Choosing between a wire rope vs chain sling for lifting and rigging depends on several critical factors. You need to match the sling to your specific needs to ensure safety and efficiency. Industry professionals recommend that you focus on the following:

Weight and strength of the load

Sling flexibility for adjusting the center of gravity

Temperature limits for the work environment

You should also consider frequency of use, safety requirements, cost, and the exact application. Powerful Machinery delivers proven expertise and certified solutions for every lifting challenge.

Key Takeaways

Consider the load’s weight and shape when choosing a sling. Chain slings excel with heavy loads, while wire rope slings offer flexibility for various applications.

Evaluate the environment where the sling will be used. Chain slings perform well in extreme temperatures and harsh conditions, while wire rope slings are ideal for corrosive environments.

Think about how often you will use the sling. Chain slings last longer and can be repaired, making them cost-effective for frequent use. Wire rope slings may be cheaper initially, but require more maintenance.

Always inspect slings before each use. Look for signs of wear, damage, or corrosion to ensure safety and compliance with industry standards.

Match the sling type to your specific needs. Consult with experts to find the best solution for your lifting challenges, ensuring safety and efficiency.

Quick Comparison

Wire Rope vs Chain Sling

When you compare wire rope vs chain sling, you see clear differences in how each performs for lifting and rigging. The right choice depends on your priorities for weight, flexibility, durability, and repair options.

Here is a quick comparison table to help you decide:

Feature | Chain Slings | Wire Rope Slings |

|---|---|---|

Weight | Very heavy | Heavy |

Flexibility | Flexible design | Less flexible |

Durability | Withstands impact, extreme temperatures, chemicals, and UV rays | Rugged and durable, but can be damaged by kinking or crushing |

Repairability | Replace individual legs or links; can be load tested and re-certified | Limited repair options |

Cost (example) | As low as $79.17 | Varies by size and type |

You will notice that chain slings offer excellent durability. You can use them in harsh environments, including those with chemicals or high temperatures. If a leg or link gets damaged, you can repair it and return the sling to service after testing. This makes chain slings a reliable choice for many heavy-duty applications.

Wire rope slings also provide strong performance. They are rugged and handle heavy loads well. However, they can be less flexible and may suffer damage from kinking or crushing if not handled properly.

Tip: Always consider the specific needs of your lifting operation. Think about the environment, the type of load, and how often you will use the sling.

When you weigh all these factors, you can make a more informed decision for your lifting and rigging needs.

Wire Rope Slings

What is a Wire Rope Sling?

You use a wire rope sling when you need a strong, flexible tool for lifting and rigging. Manufacturers create these slings by twisting multiple wire strands around a steel or fiber core. You can find wire rope slings in single-leg or multi-leg assemblies.

This construction gives you a reliable option for handling heavy loads in demanding environments.

Features and Pros/Cons

Wire rope slings stand out for their unique combination of strength and flexibility. You benefit from their ability to handle abrasive surfaces and hot objects. The intricate woven structure makes them less likely to break and helps them resist kinking.

You can reuse the main chain and hook even if the wire rope itself gets damaged.

Wire rope slings are popular due to their strength and flexibility, but they come with challenges such as low strength-to-weight ratios and inspection difficulties that can jeopardize safety.

Here is a quick overview:

Advantages | Disadvantages |

|---|---|

Strong and flexible | Low strength-to-weight ratio |

Abrasion and kink resistant | Difficult to inspect |

Can lift hot objects | Cannot be repaired if damaged |

Reusable components | Temperature limits for some types |

You should also know that wire rope slings are affordable and easy to trace with serial identification. However, you must use the right size hooks and apply specific lubricants after initial wear.

Best Uses

You will find wire rope slings in many industries because of their versatility and durability. Common applications include:

Cranes and hoists for lifting operations

Construction and infrastructure projects, such as suspension bridges

Marine and shipping for mooring and rigging

Mining and drilling for underground lifting

Elevators and lifts in vertical transport

Logging and forestry for pulling and securing loads

When you compare wire rope vs chain slings, wire rope slings offer a practical solution for many heavy lifting tasks. Powerful Machinery supplies high-quality wire rope slings that meet strict international standards. You can trust their products for safety and performance in any industrial setting.

