An eye-bolt is a strong, threaded fastener with a looped head. You often use an eye-bolt to secure ropes, chains, or cables in lifting and rigging tasks. The reliability of an eye-bolt matters because even a small angular pull can cut its working load by nearly half.

Many incidents in industrial settings happen when workers do not align the eye-bolt with the load or use it at the wrong angle.

Incident Type | Description |

|---|---|

Eye Bolt Failure | Eye bolts are crucial in lifting operations; failures often occur, especially during angular lifts. |

Load Reduction | An angular pull of 6 to 15 degrees can reduce the working load of an eye bolt to 55 percent. |

You need to select the right eye-bolt and install it correctly to keep lifting operations safe. Certified products, such as those from Powerful Machinery, help you avoid dangerous failures. Eye bolts for lifting and rigging support your work in industries where safety and reliability cannot be compromised.

Key Takeaways

Eye bolts are essential for safe lifting and rigging. Always choose certified eye bolts to ensure reliability and compliance with safety standards.

Understand the different types of eye bolts. Use shoulder eye bolts for angled lifts and regular eye bolts for vertical lifts to prevent accidents.

Inspect eye bolts regularly for wear and damage. This practice helps maintain safety and extends the life of your lifting equipment.

Always check the working load limit before use. Never exceed this limit to avoid dangerous failures during lifting operations.

Select the right eye bolt size based on load weight and application. Use size charts to ensure proper fit and safety.

Eye-Bolt Basics

What is an Eye-Bolt?

You see eye bolts in many lifting and rigging tasks. An eye bolt is a strong metal fastener with a loop at one end. You use it to attach ropes, chains, or cables to objects that need lifting or securing.

International engineering and safety organizations set strict standards for eye bolts. These standards help you choose safe and reliable products for your work.

Eyebolts for hoisting must be made from forged carbon or alloy steel with enough ductility.

Each eyebolt should show the manufacturer’s name, size or rated load, and grade for alloy eyebolts.

A minimum design factor of 5:1 is required for eyebolts.

Only shoulder-mounted eyebolts are recommended for rigging, except in special configurations.

You should always check these markings before using an eye bolt. This helps you avoid accidents and ensures the bolt can handle the load.

Tip: Always use certified eye bolts from trusted brands like Powerful Machinery. Certified products meet international safety standards and give you peace of mind during lifting operations.

Key Parts and Structure

You need to understand the main parts of an eye bolt to use it safely and effectively. Each part plays a specific role in the bolt’s strength and function.

Component | Description |

|---|---|

Eye | The circular loop at one end of the eyebolt. |

Shoulder | The raised part below the eye provides a stronger hold. |

Shank | The cylindrical portion extending down from the shoulder can be threaded or unthreaded. |

Base | The bottom part of the eyebolt, where the threading end,s if applicable. |

The eye lets you attach chains or ropes. The shoulder gives extra strength, especially for angular lifts. The shank holds the threads that secure the bolt in place. The base marks where the threading stops. When you know these parts, you can choose the right eye bolt for your job and install it correctly.

Different Types of Eye Bolts

Powerful Machinery manufactures a wide range of eye bolt types for lifting and rigging. You need to understand the different types of eye bolts to choose the right one for your project.

Each type has unique features, strengths, and best-use scenarios. Selecting the correct eye bolt type helps you maintain safety and efficiency in your work.

Note: Choosing the right type of eye bolt is critical for safety. You must consider load weight, lifting angles, and the environment to prevent accidents and equipment failure.

Regular and Shoulder Eye Bolts

You often see regular and shoulder eye bolts in lifting and securing tasks. These two types have important differences in design and application.

