Wire rope grades describe the classification of ropes based on their mechanical properties and construction. You rely on the correct rope grade to ensure reliable performance in rigging tasks.

Rope grade differs from wire tensile strength, as rope grade considers the full rope structure, while tensile strength refers only to the individual wire’s ability to withstand force.

Common wire rope grades like 1×19, 7×7, and 7×19 serve different roles—1×19 offers stiffness for guy wires, 7×7 suits flexible rigging, and 7×19 handles heavy, flexible applications. International standards set clear requirements for rope grade selection, helping you maintain safety and compliance.

Powerful Machinery delivers certified Steel Wire Rope solutions that meet the toughest demands across industries.

Key Takeaways

Understand wire rope grades to ensure reliable performance in rigging tasks. Choose the right grade based on the required breaking strength for your project.

Different wire rope grades serve specific purposes. For example, 1×19 offers stiffness, while 7×19 provides flexibility for heavy applications.

Always check both the rope grade and the wire tensile strength grade. This ensures safety and compliance with international standards.

Consider environmental factors when selecting wire rope. Galvanized ropes resist corrosion, making them ideal for outdoor or marine settings.

Consult experts for custom wire rope solutions. Tailored products can enhance performance and safety for unique project requirements.

Wire Rope Grades Overview

Rope Grade Definition

You need to understand rope grade before selecting the right wire rope for your project. Rope grade refers to the required breaking strength of the entire rope, not just the wires inside.

Industry standards, such as EN 12385-2, define rope grade as a level of breaking force, shown by numbers like 1770, 1960, or 2160. These numbers help you compare ropes and choose the best option for your needs. The table below shows the difference between rope grade and wire tensile strength grade:

Term | Definition |

|---|---|

Rope grade (Rr) | A level of requirement of breaking force designated by a number (e.g., 1770, 1960, 2160). Extract: EN 12385-2 clause 3.10.11 |

Wire tensile grade (R) | A level of requirement of tensile strength of a wire, designated by the lower limit of tensile strength, is used for specifications. Extract: EN 12385-2 clause 3.1.10. |

Wire Rope Grades vs. Wire Tensile Strength

You might wonder how rope grade and wire tensile strength grade differ. Rope grade measures the breaking strength of the whole rope, while wire tensile strength grade focuses on the minimum tensile strength of each wire strand.

The rope’s performance depends on both the rope grade and the wire tensile strength grade. The table below compares common rope grades, their wire tensile strength grade ranges, and hardness:

Rope Grade | Wire Tensile Strength Min. (N/mm²) | Wire Tensile Strength Max. (N/mm²) | Brinell Hardness (HB) | Rockwell Hardness (HRC) |