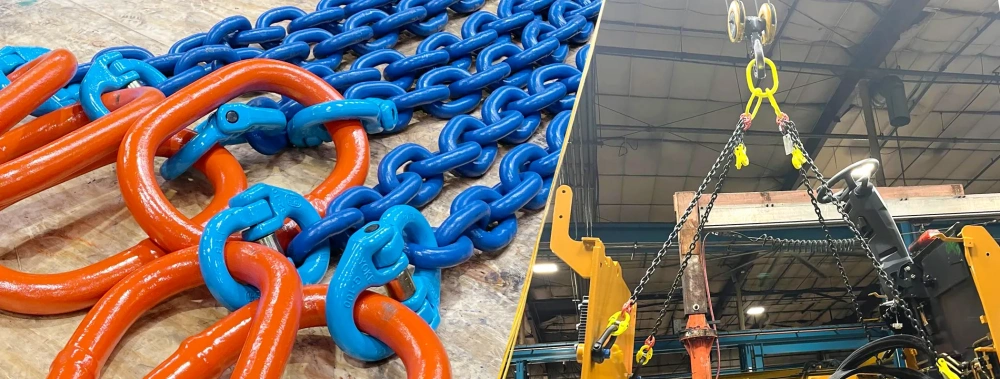

Chain Slings

What are Chain Slings?

You use chain slings when you need a lifting solution that delivers unmatched strength and reliability. Manufacturers craft these slings from high-strength alloy steel, ensuring they handle heavy loads in demanding environments.

Chain slings come in several grades, such as Grade 80 and Grade 100, which comply with international safety standards. You can select from different configurations to match your lifting requirements.

Characteristic/Type | Description |

|---|---|

Material | Made from high-strength alloy steel for durability and safety in load handling. |

Grades | Available in Grade 80, Grade 100, and Grade 120, complying with international standards. |

Applications | Used in construction, manufacturing, and logistics for lifting heavy items like steel beams. |

Sling Configuration | Selection depends on load weight, shape, and dimensions; multi-leg slings are used for heavy loads. |

Environmental Considerations | Performance is affected by temperature, chemicals, and abrasion; specific materials are required for certain conditions. |

Powerful Machinery offers a full range of chain slings, including single, double, triple, and quadruple leg designs. Each sling is engineered for maximum safety and performance.

Features and Pros/Cons

Chain slings stand out for their durability and adaptability. You can use them in extreme temperatures, from -40 °F to 400 °F, and in environments with chemicals or abrasive materials. Their robust construction allows for easy repair and re-certification, extending their service life.

Advantages:

Withstand harsh operating conditions

Function in extreme temperatures

Easy to adjust for various lifting needs

Highly durable and resistant to impacts, cuts, and chemicals

Long service life and simple inspection

Cons:

The heaviest type of lifting sling, which can make handling more difficult

May damage sensitive loads due to weight and rigidity

You can choose between welded and mechanical chain slings. Welded types offer superior durability, while mechanical types allow for easier on-site repairs.

Best Uses

You will find chain slings in industries where strength and reliability are critical. They excel in heavy-duty lifting, overhead rigging, and extreme conditions. Construction, marine, and manufacturing sectors rely on chain slings for moving steel beams, machinery, and other heavy items.

Industry/Environment | Reason for Use |

|---|---|

Heavy-duty lifting | Strength and durability |

Overhead lifting | Tailored for rigging applications |

Extreme conditions | Heat-resistant and abrasive capabilities |

When you compare wire rope vs chain sling, chain slings provide superior performance in harsh environments. Powerful Machinery’s certified chain slings deliver the flexibility and safety you need for the toughest lifting challenges.

Key Factors

Load and Application

When you select a sling for lifting and rigging, you must first consider the type and weight of the load. Chain slings excel with heavy loads and sharp-edged materials because of their durability. Wire rope slings offer versatility for many applications, including those requiring flexibility and abrasion resistance.

The Working Load Limit (WLL) determines the maximum static load a sling can safely carry. For wire rope slings, the industry standard design factor is 5:1. If a wire rope has a minimum breaking strength of 100,000 lbs, its WLL is 20,000 lbs.

Chain slings provide reliable performance for heavy-duty lifting, especially when you need to move steel beams or machinery.

Wire rope slings adapt well to loads with irregular shapes or surfaces, making them suitable for construction, marine, and transportation projects.