Feature | Shoulder Eye Bolt | Regular Eye Bolt |

|---|---|---|

Design | Reinforced shoulder between the eye and the shaft | Looped head and threaded shaft, no shoulder |

Load Type | Handles vertical and angular loads | Designed for vertical loads only |

Durability | More durable, extra structural support | Prone to bending under side loads |

Usage in Rigging | Complex rigging and hoisting | Simple, straight-line lifting |

Applications | Heavy-duty lifting, construction, machinery | Light to medium-duty securing, anchoring |

Risk of Failure | Less risk under side loads | High risk under angled forces |

Material Options | Stainless steel, carbon steel, alloy steel | Mild steel, stainless steel, galvanized |

Cost | Slightly more expensive | More affordable, limited application |

Installation Method | Precise alignment required | Easier, straight pull only |

Ideal For | Machinery, construction, marine, industrial | Cable securing, fencing, and household |

Shoulder eye bolts give you extra strength for lifting at angles. You use them in heavy-duty applications, such as construction and industrial machinery. Regular eye bolts work best for straight vertical lifts. You should avoid using regular eye bolts for angled loads because they can bend or break.

Common Uses for Shoulder Eye Bolts | Limitations |

|---|---|

Lifting loads with non-vertical angles | Use caution for extreme angles |

Rigging with complex load distribution | Failure is possible if the angle is too great |

Securing heavy machinery with lateral movement | N/A |

Machinery and Lag Eye Bolts

Machinery and lag eye bolts are two types you use for specific materials and tasks.

Type | Design Features | Usage |

|---|---|---|

Machinery Eye Bolt | Fully threaded, strong | Lifting heavy equipment |

Lag Eye Bolt | Screws into wood, designed for wood | Securing cables and attachments in wood |

Machinery eye bolts are load-rated eye bolts. You use them for lifting heavy equipment. You must drill the hole to a depth equal to the shank length plus half the shank diameter.

Proper alignment and depth are essential for safe installation. Lag eye bolts work best in wood. You screw them directly into the material to create a secure anchor point for cables or ropes.

Bent and Forged Eye Bolts

You will find bent eye-bolts and forged eye bolts in many lifting and securing jobs. These types differ in strength and reliability.

Bent eye-bolts are made by bending a straight rod into a looped head.

Forged eye bolts are shaped by heating and hammering raw metal.

Forged eye bolts are stronger and more durable than bent eye bolts.

You should use forged eye bolts for heavy-duty lifting and rigging. Bent eye-bolts work for light-duty tasks, such as securing cables or fencing. You must avoid using bent eye-bolts for critical lifting because they can deform under heavy loads.

Specialty Eye Bolts

Specialty eye bolt types serve unique purposes in industry. You see these types in specialized applications.

Type of Eye Bolt | Unique Applications |

|---|---|

Shoulder Eye Bolt | Lifting heavy loads with secure attachment |

Screw Eye Bolt | Threaded connection for fastening |

Lag Eye Bolt | Securing cables in wood |

General Applications | Hoisting equipment, rigging sailboats, suspending lights |

You use specialty eye bolts for tasks that require specific features, such as threaded connections or wood anchoring. These eye bolt types help you solve unique rigging challenges in construction, marine, and industrial settings.

Tip: Always inspect your eye bolts before use. Regular checks help you spot wear or damage and keep your lifting operations safe.

You must select the correct type of eye bolt for each job. The right choice protects you, your equipment, and your team.

Powerful Machinery offers a full range of different types of eye bolts, including forged eye bolts, bent eye bolts, machinery eye bolts, and specialty types. You can rely on their expertise to match the best eye bolt types to your needs.

Eye Bolts for Lifting and Rigging

Common Eye Bolt Uses

You rely on eye bolts for lifting and rigging in many settings. These fasteners give you secure attachment points for slings, chains, or hooks. You use eye bolts for lifting heavy machinery, beams, and concrete panels. They help you tighten cables or braces and secure parts of structures like scaffolding.

Eye bolts for lifting and rigging work with pulleys, winches, and shackles, making them essential rigging gear. You find them easy to fit and versatile, which saves you time during setup. Their straightforward design lets you use them in vertical lifting applications or more complex lifting applications.

Lifting and hoisting machinery and equipment

Securing structural components and scaffolding

Attaching rigging gear such as chains, slings, and hooks

Supporting marine operations and cargo handling

You choose the right types of eye bolts for each job to ensure safety and efficiency. For heavy-duty applications, you need lifting eye bolt designs that can handle substantial loads.

