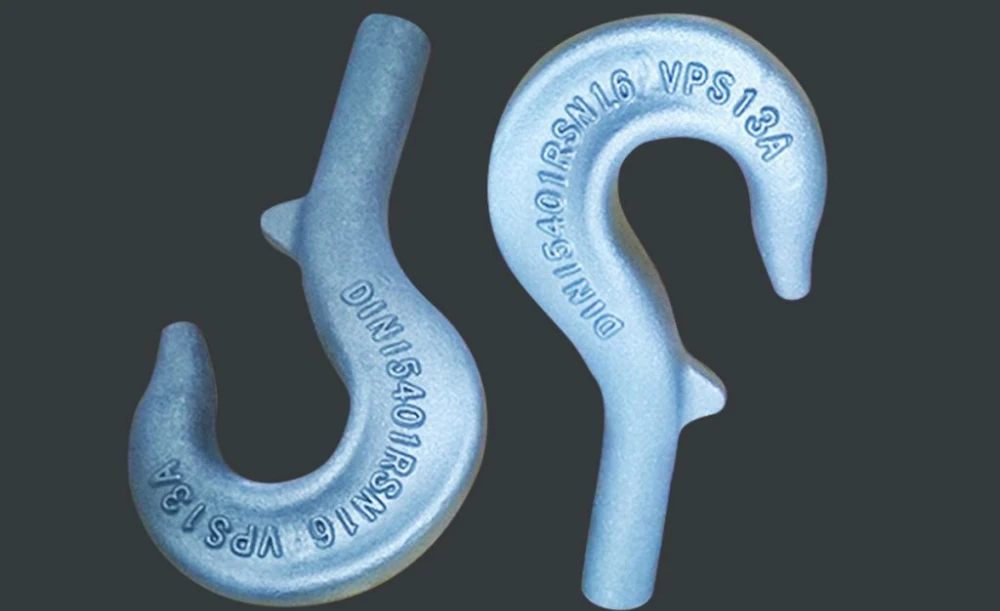

The structure of a shank hook plays a key role in its performance and safety. You will find several important components in a high-quality industrial shank hook, such as the S-319 Forged Shank Hooks from Powerful Machinery. These hooks use high-quality carbon steel or alloy steel for strength and durability.

The shank is the straight section that connects the hook body to the lifting assembly. This design allows you to attach the hook to chains, slings, or mechanical devices with ease.

Here is a table that outlines the main components of Powerful Machinery’s S-319 Forged Shank Hooks:

Component | Description |

|---|---|

Material | Made from high-quality carbon steel for strength and durability. |

Safety Features | Equipped with a safety latch for added protection during lifting operations. |

Customization Options | Offers customization to meet specific user requirements. |

Surface Finishes | Available in hot-dip galvanized, zinc-plated, and painted coatings. |

Manufacturing Origin | Factory-produced in China, ensuring high quality and reliability. |

Hook Identification Code | Forged into each hook for easy identification. |

Strength Features | Quenched and tempered for maximum strength without excessive weight. |

Material Options | Available in carbon steel, alloy steel, and bronze. |

Latch Compatibility | Pre-drilled cam for optional latch assembly, even after purchase. |

Certification | Type Approval and certification in accordance with ABS Steel Vessel Rules. |

You will also notice that the shank hook’s material matters. Most industrial shank hooks use forged alloy steel, carbon steel, or stainless steel. These materials provide the strength and resistance needed for heavy-duty lifting. The table below lists common materials used in manufacturing shank hooks:

Material Type |

|---|

Forged Alloy Steel |

Carbon Steel |

Stainless Steel |

Composites |

When you choose a shank hook, you should look for features like a safety latch, corrosion-resistant finish, and clear identification marks. Powerful Machinery’s S-319 Forged Shank Hooks include all these features, making them reliable for demanding jobs.

If you ever ask what is shank hook is in the context of lifting, remember that it is more than just a simple hook. It is a carefully engineered tool designed for safety, strength, and versatility.

Tip: Always check the certification and material of your shank hook before using it for lifting operations. This ensures you get the best performance and safety for your application.

How Shank Hooks Work?

Function

When you use a shank hook, you rely on its design to keep your lifting operations safe and stable. The shank, which is the straight part of the hook, plays a key role in how the hook performs. Its length and shape help distribute the weight of the load evenly. This design gives you a secure connection to chains or slings.

