Wire rope components include wires, strands, and a core. You rely on these parts for strength and flexibility during lifting or rigging tasks. The material and construction of your wire rope affect its durability, resistance to weather, and ability to handle heavy loads.

Choosing the right core, such as IWRC for superior strength or fiber core for flexibility, influences safety and performance. Powerful Machinery delivers certified wire rope solutions designed for demanding industries. Understanding these elements helps you select wire rope that meets your specific needs.

Key Takeaways

Understand the three main components of wire rope: wires, strands, and core. Each part contributes to the rope’s strength and flexibility.

Choose the right core type for your needs. Fiber cores offer flexibility, while steel cores like IWRC provide superior strength for heavy-duty tasks.

Select wire rope materials wisely. High carbon steel offers strength, while stainless steel provides corrosion resistance, especially in marine environments.

Consider the construction and design of wire rope. Different strand patterns and core configurations affect performance and safety in lifting applications.

Regularly lubricate the wire rope to extend its lifespan. Proper lubrication reduces friction and protects against wear and corrosion.

Wire Rope Components Overview

Parts of a Wire Rope

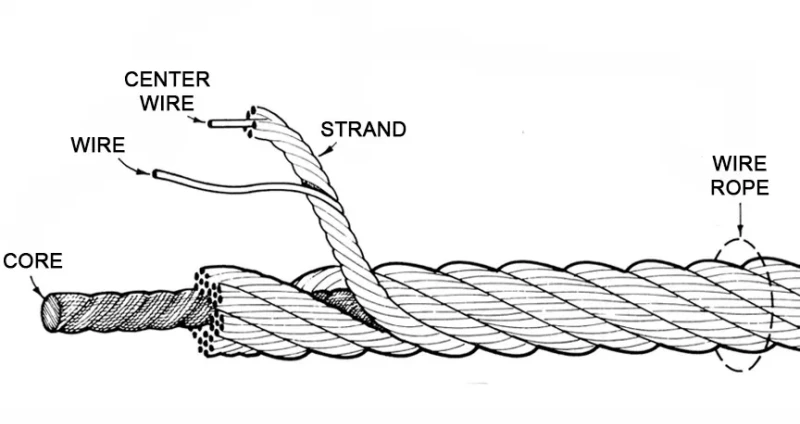

You encounter three basic components in every wire rope: wires, strands, and a core. These parts of a wire rope work together to deliver the strength and flexibility you need for lifting, rigging, or hoisting tasks.

Wires form the smallest units. They create the foundation for the rope’s structure.

Strands result from twisting several wires together. This process increases flexibility and distributes load evenly.

The core sits at the center. It supports the strands and helps the rope keep its shape during use.

The proportions and arrangement of these basic components can change based on wire rope classifications. For example, a typical steel wire rope may have six strands wrapped around a core, while specialized constructions like Warrington-Seale use more wires for unique requirements.

The table below shows how different wire rope types use these components:

Wire Rope Type | Number of Strands | Core Type | Characteristics |

|---|---|---|---|

Steel Wire Rope | 3 to 36 (commonly 6) | Fibre or Steel Core | More strands = more flexibility, thinner wires = less durability. |

Warrington-Seale Strand | 36 wires | N/A | Specific construction with layers of wires for unique requirements. |

Stranded Ropes | Varies | Fibre, Wire Strand, or IWRC | Flexible and elastic with varying durability based on core type. |

Powerful Machinery brings over two decades of expertise to the design and production of these wire rope components. You benefit from advanced manufacturing processes and strict quality control, ensuring every wire, strand, and core meets international standards for safety and performance.

Core Types and Functions

The core is one of the most important basic components in wire rope construction. It supports the strands, keeps them in position, and affects the rope’s flexibility and strength. You can choose from several core types, each with unique advantages:

Fiber Core (FC): Made from natural or synthetic fibers, this core offers high flexibility and good internal lubrication retention. It works well in light-duty lifting equipment and marine environments.

Independent Wire Rope Core (IWRC): This steel core increases strength, stability, and resistance to crushing. It provides up to 15% higher breaking strength than fiber core and performs well in cranes, mining, offshore, and construction applications.

Wire Strand Core (WSC): This core balances flexibility and strength. It is compact and lightweight, making it suitable for control cables, small winches, and mechanical movement systems.

Tip: If you need maximum flexibility, select a fiber core. For heavy-duty tasks that demand strength and durability, choose a steel core like IWRC or WSC.

The choice of core material directly affects how your wire rope performs. Fiber cores enhance flexibility but reduce overall strength. Steel cores, such as IWRC and WSC, provide superior strength and crush resistance, making them ideal for demanding applications.