Industry Use Cases

Eye bolts for lifting and rigging play a vital role in construction, marine, and industrial sectors. You see them in factories, shipyards, and building sites. In manufacturing, you use eye bolts to lift equipment and move materials.

Construction teams depend on them for hoisting beams and panels. Marine operators trust stainless steel eye bolts for corrosion resistance in harsh environments.

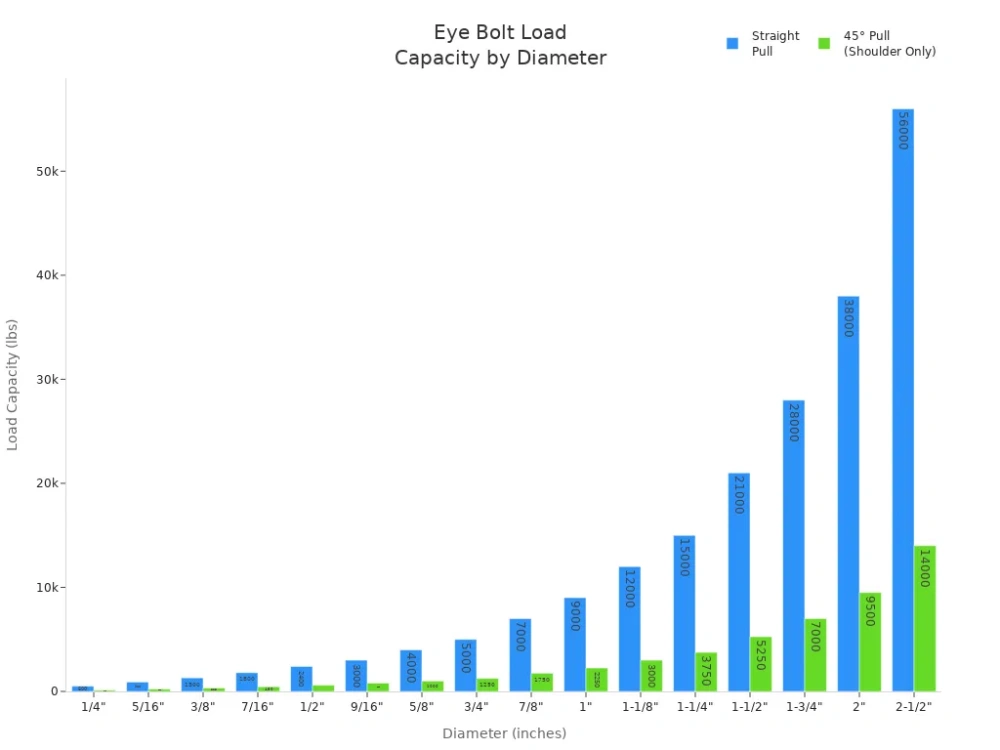

Diameter | Straight Pull (lbs) | 45° Pull (Shoulder Only) (lbs) |

|---|---|---|

1/4″ | 500 | 125 |

1/2″ | 2,400 | 600 |

1″ | 9,000 | 2,250 |

2″ | 38,000 | 9,500 |

You must use certified products to meet safety and compliance standards. Powerful Machinery’s stainless steel eye bolts meet ASTM A193 Grade B7 and B8 standards, and each bolt carries a 3.1 certification. These certifications guarantee performance in demanding environments and give you confidence in your rigging gear.

Certification/Standard | Description |

|---|---|

ASTM A193 Grade B7 | Strong, threaded bolts for heavy lifting |

ASTM A193 Grade B8 | Corrosion-resistant for marine use |

3.1 Certification | Quality tested for safety |

Tip: Always check certifications before you start any lifting operation. Certified eye bolts for lifting and rigging protect you and your team.

Eye Bolt Material Options

Stainless Steel Eye Bolts

You want eye bolts that last in tough environments. Stainless steel eye bolts from Powerful Machinery give you high corrosion resistance and excellent durability. These bolts work well in places with moisture, chemicals, or extreme temperatures.

