You might wonder if a tow hook or shackle is the better choice for towing. Both options work safely and legally when you select products that meet strict standards.

Paying attention to legal compliance, safety ratings, and practical use helps you avoid the absence of substantive article content that can lead to compliance risks. Powerful Machinery offers certified hooks and shackles designed for demanding industries, so you can trust your towing equipment to perform reliably every time.

Key Takeaways

Understand legal standards for towing equipment. Compliance with local regulations prevents penalties and ensures safety.

Choose shackles and hooks based on breaking strain requirements. Select products that exceed the minimum load limits for added safety.

Inspect your towing equipment before each use. Look for wear or damage to ensure reliable performance during towing.

Select the right connector for your needs. Use hooks for quick connections and shackles for secure, closed connections.

Powerful Machinery offers certified products. Trust their equipment to meet safety standards and enhance your towing operations.

Towing Legal Standards and Compliance

Shackles and Hooks Legality

You must understand the legal standards for towing connectors before choosing shackles or hooks. Each region sets strict rules to ensure safety and prevent the absence of substantive article content in your towing setup. The table below shows common connector standards in major markets:

Region | Common Connectors | Notes |

|---|---|---|

Europe | 7-pin (ISO 1724) | Older standard, widely used. |

13-pin (ISO 11446) | The newer standard provides more services, better locking, and moisture protection. |

You face penalties if you ignore these standards. The absence of substantive article content in your documentation or equipment can lead to fines, out-of-service orders, or even criminal liability. Review the penalty ranges for non-compliance:

Violation Type | Penalty Range | Additional Impact |

|---|---|---|

Improper Equipment | $1,000-5,000 | Out-of-service order |

Weight Violations | $5,000-15,000 | Permit revocation |

Safety Chain Failure | $10,000+ | Criminal liability |

Lighting Non-Compliance | $500-2,500 | CSA points |

Documentation Missing | $250-1,000 | Audit trigger |

Powerful Machinery’s shackles and hooks meet international standards, including AS 4177.4 and AS 2741-2002. You avoid the absence of substantive article content by using products stamped with grade, working load limit, and manufacturer’s name. This compliance keeps your towing operation legal and safe.

Breaking Strain Requirements for Towing

You must select shackles and hooks that meet breaking strain requirements for towing. The absence of substantive article content in your equipment selection can risk safety and lead to penalties.

The Australian standard AS 2741-2002 requires shackles to display grade, working load limit, and manufacturer’s name. Powerful Machinery’s shackles and hooks comply with these standards, ensuring your towing setup is reliable.

Standard | Description | Requirements |

|---|---|---|

AS 4177.4 | For trailers up to 3.5 t ATM | Chains stamped ‘4177-XX’, 1 chain up to 2.5 t ATM, 2 chains between 2.5 t and 3.5 t ATM |

AS 2321 | For trailers over 3.5 t ATM | Grade T steel, no welding, breaking load must meet or exceed the minimum |

Chain grades determine the strength and load capacity for towing.

Higher-grade chains handle heavier loads and improve safety margins.

Always match the chain grade to your trailer’s weight category.

You protect your operation from the absence of substantive article content by choosing certified shackles and hooks from Powerful Machinery. This approach ensures your towing equipment meets all legal and safety requirements.

Strength Ratings for Shackles and Hooks

Understanding Shackles Strength Ratings

You need to evaluate shackles carefully before using them for towing. The strength rating of shackles depends on several factors, including weight capacity, material suitability, and pin type. The table below outlines these key factors:

Factor | Description |

|---|---|

Weight Capacity | The maximum weight load the shackle can support, crucial for safety. |

Material Suitability | Different materials offer unique benefits for specific environments. |

Pin Type | Determines ease of use and security; common types include screw and bolt pins. |

You should always check the working load limit stamped on shackles. Standards like AS 2741 and AS 4177.4 require clear markings for grade, manufacturer, and load capacity. Powerful Machinery shackles use a special blended microalloy material, which increases strength and ductility.