When you select wire rope from Powerful Machinery, you receive products engineered with the right combination of basic components for your specific needs. The company’s commitment to quality ensures that every wire rope delivers reliable performance, whether you require flexibility, strength, or a balance of both.

Wire Rope Materials & Grades

Steel Wire Rope Materials

You depend on the right materials to ensure the performance and safety of your wire rope components. Powerful Machinery uses high-carbon steel and stainless steel in its steel wire rope products.

High carbon steel delivers excellent strength and tensile properties, making it ideal for heavy lifting and demanding environments. Stainless steel, such as grades 302, 304, and 316, offers superior corrosion resistance.

Grade 304 stands out for its lower carbon content, which increases its resistance to rust. Grade 302 is harder but less resistant to corrosion.

Galvanized steel wire rope uses carbon steel with a zinc coating. This zinc layer acts as a barrier, protecting the rope from oxidation and environmental damage. You benefit from increased durability and a longer service life, especially in marine or outdoor settings.

Property | High-Carbon Steel | Stainless Steel |

|---|---|---|

Strength | Higher due to more carbon content | Lower compared to high-carbon steel |

Hardness | Higher hardness | Relatively softer |

Ductility | Lower ductility | Better ductility and toughness |

Corrosion Resistance | Poor corrosion resistance | Good corrosion resistance |

Core Material Options

The core you select for your steel wire rope has a direct impact on its performance. You can choose from three main types: fiber core, independent wire rope core, and wire strand core. Fiber core gives you flexibility and absorbs shock, making it suitable for light-duty tasks.

Independent wire rope core provides maximum strength and durability, which is essential for heavy-duty lifting and high-tension applications. Wire strand core balances flexibility and strength, making it a versatile choice for general use.

If you work in marine environments, you should consider how environmental factors affect durability. Fiber core ropes offer flexibility, but exposure to saltwater can reduce their lifespan. Steel core ropes, especially those with an independent wire rope core, provide better resistance to harsh conditions and maintain their strength over time.

Grades and Finishes

You need to understand the grades of wire rope to select the right product for your job. Common steel grades include Improved Plow Steel, Extra Improved Plow Steel, and Extra Extra Improved Plow Steel. These steel grades determine the tensile strength and load capacity of your wire rope.

For example, Improved Plow Steel offers tensile strengths from 223 to 258 ksi, while Extra Improved Plow Steel ranges from 245 to 284 ksi.

Finishes also play a key role. Bright wire rope has no protective coating and suits indoor or dry environments. Galvanized finishes use a zinc coating to protect against corrosion, making them ideal for outdoor or marine use.

The zinc coating meets strict ASTM standards and extends the lifespan of your steel wire rope by shielding it from moisture and salt.

Note: Choosing the right combination of steel grades and finishes ensures your wire rope delivers optimal performance and safety in any application.

Wire Rope Constructions & Design

Strand Patterns and Classes

You encounter several strand patterns in wire rope design. Parallel lay strands give you both strength and flexibility, making them a popular choice for lifting and rigging. Spiral ropes feature a non-rotating design, which helps you maintain load stability and control during crane operations.

Stranded ropes consist of multiple layers around a core, offering a balance between flexibility and durability.

Common wire rope constructions include 6×19 and 35Wx7. The 6×19 construction provides a good mix of flexibility and abrasion resistance, making it suitable for general lifting and hoisting.

The 35Wx7 construction features a non-rotating design, which is essential for applications where load rotation can cause safety issues. You use these constructions in cranes, winches, and marine environments.

Powerful Machinery specializes in advanced steel wire rope constructions. You benefit from non-rotating and specialty wire rope designs that deliver enhanced safety and performance in demanding industries.

Core Configurations

Core configurations play a critical role in wire rope design. You choose between fiber core, wire strand core, and independent wire rope core. Fiber core gives you flexibility and shock absorption, which suits light-duty tasks.

Wire strand core offers higher tensile strength and durability. Independent wire rope core provides maximum strength and crush resistance, making it ideal for heavy-duty lifting.

Fatigue resistance depends on core configuration. Increasing the number of outer strands in steel wire rope constructions enhances service life by reducing abrasive wear and lateral notching stresses. You avoid exceeding 45% of ultimate tensile strength to extend rope lifespan and reduce fatigue failures.

Lay Direction and Types

Lay direction affects wire rope performance in hoisting applications. You select the right or left lay based on your equipment and operational needs. The lay direction influences rotation tendency, which can lead to uneven wear and reduced rope life.

It also determines how the load is distributed among the strands, maximizing efficiency and fatigue resistance.

Standard wire rope design uses regular lay for most lifting tasks. You find that non-rotating constructions, such as those offered by Powerful Machinery, minimize rotation and improve safety. Compatibility with elevator components and hoisting systems depends on matching the correct lay direction to your application.