You can use them in marine, construction, and industrial settings. The high chromium content in stainless steel prevents rust and keeps the bolts strong over time. Powerful Machinery uses premium 304 and 316 stainless steel grades, which means you get both strength and long-term performance.

Take a look at how stainless steel compares to other materials:

Material | Corrosion Resistance | Durability | Applications |

|---|---|---|---|

Stainless Steel | High | High | Moisture, chemicals, and extreme temperatures |

Galvanized Steel | Moderate | Moderate | General applications, less extreme conditions |

You see that stainless steel stands out for its ability to resist corrosion and handle harsh conditions. This makes it a top choice for demanding jobs.

Other Materials and Finishes

You have several options when choosing eye bolt materials. Each type offers different benefits for performance and longevity. High tensile carbon steel gives you good hardness and strength, making it suitable for heavy-duty tasks.

Galvanized steel provides moderate corrosion resistance because of its zinc coating. Some bolts come with special finishes, such as black oxide, nickel, or chrome, to improve their resistance and appearance.

Here is a quick guide to common finishes and their effects:

Finish/Coating | Effects on Performance and Longevity |

|---|---|

Uncoated/Plain | Basic protection, susceptible to corrosion. |

Black Oxide | Some corrosion resistance, mainly for looks. |

Nickel | Better corrosion resistance, shiny finish. |

Phosphate | Improved corrosion resistance, often a base for other coatings. |

Stainless Steel | High corrosion resistance, ideal for marine and architectural uses. |

Zinc | Good corrosion resistance, used outdoors. |

Cadmium | Excellent corrosion resistance for harsh environments. |

Chrome | Shiny finish, good corrosion resistance. |

When you select eye bolt materials, think about where and how you will use them. Stainless steel works best for wet or salty environments. Galvanized and zinc-coated bolts fit general outdoor use.

High tensile carbon steel suits heavy lifting, especially in cold weather. You get the best results when you match the material to your job’s needs.

Tip: Always check the material and finish before you buy. The right choice helps you avoid rust, wear, and early failure.