The shank’s stability is important because it keeps the hook from twisting or bending under heavy loads. You can trust a well-made shank hook to maintain the integrity of your lifting system, even when you handle significant stress and weight.

You might ask what is shank hook is and why it matters for safety. The answer lies in the way the shank supports the entire hook. A strong, straight shank increases the load-bearing capacity. It also helps prevent accidents by reducing the risk of hook failure.

When you choose a shank hook for lifting, you should always check for certifications and safety standards. The ASME B30.10-2019 safety standard requires regular inspections of shank hooks. You need to look for signs of wear or damage before each use.

At least once a year, a qualified person should inspect your hooks more thoroughly. If you find any damage, you must remove the hook from service until an expert approves it for use again. These steps help you keep your worksite safe and compliant.

Note: Always follow inspection guidelines and safety standards to protect yourself and your team during lifting operations.

Mechanics

The mechanics of a shank hook focus on how you attach and release loads safely. When you use a hook like the S-319 Forged Shank Hook from Powerful Machinery, you benefit from several advanced features. The high-tensile steel construction gives the hook strength and durability.

This material resists bending and breaking, even in tough conditions.

A key safety feature is the spring-loaded latch. This latch closes automatically over the throat of the hook when you attach a load. Here’s how it works:

The spring latch snaps shut, covering the hook’s opening.

This action prevents the load from slipping out, even if the chain or sling loses tension.

You can release the latch easily when you need to remove the load, but it stays secure during lifting.

This simple mechanism adds a layer of protection. You do not have to worry about accidental release, which is especially important in busy or hazardous environments.

You also get the benefit of a threaded shank design. This feature lets you attach the hook quickly to chains, slings, or mechanical assemblies. The zinc-plated or painted finish protects the hook from rust and corrosion.

You can use these hooks in marine, construction, or mining settings without worrying about damage from moisture or harsh weather.

When you understand what a shank hook is and how it works, you can see why it is a trusted tool in heavy-duty lifting. The combination of a strong shank, safety latch, and durable materials ensures that you can lift and move loads with confidence.

Tip: Choose shank hooks with certified safety features and inspect them regularly to keep your lifting operations safe and efficient.

Types of Shank Hooks

Understanding the different types of shank hooks helps you choose the right tool for your job. Each type has a unique design and purpose, whether you work in fishing or heavy lifting. Let’s look at the main types and their best uses.

Short Shank

Short shank hooks have a compact design. You often use them when you need extra strength and less risk of bending. In fishing, these hooks work well for hard-fighting fish like grouper or snapper. The short shank reduces leverage, making it harder for strong fish to bend the hook.

You also find short shank hooks useful for small baits and targeting fish with small mouths, such as trout or panfish.

The salmon egg hook is a classic short-shank style. It holds small baits securely and helps you catch a wide range of species.

Long Shank

Long shank hooks feature more distance between the bend and the eye. This extra length makes them ideal for situations where you want to prevent line cuts, especially when fishing for species like mackerel or bluefish.

In lifting applications, a longer shank can make it easier to attach or remove the hook from chains or slings. However, you should know that a longer shank can give large fish more leverage to bend the hook in some cases.

Hook Type | Design Features | Best Use |

|---|---|---|

Long Shank | Extra length between the bend and the eye | Preventing line cuts, easy attachment/removal |

Offset Shank

Offset shank hooks have a unique bend near the eye. This design improves your chances of a successful hook set. Anglers often use offset hooks for Texas-rigging soft plastics, especially in areas with heavy cover. The offset keeps the bait weedless and increases effectiveness.

Offset hooks let you use traditional rigging methods with better results.

The special alignment of the hook point helps you catch more fish.

Specialty Hooks

Specialty shank hooks include many unique designs for specific tasks. For example, nymph and wet fly hooks use heavier wire for sub-surface fishing. Salmon hooks have a thicker shank and come in larger sizes.

Bass and popper hooks feature a wide gap and special shapes for holding bulky baits or popper bodies. Saltwater hooks resist corrosion and handle tough marine conditions.

