An anchor chain connects your vessel to the anchor, securing its position and preventing drift. You rely on anchor chains to maintain stability, especially in rough waters. Powerful Machinery delivers certified anchor chain solutions that meet international standards.

Improper anchor chain length can lead to severe incidents, such as the total loss of the Bonnie G., valued at $1.5 million.

Even minor components in anchor line systems, including anchor lines and chains, directly affect overall vessel safety.

Following safety standards for anchor chain selection and use helps prevent costly accidents.

Key Takeaways

Anchor chains are essential for securing vessels and preventing drift in rough waters. Choose the right type for your vessel’s needs.

Regular inspection and maintenance of anchor chains can prevent corrosion and mechanical failure, ensuring safety at sea.

Select anchor chains made from high-quality materials like galvanized or stainless steel for durability and corrosion resistance.

Understanding the correct anchor chain length and thickness is crucial for effective anchoring and vessel stability.

Always opt for certified anchor chains to guarantee compliance with international safety standards and enhance your vessel’s reliability.

Anchor Chains Overview

Definition and Function

You depend on anchor chains to connect your vessel to the anchor, forming a critical link in your anchor equipment. The function of the anchor chain goes beyond simple connection.

It provides the strength and durability needed to secure your vessel in place, even when facing strong winds or powerful currents. Anchor chains serve as the backbone of your anchor lines, ensuring that your vessel remains stable and safe.

The main functions of the anchor chain in marine applications include:

Enduring holding power: Anchor chains secure vessels and floating structures against environmental forces such as currents, winds, and tides.

High tensile strength: They withstand strong winds and powerful currents, maintaining your vessel’s position even in severe weather.

Shock absorption: Anchor chains absorb shock loads, reducing strain on your vessel during rough conditions.

Robust mooring systems: You use anchor chains to create strong mooring systems for offshore platforms and floating structures.

Harbor and port applications: Anchor chains connect to strong points on docks, allowing for flexible mooring configurations.

Temporary barriers: Anchor chains maintain the position of floating barriers, preventing drift under wind and current.

Marine salvage operations: Anchor chains serve as strong anchor points for repositioning or refloating distressed vessels.

You can see that the function of the anchor chain extends to every aspect of vessel safety and stability. Powerful Machinery specializes in manufacturing anchor chains that meet these demanding requirements.

With over 20 years of experience, Powerful Machinery delivers certified anchor equipment, including anchor chains and anchor lines, that comply with ISO, RINA, and BV standards. You can trust their products to provide the strength and reliability you need for any marine application.

Importance of Anchor Chains

Understanding the importance of anchor chains helps you make informed decisions about your vessel’s safety. Anchor chains play a vital role in preventing anchor dragging, which can lead to vessel drift and dangerous situations.

When you use the correct anchor chain and manage your anchor lines properly, you ensure your vessel remains stable, even in adverse weather.

The importance of anchor chains becomes clear when you consider the risks of failure:

A vessel that loses its anchor chain and begins to drift faces a higher risk of collisions with other vessels.

Without a secure anchor chain, your vessel can be pushed onto hazardous or shallow areas, causing significant damage and endangering everyone on board.

Drifting vessels may collide with piers, docks, or other maritime infrastructure, leading to costly repairs and environmental harm.

Dragging anchors can damage sensitive marine environments, such as coral reefs and seagrass beds.

Tip: For optimal mooring, use a chain length of about 5 to 8 times the water depth. This scope allows the anchor to hold securely and helps you follow maritime regulations for safe anchoring practices.

The most serious threat from ships at anchor is the risk of running aground if the anchor chain cannot hold the vessel in position. This risk increases during storms or strong winds. In just minutes, a ship dragging its anchor can run aground or collide with another ship, leading to fuel spills and environmental disasters.

You can avoid these dangers by choosing high-quality anchor chains and anchor lines from trusted providers like Powerful Machinery. Their anchor equipment undergoes rigorous testing and certification, ensuring you receive products that meet the highest safety standards.

The importance of anchor chains in your anchor equipment cannot be overstated. They protect your vessel, your crew, and the marine environment.

Types of Anchor Chains

Anchor chains play a vital role in securing vessels and maintaining stability at sea. You encounter two main types of anchor chains in marine operations: stud link chains and studless anchor chains. Understanding the differences between these anchor chain links helps you select the right solution for your vessel.