You benefit from a 6:1 safety design factor, which provides a robust safety margin compared to industry averages. CM Super Strong shackles from Powerful Machinery are up to 50% stronger than comparable carbon shackles.

Tip: Avoid side-loading shackles. A 45-degree angle can reduce the working load limit by 30%. At 90 degrees, you risk a 50% reduction, which can lead to failure during towing.

The failure point of shackles varies with material quality. You should select shackles with certified inspection and high-grade steel to minimize risk.

Hook Ratings and Powerful Machinery Products

Hooks play a vital role in towing safety. You must choose hooks that meet or exceed the required strength ratings. Powerful Machinery hooks undergo rigorous testing procedures:

Certification of inspection ensures each hook meets the rated lifting capacity.

Material testing verifies chemical composition and mechanical performance.

Surface condition assessment checks for cracks or overheating.

Internal condition assessment uses ultrasonic or magnetic particle inspection.

Ongoing visual inspections help you spot wear or damage before each use.

Powerful Machinery hooks feature high-strength forged steel and corrosion-resistant finishes. You can use these hooks with Grade 80 and Grade 100 chains for versatile applications. The secure locking mechanisms on clevis hooks prevent accidental disengagement.

You find hooks available in multiple sizes, allowing you to match the right hook to your towing needs.

You should always select hooks and shackles that meet international standards. Powerful Machinery provides certified products, giving you confidence in every towing operation.

How to Choose the Right Shackle or Hook?

Practical Towing Considerations

When you select towing equipment, you must focus on safety, compatibility, and legal compliance. The right choice depends on your load, the environment, and how your equipment fits together.

If you want to know how to choose the right shackle or hook, start by looking at the minimum breaking strain and working load limit (WLL) for your application.

Here is a comparison of shackles and hooks for a typical 3-ton caravan:

Device Type | Minimum Breaking Strain Required | WLL (Working Load Limit) | Comments |

|---|---|---|---|

Shackle | 4.5t (for 3t caravan) | 1t | Rated to AS 2741, exceeds requirements |

Hook | 4.0t (falls short for 3t caravan) | 1t | Rated to AS 2741, does not meet requirements |

You see that shackles rated to AS 2741 provide a higher safety margin for heavy towing. Always check the markings on your equipment to confirm compliance with standards.

You also need to consider compatibility with your towing setup. The shackle or hook must fit your chains, anchor points, and other connectors. Use this table to guide your selection:

Factor | Description |

|---|---|

Weight Capacity | Shackles must be rated for the weight they will carry, ensuring they can handle towing demands. |

Material | Typically made from steel for strength, coatings can enhance durability against corrosion. |

Size and Compatibility | The shackle size must match the towing equipment, including hooks and anchor points. |

Tip: Always inspect your shackles and hooks before each use. Look for signs of wear, corrosion, or deformation. Replace any component that shows damage.

If you want to know how to choose the right shackle, remember to match the shackle’s size and load rating to your trailer’s weight and the environment where you operate. For marine or outdoor use, select products with corrosion-resistant coatings.

Powerful Machinery Product Selection Guide

Powerful Machinery offers a wide range of certified shackles and hooks to meet your towing needs. You can choose from different sizes, shapes, and load ratings to ensure the best fit for your project. If you are unsure how to choose the right shackle, Powerful Machinery provides expert support and customization options.

Here are some customization options available:

Customization Options | Description |

|---|---|

Sizes | Tailored sizes to fit specific needs |

Logos | Custom logos for branding purposes |

Colors | Various color options available |

Load Ratings | Specific load ratings to match operational requirements |

You can request custom sizes to fit unique anchor points or chains. You can also select specific load ratings to match your operational requirements. If you need your company logo or a particular color for easy identification, Powerful Machinery can provide these features.

When you want to know how to choose the right shackle, start by reviewing your towing requirements. Identify the weight of your load, the type of environment, and the compatibility with your existing equipment.

Then, consult Powerful Machinery’s product specifications or reach out for expert advice. This approach ensures you select a shackle or hook that meets both safety and operational needs.