Powerful Machinery offers custom-engineered wire rope and chain sling solutions. You can choose the right configuration and grade to match your specific lifting sling requirements.

Environment

The environment plays a critical role in your choice between wire rope vs chain sling. You must evaluate temperature, corrosion risk, and exposure to chemicals.

High temperatures can damage steel, changing its temper and reducing load capacity.

Corrosion causes rust and pitting, which reduces wire diameter and weakens the sling.

Both wire rope and chain slings have defined temperature tolerances. Exceeding these limits lowers their rated capacity.

Alloy chain slings maintain structural integrity in extreme heat and resist chemical hazards.

Wire rope slings feature coatings that provide excellent corrosion resistance, making them ideal for outdoor and marine use.

In corrosive environments, wire rope slings require regular lubrication to prevent rust.

Sling Type | Maintenance Requirement in Corrosive Environments |

|---|---|

Wire Rope Slings | Requires lubrication during service life to prevent rusting or corrosion. |

You should select the sling material and grade based on your worksite’s environmental conditions. Powerful Machinery supplies rigging hardware designed for harsh climates and demanding industrial settings.

Frequency and Maintenance

How often you use a sling affects its lifespan and safety. Frequent use leads to accelerated wear and tear, while infrequent use can extend service life if you store and maintain the sling properly.

The lifespan of wire rope slings ranges from 5 to 10 years under optimal conditions.

Chain slings can last 10 years or longer with proper care.

Exposure to harsh elements shortens the lifespan of wire rope.

Regular inspections are essential for both wire rope and chain slings. You must document periodic inspections according to ASME B30.9 standards and retain records.

Service Condition | Inspection Frequency |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

Normal service requires yearly inspections.

Severe service calls for monthly or quarterly checks.

Special service needs inspection intervals are set by a qualified person.

Powerful Machinery guides inspection schedules and maintenance practices. You can rely on their expertise to maximize the safety and longevity of your rigging hardware.

Cost

Cost is a major factor in choosing between wire rope slings and chain slings. You must evaluate both initial purchase price and long-term maintenance expenses.

Sling Type | Initial Cost | Long-term Maintenance Cost |

|---|---|---|

Chain Slings | Higher | Cost-effective due to durability and repairability |

Wire Rope Slings | Generally cheaper | Higher due to shorter lifespan and maintenance needs |

Chain slings have a higher initial cost but offer cost-effective long-term value because you can repair and recertify them.

Wire rope slings are generally cheaper to purchase but require more frequent replacement and maintenance.

Budget constraints influence your selection. You should consider the total cost of ownership, including maintenance intervals and replacement cycles.

Powerful Machinery helps you balance cost, safety, and performance. Their custom solutions ensure you get the most value from your investment in lifting and rigging hardware.

Tip: Always match your sling choice to your project’s load, environment, usage frequency, and budget. Consult Powerful Machinery for tailored recommendations that meet your lifting sling needs.

Lifting and Rigging Scenarios

When to Use Wire Rope Slings?

You should choose a wire rope sling when you need a balance of strength and flexibility. These slings work well for lifting loads with rough or sharp edges. In construction, you might use wire rope slings to move steel girders or beams.

For example, on a recent high-rise project, crews used wire rope slings to lift 10-ton steel girders. The slings provided the strength and durability needed for safe and efficient operations. You can also use wire rope slings in marine environments, where corrosion resistance is important.

They handle outdoor conditions and resist abrasion, making them ideal for mooring or securing cargo on ships. In transportation, wire rope slings help you load and unload heavy machinery or containers.

Note: Wire rope slings offer excellent performance for jobs that require both flexibility and ruggedness. You can rely on them for many lifting and rigging tasks, especially when you need a lifting sling that adapts to different shapes and surfaces.

When to Use Chain Slings?

You should select a chain sling when you face the toughest lifting challenges. Chain slings excel in environments with extreme temperatures, chemicals, or heavy impacts. In construction, you often use chain slings to lift concrete blocks, steel plates, or large equipment.

Their robust design allows you to adjust the length and configuration for each lift. In marine operations, chain slings handle anchor chains, mooring lines, and heavy cargo.

They resist corrosion and wear, even in saltwater. For transportation, chain slings help you secure and move oversized loads, such as industrial machinery or vehicles.

