Wire rope clamping plays a vital role in securing wire rope termination for lifting, rigging, and hoisting tasks. You rely on these clamps to achieve safety and stability in demanding environments. When you use proper wire rope fixing methods, you benefit from:

Load-bearing efficiency that lets the rope support its full-rated load.

Enhanced safety, reducing the risk of accidents or injuries by preventing clamp slippage.

Even stress distribution, which extends the lifespan of your wire rope and clamps.

Reliable performance in extreme conditions such as corrosion or vibration.

Powerful Machinery stands out as a trusted provider of certified wire rope solutions, helping you achieve peace of mind on every project.

Key Takeaways

Wire rope clamping is essential for safety in lifting and rigging tasks. Proper clamping prevents slippage and maintains the integrity of connections.

Always inspect wire rope clamps before use. Look for signs of wear or damage to ensure safety and reliability during operations.

Select the right clamp size for your wire rope. Using the correct size enhances performance and prevents accidents.

Follow manufacturer guidelines for installation and maintenance. Adhering to torque specifications and clamp placement maximizes safety.

Regularly maintain and inspect your wire rope system. Consistent checks help identify issues early, extending the lifespan of your equipment.

What Is Wire Rope Clamping?

Purpose and Importance

Wire rope clamping secures the ends of wire ropes or creates strong loops and terminations. You use clamps to prevent slippage and maintain the integrity of your connection. A typical wire rope clamp includes a U-bolt or saddle placed over the wire, with bolts or screws that tighten the clamp.

This pressure ensures the rope stays in place, which is critical for safety in lifting and rigging tasks. When you clamp wire rope correctly, you protect your equipment and the people working with it.

Wire rope clamps are mechanical devices designed to secure wire rope ends.

The clamp’s design distributes pressure evenly, reducing the risk of rope damage.

Proper clamping helps you achieve reliable performance in demanding environments.

Common Applications

You will find wire rope clamping in many industries. These clamps play a key role in heavy-duty tasks where safety and stability matter most.

You use wire rope clamps in construction to secure ropes during lifting operations.

In mining, clamps anchor and rig wire ropes for safe material handling.

Marine industries rely on clamps for securing loads and mooring vessels.

Rigging professionals use wire rope clips to create secure connections between ropes.

Clamps help fasten wire ropes to structures and anchor them to fixed points.

Wire rope clamping supports your work in environments where strength and reliability are essential.

Safety Considerations

You must follow strict safety standards when working with wire rope clamps. International organizations such as OSHA and ISO provide guidelines to keep you safe.

ISO 4309 outlines procedures for wire rope care, maintenance, inspection, and discarding.

The ISO 16881 series offers safety recommendations for steel wire ropes.

OSHA regulation 1926.251 requires you to inspect rigging equipment before each use and during operation.

Rigging equipment must have clear identification markings for safe working load, and you must never exceed this limit.

Tip: Always inspect your wire rope clamps before use. Look for signs of wear, corrosion, or damage. Replace any component that does not meet safety standards.

By following these standards, you ensure the safety of your team and the reliability of your equipment.

Wire Rope Fixing Methods

You encounter several wire rope fixing methods in industrial environments. Each method offers unique advantages for securing wire ropes, depending on your application and safety requirements. The table below gives you a quick overview of the main fixing methods, their descriptions, and typical uses.

Fixing Method | Description | Applications |

|---|---|---|

Cable fixing | Involves wrapping the wire rope around a winch to withstand traction. | Cable, traction, stretching |

Fastening jig fixing | Uses clamps for quick adjustments and reliable securing. | Ropeways, slings |

Weaving net fixing | Passes a wire rope through a mesh for net structures. | Net boxes, protection nets |

Welding fixing | Strong connections through welding for heavy-duty applications. | Bridge towers, cranes, and marine work |

Crush fixing | Uses clamps to press and secure the wire rope in equipment. | Ships, lifting equipment |

Cable Fixing

Cable fixing stands out as one of the most common wire rope fixing methods. You wrap the wire rope around a winch or drum, allowing it to withstand significant traction and stretching forces. This method works well for applications where you need to move or lift heavy loads.

You often see cable fixing in construction, mining, and transportation. Powerful Machinery’s Steel Wire Rope provides the strength and durability you need for cable fixing, ensuring reliable performance under tension.

Fastening Jig Fixing

Fastening jig fixing uses clamps or jigs to secure wire ropes quickly and efficiently. You benefit from easy adjustments and a strong hold, making this method ideal for ropeways, slings, and temporary installations. Stainless Steel Wire Rope Clips from Powerful Machinery offer a dependable solution for fastening jig fixing.

You can install and adjust these clips with minimal effort, giving you flexibility and safety in your rigging tasks.