Stud Link Chain

Stud link chains feature a stud in the center of each link. This design increases strength and prevents the chain from bending under heavy loads. You often see stud link anchor chains used on large cargo ships, tankers, and offshore platforms.

Their robust construction makes them ideal for anchoring in deep waters and harsh marine environments.

Feature | Stud Link Anchor Chain |

|---|---|

Shape | Contains a stud in the middle of each link |

Purpose | Used on ships and boats for anchoring |

Proof Load and Breaking Load | Larger due to the stud |

Weight | Heavier because of the stud |

You benefit from several advantages when you choose stud link anchor chains:

The stud boosts strength and prevents bending under heavy loads.

The chain resists wear caused by friction between links.

The rigid design simplifies maintenance and inspections.

The stud prevents tangling, ensuring smoother operation.

Stud link anchor chains are essential for:

Anchoring large vessels in deep water

Mooring equipment, like oil rigs and buoys

Operations in harsh marine environments

Powerful Machinery manufactures stud link anchor chains that meet ISO 1704 standards. You can select from Grade 2 or Grade 3 chains, available in black, galvanized, or stainless steel finishes. These anchor chains undergo rigorous testing to ensure high tensile strength and durability.

Certifications from organizations such as Bureau Veritas (BV), Lloyd’s Register (LR), and DNV GL guarantee compliance with international safety standards.

Tip: Choose stud link anchor chains for heavy-duty anchoring where maximum strength and reliability are required.

Studless Anchor Chain

Studless anchor chains do not have a stud in the middle of each link. This design makes them lighter and more flexible compared to stud link chains. You find studless anchor chains suitable for smaller vessels, fender chains, and equipment that requires less force.

Their flexibility allows them to adapt to seabed contours and makes handling easier during deployment and retrieval.

Feature | Studless Anchor Chain |

|---|---|

Shape | No stud in the middle of each link |

Purpose | Used on boats, fender chains, and equipment with less force |

Proof Load and Breaking Load | Smaller due to the absence of the stud |

Weight | Lighter due to the lack of a stud |

Studless anchor chains offer several benefits:

Lighter weight helps save tonnage on smaller boats.

Increased flexibility makes them easier to handle in rough seas.

Compact design improves storage efficiency on board.

The absence of protruding studs reduces the risk of snagging on debris.

You use studless anchor chains for:

Anchoring smaller vessels and pleasure boats

Fender chains for docks and piers

Applications where weight efficiency is crucial

Powerful Machinery produces studless anchor chains from galvanized steel and AISI 316 stainless steel. These anchor chain links comply with ISO standards and are certified by RINA and BV. You can customize the length, material, and finish to match your specific anchoring system.

Certifications from organizations such as China Classification Society (CCS), American Bureau of Shipping (ABS), and Korean Register (KR) ensure safety and reliability.

Certification | Organizations |

|---|---|

CCS | China Classification Society |

ABS | American Bureau of Shipping |

BV | Bureau Veritas |

NK | Nippon Kaiji Kyokai |

KR | Korean Register |

GL | Germanischer Lloyd |

LR | Lloyd’s Register |

DNV | DNV GL |

RINA | Registro Italiano Navale |

RMRS | Russian Maritime Register of Shipping |

Note: Studless anchor chains are not suitable for lifting applications. Use them for anchoring and securing vessels only.

Comparison Table: Stud Link vs Studless Anchor Chains

Feature | Stud Link Anchor Chains | Studless Anchor Chains |

|---|---|---|

Strength | High tensile strength and wear resistance | Lighter and more flexible |

Flexibility | Less flexible, suitable for larger vessels | More flexible, ideal for smaller vessels |

Snagging Risk | Less likely to snag and foul | Safer in heavy waves, less vulnerable to tangling |

Weight Consideration | Heavier, suitable for larger vessels | Lighter, helps save tonnage on smaller boats |

You must evaluate the types of anchor chains based on your vessel size, anchoring needs, and operational environment. Powerful Machinery offers both stud link and studless anchor chains, ensuring you receive certified products that match your requirements.

Their anchor chain links provide the durability, flexibility, and safety you need for reliable marine operations.

Anchor Chain Materials

Choosing the right materials used to make anchor chains is essential for vessel safety and mooring reliability. You must consider corrosion resistance, durability, and suitability for marine environments.

Powerful Machinery offers anchor chains crafted from high-quality galvanized steel, stainless steel, and other specialized materials. Each option provides unique benefits for mooring and anchoring applications.