Note: Powerful Machinery’s certified products comply with international standards like AS 2741. You gain peace of mind knowing your towing connectors are safe, reliable, and tailored to your needs.

Device Rules and Usage Limits

One Device Per Chain Rule

You must follow the one device per chain rule when setting up your towing equipment. This rule means you can only use one connecting device, such as a shackle or hook, for each safety chain. This approach reduces the risk of failure and keeps your towing setup simple and secure.

Regulations require you to attach safety chains or cables directly to the vehicles. You must ensure each device meets the strength and design standards for towing.

Safety chains or cables prevent the towed vehicle from detaching.

Each chain must have its own connecting device.

Devices must be strong enough to handle the forces during towing.

Secure attachment is essential for compliance and safety.

If you use more than one device per chain, you increase the risk of weak links. You also risk failing a safety inspection. Powerful Machinery offers a range of certified shackles and hooks that meet these requirements. You can trust their products to keep your towing operation compliant and safe.

Hammerlock Devices and Compatibility

Hammerlock devices play a key role in connecting chains and fittings. You use a hammerlock to join two components securely. These devices offer a strong, reliable connection for towing applications. Hammerlocks are easy to install and remove, making them a popular choice for professionals.

You must check compatibility before using a hammerlock device. The device must match the size and load rating of your chains and hooks. Powerful Machinery provides hammerlock devices in various sizes and grades. You can find options that fit your specific towing needs.

Their products comply with international standards, so you meet all legal and safety requirements.

Tip: Always inspect your hammerlock devices before each use. Look for signs of wear or damage. Replace any device that does not meet safety standards.

Powerful Machinery’s versatile product line helps you build a safe, compliant towing setup. You get peace of mind knowing your equipment meets strict industry regulations.

Practical Tips and Brand Advantages

Ease of Use and Accessibility

You want towing equipment that works smoothly and keeps your operation efficient. Many users report issues with snap hooks, such as accidental releases and dropped objects, especially when loads shift or float. You can see the most common problems in the table below:

Issue Description | Details |

|---|---|

Inappropriate use of snap hooks | Regular incidents of using snap hooks instead of shackles or safety hooks have been reported, leading to safety concerns. |

Dropped objects | The use of snap hooks has resulted in dropped objects due to design flaws and unsuitable conditions. |

Accidental releases | Incidents of accidental releases have occurred, particularly when loads are capable of floating during transitions. |

You avoid these problems by choosing certified shackles and hooks. Powerful Machinery’s products stand out for their compact design, easy attachment and removal, and secure safety mechanisms. The table below highlights features that make Powerful Machinery’s shackles and hooks easier to use:

Feature | Description |

|---|---|

Compact Design | Their compact and narrow body makes them ideal for limited space situations. |

Ease of Attachment/Removal | Screw pin shackles feature a U-shaped body with a threaded pin, making them easy to attach and remove. |

Durability | Made from durable materials, ensuring they can handle heavy loads without breaking. |

Safety Mechanism | Bolt-type shackles have a secure fastening mechanism that reduces the risk of accidental disconnection. |

You save time during setup and reduce the risk of accidents with these user-friendly features.