Eye Bolt Sizes

Size Guide

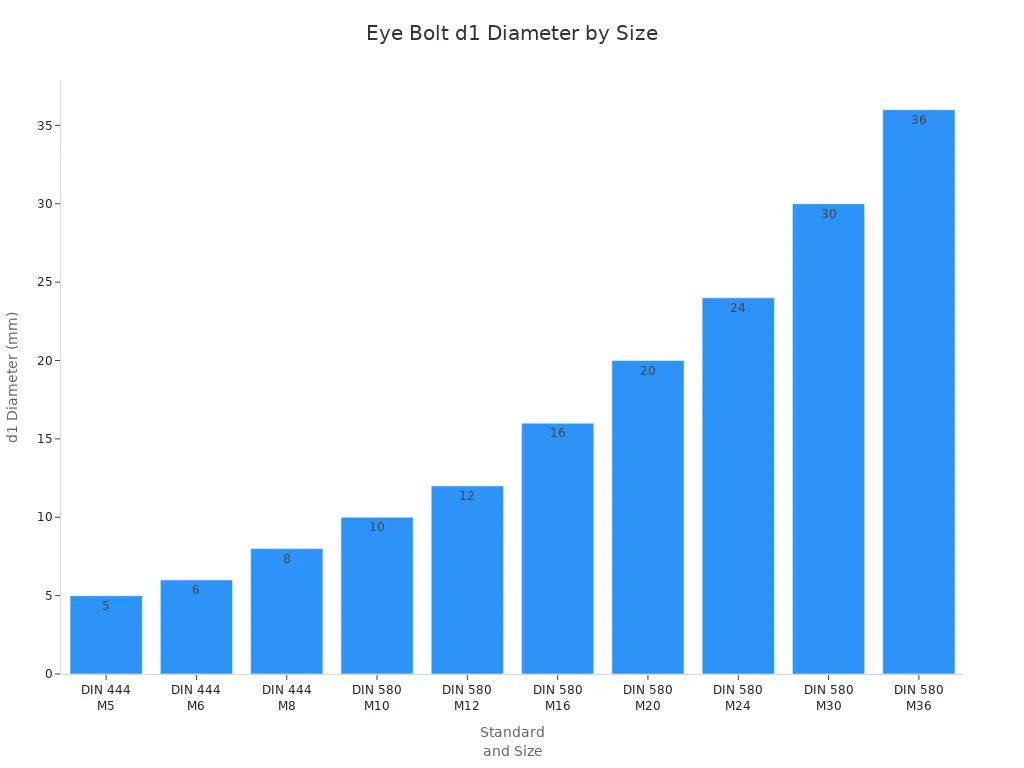

You need to understand sizes before you select an eye bolt for your project. The size of an eye bolt affects its strength, working load limit, and application. You see eye bolts measured by thread diameter, length, and eye dimensions.

Common sizes range from M6 to M36, which cover most industrial needs. You match the size to your expected load and the material you anchor into.

When you choose eye bolt sizes, consider these steps:

Load Weight & WLL: Match your bolt to your expected load.

Material: Choose stainless steel, galvanized, or alloy based on your environment.

Thread Size & Length: Fit matters.

Application Type: Are you lifting, anchoring, or securing at angles?

Angle of Use: Shoulder eye bolts can handle angular loads up to a point, but angles beyond 45 degrees are not recommended.

Tip: Never exceed the working load limit. Always inspect your bolts for wear and damage.

You find that M10 bolts work for lighter loads in construction or DIY projects. M12 bolts suit moderate loads in metal fabrication. M16 bolts handle heavy loads in engineering and construction. You must ensure proper thread engagement with the anchor material for safety.

Size Chart

You can use a size chart to compare dimensions and working load limits. This helps you select the right eye bolt for your job.

Standard | Size (M) | Dimensions (d1, h, b, d2, d3) |

|---|---|---|

DIN 444 | M5 | 5, 27.5, 12, 27, 19 |

DIN 444 | M6 | 6, 36, 13, 36, 20 |

DIN 444 | M8 | 8, 45, 17, 45, 25 |

M10 | 10, 53, 20.5, 54, 30 | |

DIN 580 | M12 | 12, 62, 27, 63, 35 |

DIN 580 | M16 | 16, 71, 30, 72, 40 |

DIN 580 | M20 | 20, 90, 36, 90, 50 |

DIN 580 | M24 | 24, 109, 45, 108, 65 |

DIN 580 | M30 | 30, 128, 54, 126, 75 |

DIN 580 | M36 | 36, 147, 63, 144, 85 |

Thread Diameter | Maximum Load (kg) | For Two Bolts (kg) |

|---|---|---|

M6 | 70 | 50 |

M8 | 140 | 95 |

M10 | 230 | 170 |

M12 | 340 | 240 |

M16 | 700 | 500 |

M20 | 1200 | 830 |

M24 | 1800 | 1270 |

M30 | 3600 | 2600 |

M36 | 5100 | 3700 |

You use these charts to compare sizes and load limits. You select the right eye bolt sizes by matching the diameter and working load to your application. You improve safety and efficiency when you follow these guidelines.

Eye Bolt Working Load Limit

Load Ratings Explained

You need to understand the working load limit before you start any lifting or rigging job. The working load limit tells you the maximum weight an eye bolt can safely support during normal use.

Manufacturers determine this value through strict testing and engineering calculations. You should always follow the working load limit to keep your lifting operations safe and reliable.

The working load limit shows the highest load you can apply without risking failure.

Manufacturers use advanced tests and calculations to set this limit.

You must never exceed the working load limit during lifting or hanging tasks.

Safety factors protect you from unexpected problems. These factors make sure the eye bolt can handle more than its stated working load limit, giving you extra security.

When you see a rated weight on an eye bolt, you know it has passed these safety checks. Always check the markings and certifications before you use any lifting hardware.

Factors Affecting Capacity

Several important factors can change the actual load an eye bolt can handle. You need to pay attention to these details to avoid accidents.