Powerful Machinery has supported clients in the construction, marine, and transportation industries worldwide. You benefit from their certified rigging hardware and custom-engineered solutions. Their products ensure you have the right sling and rigging hardware for every scenario.

How to Decide?

Checklist

Before you select a sling for your next project, review this checklist. It covers the most important factors that affect safety, performance, and cost. Use it to compare chain slings and wire rope slings side by side.

Feature | Chain Slings | Wire Rope Slings |

|---|---|---|

Strength | Good strength, but less than chains | |

Heat Resistance | High heat resistance | Limited heat resistance |

Durability | Highly durable for heavy-duty use | Less durable under extreme conditions |

Configurations | Multiple configurations available | Limited configurations |

Load Stability | Excellent load stability | Moderate load stability |

You should also ask yourself these questions:

What is the weight and shape of the load?

Will you lift in high temperatures or around chemicals?

Do you need a sling that can be repaired and re-certified?

How often will you use the lifting sling?

What are your safety and inspection requirements?

Does your project require specific rigging hardware or custom attachments?

Tip: Always perform a thorough inspection before each lift. Check for signs of wear, damage, or improper storage. Proper maintenance and storage extend the life of your rigging hardware and help prevent accidents.

Decision Flow

Use this simple decision flow to guide your choice. Follow each step to match the right sling to your lifting needs.

Identify the Load

Is the load extremely heavy or has sharp edges?

→ Choose a chain sling.Is the load lighter or requires more flexibility?

→ Consider a wire rope sling.

Assess the Environment

Will you lift in high heat, around chemicals, or in harsh outdoor conditions?

→ Chain slings offer better resistance.Will you work in a marine or corrosive environment?

→ Wire rope slings with proper coatings may suit your needs.

Check Frequency of Use

Will you use the sling daily or for repeated heavy lifts?

→ Chain slings provide longer service life and easy repair.Will you use the sling occasionally or for lighter tasks?

→ Wire rope slings can be a cost-effective option.

Review Safety and Inspection Needs

Do you need a sling that can be easily inspected and re-certified?

→ Chain slings allow for individual leg or link replacement.Do you need a sling with traceable identification and easy documentation?

→ Wire rope slings often come with serial numbers for tracking.

Consider Rigging Hardware Compatibility

Does your lift require specific hooks, shackles, or master links?

→ Both sling types can be customized, but chain slings offer more configuration options.

Note: Never overload your sling or use it outside its rated capacity. Always match the sling and rigging hardware to the exact requirements of your lift.

If you face a complex lifting scenario or have doubts about the best choice, consult with the experts at Powerful Machinery. Their team can help you select the right lifting sling and rigging hardware for your unique application. You gain access to certified products, custom solutions, and decades of industry experience.

Conclusion

Choosing between wire rope and chain slings depends on your load, environment, and safety needs. Always match sling material to your application and never exceed the Working Load Limit. The table below highlights key industry guidelines:

Key Takeaway | Description |

|---|---|

Match the sling material | Always match the sling material to the load and environment. |

Inspection | Inspect all slings for rigging before each use without exception. |

Certification | Verify annual certification and traceability for each sling. |

Certified lifting solutions from Powerful Machinery meet international standards and deliver reliable performance. You gain peace of mind knowing your rigging hardware is tested and trusted by professionals worldwide.

FAQ

What is the main difference between wire rope slings and chain slings?

Wire rope slings offer flexibility and abrasion resistance. Chain slings provide superior strength and durability in harsh environments. You should choose based on your load type, working conditions, and frequency of use.

How do you inspect lifting slings for safety?

You need to check for visible damage, wear, corrosion, and deformation before each use. Follow industry standards for inspection frequency. Always document your inspections and remove any sling that shows signs of failure.

Can you repair a damaged sling?

You can repair chain slings by replacing individual links or legs. Wire rope slings usually require full replacement if damaged. Always have repairs and re-certifications performed by qualified professionals.

Which sling type works best in high-temperature environments?

Chain slings handle extreme temperatures better than wire rope slings. You should select alloy steel chain slings for lifting tasks in hot or chemically aggressive settings.

How do you choose the right sling configuration?

You need to match the sling configuration to your load’s weight, shape, and lifting points. Powerful Machinery offers single, double, triple, and quadruple leg chain slings to fit your specific requirements.