When you ask what size chain binder I need, you should match your binder size to your chain size and the weight of your load. For example, most heavy equipment transport jobs use 5/16″ or 3/8″ chains with matching binders, as shown in the industry table below:

Chain Size | Binder Size |

|---|---|

5/16 | 5/16 |

3/8 | 3/8 |

Following safety guidelines is critical because improper securement causes 4% of truck accidents, with a 56.3% higher risk when loads are not properly tied down. Always choose certified products from trusted brands like Powerful Machinery to ensure compliance and safety.

Key Takeaways

Match your chain binder size to your chain size and load weight for safe transport.

Always check the working load limit (WLL) to ensure your equipment can handle the cargo weight.

Select the right type of binder—ratchet binders offer safety, while lever binders provide speed.

Inspect your chains and binders before each use to prevent accidents and ensure compliance.

Use certified products from trusted brands to enhance safety and build customer trust.

What Size Chain Binder Do I Need?

Choosing the right chain binder size starts with understanding your chain size and the weight of your load. You must match your binder to both the chain and the cargo to ensure safety and compliance.

Many beginners ask, What size chain binder do I need? The answer depends on the chain size you use and the working load limits required for your application.

Chain Size Reference Table

You will find that chain size is measured in inches or millimeters. The most common sizes for flatbed trucking are 5/16″ and 3/8″. Each chain size pairs with a specific binder size and has a recommended working load limit.

Use the table below to quickly match your chain size to the correct binder and see the working load limits for different chain grades:

Chain Size (mm/inches) | Grade 30 proof coil (lbs) | Grade 43 high test (lbs) | Grade 70 transport (lbs) | Grade 80 alloy (lbs) | Grade 100 alloy (lbs) |

|---|---|---|---|---|---|

1/4 (7) | 1,300 | 2,600 | 3,150 | 3,500 | 4,300 |

5/16 (8) | 1,900 | 3,900 | 4,700 | 4,500 | 5,700 |

3/8 (10) | 2,650 | 5,400 | 6,600 | 7,100 | 8,800 |

7/16 (11) | 3,700 | 7,200 | 8,750 | N/A | N/A |

1/2 (13) | 4,500 | 9,200 | 11,300 | 12,000 | 15,000 |

5/8 (16) | 6,900 | 13,000 | 15,800 | 18,100 | 22,600 |

Tip: Always check the chain size stamped on your chain links before selecting a binder. Using the wrong size can reduce the effectiveness of your securement.

Working Load Limits

Working load limits define the maximum weight your chain and binder can safely handle. You must never exceed these limits.

The Department of Transportation requires you to use equipment that meets or exceeds the working load limits for your cargo. For example, if you use a 3/8″ Grade 70 chain, your working load limit is 6,600 lbs. You should select a binder that matches or exceeds this limit.

When you ask what size chain binder I need, you should also consider the type of binder. Most flatbed operators use either ratchet binders or lever binders. Ratchet binders are popular for their safety and ease of use.

Lever binders offer quick operation but require more strength. Both types work well when matched to the correct chain size and working load limits.

Here are some common chain and binder pairings you will see in the field:

5/16″ Grade 70 chain with a 5/16″ ratchet binder (WLL: 4,700 lbs)

3/8″ Grade 70 chain with a 3/8″ ratchet binder (WLL: 6,600 lbs)

1/2″ Grade 70 chain with a 1/2″ ratchet binder (WLL: 11,300 lbs)

Powerful Machinery’s load binders stand out in the industry. You can use them with 5/16″ to 3/8″ chains, and they handle loads up to 6,600 lbs. These binders feature a robust ratchet mechanism for secure tensioning, a durable steel body, and a corrosion-resistant finish.

You will find them easy to operate, even in tough conditions. Powerful Machinery designs each binder to meet or exceed FMCSA and DOT standards, giving you peace of mind on every haul.

Note: Always use binders and chains that meet or exceed the working load limits for your cargo. Never mix chain sizes or grades, and always inspect your equipment before each use.

If you still wonder what size chain binder I need, start by checking your chain size, then match it to the binder and confirm the working load limits. This approach ensures your cargo stays secure and you remain compliant with safety regulations.

How to Choose the Right Load Binder?

Selecting the correct binder chain for your cargo securement process ensures safety, compliance, and efficiency. You need to follow a systematic approach to achieve proper chain selection and avoid costly mistakes. Here is a step-by-step guide to help you make the right choice.

Check Chain Size

Start by identifying the size of your binder chain. Look for the size stamped on the chain links or refer to your equipment manual. Most flatbed and heavy-duty applications use 5/16″, 3/8″, or 1/2″ binder chain.

Proper chain selection begins with matching the chain binder to the exact diameter of your chain. Using the wrong size can compromise cargo securement and increase the risk of failure.

Measure the diameter of your binder chain with a caliper or tape measure.

Confirm the grade of the binder chain, such as Grade 70 or Grade 80, since this affects strength.

Record the chain size and grade for reference during the selection process.