Galvanized Steel

Galvanized steel remains one of the most popular materials used to make anchor chains. You benefit from its exceptional strength, durability, and resistance to corrosion.

Hot-dip galvanization creates a protective layer that shields the anchor chain from rust, making it ideal for mooring in saltwater environments. You can rely on galvanized steel anchor chains for consistent breaking load performance and long service life.

Tip: To maximize the lifespan of galvanized steel anchor chains, you should inspect each link regularly, lubricate the chain every two weeks, rinse with freshwater after use, and keep the anchor locker dry.

Galvanized steel anchor chains offer a cost-effective solution for most mooring needs. You can trust their chain break load ratings for secure anchoring, even in challenging conditions.

Stainless Steel

Stainless steel anchor chains provide superior corrosion resistance, especially in harsh marine environments. You often choose stainless steel for mooring systems exposed to saltwater, where longevity and minimal maintenance matter most.

Stainless steel chains maintain their appearance and resist rust, making them a preferred choice for yachts and high-value vessels.

Stainless steel offers high breaking load capacity and excellent durability.

You experience reduced maintenance and enjoy the aesthetic appeal of a stainless steel chain.

Stainless steel anchor chains cost more than galvanized steel, but you gain extended service life and reliability.

Note: While stainless steel anchor chains excel in corrosion resistance, you must monitor for pitting and electrochemical corrosion in saltwater. Always select certified stainless steel from trusted suppliers like Powerful Machinery to ensure safety and consistent breaking load performance.

Other Materials

You may encounter alternative materials used to make anchor chains, such as aluminum, titanium, and synthetic options. These materials serve specific mooring applications where weight, strength, or corrosion resistance is critical.

Material | Properties | Typical Applications |

|---|---|---|

Galvanized Steel | Durable, corrosion-resistant, affordable | Most commonly used for anchor chains |

Stainless Steel | More corrosion-resistant, expensive | Used in environments with high corrosion |

Aluminum | Lightweight, less strong | Suitable for applications where weight is a concern |

Titanium | Lightweight, high-strength-to-weight ratio | Specialized mooring systems |

Plastic/Synthetic | Buoyant, soft, corrosion-resistant | Small boats and temporary mooring |

You should match the anchor chain material to your vessel type, mooring environment, and required breaking load. Powerful Machinery provides anchor chains in a range of materials used to make anchor chains, ensuring you find the right solution for every mooring challenge.

Anchor Chain Thickness and Chain Size

Choosing Anchor Chain Thickness

Selecting the right anchor chain thickness is essential for vessel safety and reliable mooring. You must match the anchor chain thickness to your boat’s length, displacement, and anchoring conditions. Larger vessels require thicker anchor chains to withstand greater forces from wind and currents.

Thicker chains deliver bigger holding forces, especially when you anchor in challenging weather or soft seabed conditions.