|---|---|---|---|---|

1570 | 1370 | 1770 | 405/425 | 45 |

1770 | 1570 | 1960 | 445/470 | 49 |

1960 | 1770 | 2160 | 470/480 | 51 |

2160 | 1960 | 2160 | 480/500 | 52 |

Common Grade Types and Standards

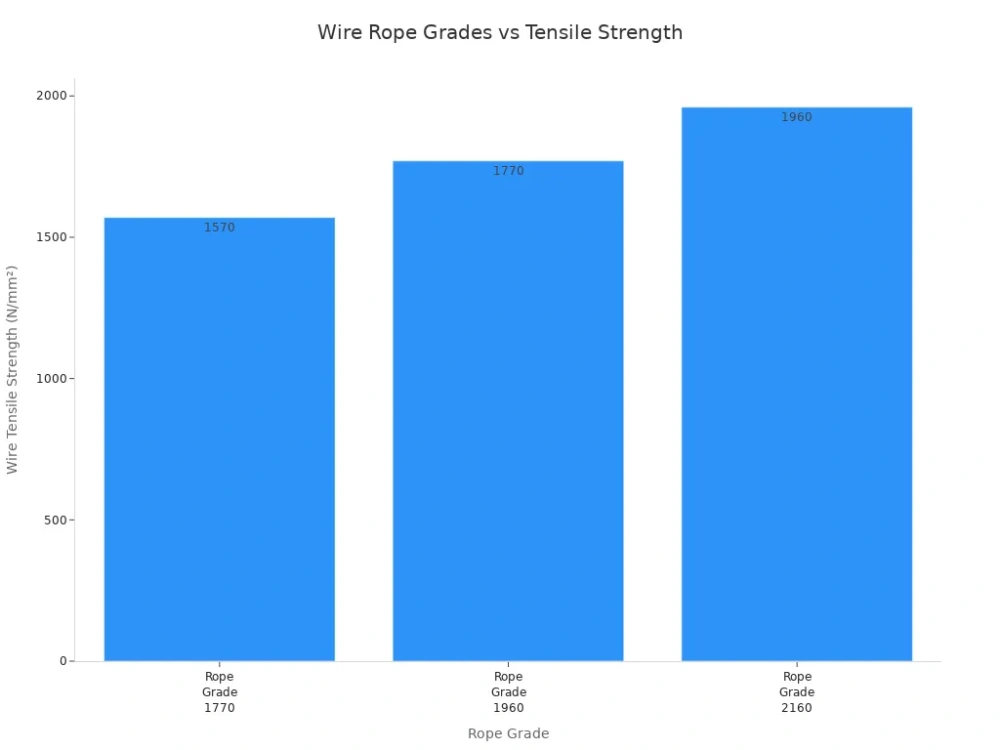

You will see several common wire rope grades in the market, each with its own wire tensile strength grade. The most widely recognized rope grades include 1770, 1960, and 2160. These grades match specific wire tensile strength grades and minimum tensile strength values. The table below summarizes the main types:

Rope Grade | Wire Tensile Strength Grades (N/mm²) |

|---|---|

1770 | 1570 |

1960 | 1770 |

2160 | 1960 |

Another way to classify wire rope grades is by using terms like IPS (Improved Plow Steel), EIPS (Extra Improved Plow Steel), and EEIPS (Extra Extra Improved Plow Steel). Each type covers a range of tensile strength grades and minimum tensile strength values:

Rope Grade | Wire Tensile Strength Guide |

|---|---|

IPS (Improved Plow Steel) | Level 2 or 1570 to Level 4 or 1960 |

EIPS (Extra Improved Plow Steel) | Level 3 or 1770 to Level 5 or 2160 |

EEIPS (Extra Extra Improved Plow Steel) | Level 4 or 1960 to Level 6 or 2160 |

Tip: Always check both the rope grade and the wire tensile strength grade when choosing wire rope for your application. This ensures you meet the required breaking strength and safety standards.

International Rope Grade Standards

EN 12385 Rope Grade Requirements

You need to understand how EN 12385 shapes wire rope selection. This European specification sets strict rules for safety and durability. EN 12385 defines rope grade by breaking force and material specification.

You must choose a wire rope that meets the required safety factors and uses approved steel types. The table below highlights the main requirements:

Requirement | Description |

|---|---|

Safety Factors | Determines the load a rope can safely handle compared to its breaking point. |

Material Specifications | Defines acceptable types of steel and coatings that enhance durability. |

You should always check the rope’s safety factor and material specification before making a decision. These rules help you select wire rope that performs reliably in demanding environments.

ASTM and API Rope Grade Specifications

You will see ASTM specifications and API specifications used worldwide. ASTM specification A1023/A1023M covers mechanical testing for wire ropes. API specification 9A applies to ropes used in oil and gas drilling. Both standards require you to verify rope grade, tensile strength, and construction.

ASTM specification focuses on mechanical properties, while API specification emphasizes performance in harsh conditions. You must review the specification for each project to ensure the wire rope matches the required grade and application.

Certification and Compliance Process

You must follow a strict certification and compliance process to guarantee safety. Manufacturers document every load test and rope specification. Inspectors record details such as rope type, diameter, length, and test procedure. The table below shows what you should expect in a certification report:

Load Test Documentation | Applicable Standards for Load Testing |

|---|---|

Manufacturer’s details | EN 12385-1: European standard for steel wire rope safety and testing |

Rope type and construction | ISO 3108: Methods for determining breaking force |

Diameter and length | ASTM A1023/A1023M: American standard for mechanical testing |

Test type and procedure | ASME B30.9: U.S. safety standard for slings, including wire rope |

Proof load or breaking load achieved | Lloyd’s Register / DNV / ABS: Marine and offshore classification bodies with specific testing protocols |

Pass/fail results | |

Date and location of test | |

Signatures of inspectors or certifying bodies |

You can trust Powerful Machinery to deliver wire rope that meets every specification and passes all compliance checks. The company holds certifications from ISO, TUV Rheinland, EURO CERT, and other international standards organizations.