Tip: Never guess the size of your binder chain. Always verify before choosing a chain binder.

Calculate Working Load Limit

Once you know your binder chain size, calculate the working load limit (WLL) required for your cargo securement. The WLL tells you the maximum weight your binder chain and chain binder can safely handle. You must never exceed this limit.

Add up the total weight of your cargo.

Divide the weight by the number of binder chain tie-downs you plan to use.

Check the WLL for your binder chain and chain binder in the manufacturer’s table.

If you exceed the WLL, you risk severe consequences:

Equipment failure can cause dropped loads and accidents.

Overloading leads to accelerated wear, metal fatigue, and deformation of binder chain components.

Exceeding the WLL increases the risk of personal injury or death.

Regulatory agencies may issue fines or penalties for non-compliance.

You become legally liable for damages or injuries resulting from improper cargo securement.

Alert: Always use binder chains and chain binder combinations that meet or exceed the required WLL for your cargo securement. Never compromise on safety.

Select Binder Type

After confirming your binder chain size and WLL, choose the right type of chain binder for your application. The two main types are the ratchet load binder and the lever load binder. Each offers unique advantages for cargo securement.

Type of Load Binder | Mechanism Description | Safety Features | Efficiency |

|---|---|---|---|

Ratchet Load Binder | Uses a ratcheting mechanism for gradual tension application, allowing precise control. | Often includes locking mechanisms to prevent accidental release. | Achieves higher tension levels, suitable for delicate cargo. |

Lever Load Binder | Operated by applying force to a lever, generating tension quickly. | It may have fewer built-in safety features. | Quicker to operate, advantageous for time-sensitive applications. |

Ratchet load binder stands out for safety and control. You can apply tension gradually, reducing the risk of sudden release. A lever load binder works well for quick jobs but requires more physical strength and carries a higher risk of injury if not handled properly.

For long-distance freight or oversized loads, a ratchet load binder provides better control and less physical effort. For short-haul or time-sensitive jobs, the lever load binder offers speed and simplicity.

Powerful Machinery offers both ratchet and lever load binder options, engineered for durability and ease of use. Each load binder features high-strength steel construction, corrosion-resistant coatings, and ergonomic handles.

You can trust Powerful Machinery binder chain products to meet or exceed FMCSA and DOT standards for cargo securement. Their load binder range fits common binder chain sizes from 5/16″ to 1/2″, supporting a wide range of cargo securement needs.

Note: Always inspect your binder chain and load binder before each use. Replace any component showing signs of wear, deformation, or corrosion. Regulatory compliance and proper chain selection protect you from legal liability and ensure safe cargo securement.

By following these steps—checking binder chain size, calculating working load limit, and selecting the right chain binder—you ensure proper chain selection and reliable cargo securement every time.

Load Securement and Safety Factors

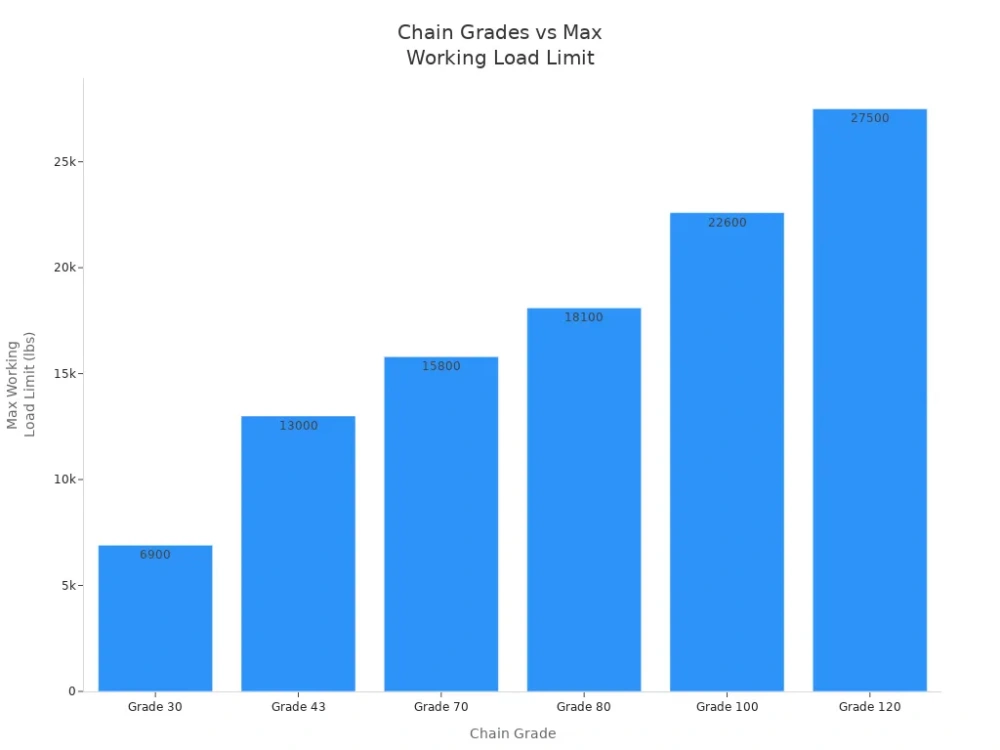

Chain Grade and Strength

You must select the right chain grade and strength for every load securement job. Chain grade determines how much weight and force your chain can handle. Lower grades, like Grade 30, work for light loads, but you need higher grades for heavy cargo.