Hook Type | Unique Features |

|---|---|

Nymph, Wet Fly | Heavier wire, down-turned or straight eyes |

Salmon | Larger size, thick shank, black or nickel color |

Bass, Popper | Wide gap, special humps for body retention |

Saltwater | Corrosion-resistant, strong shank |

Powerful Machinery’s S-319 Forged Shank Hooks offer versatility for many of these applications. You can choose from different sizes and finishes, making them suitable for construction, marine, or industrial use. Their strong, forged design ensures safety and reliability, no matter which type you need.

Tip: Match the shank hook type to your specific task for the best performance and safety.

Choosing the Right Shank Hook

Key Factors

When you select a shank hook, you need to consider several important factors. The type of load, the environment, and safety standards all play a role in your decision. Each factor can affect the performance and safety of your lifting operation.

Environmental conditions can change how a shank hook performs. For example, extreme cold can make steel brittle, while high humidity can cause corrosion. The table below shows how different environments impact shank hooks:

Environmental Condition | Effect on Shank Hooks |

|---|---|

Extreme Cold | Steel becomes brittle, reducing shock resistance and increasing fracture risk. |

Extreme Heat | Strength and hardness decrease, so you must lower the working load limit (WLL). |

High Humidity | Corrosion can start, leading to cracks and weakening the hook over time. |

You also need to follow strict safety standards. These standards help you avoid accidents and keep your team safe. The table below highlights key safety requirements:

Standard or Rule | Description |

|---|---|

OSHA Requirement | Use hooks that meet manufacturer guidelines and have safety latches. |

Safety Hook Definition | A safety hook has a latch to prevent accidental load release. |

Maritime/Construction Rule | Crane hooks must be latched or secured. |

ASME Standard | Use latch-equipped hooks unless not practical. |

If you use the wrong shank hook, you risk serious problems. Loads can slip, fall, or cause injury. Always inspect your hook and never exceed its rated capacity.

Tip: Never use a hook that shows signs of wear, corrosion, or damage. Regular inspections keep your operations safe.

Application Fit

You must match the shank hook to your specific application. The correct hook size and type improve both safety and efficiency. For example, a hook that fits the load’s weight and shape will prevent slippage or detachment. Proper attachment points and rated lifting systems are also crucial.

Powerful Machinery offers a wide range of S-319 Forged Shank Hooks. You can choose from different sizes, finishes, and materials. If you have unique needs, you can request custom dimensions or coatings.

Every hook comes with certifications that meet international standards, so you know you are using a safe and reliable product.

The right shank hook boosts operational efficiency.

You reduce the risk of accidents and equipment failure.

Certified hooks help you meet legal and industry requirements.

Note: Always choose a shank hook that matches your load and environment. Custom options from Powerful Machinery ensure you get the best fit for your job.

You now understand that shank hooks play a vital role in lifting and rigging. Their robust design, high load capacity, and versatility make them essential for many industries:

Feature/Application | Description |

|---|---|

Design and Construction | High-strength alloy steel for durability |

Latch Mechanism | Prevents accidental disengagement |

Versatility | Fits various lifting equipment and environments |

Choosing the right shank hook keeps your workplace safe and your equipment lasting longer. You protect your team and meet safety standards by following inspection guidelines and using certified products.

Powerful Machinery offers:

Quality craftsmanship and innovative solutions

Exceptional customer service

Access to product details, manuals, and training resources

Visit Powerful Machinery to explore certified shank hooks and find the right solution for your lifting needs.

FAQ

What is the main purpose of a shank hook?

You use a shank hook to connect and lift heavy loads safely. The design allows you to attach it to chains, slings, or ropes for secure lifting in construction, marine, and industrial settings.

How do you inspect a shank hook before use?

You should check the hook for cracks, wear, or deformation. Look at the latch and shank for damage. Always confirm the identification code and certification. Remove any hooks from service if you find defects.

Can you use shank hooks in outdoor or marine environments?

Yes, you can use shank hooks in outdoor or marine environments. Choose hooks with corrosion-resistant finishes, such as zinc plating or painting. These finishes protect the hook from rust and extend its service life.

What is a shank hook, and why does certification matter?

A shank hook is a forged metal hook with a straight or slightly curved shank for lifting. Certification shows the hook meets safety standards. Certified hooks help you avoid accidents and ensure reliable performance.

How do you choose the right size shank hook?

You select the right size by checking the load weight and application. Always match the hook’s working load limit to your lifting needs. Consult manufacturer guidelines for proper sizing and safety.