You benefit from products that meet the highest safety and performance specifications, ensuring reliable operation in every application.

Note: Always request certification documents for each wire rope batch. This step confirms compliance with international standards and guarantees safe use in your project.

Wire Rope Construction Essentials

Wire Rope Construction Types

You encounter several wire rope construction types, each designed for specific performance needs. The way wires and strands are arranged impacts how the rope behaves under load. The table below summarizes the most common types and their mechanical properties:

Wire Rope Type | Characteristics | Mechanical Properties Impact |

|---|---|---|

Regular Lay | Wires and strands wind in opposite directions. | Simplifies splicing, reduces rotation under load, predictable lifting behavior. |

Lang Lay | Wires and strands twist in the same direction, running nearly parallel. | Enhances wear life and lateral flexibility, ideal for repeated bending. |

Alternate Lay | Combines both regular and Lang lays. | Used for specialized applications needing unique load distribution or flexibility. |

You select the right type based on your application’s requirements for strength, wear resistance, and flexibility. Wire rope classifications help you match the construction to your project’s demands.

Impact on Wire Rope Strength and Flexibility

Wire rope construction directly influences both strength and flexibility. The arrangement and size of wires within the rope determine how it performs in different environments.

For example, a 6×19 rope offers high surface wear resistance but less flexibility, making it suitable for winch lines and haulage. A 6×37 rope provides greater flexibility, which is essential for applications involving frequent bending over sheaves.

Wire Rope Class | Characteristics | Best Use Cases |

|---|---|---|

6×19 | High surface wear resistance, less flexibility | Winch lines, drag lines, haulage operations |

6×26 | Balanced abrasion resistance and flexibility | Crane hoist lines, general lifting operations |

6×37 | High flexibility, suitable for frequent bending | Applications with repeated bending over sheaves |

Resistance to wear means the rope can handle scraping and surface contact.

Flexibility allows the rope to bend repeatedly without breaking.

Larger outer wires increase abrasion resistance but reduce flexibility. Smaller wires improve flexibility but wear faster.

You must balance these factors to ensure the rope delivers the required strength and service life for your application.

Powerful Machinery Steel Wire Rope Features

Powerful Machinery offers advanced steel wire rope construction that meets the highest industry standards. You benefit from multiple configurations, such as 35W×7, 18×19, and 8×55SWS, each engineered for specific strength and flexibility needs.

The non-rotating design prevents twisting and kinking, which increases safety and extends the rope’s lifespan. High-grade steel and innovative manufacturing processes provide excellent resistance to abrasion and corrosion.

Technological advancements, like precision-controlled construction and improved coatings, further enhance durability and load capacity. You can rely on Powerful Machinery’s wire rope for consistent performance in demanding environments.

Tip: Choose a wire rope construction that matches your project’s load, bending, and environmental requirements. Powerful Machinery’s expert team can help you select the best configuration for maximum strength and flexibility.

Wire Rope Finishes

Bright Finish Characteristics

You often encounter bright-finish wire ropes in heavy-duty environments. These ropes use uncoated wire, which gives them a clean, metallic appearance. Bright finish wire ropes deliver high strength and flexibility, making them suitable for demanding applications.

Their design minimizes rotation under load, which helps maintain stability during lifting operations. The table below outlines key characteristics and common uses:

Characteristic | Description | Application Examples |

|---|---|---|

Made from uncoated wire | Constructed without any protective coating | Offshore pedestal cranes, crawler cranes |

Rotation resistance | Engineered to reduce twisting and spinning under heavy loads | Heavy-duty lifting tasks |

Flexibility and strength | Provides both flexibility and high breaking strength | Resistance to cabling in tough settings |

Bright finish wire rope works well in indoor or controlled environments where corrosion risk is low.

Galvanized Finish Benefits

You gain several advantages when you select galvanized wire ropes. These ropes feature a zinc coating that provides reliable corrosion protection, especially in outdoor or marine settings.

Galvanized wire ropes resist rust and extend service life, but you must inspect and maintain them regularly. Consider the following benefits:

Zinc coating shields the rope from moisture and chemicals.

Lifespan ranges from several years in harsh marine conditions to up to 20 years indoors.

Longevity depends on environment, coating quality, and maintenance.

In mild indoor settings, galvanized wire rope can last 10-20 years without significant rust.