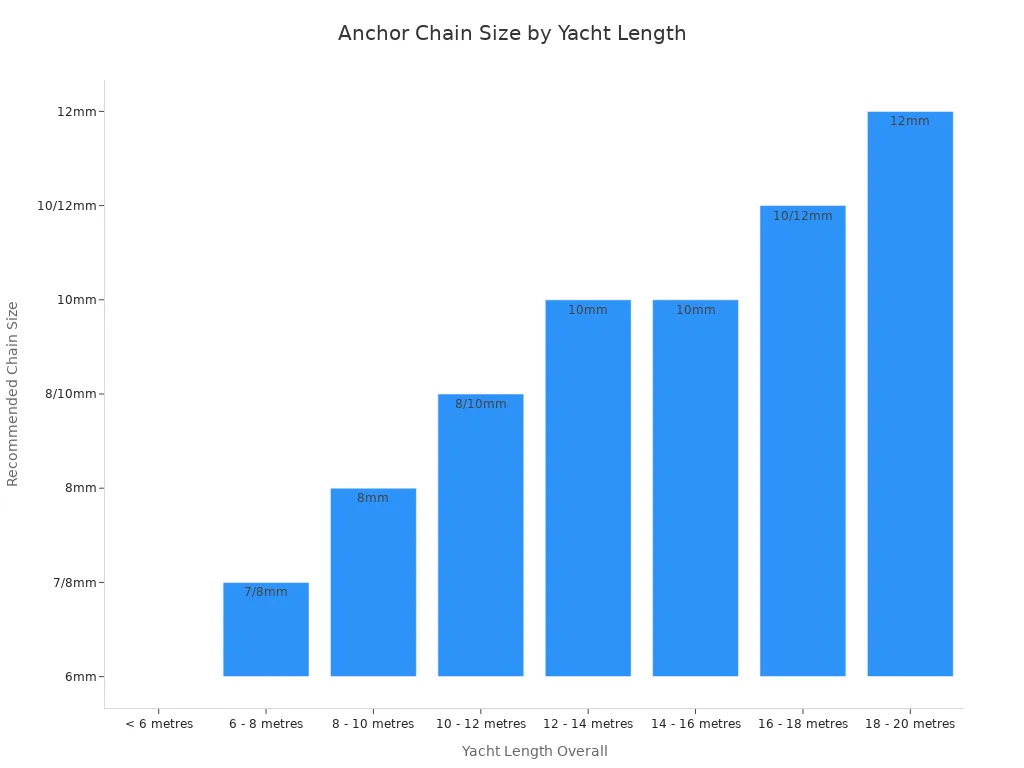

The following table provides guidelines for anchor chain thickness based on yacht length and displacement:

Yacht Length Overall | Displacement in Tonnes | Chain Size |

|---|---|---|

< 6 metres | 1 tonnes | 6mm |

6 – 8 metres | 2.5 tonnes | 7/8mm |

8 – 10 metres | 5 tonnes | 8mm |

10 – 12 metres | 9 tonnes | 8/10mm |

12 – 14 metres | 13 tonnes | 10mm |

14 – 16 metres | 16 tonnes | 10mm |

16 – 18 metres | 20 tonnes | 10/12mm |

18 – 20 metres | 25 tonnes | 12mm |

You should also consider the anticipated anchoring conditions and the weight of your anchor. If your vessel is a multihull or has a displacement above the listed tonnage, choose a thicker anchor chain for added safety.

The length of the anchor chain between the anchor and the nylon line improves holding power by keeping the anchor flat on the seabed.

Tip: In heavy weather, increase the scope ratio to 7:1 or 10:1 to maximize the anchor’s holding power.

Selecting Chain Size

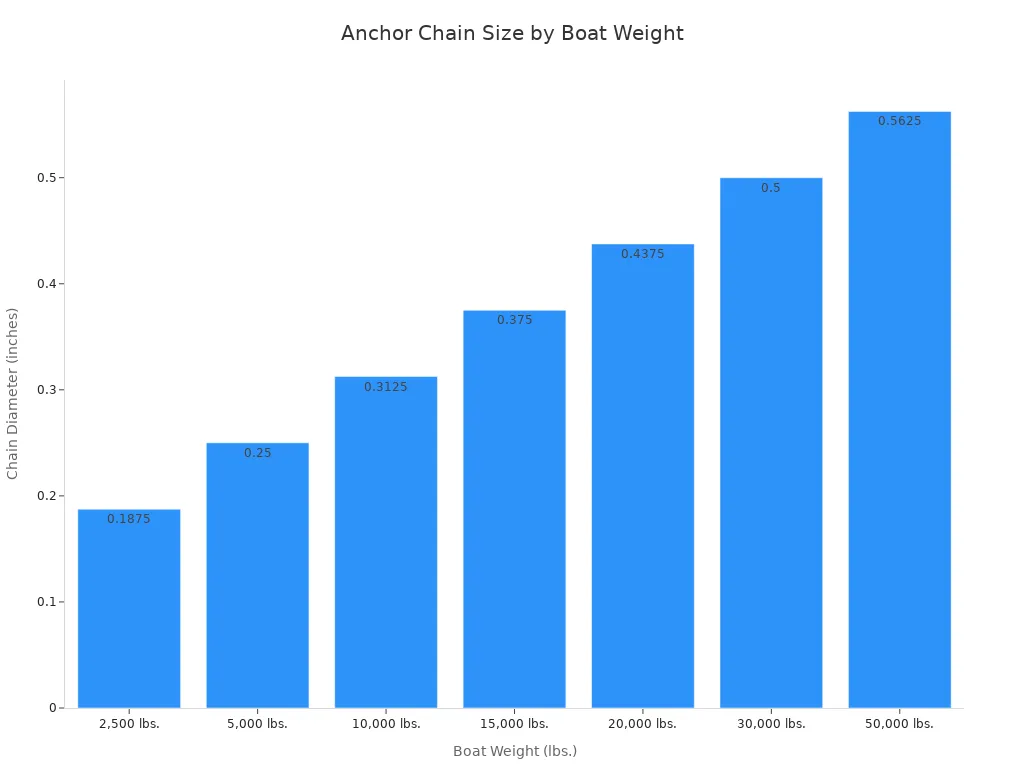

Chain size refers to the diameter of each link and the overall strength of the anchor chain. You must select the chain size based on your vessel’s weight and the intended application. The following table outlines recommended chain sizes for different boat lengths and weights:

Boat Length | Boat Weight | Chain Diameter |

|---|---|---|

20 to 25 feet | 2,500 lbs. | 3/16-inch |

26 to 30 feet | 5,000 lbs. | 1/4-inch |

31 to 35 feet | 10,000 lbs. | 5/16-inch |

36 to 40 feet | 15,000 lbs. | 3/8-inch |

41 to 45 feet | 20,000 lbs. | 7/16-inch |

46 to 50 feet | 30,000 lbs. | 1/2-inch |

51 to 60 feet | 50,000 lbs. | 9/16-inch |

Powerful Machinery offers anchor chains in a wide range of chain sizes and thicknesses, with customization options to fit your vessel’s specifications. You can select the length of anchor chain, material, and grade to match your anchoring system.

Their anchor chains meet international standards and provide reliable performance for every marine application.

Note: Always verify the length of the anchor chain and chain size with your supplier to ensure compatibility with your anchor and vessel.

Anchor Chain Standards and Certification

ISO and Industry Standards

You rely on anchor chain standards to ensure safety and reliability in marine operations. International standards set strict requirements for the design, manufacturing, and testing of anchor chains. These standards help you avoid failures and maintain vessel stability.

The most recognized guidelines include ISO 1704 and BS ISO 1704:2022. These standards specify the shape, proportions, dimensions, and tolerances for stud-link anchor chains. You can see how these standards guide manufacturers in the table below:

Standard | Description |

|---|---|

BS ISO 1704:2022 | Essential guidelines for design, manufacturing, testing, and operation of anchor chains in the maritime industry, ensuring safety and reliability. |

ISO 1704:2008 | Specifies the shape, proportions, dimensions, and tolerances of stud-link anchor chains. |

Certifications from organizations such as RINA and BV confirm that your anchor chain meets these international standards. You gain confidence knowing your anchor chains have passed rigorous inspections and testing.

Quality Assurance

You want assurance that every anchor chain you use will perform under pressure. Certification bodies like RINA and BV require manufacturers to follow strict quality control steps. These steps include material testing, manufacturing process audits, and final product testing. The table below outlines the certification process:

Certification Steps | Description |

|---|---|

Material Testing | Testing the raw materials used in the anchor chain for quality and durability. |

Manufacturing Process Audits | Audits to ensure manufacturing processes comply with international standards. |

Final Product Testing | Proof load and break tests to verify the strength and safety of the finished product. |

Powerful Machinery takes quality assurance seriously. You benefit from their in-house testing facility, where every anchor chain undergoes non-destructive testing, metallurgical analysis, proof load testing, breaking load tests, and corrosion resistance checks.

These procedures reveal internal flaws, confirm steel composition, and ensure each anchor chain exceeds minimum certification requirements. You receive anchor chains that meet or surpass ISO, RINA, and BV standards, giving you peace of mind on every voyage.

Tip: Always choose anchor chains from certified manufacturers. This guarantees safety, reliability, and compliance with global maritime regulations.

Anchor Chain Accessories

Anchor chain accessories play a crucial role in marine operations. You rely on these components to connect, secure, and maintain your anchor chain system. Powerful Machinery offers a complete range of anchor chain accessories designed for safety and reliability in demanding environments.

Shackles and Swivels

You use shackles and swivels to connect anchor chains to anchors, mooring points, or other hardware. Shackles come in different shapes, such as bow shackles and D shackles.

Bow shackles provide flexibility for multi-directional loading, while D shackles work best for inline connections. Swivels allow the anchor chain to rotate freely, preventing twists and tangles during deployment or retrieval.

Shackles

Swivels

Chain stoppers

Connectors

Swivels enhance marine safety by allowing smooth rotation and preventing chain twisting. You benefit from corrosion-resistant materials like stainless steel or galvanized steel, which ensure long-lasting durability in saltwater environments.

The swivel shackle creates a safe and efficient connection between the anchor chain and anchor, giving you confidence in your anchoring system.