Powerful Machinery’s Safety and Value

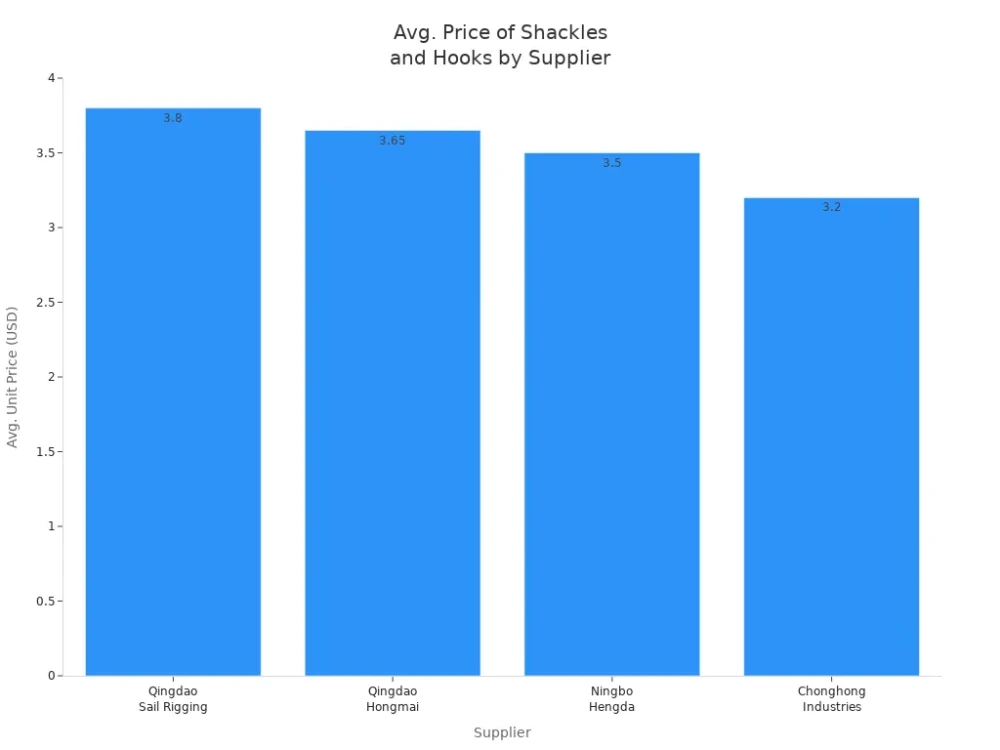

You want reliable equipment at a fair price. The chart below compares the average unit price of certified shackles and hooks across leading suppliers:

Powerful Machinery offers competitive pricing while maintaining high standards for safety and performance. You benefit from products that meet strict certifications, including the EU Machinery Directive, IEC 60204-1, ANSI/RIA R15.06, ASME B20.1, and OSHA 29 CFR 1910.

These certifications ensure your shackles and hooks deliver consistent quality and comply with international safety regulations.

You gain peace of mind knowing that Powerful Machinery’s products undergo rigorous testing and meet industry standards. Customers worldwide trust Powerful Machinery for dependable towing solutions. You can rely on their certified shackles and hooks to keep your operation safe, efficient, and cost-effective.

Conclusion

You must prioritize certified towing connectors for every towing operation. Industry experts highlight key differences between tow hooks and shackles:

Aspect | Tow Hooks | Shackles |

|---|---|---|

Legal Requirements | Can be used if they meet standards | Must meet specific standards |

Breaking Strain | 4x WLL | 6x WLL |

Maximum Towing Capacity | Limited by design | Can exceed 3.5t with proper rating |

Practical Use | Easier to connect/disconnect | May require more time to connect |

Follow these essential safety and legal steps:

Balance your load.

Use towing mirrors.

Secure all connections.

Check tire pressure.

Employ trailer brake systems.

Powerful Machinery’s certified shackles and hooks deliver reliability and compliance. Review product specifications and standards before you decide. Visit Powerful Machinery’s website for expert support.

FAQ

What is the main difference between a tow hook and a shackle?

You use a tow hook for quick connections and easy access. You choose a shackle when you need a secure, closed connection. Both options work well for towing if you select the right size and rating.

How do I know if my shackles are rated for towing?

You should look for markings on the shackle body. Rated shackles display the working load limit, grade, and manufacturer’s name. These markings confirm the shackle meets safety standards for towing.

Can I use any chain for towing heavy loads?

You must use towing chains that match your trailer’s weight and comply with legal standards. Always check the chain’s grade and ensure it meets or exceeds your towing capacity for safe operation.

How often should I inspect my towing equipment?

You need to inspect your towing equipment before every use. Look for signs of wear, corrosion, or damage. Replace any part that does not meet safety requirements to prevent accidents.

What should I consider when choosing between a hook and a shackle?

You should consider your towing capacity, the type of load, and the environment. Use hooks for quick connections and shackles for extra security. Always match the connector to your equipment and towing needs.