Weaving Net Fixing

Weaving net fixing involves passing a wire rope through a mesh or grid to create net structures. You use this method to build protective barriers, cargo nets, and safety enclosures. In construction and marine environments, weaving net fixing helps you:

Secure loose items in trucks, trailers, and containers.

Create safe swimming areas and prevent debris from falling overboard.

Transport heavy materials in industrial plants and construction sites.

Steel Wire Rope from Powerful Machinery offers the flexibility and strength required for weaving net fixing. You achieve stable and secure net structures that withstand heavy loads and harsh conditions.

Welding Fixing

Welding fixing creates permanent and robust connections for wire ropes in heavy-duty applications. You rely on welding for bridge towers, cranes, and marine work, where maximum strength is essential. When you use welding, you must follow strict safety practices:

Wear personal protective equipment to prevent burns and exposure to arc rays.

Inspect wire ropes before welding to ensure they are in good condition.

Take precautions against electric shock.

Keep your work area clean to avoid tripping hazards.

Follow all safety information on products and material safety data sheets.

Powerful Machinery’s Steel Wire Rope meets the demands of welding fixing, providing high tensile strength and resistance to abrasion.

Crush Fixing

Crush fixing uses clamps to press and secure wire ropes within equipment. You see this method in ships and lifting equipment, where a strong and stable connection is crucial. Stainless Steel Wire Rope Clips from Powerful Machinery deliver reliable performance for crush fixing.

You achieve a secure grip that maintains safety and stability, even in challenging environments.

Tip: Always select the wire rope fixing methods that match your application and safety requirements. Powerful Machinery’s certified products help you achieve secure and long-lasting connections.

You improve safety and efficiency when you choose the right fixing methods and use high-quality components. Powerful Machinery’s Stainless Steel Wire Rope Clips and Steel Wire Rope support all major wire rope fixing methods, giving you confidence in every project.

Clamping Steps

Preparation

You must prepare thoroughly before starting any wire rope clamping task. Begin by inspecting the wire rope for damage such as fraying, kinks, or corrosion. Replace any wire rope that shows signs of wear to maintain safety. Gather all necessary tools, including wire rope clips, a wrench or socket set, and a tape measure.

Ensure you have the correct size of cable clamp that matches the diameter of your wire rope. Determine the required length for the loop and leave enough excess on the dead end for secure installation.

Preparation Checklist:

Inspect the wire rope for damage or wear.

Replace damaged wire rope before installation.

Gather wire rope clips, wrench, socket set, and tape measure.

Confirm clamp size matches wire rope diameter.

Measure and prepare the wire rope for the intended loop.

Tip: Careful preparation helps you avoid mistakes and ensures a safe, efficient installation.

Choosing the Right Clamp

Selecting the right wire rope clamp is essential for safety and performance. Choose products from a reputable manufacturer known for quality rigging hardware. Review the instruction manual to understand installation procedures and load capacity. Consult an expert if you have unique requirements or need guidance.

Make sure the clamp fits the wire rope diameter precisely. Consider environmental factors such as exposure to moisture or chemicals, and select clamps with weather-resistant materials if needed. Regularly inspect clamps for wear and store them in a dry, cool place to extend their lifespan.

Key Criteria for Clamp Selection:

Manufacturer’s reputation for quality.

Clear instruction manual with installation and load details.

Expert advice for specific applications.

Accurate size and fit for the wire rope diameter.

Weather resistance for harsh environments.

Routine inspection and maintenance.

Proper storage to prevent deterioration.

Note: Using certified clamps from trusted brands like Powerful Machinery ensures reliability and compliance with industry standards.

Placement and Installation

You must follow a proper clamping method to achieve a secure and stable connection. Select the correct size of cable clamp for your wire rope. Prepare the wire rope by measuring the loop and leaving enough excess on the dead end.

Position the first clamp close to the loop, ensuring the saddle sits on the live end of the rope. For larger ropes, install additional clamps spaced 6-8 rope diameters apart to distribute the load evenly. Tighten each clamp securely using a torque wrench, following the manufacturer’s specifications.

After initial loading, recheck and retighten the clamps to maintain grip and prevent slippage.

Select the correct clamp size for your wire rope.

Measure and prepare the wire rope for the loop.

Place the first clamp near the loop with the saddle on the live end.

Install additional clamps for larger ropes, spaced evenly.

Tighten clamps securely with a torque wrench.

Inspect and retighten clamps after initial use.

Alert: Always follow manufacturer guidelines for clamp placement and torque settings to maximize safety.

Inspection and Maintenance

Regular inspection and maintenance keep your wire rope clamps in optimal condition. Conduct frequent visual checks for signs of damage, wear, or corrosion, especially near drums, sheaves, and terminations. Apply lubricant to the wire rope as recommended to reduce friction and prevent rust.