In harsh outdoor conditions, rust may develop in a few years unless you use extra protective measures.

You should choose galvanized wire ropes for projects exposed to weather or corrosive elements.

Powerful Machinery’s Corrosion-Resistant Solutions

You can rely on Powerful Machinery for advanced corrosion protection in wire rope finish options. The company uses environmentally friendly coatings like PVC and TPU nylon to boost durability and reduce pollution.

These coatings enhance flame retardancy and minimize smoke emissions, improving safety for both personnel and the environment. Powerful Machinery adopts energy-efficient production methods and incorporates recycled materials, aligning with green manufacturing standards.

You benefit from wire ropes that meet strict environmental regulations and deliver long-lasting performance in challenging conditions.

Tip: Select wire rope finishes that match your project’s environment and safety requirements. Powerful Machinery’s expert team can help you choose the best solution for maximum durability and compliance.

Selection Criteria for Rigging

Assessing Wire Rope Strength and Load Requirements

You must start every rigging project by evaluating wire rope strength and load requirements. The right rope grade depends on the expected working load and the type of rigging operations you plan to perform.

You need to know the maximum load the wire rope will carry, the frequency of lifts, and the nature of the materials being moved. Accurate assessment ensures you select wire rope grades that match your project’s demands.

To determine wire rope strength, you use several methods:

Method | Description |

|---|---|

Tensile Testing | Pull-to-break tests measure breaking forces and elongation. |

Fatigue Life Prediction | Estimates fatigue life using wear and stress factors. |

Statistical Modeling | Analyzes experimental results to estimate tensile strength and breaking force. |

You also rely on techniques such as the Manson universal slope method, median method, and fatigue S-N curve method to predict how wire rope grades will perform over time. These approaches help you choose a rope grade that delivers the required strength for your rigging operations.

Tip: Always verify the working load and expected stress before selecting a wire rope. This step prevents overload and ensures long-term reliability.

Safety Factors and Environmental Considerations

You must consider safety factors and environmental conditions when choosing wire rope grades for rigging. The safety factor represents the ratio between the wire rope strength and the maximum working load. You select a rope grade with a safety factor that meets or exceeds industry standards, protecting both personnel and equipment.

Environmental conditions play a major role in wire rope selection. You need to assess exposure to moisture, chemicals, and temperature extremes. Corrosion resistance becomes critical in marine or outdoor settings.

You must also plan for long-term maintenance, including careful offloading, dry storage, and regular inspections for corrosion or wear. Pre-installation checks and proper installation techniques prevent kinks and misalignment.

Running-in at reduced speeds allows the rope to adjust, while ongoing maintenance and timely replacement keep your rigging operations safe and efficient.

Note: Regular inspection and maintenance extend the service life of your wire rope and reduce lifecycle costs.

Choosing the Right Rope Grade

You select the right rope grade by balancing load, strength, environment, and compliance. The following table summarizes the main criteria:

Criteria | Description |

|---|---|

Load Type and Weight | Match the rope grade to the nature and weight of the load. |

Environment | Choose corrosion-resistant grades for harsh or outdoor settings. |

Frequency and Intensity of Use | Opt for durable wire rope grades for high-cycle rigging operations. |

Compliance and Safety Standards | Ensure all wire rope grades meet legal and safety requirements. |

You must analyze each factor to ensure the wire rope grade delivers the required strength and reliability. For example, lifting fragile architectural panels requires a rope grade that prevents damage and supports precise handling.

High-frequency lifts demand wire rope grades with superior fatigue resistance. When you select the correct rope grade, you increase lifting efficiency, reduce setup time, and boost crew confidence.

Tip: Always match the rope grade to your specific rigging application. This step guarantees optimal strength and safety.

Consulting Powerful Machinery for Custom Solutions

You benefit from consulting Powerful Machinery when you need tailored wire rope grades for complex rigging operations. The company offers custom engineering services that address unique load, strength, and environmental requirements.

You work directly with experts who analyze your project and recommend the best rope grade, configuration, and finish.

Powerful Machinery’s steel wire rope features advanced non-rotating designs, high tensile strength, and multiple configurations such as 35W×7, 18×19, and 8×55SWS. You receive products that meet strict safety standards and deliver consistent strength in demanding environments.

The team guides you through every step, from initial assessment to final installation, ensuring your rigging operations run smoothly.