Tip: Always consult with Powerful Machinery’s experts to select the best wire rope design and construction for your specific requirements.

Construction Type | Application | Key Benefit |

|---|---|---|

6×19 | General lifting, hoisting | Flexibility and abrasion resistance |

35Wx7 | Cranes, marine, mining | Non-rotating, enhanced safety |

Spiral Rope | Precision lifting | Load stability, control |

You ensure optimal performance and safety by choosing the right steel wire rope constructions and design features for your industry.

Performance, Lubrication & Application

Lubrication in Wire Rope Design

You rely on proper lubrication to extend the life and safety of wire rope components in rigging and lifting operations. Lubrication reduces friction between wires and strands, which helps prevent internal wear and fatigue failure.

A well-lubricated steel wire rope can last up to three times longer than one without adequate lubrication. You also protect the rope from corrosion and external contaminants, especially in high-cycle applications.

Regular checks and maintenance lower the risk of failure and keep your wire rope slings performing at their best.

Lubricant | Description |

|---|---|

BRILUBE 70 | Medium thixotropic gel for corrosion protection in marine conditions |

BRILUBE 90 | Biodegradable heavy-duty lubricant for sensitive and harsh environments |

Tip: Choose lubricants designed for your environment. Marine applications benefit from corrosion-resistant gels, while heavy-duty lifting may require biodegradable options.

Application Considerations

You must consider several factors when selecting wire rope for rigging and lifting tasks. The working load limit is critical for safety. You need a wire rope that meets industry standards such as OSHA and ASME B30.9. Core type affects flexibility and load-bearing capacity.

Steel wire rope with an independent wire rope core offers maximum strength for heavy-duty applications. Environmental conditions also matter. Galvanized steel wire rope resists corrosion, making it ideal for outdoor and marine settings.

Application-specific requirements determine flexibility, abrasion resistance, and fatigue strength.

Machinery type, such as cranes or winches, influences wire rope diameter and construction.

Environmental factors, like exposure to saltwater or abrasive surfaces, guide your choice of wire rope slings and coatings.

Selecting Powerful Machinery Wire Rope

You benefit from Powerful Machinery’s certified wire rope solutions for construction, marine, and industrial rigging and lifting. Each steel wire rope meets international standards, including ISO 2408, EN 12385, and ISO 9001:2015.

You can customize wire rope slings, strand configurations, and hardware to fit your unique applications. Powerful Machinery offers tailored wire rope components for heavy lifting, ensuring high load capacity, abrasion resistance, and long service life.

Certification/Standard | Description |

|---|---|

ISO 2408 | Wire rope construction and testing requirements |

EN 12385 | European safety and performance standard |

DIN 3060 | German wire rope specifications |

ISO 9001:2015 | Quality management for reliability and safety |

Note: Consult Powerful Machinery’s experts to select a wire rope that matches your working load limit, environmental needs, and rigging and lifting requirements.

Conclusion

You improve workplace safety and equipment reliability when you understand wire rope components, materials, and design. Selecting the right wire rope helps you avoid common failures, as shown below:

Cause | Description |

|---|---|

Overload or Shock Loading | Excess tension breaks. |

Abrasion Breaks | Damage from improper contact with drums and sheaves. |

Corrosion Breaks | Wire erosion from poor lubrication. |

Fatigue Breaks | Cracks from repeated bending. |

Powerful Machinery delivers certified solutions, strict quality standards, and expert support. You can access resources for selection, inspection, and maintenance, ensuring your wire rope matches your industry needs.

Wire Rope Selection Guidelines

Visual Inspection Tips

Defect Management advice

Consult Powerful Machinery for reliable products and expert guidance.

FAQ

What factors should you consider when choosing wire rope for lifting?

You should check load capacity, rope construction, core type, and environmental conditions. Select a wire rope that meets safety standards and matches your application requirements.

How often should you inspect wire rope in heavy-duty operations?

You need to inspect the wire rope before each use. For continuous operations, schedule weekly inspections. Look for broken wires, corrosion, and signs of wear.

What certifications do Powerful Machinery wire ropes carry?

Certification | Description |

|---|---|

ISO 9001 | Quality management |

EN 12385 | European safety |

ISO 2408 | Construction standard |

You receive wire ropes that meet international safety and quality standards.

Can you order custom wire rope configurations from Powerful Machinery?

You can request custom diameters, strand patterns, coatings, and core types. Powerful Machinery engineers wire rope to fit your specific project needs.

How does lubrication affect wire rope lifespan?

Lubrication reduces friction and protects against corrosion. You extend wire rope life and improve safety by using the right lubricant for your environment.