Tip: Always inspect shackles and swivels for signs of wear or corrosion before each voyage. Replace any damaged anchor chain accessories to maintain safety.

Marking and Identification

Marking and identification help you track anchor chain length and ensure proper deployment. You can use several methods to mark anchor chains for traceability:

Apply three colors three times each, with each color representing a different length of chain.

Paint or dye chain links and connecting links to signify different sections.

Wrap metal wire or white steel rings around chain links to indicate specific lengths.

Attach webbing tabs at intervals, using different colors or numbers to show distance.

A clear marking system allows you to measure how much chain you have deployed. You avoid guesswork and improve safety during anchoring. Powerful Machinery recommends using durable materials for marking anchor chain accessories, ensuring visibility and longevity in harsh marine conditions.

Note: Accurate identification of anchor chain accessories and chain length helps prevent anchor dragging and ensures compliance with maritime regulations.

Anchor Chain Care and Maintenance

Proper care extends the lifespan of anchor chains and ensures reliable performance at sea. You must follow maintenance tips for anchor chains to prevent corrosion and mechanical failure. Powerful Machinery recommends a proactive approach to inspection, cleaning, and storage.

Inspection and Cleaning

Routine inspection helps you detect wear, corrosion, and damage before problems arise. You should always clean anchor chains after each use. Follow these maintenance tips for anchor chains to keep your equipment in top condition:

Rinse the anchor chain with freshwater after retrieval. This step removes salt residues that accelerate corrosion.

Clean the chain thoroughly using high-pressure water jets or manual brushing. Remove all debris before inspection.

Lubricate contact points regularly. Apply marine-grade lubricant to reduce friction and slow corrosion.

Touch up coatings on worn areas. Use anti-corrosive paint if recommended by your supplier.

Rotate different sections of the anchor chain frequently. This practice ensures even wear across the entire length.

Train your crew on inspection routines and safety protocols. Consistent training improves safety and maintenance results.

You should inspect anchor chains for cracks, deformation, and rust. Early detection allows you to address issues before they compromise vessel safety.

Tip: Schedule anchor chain inspections at regular intervals, especially before long voyages or after exposure to harsh conditions.

Storage and Corrosion Prevention

Storing anchor chains correctly protects them from moisture and physical damage. You can maximize lifespan and minimize corrosion risk by following these maintenance tips for anchor chains:

Store anchor chains in dry, ventilated areas. Good airflow prevents moisture accumulation and rust.

Flake the chain systematically after recovery. This method avoids tangling and kinks.

Lift the anchor chain during stowage. Prevent abrasion by avoiding dragging across hard surfaces.

You should always check storage areas for leaks or standing water. Proper storage keeps anchor chains ready for deployment and reduces the need for frequent repairs.

Note: Reliable anchor chain maintenance ensures your vessel remains secure and operational in all marine environments.

Conclusion

You now understand the essentials of anchor chains, including their types, materials, sizing, and care. Selecting a certified anchor chain from a trusted provider like Powerful Machinery ensures safety and reliability for your vessel.

Regular inspection and maintenance help you extend service life and prevent failures. For expert advice or custom solutions, reach out to Powerful Machinery and secure your marine operations with confidence.

FAQ

What is the difference between stud link and studless anchor chains?

Stud link chains have a central stud for added strength and reduced twisting. Studless chains offer more flexibility and lighter weight. You choose a stud link for heavy-duty anchoring and a studless for easier handling on smaller vessels.

Tip: Select the chain type based on your vessel size and anchoring needs.

How do you maintain an anchor chain for maximum lifespan?

You rinse the chain with freshwater after each use. Inspect for wear and corrosion regularly. Lubricate moving parts and store in a dry, ventilated area. Follow Powerful Machinery’s maintenance guidelines for best results.

Which certifications should you look for when buying anchor chains?

Look for certifications such as ISO, RINA, and BV. These confirm that your anchor chain meets international safety and quality standards. Powerful Machinery provides certified products for reliable marine operations.

Certification | Organization |

|---|---|

ISO | International Standards |

RINA | Registro Italiano Navale |

BV | Bureau Veritas |

Can you customize anchor chain length and material?

You can request custom lengths, materials, and finishes to match your vessel’s requirements. Powerful Machinery offers tailored solutions, including galvanized steel and stainless steel options, ensuring your anchor chain fits your anchoring system perfectly.

Note: Customization improves safety and performance for unique marine applications.