Callout: Reach out to Powerful Machinery for expert advice and custom wire rope grades. You gain access to certified products and engineering support that maximize strength, safety, and efficiency.

Application Scenarios and Examples

Comparing Rope Grades in Practice

You encounter wire rope grades in a wide range of applications. Each grade delivers specific strength and durability for its intended use. In mining, you rely on improved plow steel and extra improved plow steel grades for hoists, elevators, and haulage cables.

These grades provide the strength needed for drilling and lifting heavy loads. In oil and gas, you select wire ropes that withstand high pressure and extreme temperatures, ensuring reliable strength during drilling and mooring.

Marine operations demand corrosion-resistant ropes for mooring and towing, where strength and longevity are critical. Construction projects use wire ropes for general lifting applications, hoisting, and rigging, driven by urbanization and infrastructure growth.

Tip: Always match the wire rope grade to your application’s load and environment. This approach maximizes strength and service life.

Powerful Machinery Steel Wire Rope in Real-World Use

You see Powerful Machinery steel wire rope in demanding environments worldwide. Drilling rig lines support heavy equipment and dynamic movements, relying on superior strength and a non-rotating design.

Offshore platforms use these ropes for anchoring, lifting, and towing, where corrosion resistance and strength are essential. Suspension bridges depend on steel wire rope for stability and support, handling immense loads and ensuring safety for vehicles and pedestrians.

In general lifting applications, tower cranes and hoisting equipment use Powerful Machinery wire rope to lift heavy materials with consistent strength. Cable cars and funiculars transport passengers safely on steep inclines, while logging operations use these ropes for skidding and yarder systems, moving felled trees across rough terrain.

Application Scenario | Wire Rope Role | Key Feature |

|---|---|---|

Drilling Rig Lines | Support heavy equipment | High strength |

Offshore Platforms | Anchoring, lifting, towing | Corrosion resistance |

Suspension Bridges | Structural support | Stability and strength |

Tower Cranes | General lifting applications | Load-bearing strength |

Logging Operations | Skidding and yarding | Durability |

When to Opt for Custom or High-Performance Solutions?

You should consider custom or high-performance wire rope solutions when standard grades do not meet your project’s requirements. Construction, mining, transportation, and aerospace industries often need specialized assemblies to handle high pressure, stress, or unique environmental challenges.

Custom wire ropes provide longer lifespan and lower maintenance costs, making them cost-effective for high-load applications. In oil and gas, you rely on these solutions to endure extreme conditions and maintain strength under high pressure and temperature.

Transportation projects, such as suspension bridges and elevators, require wire ropes designed for reliable support and stability.

Custom wire rope assemblies deliver strength for critical operations.

High-performance solutions ensure safety and efficiency in specialized scenarios.

You benefit from tailored products that match your exact load and environmental needs.

Note: Consult Powerful Machinery for custom engineering support. You gain access to wire rope solutions that maximize strength, reliability, and cost-effectiveness for your most demanding applications.

Conclusion

You play a key role in safe rigging by understanding wire rope grades, standards, construction, and finishes. Recent industry changes focus on safety and performance, especially as automated cranes and advanced platforms become common.

Powerful Machinery’s certified steel wire rope stands out for high safety, ISO 9001:2015 compliance, and strong customer satisfaction.

Why Choose Powerful Machinery? | What You Gain |

|---|---|

Over 20 years of expertise | Custom-engineered solutions |

Rigorous quality assurance | Reliable, certified products |

For tailored solutions and expert support, explore Powerful Machinery’s full range of steel wire ropes at qdpowerful.com.

FAQ

What does wire rope grade mean for my project?

Wire rope grade shows the minimum breaking strength of the rope. You use this number to match the rope to your load and safety needs. Always check the grade before you start any rigging job.

How do I choose between bright and galvanized wire rope?

You select bright wire rope for indoor or dry settings. You choose galvanized wire rope for outdoor or marine use. Galvanized ropes resist rust and last longer in harsh environments.

Why should I consider a non-rotating wire rope?

You pick a non-rotating wire rope when you need stability during lifting. This design prevents twisting and kinking. You get safer and smoother operations, especially for cranes and hoists.

Does Powerful Machinery provide custom wire rope solutions?

Yes. You can request custom-engineered wire rope from Powerful Machinery. The team will help you select the right grade, construction, and finish for your unique project needs.