Keep the wire rope clean and free from debris to avoid accelerated wear. Store wire ropes and clamps in a dry, well-ventilated area, away from chemicals and extreme temperatures. Replace wire ropes and clamps according to manufacturer recommendations or when they reach the end of their service life.

Maintenance Best Practices:

Inspect wire rope and clamps regularly for damage or corrosion.

Lubricate the wire rope to prevent friction and rust.

Clean the wire rope and clamps to remove dirt and contaminants.

Store equipment in a dry, ventilated space.

Replace components as needed to maintain safety.

Tip: Consistent inspection and maintenance prevent failures and extend the lifespan of your wire rope system.

Product Highlights

Stainless Steel Wire Rope Clips

You need wire rope clips that deliver consistent performance in demanding environments. Powerful Machinery’s Stainless Steel Wire Rope Clips stand out for their durability and reliability. You benefit from a robust design that resists corrosion and minimizes maintenance.

These clips secure cables with a strong grip, reducing the risk of slippage during critical operations.

Feature/Advantage | Description |

|---|---|

Durability | Withstand significant loads without deforming. |

Corrosion Resistance | Protective chromium oxide layer resists rust and degradation. |

Low Maintenance | Robust construction saves you time and effort. |

Cost-Effectiveness | Long-term savings by avoiding frequent replacements. |

Reliability | Consistent performance keeps cables securely fastened. |

You achieve secure fastening for cables in marine, industrial, and construction settings.

The design minimizes slippage, enhancing safety for lifting and rigging tasks.

You spend less time on upkeep, allowing you to focus on your project.

Tip: Choose stainless steel clips for environments where corrosion resistance and reliability matter most.

Steel Wire Rope

You require wire rope that delivers strength and stability in every application. Powerful Machinery’s Steel Wire Rope features a non-rotating design, which prevents twisting and kinking. You gain peace of mind knowing your equipment operates safely and efficiently.

Improvement Aspect | Details |

|---|---|

Sling Lifespan Increase | Regular maintenance increases lifespan by 35% |

Downtime Reduction | Equipment downtime decreases by 40% |

Safety Incidents | Safety incidents drop to zero |

You experience fewer interruptions and longer service life for your wire rope systems.

The high-grade steel construction resists abrasion and corrosion, making it suitable for harsh environments.

You meet international safety standards, including ISO 2408 and OSHA regulations, ensuring compliance and minimizing risks.

Evidence Description | Type of Standard |

|---|---|

ISO 2408 specifies essential requirements for the construction, dimensions, and performance of steel wire ropes. | International Safety Standard |

Regular inspections and maintenance as per OSHA regulations ensure compliance and minimize risks. | Regulatory Compliance |

Note: Powerful Machinery’s certified wire rope products help you maintain safety and reliability in every project.

Safety and Maintenance Tips

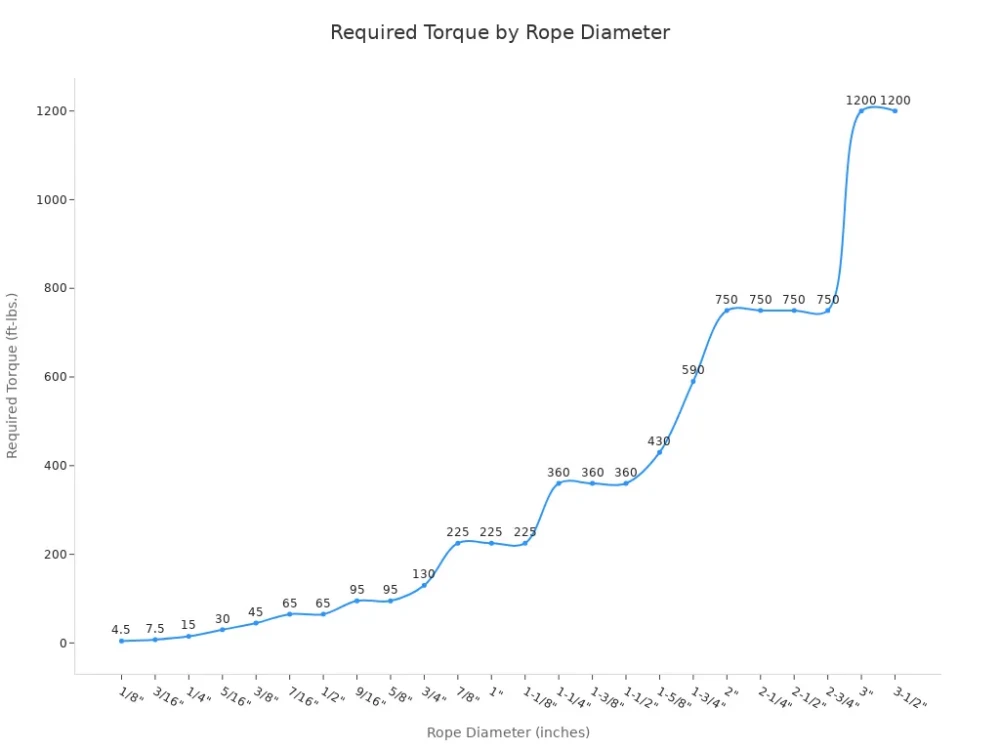

Manufacturer Guidelines

You must always follow the manufacturer’s guidelines when installing and maintaining wire rope clamps. Using the correct number of clips, matching the hardware to the rope diameter, and applying the right torque are essential steps for safety.