The working load limit is your maximum safe load. If you go over this limit, you put yourself and your team in danger.

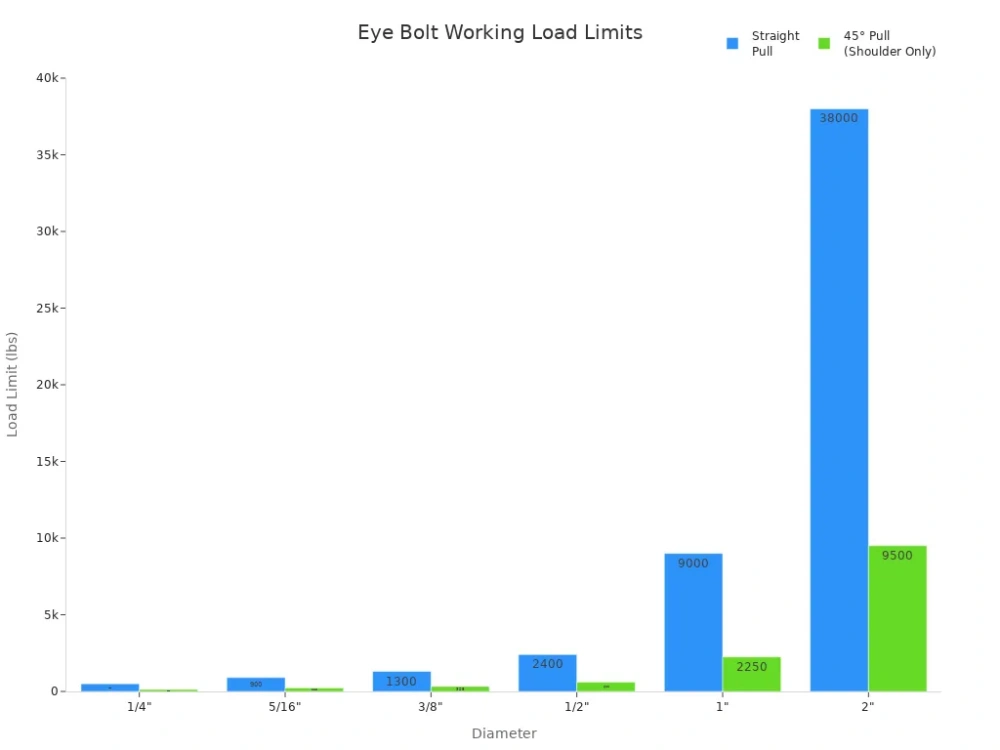

Angle loading has a big impact on capacity. When you lift at an angle, the working load limit drops quickly.

Regular inspections help you spot wear, corrosion, or damage. A quick check can prevent serious accidents.

Proper installation is just as important as the eye bolt itself. Make sure you install the bolt securely and follow the manufacturer’s instructions.

You should always use eye bolts for vertical loading when possible. This position gives you the highest working load limit. If you must use angle loading, remember that the capacity decreases as the angle increases. For example, a 45-degree angle can cut the working load limit by more than half.

Tip: Never guess the load or angle. Use a load chart and measure the angle to stay within safe limits.

Load Limit Charts

You can use load limit charts to find the right eye bolt for your job. These charts show you how much weight each size and type can handle in both vertical loading and angle loading situations.

Diameter | Straight Pull (lbs) | 45° Pull (Shoulder Only) (lbs) |

|---|---|---|

1/4″ | 500 | 125 |

5/16″ | 900 | 225 |

3/8″ | 1,300 | 325 |

1/2″ | 2,400 | 600 |

1″ | 9,000 | 2,250 |

2″ | 38,000 | 9,500 |

You can see from the table that the working load limit drops sharply with angle loading. For example, a 1/2″ eye bolt supports 2,400 lbs in a straight pull but only 600 lbs at a 45-degree angle.