Grade 70, Grade 80, Grade 100, and Grade 120 chains offer greater strength and durability. The working load limit and breaking strength increase as the grade rises.

Chain Grade | Description | Working Load Limit (lbs) | Applications |

|---|---|---|---|

Grade 30 | General purpose; low strength | 1,300 to 6,900 | Light construction, agriculture |

Grade 43 | Medium strength | 2,600 to 13,000 | Logging, towing |

Grade 70 | High strength, DOT recognized | 3,150 to 15,800 | Load securement, flatbed hauling |

Grade 80 | Alloy, very high strength | 3,500 to 18,100 | Overhead lifting, heavy cargo |

Grade 100 | Premium alloy, maximum strength | 4,300 to 22,600 | Construction, manufacturing |

Grade 120 | Ultra-premium strength | 5,200 to 27,500 | Specialized lifting |

Federal regulations require a minimum safety factor of 4:1 for chains. This means the working load limit is only one-fourth of the chain’s breaking strength.

Safety Factor | Description |

|---|---|

4:1 | The working load limit is 1/4 of the chain’s breaking strength |

Powerful Machinery’s chains and load binders meet or exceed these standards. You can rely on their certified products for consistent strength and safety, even when securing heavy cargo.

Legal Requirements

You must follow strict legal requirements for load securement. Federal and state regulations specify the number of tie-downs, inspection intervals, and minimum working load limits.

For example, cargo over 1,100 pounds needs at least two tie-downs. Vehicles over 10,000 pounds require four tie-downs at all corners. Regular inspections are mandatory, and the combined strength of your tie-downs must be at least 50% of the cargo’s weight.

Requirement Type | Details |

|---|---|

Minimum Tie-Downs for Cargo | Over 1,100 lbs: at least two tie-downs |

Tie-Downs for Vehicles | Over 10,000 lbs: four tie-downs |

Additional Securement | Over 10 feet: extra securement |

Inspection Requirements | Regular inspections required |

Working Load Limit (WLL) | Tie-downs must equal at least 50% of cargo weight |

CFR Reference | Title 49, Part 393 |

Non-compliance can result in heavy fines, out-of-service orders, and legal action. You protect yourself and your business by using certified equipment and following all regulations.

Common Mistakes

Many operators make mistakes that compromise load securement and safety. You should avoid these errors to prevent accidents and penalties.

Improper tensioning

Neglecting maintenance

Using incompatible equipment

Failing to conduct pre-use inspections

Failing to secure the load binder handles

Neglecting environmental factors

Failing to account for dynamic forces

Reusing damaged load binders

Using the wrong type of chain

Improper storage of load binders

Tip: Always inspect your chains and binders before each trip. Replace damaged equipment immediately. Use a checklist to confirm every step of your load securement process.

Safety organizations recommend regular inspections, comprehensive training, and strict adherence to procedures. Powerful Machinery’s products undergo rigorous testing and certification, giving you confidence in their strength and reliability for every load securement job.

Conclusion

To choose the right chain binder size, you should:

Measure your cargo’s dimensions and weight.

Match the chain size and grade to your load.

Check the Working Load Limit (WLL) before use.

Select DOT-approved, certified equipment for compliance.

Using certified products like Powerful Machinery Load Binders reduces damage claims, improves efficiency, and builds customer trust. Always follow safety procedures, secure your load properly, and inspect your equipment. Reliable securement keeps your cargo safe and your operations compliant.

FAQ

What is the working load limit for load binders?

You determine the working load limit by checking the manufacturer’s specifications. The working load limit tells you the maximum weight your load binders can safely secure. Always match the working load limit to your cargo and never exceed it.

How do I select the right load binders for my cargo?

You start by identifying your cargo’s weight and chain size. Then, check the working load limit for both the chain and load binders. Choose load binders that meet or exceed the working load limit required for your load.

Can I use load binders with any type of chain?

You must use load binders with chains that match in size and grade. The working load limit of both must meet your cargo requirements. Never mix incompatible chains and load binders, as this reduces the working load limit and puts your load at risk.

How often should I inspect load binders before securing cargo?

You should inspect load binders before every use. Look for wear, deformation, or corrosion. Confirm the working load limit markings are visible. Damaged load binders can fail, putting your cargo and safety at risk.

Why is the working load limit important for cargo securement?

The working load limit ensures your load binders can handle the weight of your cargo. If you exceed the working load limit, you risk equipment failure. Always use load binders and chains with a working load limit that matches your cargo.