Manufacturers provide detailed tables to help you select the right setup for your project.

ROPE DIAMETER | MINIMUM # OF CLIPS | MINIMUM TURN BACK FROM THIMBLE | REQUIRED TORQUE (ft-lbs.) |

|---|---|---|---|

1/4″ | 2 | 4-3/4″ | 15 |

1/2″ | 3 | 11-1/2″ | 65 |

1″ | 5 | 26″ | 225 |

1-1/2″ | 8 | 54″ | 360 |

2″ | 8 | 71″ | 750 |

You should always apply the recommended torque to the nuts on U-bolt clips and fist grip clips. After loading, re-torque the clips to maintain a secure hold. Use the number of clips specified for your rope diameter and inspect all hardware for damage or corrosion before each use.

Tip: Proper installation and regular re-torquing prevent slippage and keep your system safe.

Regular Inspections

You need to inspect your wire rope clamps and hardware on a regular schedule. Visual checks every week help you spot early signs of wear or damage. Monthly detailed inspections give you a deeper look at the system’s condition. For extra safety, schedule professional evaluations twice a year.

Maintenance Practice | Frequency | Purpose |

|---|---|---|

Visual checks | Weekly | Early detection of issues |

Detailed inspections | Monthly | Comprehensive assessment |

Professional evaluations | Bi-annual | Expert analysis and assurance |

Focus on high-risk areas like sheave grooves and drum contact points. Use proper lubrication to block moisture and dirt, which reduces corrosion. In harsh environments, increase inspection frequency to match the risk.

When to Replace Clamps

You should replace wire rope clamps if you see any signs of deformation, corrosion, or mechanical wear. If a clamp no longer holds the recommended torque or shows visible cracks, swap it out immediately. Follow these best practices:

Remove clamps that show rust, cracks, or bent parts.

Replace hardware if you notice slippage after re-torquing.

Discard clamps that fail inspection or do not meet manufacturer standards.

🛠️ Alert: Never reuse damaged or worn clamps. New, certified hardware keeps your lifting system safe and reliable.

Conclusion

You improve safety and reliability when you select the right wire rope fixing method and follow each clamping step carefully. Certified products from Powerful Machinery deliver long-term benefits, as shown below:

Key Aspect | Description |

|---|---|

Minimum Breaking Strength | Ensures ropes meet or exceed required load capacities for safety-critical tasks. |

Fatigue Resistance | Tests for durability under repeated bending and stress cycles. |

Corrosion Protection | Specifies coatings and treatments to extend lifespan in harsh environments. |

Construction Requirements | Defines acceptable rope constructions, diameters, tolerances, and core types for compatibility. |

Quality Control and Traceability | Mandates inspection, testing, and certification for consistent performance and accountability. |

Installation and Use | Outlines best practices for safe handling, installation, and maintenance to prevent accidents. |

Proper clamping secures wire rope ends, preventing movement.

Techniques like selecting the right clamp size and ensuring cleanliness contribute to stability.

Following torque specifications ensures the clamp compresses the wire rope adequately, reducing the risk of failures.

Regular inspections and maintenance help you spot wear early, keep clamps lubricated, and maintain correct tension. These habits prevent failures and extend the lifespan of your wire rope system. Always make safety your top priority.

FAQ

How do you choose the correct wire rope clamp size?

You match the clamp size to your wire rope diameter. Check the manufacturer’s specifications for compatibility. Using the wrong size can compromise safety and performance.

Can you reuse wire rope clamps after removal?

You should not reuse wire rope clamps. Removal can weaken the hardware. Always install new, certified clamps to maintain safety and reliability.

What is the recommended number of clamps for a secure connection?

You follow the manufacturer’s table for the minimum clamp quantity. For example, a 1/2″ rope requires at least three clamps. More clamps may be needed for larger diameters.

How often should you inspect wire rope clamps?

You inspect wire rope clamps weekly for visible damage. Schedule monthly detailed checks and bi-annual professional evaluations. Frequent inspections help you catch issues early.

Are stainless steel wire rope clips suitable for marine environments?

You benefit from stainless steel wire rope clips in marine settings. Their corrosion resistance ensures long-term durability and safety near water or salt exposure.