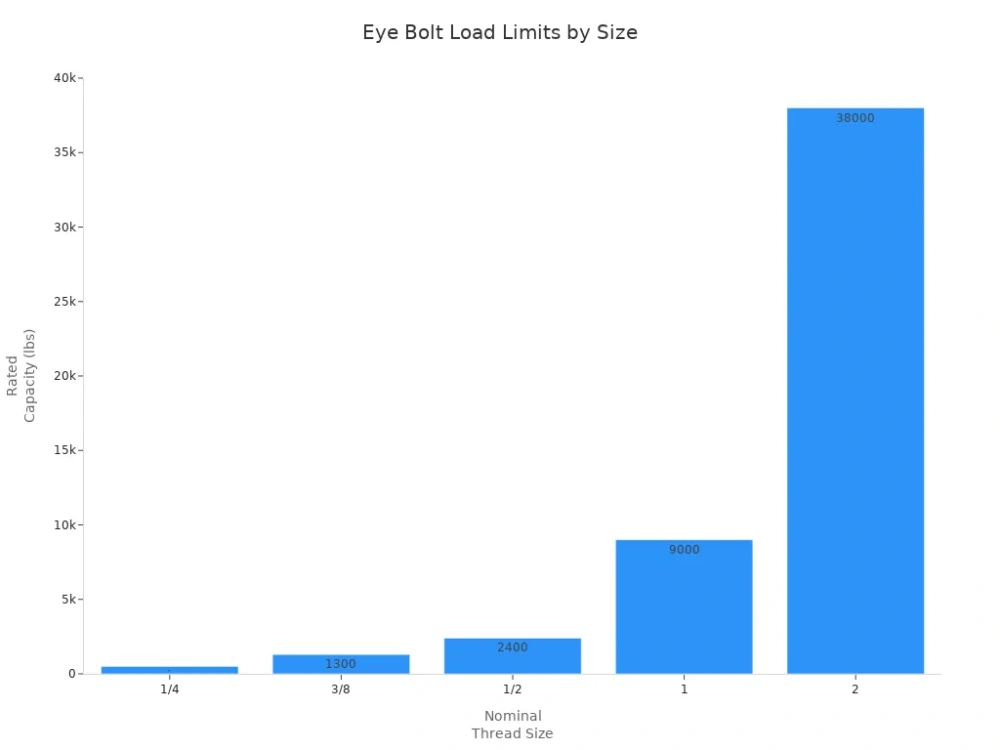

Here is another chart showing the rated capacities for different thread sizes:

Nominal Thread Size | Rated Capacity lbs |

|---|---|

1/4 | 500 |

3/8 | 1,300 |

1/2 | 2,400 |

1 | 9,000 |

2 | 38,000 |

You should always use these charts to select the right eye bolt for your load and lifting angle. Never exceed the working load limit, and always consider the effects of angle loading. This practice keeps your lifting operations safe and efficient.

Note: For the best safety, choose certified eye bolts from trusted brands like Powerful Machinery. Certified products give you confidence in every lift.

Selection Guide

Choosing the Right Eye-Bolt

You need to think carefully when selecting the right bolt for your lifting or rigging job. The types of eye bolts you choose depend on your load, the angle of lift, and the environment. You should always check the working load limit and make sure it matches or exceeds the weight you plan to lift.

If your load needs to rotate, you must use swivel eye bolts instead of regular ones. Shouldered eye bolts work best for angled lifts, while non-shouldered eye bolts are safe only for vertical lifts.

You should inspect each eye bolt before use. Look for signs of heavy wear, corrosion, or damage. Check that the threads are clean and undistorted. Make sure the receiving holes are free from wear. Always confirm that the working load limit is enough for your job.

Tip: Powerful Machinery offers custom-engineered solutions. You can consult their experts to match the right eye bolt to your project and ensure compliance with international standards.

Standards and Markings

You must look for proper standards and markings when selecting the right bolt. Certified eye bolts carry markings that show the manufacturer’s name, size or rated load, and grade for alloy bolts. These markings help you identify safe and reliable products.

Here are some common standards you may find:

Standard Type | Standard Name |

|---|---|

Fastener Dimensional Standards | DIN 444 |

Fastener Dimensional Standards | ASME B18.15 |

Fastener Dimensional Standards | UNI 6058 |

You should always check for these markings:

Name or trademark of manufacturer

Size or rated load

Grade for alloy eyebolts

Every component from Powerful Machinery goes through strict testing to meet international safety standards. You get peace of mind knowing your lifting hardware is reliable and compliant.

Note: Always choose certified products and inspect markings before you start any lifting operation.

Safe Use and Best Practices

Installation Tips

You want to install eye bolts correctly to maximize safety and load capacity. Start by inspecting each eye bolt for damage before use. Look for cracks, bends, or corrosion. Select the right eye bolt for your job by checking the load rating, material, thread type, and lifting angle.

Make sure the mounting surface is flat, clean, and strong enough to support the load. Drill and tap a proper hole if needed. Hand-tighten the eye bolt and position it so the load will pull in line with the shank. Test the connection with a light load to check stability.

Tip: Never paint eye bolts. Paint can hide damage and make inspection difficult.

Best practices for installation:

Inspect for damage before use.

Confirm the Working Load Limit (WLL) matches your load.

Ensure threads are clean and compatible.

Avoid painting eye bolts.

Respect load limits and avoid side loads on plain bolts.

Mind lifting angles and inspect regularly.

Inspection and Maintenance

Regular inspection and maintenance help you extend the life of your eye bolts. Check for signs of wear, such as cracks, bends, or rust. Verify that the load does not exceed the manufacturer’s specifications. Make sure each eye bolt is threaded in securely and aligned with the intended direction of force.

Clean bolts often to remove dirt and debris. If you work in harsh environments, choose corrosion-resistant materials like stainless steel.

Inspection Step | Why It Matters |

|---|---|

Inspect for damage | Prevents failure during lifting |

Verify load limits | Avoids overloading and accidents |

Ensure proper installation | Maintains strength and safety |

Keep bolts clean | Reduces risk of malfunction |

Use corrosion-resistant materials | Extends service life in tough conditions |

Common Mistakes

You can avoid many problems by knowing the most common mistakes with eye bolts. Never force a sling or fitting through the eye. Do not over-tighten bolts. Refrain from painting or color-coding, since this can hide flaws.

Always use a shackle instead of a hook in the eye. Avoid shock loading; lift slowly and steadily. Never use a single eye bolt for loads that rotate freely. Replace any bolt showing wear or damage. Do not exceed the rated capacity. Never alter an eye bolt, as this can weaken it.

Using a plain eye bolt for angled loads

Overloading the eye bolt

Ignoring signs of wear and damage

Improper installation

Note: Following these best practices keeps your lifting operations safe and reliable. You protect your team and equipment by staying alert and using certified products.

Conclusion

You now understand what eye bolts are, their types, materials, sizing, and working load limits. Choosing certified products like Powerful Machinery’s Stainless Steel Eye Bolts keeps your lifting operations safe and reliable. For best results:

Inspect eye bolts for residue or damage before each use.

Use only within rated working load limits.

Keep bolts tight and flush with the object.

Remove any eye bolts that show wear or damage.

Consult experts and trusted suppliers to ensure safe and effective lifting in every application.

FAQ

What is the main purpose of an eye bolt?

You use an eye bolt to create a secure anchor point for lifting, pulling, or attaching ropes and chains. Eye bolts help you move heavy loads safely in construction, marine, and industrial settings.

How do you choose the right size eye bolt?

You match the eye bolt size to your load weight and application. Always check the working load limit. Use a size chart to compare thread diameter and length. If unsure, consult a certified supplier.

Can you use stainless steel eye bolts outdoors?

Yes, you can use stainless steel eye bolts outdoors. Stainless steel resists rust and corrosion. This makes it ideal for marine, construction, and outdoor environments where moisture is common.

How often should you inspect eye bolts?

You should inspect eye bolts before each use. Look for cracks, bends, or rust. Regular checks help you spot damage early and prevent accidents.

What markings should you look for on a certified eye bolt?

Look for the manufacturer’s name, size, or rated load, and grade. These markings show you the eye bolt meets safety standards and is safe for lifting.